Best DTF Printer for T Shirt Printing: Top Picks & Guide

Share

When you're trying to find the best DTF printer for T-shirt printing, the right answer really boils down to your production scale. A hobbyist just starting out has vastly different needs than a full-blown commercial operation. The trick is to find that sweet spot between what you can afford upfront and what you need to produce.

Navigating Your DTF Printer Options

Let's be clear: there isn't one single "best" DTF printer. Instead, it’s about finding the right machine for your goals. The market is pretty neatly segmented to serve everyone from a crafter working out of their garage to a high-volume print shop running multiple shifts. This variety is a direct result of how quickly DTF has caught on in the custom apparel world.

The Direct to Film printing market is exploding. It was valued at around USD 2.72 billion in 2024 and is expected to climb to USD 3.92 billion by 2030. That growth is all thanks to the insatiable demand for custom, on-demand T-shirts and other gear. You can dig deeper into the DTF printing market's impressive growth and see where it's headed.

Understanding the Tiers

To make sense of the options, it helps to think of them in three main tiers. Each one is built for a different kind of user, with its own performance level and price tag.

- Entry-Level (Hobbyist & Startup): These are typically compact, all-in-one machines or sometimes even modified desktop printers. They're perfect for learning the ropes, experimenting, and fulfilling small, one-off custom orders.

- Mid-Range (Small to Medium Business): Here’s where you see a real jump in speed and durability. These are the workhorses for businesses that are starting to scale up and need a reliable machine that can handle daily orders without breaking a sweat.

- Industrial (High-Volume Commercial): These are the big guns. Built for 24/7, lights-out operation, these are large, roll-to-roll systems engineered for maximum throughput in a serious commercial environment.

The most critical decision you'll make is matching the printer's capabilities to your business plan. Spending too much can sink your budget before you even start, but spending too little can create production bottlenecks that will absolutely kill your growth.

DTF Printer Tiers at a Glance

This table gives you a quick, high-level look at the different printer categories. Use it to get a feel for where you might fit based on who you are, how much you need to print, and what you're prepared to invest.

| Printer Tier | Ideal User | Typical Output (Shirts/Hour) | Average Initial Cost |

|---|---|---|---|

| Entry-Level | Hobbyists, Startups | 5 - 15 | $1,500 - $5,000 |

| Mid-Range | Growing Print Shops | 20 - 50 | $6,000 - $15,000 |

| Industrial | Commercial Operations | 60+ | $16,000+ |

As you can see, the jump between tiers is significant in both output and cost. This is why it's so important to have a realistic grasp of your current and near-future needs before you pull the trigger on a purchase.

Understanding the Tech: What Really Matters in a DTF Printer

Before you can pick the right DTF printer for your t-shirt business, you have to know what you're looking at. A spec sheet can feel like a foreign language, but once you grasp a few key terms, you'll be able to cut through the marketing fluff and see how a machine will actually perform in the real world. These details directly impact your print quality, how fast you can get jobs done, and what it'll cost to keep the machine running.

The single most important part of any DTF printer is its printhead. It's the heart of the operation. You’ll constantly see two models from Epson mentioned: the XP600 and the i3200-A1. They both get the job done, but they’re built for very different scales and budgets.

- Epson XP600: This is the go-to for many entry-level printers. It’s affordable and produces perfectly good quality, making it a smart starting point for a new business or a shop handling smaller batches. The trade-off? It's slower and won't last as long as a more industrial head.

- Epson i3200-A1: When you see this printhead, you're looking at a mid-range to industrial workhorse. It delivers much better resolution, prints significantly faster, and is built to withstand the demands of a high-volume business. It’s for shops where speed and top-tier quality are everything.

I tell people to think of the printhead like a car engine. The XP600 is your reliable 4-cylinder—great for getting around town. The i3200 is a powerful V6 built for long, high-speed highway trips. The initial investment is bigger, but so are the performance and the reliability.

Print Quality and Ink Systems

Next up is resolution, which is measured in Dots Per Inch (DPI). A higher DPI means the printer can lay down more ink dots in a small area, resulting in finer details and smoother color blends. This is critical for t-shirt designs that look photographic. While a resolution like 720x1200 DPI is solid, printers capable of 1440x1440 DPI or more will give you that noticeably sharper, more vibrant look that customers love.

Resolution goes hand-in-hand with the ink configuration. The industry standard for DTF is a CMYK+W setup: Cyan, Magenta, Yellow, Black, and White. That white ink is the secret sauce. It’s laid down first as a base layer on the film, which is what makes your colors really pop on dark or colored garments. Some higher-end printers even include extra channels for fluorescent or light colors, giving you an even bigger range of colors to work with.

Film Width and Production Efficiency

Finally, consider the print width. This spec determines the maximum size of the transfers you can produce. Common widths are 13 inches (A3+), 24 inches, and massive 48-inch rolls for industrial setups.

A wider format isn't just about making bigger designs. It's about efficiency. With a wider film, you can "gang" multiple smaller designs onto a single sheet. This is a game-changer for productivity, as it dramatically lowers your cost and time per print. This kind of flexibility is a key advantage of DTF, a topic we cover in more detail in our DTF vs. DTG printing comparison.

Comparing Leading DTF Printer Models Head-to-Head

Alright, let's get down to brass tacks. Choosing the best DTF printer for your t-shirt business means looking beyond the glossy brochures and spec sheets. You need to know how these machines actually handle the daily grind. To show you what I mean, we'll pit three common printer types against each other: a popular starter model, a go-to mid-range workhorse, and a high-volume industrial beast. This isn't just about specs; it's about the real-world trade-offs you'll make in speed, quality, ink costs, and sheer usability.

The Entry-Level Contender

For many small shops and hobbyists just dipping their toes into DTF, the entry-level printer is the logical starting point. We're talking about machines that typically come in under $5,000. They're designed to be accessible, usually built around a single Epson XP600 printhead and handling a print width of about 13 inches (A3+).

The big trade-off here is speed for cost. The price tag is easy to swallow, but your output will be capped. Realistically, you’re looking at around 10 to 15 full-sized shirt transfers per hour, maybe a bit more on a good day. While the quality is perfectly fine for most retail work, you might notice it doesn't quite have the super-fine detail or color pop of pricier machines. You'll also be more hands-on with maintenance—daily cleanings are a must to keep those printheads from clogging.

This kind of printer is perfect if you're a startup testing the waters or an Etsy seller focusing on one-off custom orders. It gets you in the game without a huge financial leap, but just be aware that you'll hit a production wall pretty fast if orders start pouring in.

The Mid-Range Workhorse

Once you move into the $6,000 to $15,000 bracket, you're in workhorse territory. These are the machines that power a huge number of growing print shops. They usually come armed with dual Epson i3200-A1 printheads and a much wider 24-inch print area. This setup is a game-changer for productivity, not just because it prints faster, but because you can gang up way more designs on a single roll of film.

Here, the game shifts to efficiency and reliability. These printers can churn out 20-50 shirt designs per hour without breaking a sweat. The i3200 printheads offer a noticeable jump in resolution, which means your text will be crisper and your photo-realistic prints will really pop. They’re also built for the long haul, often featuring automated perks like white ink circulation and scheduled head cleanings that drastically cut down on your manual upkeep.

The leap from an entry-level to a mid-range printer is where most businesses feel a genuine return on investment. The boosted speed and dependability translate directly into better profit margins and the confidence to take on bigger, more complex jobs.

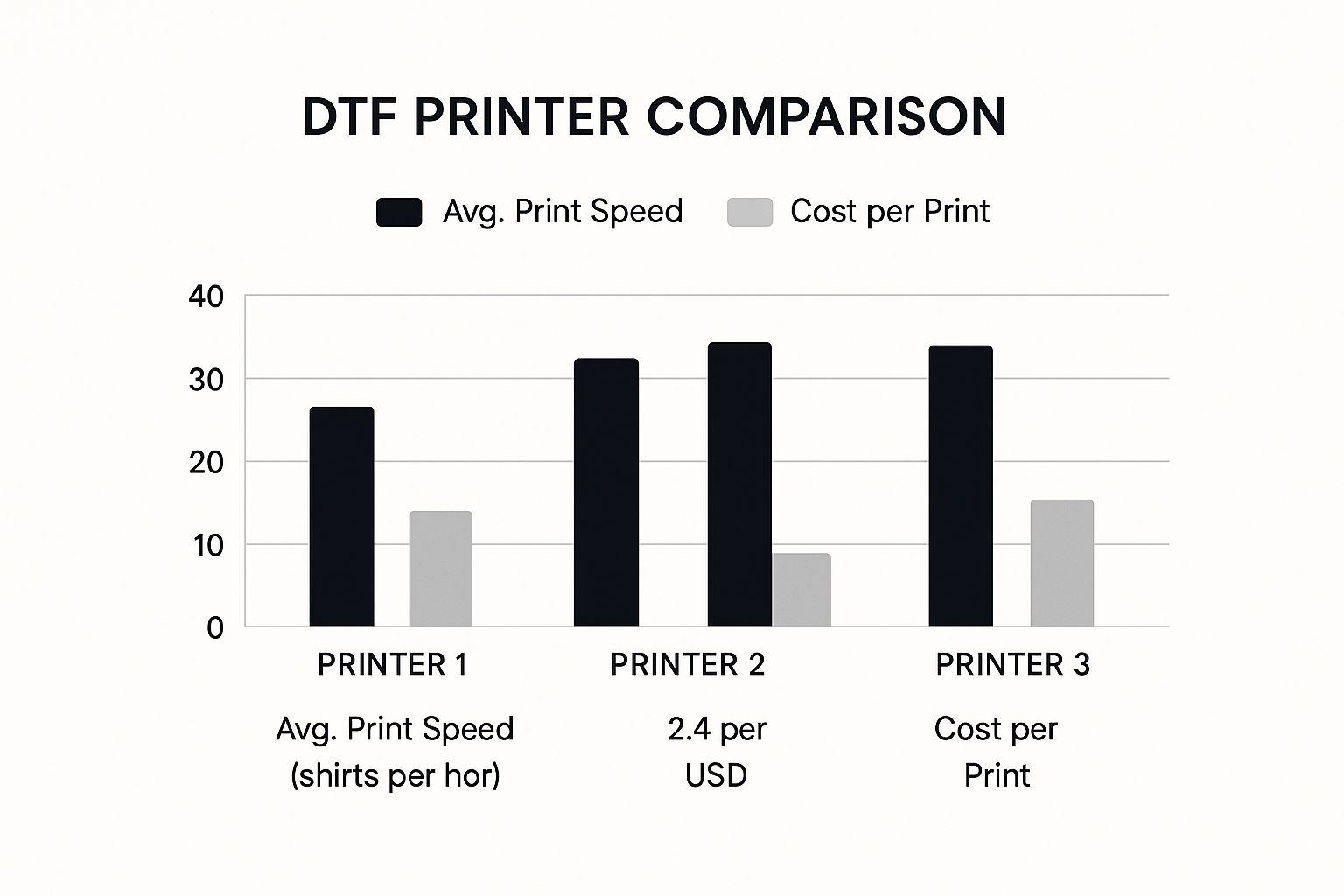

This visual helps break down the trade-offs you'll face between speed, upfront cost, and the cost per print for each tier.

As you can see, while the big industrial printers are the speed kings, the mid-range models really hit that sweet spot of efficiency without the massive initial price tag.

The Industrial Powerhouse

At the very top of the food chain, you'll find the industrial DTF printers, with price tags starting at $16,000 and climbing much, much higher. These machines are engineered for one purpose: maximum output. They often pack four or more printheads into a fully integrated system—complete with an automatic powder shaker, dryer, and take-up roller for true, unattended roll-to-roll production.

The entire focus here is on scale and automation. These systems can push out over 60 designs per hour and are built to run around the clock with minimal human intervention. The build quality is on another level, designed to handle the vibrations and demands of a high-volume factory floor. This segment of the market is massive for a reason; dedicated DTF printers pulled in revenues of USD 1,314.7 million in 2025 alone by serving this need for speed and quality. You can dive deeper into the numbers with this direct-to-film printing market analysis.

An industrial printer really only makes sense for large-scale commercial operations fulfilling bulk orders for merchandise companies, established apparel brands, or major promotional events. The investment is steep, but if your business model demands it, the production power is simply unmatched.

Ultimately, picking the best DTF printer for t-shirt printing comes down to an honest look at your current order volume and where you realistically see your business going.

Calculating the True Cost of DTF Printing

When you're choosing a DTF printer for your t-shirt business, the sticker price is just the beginning of the story. The real financial picture—the true cost of ownership—is painted by the ongoing expenses you'll face to produce every single shirt. It's easy to get lured in by a cheap printer, but if it burns through expensive ink, you'll see your profits disappear over time.

Your biggest operational costs will always be consumables. These are the materials you’ll be buying again and again, so getting a handle on them is key.

- DTF Ink: This is your primary recurring expense. You need to look at both the cost per liter and how efficiently the printer uses it. Industrial machines might have a higher upfront cost, but their ink systems are often far more efficient, dropping your cost per print significantly.

- DTF Film: This is the carrier sheet for your designs. Its cost depends on the roll's width and length. For serious production, wider rolls designed for commercial printers usually offer better value because you can "gang" more designs onto one sheet.

- Adhesive Powder: This is the magic dust that binds your ink to the fabric. Buying in bulk is a great way to save money, but just make sure you have a cool, dry place to store it properly.

Breaking Down the Cost Per Shirt

To really understand your profitability, you have to calculate your cost per shirt. This means adding up the cost of the ink, film, and powder for an average design, like a 10x12 inch graphic. With an entry-level machine, you might find your consumable costs are somewhere between $1.50 and $2.50 per shirt. A high-volume, super-efficient industrial printer, on the other hand, could get that cost well under $1.00.

The goal isn't just to make transfers; it's to make them profitably. Understanding your cost per print allows you to set competitive pricing while ensuring healthy margins on every single sale.

Uncovering the Hidden Expenses

Beyond the daily consumables, a few other "hidden" costs can sneak up on you. For a realistic budget, you absolutely have to factor these in.

Auxiliary Equipment Costs:

- Powder Shaker & Curing Oven: While some all-in-one systems have these built-in, most professional setups need a separate automatic powder shaker and a curing oven or tunnel dryer. These can add thousands to your initial investment, but they are absolutely essential for a smooth workflow and consistent quality.

- RIP Software: Raster Image Processing (RIP) software isn't optional—it's how you control color accuracy and manage your white ink layers. Some printers bundle it, but for others, you'll need to buy it separately or pay a monthly subscription.

These components are what make the difference between a print that just looks good and one that actually lasts. If you want to dive deeper into durability, our guide on how long DTF transfers last has some great information.

Finally, don't forget to budget for the small stuff like cleaning solutions and swabs, and it’s always smart to have a repair fund set aside for when your warranty eventually runs out.

Matching a DTF Printer to Your Business Scale

When you’re looking for the best DTF printer for T-shirt printing, it’s easy to get lost in a sea of specs. But the truth is, the "best" printer isn't a single machine—it's the one that fits your business like a glove. The right choice for a small Etsy shop would cripple a commercial operation, and buying an industrial machine for a home-based business is just burning cash.

The real goal here is to match your investment to your actual production needs. Spending too much on a printer you can't keep busy will drain your resources. On the other hand, a machine that can't keep up with your orders will create frustrating bottlenecks and stall your growth. Let's walk through three common business scenarios to pinpoint where you fit.

The Etsy Seller and Home-Based Startup

So, you're just starting out. Maybe you're launching a brand from your garage or running a small shop on Etsy. Your world revolves around creativity, keeping startup costs low, and staying flexible. You need a machine that can handle small batches and one-off custom orders without requiring a massive loan.

A compact, entry-level printer is your best friend here. Look for something in the 13-inch (A3+) print width range. These machines are built for smaller spaces and won't overwhelm you. Sure, they aren't built for speed, but they deliver fantastic quality that’s perfect for building a reputation. Plus, their hands-on nature is a great way to learn the ins and outs of the DTF process.

Key Takeaway: If you're a home-based entrepreneur, your top priorities should be a low initial investment and ease of use. A smaller printer lets you test the waters, try out new designs, and develop your skills without the pressure of a huge equipment payment.

The Growing Print Shop

This is for the business that's already found its rhythm. You're past the hobbyist phase, and orders are coming in steadily. You might be upgrading from an older method like heat transfer vinyl or you've simply outgrown your first entry-level DTF printer. Your biggest challenge now is pushing out more shirts without letting quality slip.

This is where you step up to a mid-range, 24-inch roll-fed DTF printer. These systems are the workhorses of the industry, often featuring dual i3200 printheads that give you a serious boost in productivity. A 24-inch printer can handle a constant flow of orders, and the wider format is a game-changer. It lets you "gang" multiple designs onto a single transfer sheet, which dramatically cuts your cost per print. This is the sweet spot where you get a great mix of speed, quality, and affordability.

The High-Volume Commercial Merchandiser

At this scale, printing is all about the numbers. You're pumping out massive, time-sensitive orders for corporate clients, big apparel brands, or major events. Your entire operation depends on producing thousands of prints a day, day in and day out, with near-perfect consistency and minimal downtime.

Forget everything else—you need an industrial, fully integrated roll-to-roll system. These are the beasts of the DTF world, built with multiple printheads, automated powdering and curing, and designed for 24/7 operation. The focus shifts entirely to maximizing output and slashing labor costs. The explosive growth of the DTF market, which is on track to hit USD 3.99 billion by 2030, is fueled by the demand for exactly this kind of production power. You can dive into the data yourself by checking out the latest DTF market intelligence reports.

While the upfront cost is significant, the cost-per-print is the lowest you can achieve, making it the only practical choice for true commercial-scale t-shirt printing.

Common Questions About DTF T-Shirt Printers

Jumping into DTF printing is a big step, and it's totally normal to have a few questions before you pull the trigger on a new machine. It's a significant investment, after all. Let's walk through some of the most common things people ask so you can move forward with confidence.

What’s the Real Difference Between DTF and DTG?

At its core, the main difference comes down to the application process and what fabrics you can print on. With DTF, your design is first printed onto a special transfer film. That film is then heat-pressed onto the t-shirt. This two-step process is incredibly versatile—it works great on cotton, polyester, blends, and even hard surfaces.

DTG (Direct-to-Garment), on the other hand, prints the ink right onto the fabric, almost like a desktop paper printer. It’s fantastic for 100% cotton, but it struggles with synthetics. DTG also usually needs a pre-treatment spray, especially for dark shirts, which is an extra step DTF doesn't require. Most people find DTF prints look a bit more vibrant on dark garments and open up a whole world of different products you can offer.

Key Insight: Think of DTF's versatility as its superpower. You can print one batch of transfers and apply them to a cotton tee, a polyester performance hoodie, or even a nylon gym bag. That kind of flexibility is a game-changer for anyone looking to build a diverse product line.

How Much Maintenance Does a DTF Printer Really Need?

Let's be direct: DTF printers need consistent, daily attention. This is not a "set it and forget it" kind of technology. The white ink is the main reason—it's packed with heavy titanium dioxide pigments that will settle and clog your printheads if the machine sits idle for too long.

A typical daily maintenance routine involves:

- Gently shaking the white ink cartridges or bags to keep everything mixed.

- Running a quick printhead cleaning cycle through the printer's software.

- Wiping down crucial parts like the capping station to prevent gunk buildup.

Skipping these simple steps is the number one cause of print quality problems and can lead to some seriously expensive repair bills down the road. While higher-end machines often have automated white ink circulation and self-cleaning functions, they just reduce the hands-on time—they don't eliminate it completely.

Can I Just Convert a Desktop Epson Printer?

Yes, technically you can. Many people get their start by modifying a consumer-grade Epson printer for DTF to keep the upfront costs down. But this path is loaded with compromises that make it a poor choice for anyone serious about running a business.

These desktop printers were never built to handle the thick, sticky pigments in DTF ink. This leads to constant clogs and a much higher risk of mechanical breakdowns. You also miss out on essential features like an automatic white ink circulation system. Plus, you’ll have to rely on third-party RIP software to get it to print correctly. The biggest kicker? The moment you modify it, you've voided the warranty, leaving you completely on your own when something goes wrong.

What Other Gear Do I Need to Get Started?

A DTF printer is just one piece of the puzzle. To run a smooth operation that takes you from a digital file to a finished shirt, you’ll need a few other critical pieces of equipment.

Essential Auxiliary Gear:

- Powder Applicator and Shaker: After printing, you need to apply an adhesive powder to the wet ink on the film. You can do this by hand if you're only making a few shirts, but an automated shaker is a must-have for any real volume.

- Curing Oven: This is a small oven or even a heat press used in a "hover" position to melt the adhesive powder into a smooth, even layer. This step is crucial for getting a good transfer.

- Heat Press: A high-quality, reliable heat press is absolutely non-negotiable. This is what you'll use to transfer the final design from the film to the garment. Don't skimp here!

If you want to take a closer look at the entire workflow, our guide on understanding DTF printing for beginners is a great place to start.

Feeling a bit overwhelmed by the equipment and maintenance? If you're looking for a simpler way to get vibrant, long-lasting prints, Raccoon Transfers is your answer. We handle all the printing and prep for you, delivering professional-grade DTF transfers that are ready for you to press. Check out our super easy-to-use service at https://raccoontransfers.com.