Best Printer for Sublimation and Heat Transfer Guide

Share

So, you're ready to dive into custom apparel and products. Fantastic! But the first big hurdle is picking the right printer, and let's be honest, it can feel like a maze of options. The truth is, there isn't one single "best printer for sublimation and heat transfer"—it all comes down to what you want to achieve.

If you're a hobbyist just dipping your toes in, a converted Epson EcoTank printer can be a great, budget-friendly starting point. But if you're running a business where every minute counts, you'll want the plug-and-play reliability of a dedicated system, like a Sawgrass printer, which is the gold standard for many pros.

Your Guide to Sublimation and Heat Transfer Printers

There's no denying that the world of custom merchandise is on fire right now. Thanks to the boom in e-commerce and a growing hunger for personalized gear, the global dye sublimation printing market was valued at around $14.9 billion in 2024. That number is expected to nearly double, rocketing to almost $28.0 billion by 2030. You can read more about this incredible growth on The Cannata Report. That’s a huge opportunity for creators.

This guide is here to help you navigate your two main paths: dedicated sublimation systems versus converted inkjet printers. We'll get into the nitty-gritty of what separates them in terms of cost, setup, and performance. But more importantly, we’ll break down the core concepts you absolutely need to grasp—like ink chemistry and printhead tech—to choose with confidence.

The Inherent Problem with Fabric Sublimation

Before you even think about a printer, you have to understand a fundamental limitation of sublimation itself. Sublimation is incredible for hard goods like mugs and tumblers, creating vibrant, permanent designs. But when it comes to fabric, it’s a different story. The process is incredibly picky.

The dye in sublimation ink only bonds with polyester fibers. Because the ink is also transparent, this creates two major roadblocks:

- Material Limitation: You're stuck with light-colored, high-polyester-count apparel. It flat-out will not work on 100% cotton.

- Color Limitation: Since the ink isn't opaque, you can't print on dark or black shirts. Your beautiful design would just disappear into the fabric.

These rules can seriously box you in, especially if you want to offer hot-ticket items like classic black cotton t-shirts. This is where you need a more flexible printing method in your toolkit.

Why DTF Is the Go-To for Apparel

This is exactly where Direct-to-Film (DTF) technology shines, solving the very problems that hold sublimation back. DTF prints work on practically any fabric you can throw at them—cotton, polyester, blends, canvas, you name it. And it works on any color, including jet black.

The secret is a brilliant white ink underbase. This layer makes your designs completely opaque, ensuring they pop with eye-catching vibrancy, even on the darkest garments. It offers the kind of freedom and versatility that modern apparel brands need to succeed.

To get a clearer picture of these two popular methods, let's look at a side-by-side comparison of the printer options.

Quick Comparison of Sublimation Printer Options

This table breaks down the key differences between the two primary routes you can take for in-house sublimation printing.

| Feature | Dedicated Sublimation Printer (e.g., Sawgrass) | Converted Inkjet Printer (e.g., Epson EcoTank) |

|---|---|---|

| Initial Cost | Higher upfront investment | Lower initial cost, making it budget-friendly |

| Setup & Warranty | Plug-and-play, designed for sublimation. Comes with full manufacturer warranty and technical support. | Requires manual conversion. Voids the printer warranty. Support comes from forums and community groups. |

| Ink System | Uses sealed, proprietary ink cartridges. Consistent, high-quality results with minimal hassle. | Refillable ink tanks require you to source third-party sublimation ink. Quality can vary. |

| Reliability | Built for the job. Excellent long-term reliability and color management with included software. | Prone to clogging if not used regularly. Color profiling can be a challenge without proper software (RIP). |

| Best For | Businesses, serious creators, and anyone who needs out-of-the-box reliability and professional support. | Hobbyists, crafters on a tight budget, and those willing to tinker and troubleshoot. |

While both paths can lead to great products, the journey is quite different. A dedicated printer is a professional tool built for a specific job, while a converted printer is more of a DIY solution that requires more hands-on effort.

But here’s the best part: you don't actually need to buy any printer to get started with DTF. You can order top-quality, ready-to-press DTF transfers from a specialized provider like Raccoon Transfers. This lets you completely sidestep the cost of equipment, the headaches of maintenance, and the steep learning curve. All you need is a heat press, and you can start producing retail-quality custom apparel today.

How Sublimation and Heat Transfer Actually Work

To pick the right printer, you first need to get a feel for what’s happening at a scientific level with these decoration methods. They might seem similar on the surface, but they work in fundamentally different ways.

Sublimation isn't just printing; it's a bit of a magic trick. Think of an ice cube turning straight into steam, completely skipping the puddle of water in between. That’s the core idea.

When you put your printed sublimation paper under a heat press, the solid ink transforms directly into a gas. This gas then embeds itself into the polymer fibers of your item, becoming one with the material. Because the ink is in the fabric, not just sitting on top of it, the finished design has absolutely no feel to it. It will never crack, peel, or fade.

This process is one technique under the big umbrella of heat transfer, which is really just a catch-all term for using heat to stick a design onto something. Other common methods like Heat Transfer Vinyl (HTV) or inkjet transfers also fall into this category, but they all work by applying a physical layer on top of the product.

Sublimation on Fabrics: The Critical Weakness

While sublimation sounds like the perfect solution, it has a couple of major deal-breakers, especially when it comes to apparel. The chemical reaction at its heart is incredibly picky. It needs two very specific things to work, and this can throw a serious wrench in your plans if you want to build a versatile clothing brand.

First, there's the fabric issue. That sublimation gas we talked about needs polyester molecules to bond with. This means it’s completely useless on 100% cotton—one of the most popular and profitable t-shirt materials out there. The design simply has nothing to stick to.

Second, sublimation ink is transparent. This is a huge limitation because it means you can only print on white or very light-colored items. Trying to sublimate on a black shirt is like using watercolors on black construction paper. Your beautiful design will just disappear.

When you put those two things together, you realize you can't offer things like black cotton tees, which can seriously hamstring your product catalog. It's a critical point to think about as you map out your business.

DTF: The Superior Solution for Apparel

This is where an alternative technology really shines. Direct-to-Film (DTF) was specifically developed to solve the exact problems that hold sublimation back. It gives you incredible flexibility, working perfectly on any fabric—cotton, polyester, blends, even denim—and on any color.

DTF pulls this off with a clever trick: it prints a brilliant white ink underbase beneath your colors. This opaque foundation acts like a primer, making your designs pop with vibrant color, even on the darkest fabrics. It gives you the creative freedom that sublimation on apparel simply can't match.

The demand for custom products is booming. Just look at the market for sublimation paper alone—it’s projected to grow from $723.8 million in 2025 to $1,224.6 million by 2035. People clearly want decorated goods. But to tap into the entire apparel market, you need a process that isn't held back by fabric type or color. You can discover more insights about the market growth on Future Market Insights.

The Raccoon Transfers Advantage

Buying a DTF printer is a big commitment. But what if you could get all the benefits of this superior apparel method without the huge upfront cost, maintenance headaches, and steep learning curve?

That's where we come in. By ordering high-quality, ready-to-press transfers from a specialist like Raccoon Transfers, you can sidestep the equipment investment completely. We do all the heavy lifting with the printing, so you can focus on what you do best: creating and selling. All you need is a good heat press to apply our vibrant, durable, and incredibly soft transfers to any garment, unlocking your brand's full potential.

What Makes a Great Sublimation Printer?

Not all printers are created equal, and this is especially true when you’re hunting for the best printer for sublimation and heat transfer. The real magic—or failure—happens inside the printer, all thanks to a single, critical component: the printhead.

Think of the printhead as the very heart of your printer. It's the part responsible for jetting microscopic droplets of ink onto the paper with incredible precision. If you’ve got the wrong kind of printhead for sublimation ink, your entire project is dead in the water before you even start.

It really boils down to two main types of printhead technology. Picking the wrong one isn't a small mistake; it's a showstopper.

Printhead Technology: The Make-or-Break Factor

The fundamental difference between printhead types is how they get ink from the cartridge onto the paper. The two technologies that dominate the market are Piezo and Thermal.

-

Piezo Printheads: You'll find these in Epson printers. They use tiny piezoelectric elements that physically flex when an electric charge hits them. This flexing motion squeezes out a perfect droplet of ink. It’s a completely mechanical process, and critically, it involves no heat.

-

Thermal Printheads: These are standard in printers from brands like HP and Canon. They work by using a tiny resistor to rapidly heat the ink, which creates an expanding vapor bubble that forces a droplet out of the nozzle. In short, it literally boils the ink to get it on the page.

For sublimation, this difference is everything. Sublimation ink is specifically designed to turn into a gas when heated during the final pressing stage. If you run that ink through a thermal printhead, the printer boils the dye before it ever gets to the paper. This instantly destroys the ink’s properties, creates nasty clogs in the printhead, and makes the whole setup useless.

This is precisely why Epson printers have become the go-to for DIY sublimation conversions and why dedicated brands like Sawgrass build their systems around Piezo technology. It's the only game in town for handling the thick, heat-sensitive nature of sublimation dye without wrecking it on the way out.

Ink Delivery Systems: Convenience vs. Cost

Once you’ve locked in on a printer with a Piezo printhead, your next big decision is about how it gets its ink. Are you a fan of the simple, no-fuss convenience of sealed cartridges, or do you prefer the long-term savings that come with refillable tanks?

Dedicated sublimation printers, like the ones from Sawgrass, typically use sealed ink cartridges. This creates a closed ecosystem where the ink, software, and hardware are all engineered to work together flawlessly. It’s a true plug-and-play setup that delivers amazing color consistency and comes with professional support. The trade-off? Those proprietary cartridges have a higher cost per print.

On the other side of the coin, you have many Epson printers featuring their EcoTank system. These printers come with large, built-in ink reservoirs that you fill yourself from bottles. This approach can drastically slash your long-term ink costs, but it also means you're responsible for sourcing third-party sublimation ink and managing your own color profiles, which definitely involves a steeper learning curve.

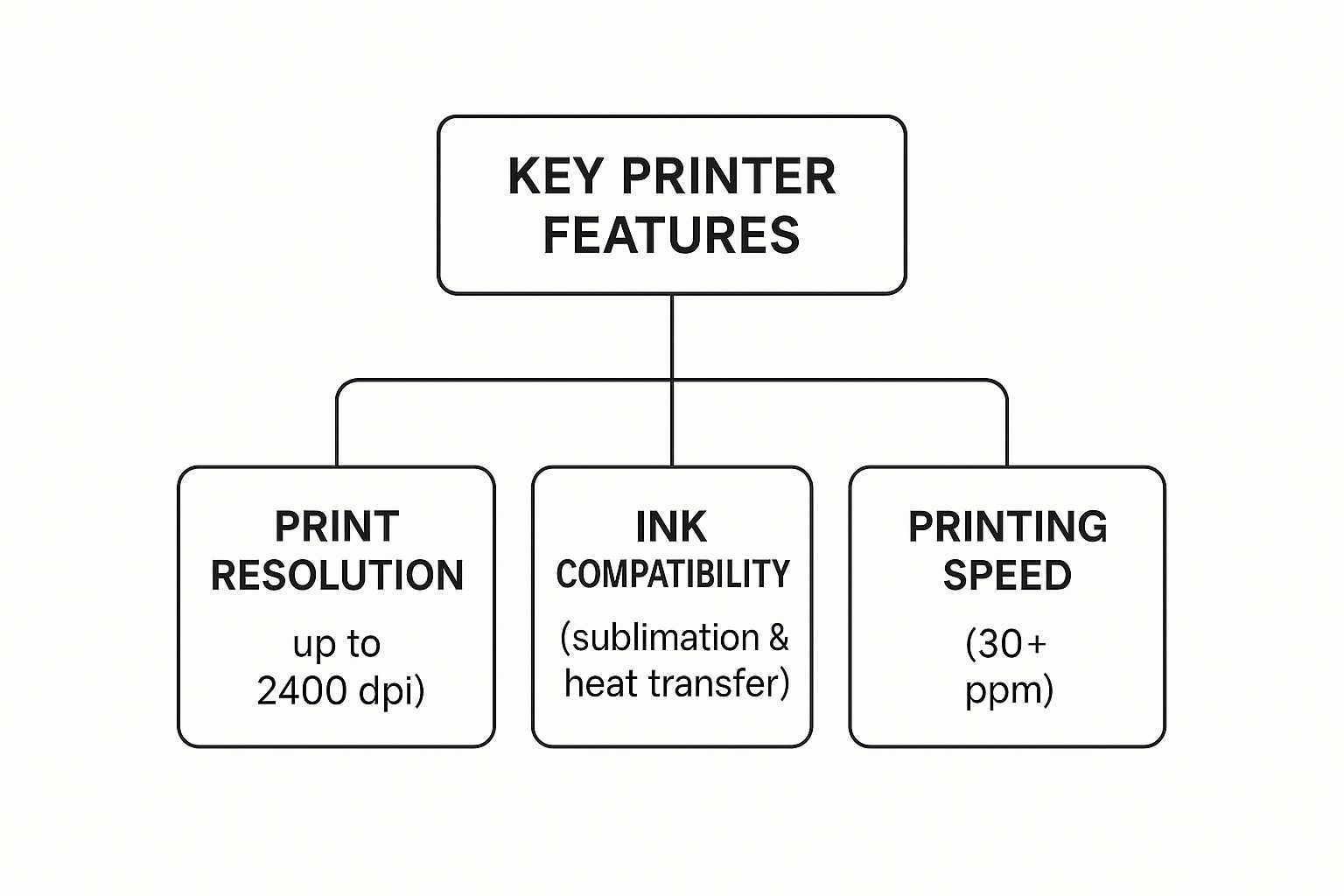

The infographic below breaks down the key features to look for, from ink compatibility to resolution and speed.

As you can see, getting the ink right is just as important as the technical specs if you're aiming for professional-quality results.

Beyond the Basics: Print Quality and Color Accuracy

Getting the core mechanics right is step one, but a few other features separate a good printer from the best printer for sublimation and heat transfer. High print resolution, measured in dots per inch (DPI), is absolutely essential for creating sharp, detailed images that don't look pixelated. You should be looking for a minimum of 1200 x 1200 DPI, but printers that go up to 2400 DPI will give you stunning, photorealistic quality.

Media handling is another practical thing to think about. Can the printer actually handle the size and thickness of the sublimation paper you want to use? Make sure the printer’s paper trays and feed system are a good match for your planned projects, whether you're making small keychains or massive apparel designs. The process of using this paper is just as important; for a complete walkthrough, you can read our guide on how to use heat transfer paper.

Finally, if you're serious about professional color, Raster Image Processor (RIP) software is a true game-changer. This specialized software steps in and overrides the printer's standard drivers, giving you total control over ink levels, color profiles, and print layouts. While you can get by with standard drivers, RIP software is what lets you achieve perfect color matching, ensuring the brilliant red on your screen is the exact same brilliant red on your finished t-shirt. It perfectly translates your digital design into instructions the printer can execute, maximizing both quality and efficiency.

Understanding Sublimation's Limitations on Fabric

The science behind sublimation is pretty cool, but when you bring it into the real world of apparel printing, you start to hit some serious walls. If you're looking to build a custom apparel brand, these aren't just minor quirks—they're fundamental limits that can dictate what you can sell and who you can sell it to. The biggest hurdle by far is how incredibly picky sublimation is about fabric.

Simply put, the sublimation process demands polyester. This isn't a friendly suggestion; it's a chemical non-negotiable. The ink turns into a gas under heat, and that gas needs to fuse directly with polyester fibers to become permanent. If there's no polyester, the ink has nothing to bond with. That means 100% cotton is completely off-limits.

This one rule can stop a new apparel business in its tracks. Cotton tees are the bread and butter of the industry, loved for their soft feel and breathability. Not being able to print on them means you can't serve a huge part of the market that flat-out prefers natural fibers.

The Invisibility Problem on Dark Garments

On top of the fabric issue, there's another major weakness: sublimation ink is transparent. A good way to think about it is like watercolor paint on paper. The colors are vibrant on a white sheet, but if you try painting on black construction paper, the colors just disappear. The fabric's color is your "paper."

Because the ink is see-through, sublimation only really works on white or very light-colored garments. If you try to press a stunning, full-color design onto a black or navy shirt, the dark fabric will completely absorb the light, making your design invisible. It's a frustrating waste of time, ink, and a perfectly good t-shirt.

This pretty much rules out selling one of the most popular pieces of clothing in the world: the classic black t-shirt. For a lot of brands, that's a deal-breaker and a huge reason to look for a different printing method.

Common Production Headaches

Even when you follow the rules and use the right fabric, the day-to-day process of sublimation can be a headache. A couple of common production flaws can easily ruin a whole batch of products, hitting your wallet and your deadlines.

- Ghosting: This is what happens when the transfer paper moves—even a millimeter—while in the heat press. You're left with a blurry, smeared shadow around your design that looks terrible and makes the item unsellable.

- Gassing Out: Sometimes called color migration, this frustrating issue happens when the dye turns back into a gas after the initial pressing, maybe during storage or if it's pressed a second time. The colors can bleed into each other, creating a fuzzy, low-quality look.

When you add up these practical frustrations with the strict fabric and color limitations, the picture becomes clear. Sublimation is a fantastic choice for things like polyester sportswear or hard goods like mugs and mousepads. But for building a diverse, modern apparel line? It's fundamentally flawed.

DTF: The Superior and Simpler Path

This is where knowing your options really pays off. The very problems that make sublimation a pain for apparel are the exact problems Direct-to-Film (DTF) was engineered to solve. DTF doesn't care about fabric type or color. It works beautifully on cotton, polyester, tri-blends, and more, on any color from crisp white to deep black.

The magic is in its opaque white ink layer. It's printed first, acting as a solid, vibrant primer on the garment. Every color printed on top of it pops, looking exactly how you designed it. This makes DTF a far more versatile and powerful tool for anyone serious about apparel.

Instead of hunting for the best printer for sublimation and heat transfer and boxing yourself into a limited system, you can skip the equipment headaches altogether. By ordering high-quality DTF transfers from a specialist like Raccoon Transfers, you get all the benefits of a superior printing method without the big upfront investment or maintenance hassles. All you need is a good heat press, and you can start creating durable, retail-quality designs on any garment your customers could possibly want.

Why DTF Transfers Are a Game Changer for Apparel

After seeing the roadblocks sublimation throws up for apparel creators, you’re probably asking yourself: "Isn't there a better way?" The good news is, there is. A technology called Direct-to-Film (DTF) is far better than sublimation for anyone serious about building a versatile clothing brand, solving the very problems that hamstring sublimation.

The single biggest win for DTF is its incredible material freedom. It completely shatters the polyester-only rule. With DTF, you can print stunning, full-color designs on just about any fabric you can think of—100% cotton, polyester, tricky poly-cotton blends, denim, canvas, and beyond. Suddenly, your creative options aren't limited by your printing method; the entire catalog of popular apparel is now fair game.

Unlocking Dark and Vibrant Colors

So, how does DTF pull this off on any fabric color, especially on pure black? The secret weapon is a brilliant layer of white ink underbase. This is fundamentally different from sublimation, where the dyes are transparent.

Think of it like trying to paint on a black wall. If you just slapped on some yellow paint, it would look muddy and dull. But if you put down a solid coat of white primer first, that yellow would pop. DTF works exactly the same way. The printer lays down a crisp, opaque layer of white ink first, creating the perfect canvas, and then prints your color design right on top. This underbase guarantees your artwork looks vibrant and professional, no matter how dark the shirt is.

This simple but powerful innovation means you're no longer creatively handcuffed. You can finally offer those best-selling black cotton t-shirts with intricate, colorful designs, giving customers exactly what they want without compromise.

The Feel and Durability Factor

Another key difference comes down to how the final print feels. A sublimated design has zero hand-feel because the ink literally becomes part of the fabric. While that sounds great on paper, a DTF transfer often delivers a result that feels better to the touch and holds up longer.

High-quality DTF transfers, like the ones we make at Raccoon Transfers, are engineered for a soft, flexible finish that stretches and moves with the fabric. They aren't thick or rubbery like the iron-ons you might remember from the past. Instead, they have a smooth, premium feel that rivals classic screen printing, all while being incredibly tough. If you're curious just how long these prints can last, check out our deep dive into DTF transfer durability.

To make it even clearer, let's put these two methods head-to-head.

Sublimation vs. Direct-to-Film (DTF) for Apparel

When you're building an apparel business, versatility is everything. This table shows exactly why DTF gives you a massive competitive advantage right from the start.

| Feature | Sublimation | Direct-to-Film (DTF) |

|---|---|---|

| Fabric Compatibility | Only works on high-count polyester fabrics. | Works on cotton, polyester, blends, denim, canvas, and more. |

| Color Compatibility | Only effective on white or very light-colored garments. | Prints vibrant, opaque designs on any color, including black. |

| Feel of Print | No feel; ink is infused into the fibers. | Soft, flexible, and smooth feel, similar to screen printing. |

| Durability | Excellent; will not crack or peel. | Excellent; highly wash-resistant and long-lasting. |

| Versatility | Limited to specific products. | Extremely versatile for a wide range of apparel and accessories. |

As you can see, DTF opens up a world of possibilities that sublimation simply can't match, allowing you to create the products your customers are actually asking for.

A Smarter Way to Start Your Business

At this point, you might be thinking, "This sounds amazing, but do I really have to buy a whole new DTF printer setup now?" This is where the business model gets even better. You don't need a printer at all.

Instead of sinking thousands of dollars into equipment, ink, and ongoing maintenance, you can just order ready-to-press DTF transfers. When you partner with a specialist like Raccoon Transfers, you get to skip the entire production headache. We handle all the technical printing on our professional-grade machines, ensuring every single transfer you receive is flawless.

This approach lets you focus your energy on what you do best—designing and selling—not troubleshooting machinery. All you need is a quality heat press to apply the transfers to your garments. It dramatically lowers your startup costs and gives you immediate access to a superior printing technology, empowering you to produce top-tier custom apparel from day one.

Common Questions About Sublimation and DTF Printing

As you dive into the world of custom apparel, a few questions always seem to surface. Let's tackle some of the most common ones I hear from people just getting started. Getting these answers straight will help you move forward with your projects confidently.

Can I Use My Regular Home Printer for Sublimation?

This is easily the question I get asked the most, and the answer is a hard no—at least for the vast majority of printers out there. It all boils down to the printhead technology inside.

Most standard home and office printers, like those from HP or Canon, use what's called a thermal printhead. This technology literally boils a tiny droplet of ink to shoot it onto the paper. If you try that with sublimation ink, you'll cook it solid before it even leaves the printhead. The result? A hopelessly clogged printer and a lot of frustration.

To make sublimation work, you need a printer with a Piezo printhead, which uses mechanical pressure—a tiny vibration—to jet the ink. This is why Epson printers are the go-to choice for DIY conversions; they use Piezo tech. But, and this is crucial, the printer must be brand new. It can never have had regular ink run through it, because even the slightest residue will contaminate the entire system and ruin your prints.

What Is the Best Printer for a Beginner Starting Sublimation?

When you're just starting out, picking the best printer for sublimation and heat transfer really depends on two things: your budget and how much you enjoy tinkering.

You generally have two paths to choose from:

- The Budget-Friendly Route: A converted Epson EcoTank is the classic entry point. It's affordable to buy, but you're in charge of everything—manually filling it with third-party sublimation ink, installing the right color profiles, and troubleshooting any issues that pop up. It’s a great way to learn, but it definitely has a learning curve.

- The "It Just Works" Route: If you'd rather spend your time creating than troubleshooting, the Sawgrass SG500 is the clear winner. It's a purpose-built sublimation printer. You take it out of the box, set it up, and it works. The results are consistent, the quality is professional, and it comes with full support, making it perfect for anyone starting a small business.

How Is DTF Different From Screen Printing?

Both Direct-to-Film (DTF) and screen printing will get a design onto a shirt, but they excel in very different scenarios. Think of DTF as your go-to for small-to-medium batches with complex, photorealistic designs. Because it's a digital process, you can print one-offs or fifty-offs with unlimited colors, and there are no expensive setup fees for each color in your artwork.

Screen printing, on the other hand, is the undisputed king of high-volume jobs with simple graphics. We're talking orders of 100+ t-shirts with a one or two-color logo. The time-consuming setup (creating a separate screen for each color) makes it impractical for small jobs, but it becomes incredibly cost-effective once you hit those higher quantities.

For a business that wants to offer a huge variety of designs without being buried in inventory, DTF offers unbeatable flexibility. You can dig even deeper into this by seeing how it stacks up against another digital method in our guide on DTF vs DTG printing methods.

What Other Equipment Do I Absolutely Need?

Aside from the printer, there is one piece of gear that is completely non-negotiable for getting professional results: a quality heat press. Your standard home iron just won't cut it. It can't deliver the consistent, even pressure and precise temperature needed for a flawless transfer, whether you're working with sublimation or DTF.

A reliable heat press is the single most important investment you'll make after your printer (or transfers). It's the key to ensuring your designs are vibrant, permanent, and look professionally made every single time.

On top of a good heat press, you'll want to have a few other key supplies in your toolkit:

- Sublimation Paper (for sublimation): This isn't just any paper. It's specially coated to release the ink gas cleanly under heat.

- Heat-Resistant Tape: Absolutely essential for taping your transfer down. It prevents the dreaded "ghosting" effect where the design shifts slightly during pressing.

- Protective Butcher Paper: A non-waxed sheet that goes between your transfer and the heat press. It’s cheap insurance to protect your press platen from any stray ink.

With these tools in your arsenal, you'll be ready to create some amazing custom products.

Ready to skip the equipment headaches and start creating amazing apparel on any fabric and any color? At Raccoon Transfers, we provide high-quality, ready-to-press DTF transfers that give you professional results without the printer. Explore our easy-to-use gang sheet builder and get started today at https://raccoontransfers.com.