How to Find Custom DTF Transfers Near Me

Share

When you need vibrant, ready-to-press designs now, there's nothing more frustrating than waiting on shipping. Searching for "custom dtf transfers near me" is your best bet, and the secret lies in knowing exactly where—and how—to look. The most effective way is to use specific search terms on Google Maps and dive into local social media groups where smaller, agile print shops often hang out. This strategy gets you in direct contact with a provider, which often means you can pick up your transfers the very same day.

Your Guide to Finding Local DTF Transfers Fast

Let's be real: when a client needs shirts for an event tomorrow, waiting for a package to travel across the country just won't cut it. Finding a local DTF partner gives you a massive speed advantage, shrinking turnaround times from several days down to just a few hours.

Beyond speed, you also get to skip the shipping fees and dodge the dreaded "package delayed" notification. It's about control and peace of mind.

Pinpoint Local Shops with Smart Searches

Your first stop should be Google Maps, but you need to think like a printer. Generic searches like "t-shirt printing" will pull up all sorts of businesses, many of which don't even offer DTF services. You have to be more specific to find the specialists.

Try these search terms instead:

- "DTF print shop" or "DTF printing service"

- "Custom garment transfers"

- "Local heat transfer printing"

These targeted queries cut through the noise. They're designed to surface the smaller, dedicated shops that focus on transfer production. I've found some of my most reliable partners this way—often small, lean operations tucked away in a local business park, focused entirely on pumping out high-quality work with incredible speed.

Tap Into Local Creator Communities

Don't stop at Google. Social media platforms are a goldmine for finding under-the-radar local businesses. I've had great luck on Facebook Marketplace and in local small business or craft groups. Just run a quick search for "custom DTF" or "apparel transfers" within those communities.

You'll often find solo operators or small teams who are incredibly passionate and responsive.

One of the biggest wins of going local is the chance to actually see and touch the product. Before you place a big order, just ask, "Hey, can I swing by and see a sample print?" This simple step lets you vet the color vibrancy, the feel of the transfer, and the overall quality firsthand. It’s a level of quality control you just can't get when ordering online.

Ultimately, looking for custom dtf transfers near me is about more than just convenience. It's about building a real partnership with a supplier you can rely on for fast turnarounds and consistent quality, ensuring your final apparel looks exactly how you imagined it.

Why Local DTF Printing Is Gaining Momentum

If you’ve been searching for "custom dtf transfers near me" and suddenly find yourself with more options than you know what to do with, it’s not just a fluke. You're seeing a fundamental shift in the custom apparel world, and it's all thanks to a technology that feels almost tailor-made for today's creators and small businesses.

For the longest time, screen printing was the undisputed king. It’s fantastic for big runs, but the steep setup costs and minimum order requirements were a huge barrier for anyone needing just a handful of shirts or a one-off design. This is where DTF printing completely changes the game.

The technology is brilliant in its simplicity: print a vibrant, full-color design onto a special film, then transfer it directly onto the fabric. No screens, no messy color separations, and—most importantly—no minimum orders. Whether you need a single transfer or a hundred, the workflow remains incredibly efficient.

The ability to order exactly what you need, when you need it, is a game-changer. It empowers Etsy sellers, local bands, and small brands to produce professional-quality merchandise without the risk of investing in large, unsold inventory. This flexibility is a core reason why local print shops are rapidly adopting DTF technology.

The Power of On-Demand Personalization

We live in an age of personalization, and the demand for unique products is through the roof. Local DTF providers are perfectly positioned to capitalize on this. They can churn out intricate, photorealistic designs with a speed that traditional methods simply can't touch, sparking a new wave of localized manufacturing that brings production right back into our communities.

The numbers don't lie. The global Direct to Film (DTF) printing market, valued at approximately USD 2.72 billion, is on a sharp upward trajectory, projected to hit nearly USD 3.92 billion by 2030. This explosive growth shows just how quickly both businesses and everyday customers are embracing the benefits of on-demand printing.

What This Means for You

So, why does all this momentum matter for your project? Simple. It means you have more high-quality, competitive, and accessible options right in your own backyard than ever before. The technology itself is constantly improving, which translates to better, more durable prints for you.

If you're new to the process, our comprehensive guide to understanding DTF printing for beginners is a great place to start.

This shift puts the power squarely in your hands, allowing you to:

- Test new designs without breaking the bank.

- Fulfill custom orders for your clients quickly and reliably.

- Access professional-grade prints without investing in your own expensive equipment.

The rise of local DTF printing isn't just a fleeting trend. It's a direct, practical response to the demands of a creative economy that thrives on speed, quality, and endless customization.

How to Vet and Choose a Local DTF Provider

Alright, you've got a list of potential local print shops. Now comes the important part: picking the right one. This is about more than just finding the cheapest or closest option. You're looking for a partner, someone whose work will make your designs shine and who you can rely on when deadlines are tight.

Alright, you've got a list of potential local print shops. Now comes the important part: picking the right one. This is about more than just finding the cheapest or closest option. You're looking for a partner, someone whose work will make your designs shine and who you can rely on when deadlines are tight.

Your first move is a digital deep dive. A good provider's website should feel professional and be easy to navigate. If you have to hunt for basic information, that’s not a great sign.

Here’s what you should be able to find easily:

- Clear Pricing: Can you figure out what you'll pay? Look for straightforward costs, whether it's per transfer or by the square foot. Be wary of any shop that isn't upfront about its pricing structure.

- Realistic Turnaround Times: Vague promises like "fast turnarounds" are a dime a dozen. What you really want to see are specific commitments, such as "24-48 hour production".

- Specific File Requirements: A seasoned printer knows that good prints start with good files. They'll tell you exactly what they need: 300 DPI resolution, transparent backgrounds, and preferred file types (like PNG or TIFF).

Digging Deeper Than Star Ratings

Online reviews on platforms like Google or Yelp are a good starting point, but you need to read between the lines. A five-star rating is nice, but a detailed comment that says, “The colors were incredibly vibrant and the transfer still felt soft after five washes,” gives you real insight. Look for patterns in the feedback—good or bad—especially anything related to print quality, durability, and customer service.

One of the biggest market trends fueling the demand for "custom DTF transfers near me" is how local shops are stepping up to offer faster turnarounds. This shift away from massive, centralized production facilities is a huge win for customers like you.

Don't be afraid to ask direct questions before you place an order. A shop that’s serious about quality will appreciate your attention to detail. It proves you're a serious customer who cares about the final product.

Questions to Ask a Potential DTF Provider

Get them on the phone or send a quick email with a few pointed questions. Their answers will tell you a lot about their expertise.

- "What brand of film, ink, and powder do you use?" Even if you don't recognize the brand names, a confident, immediate answer shows they know their equipment and materials inside and out. Hesitation is a red flag.

- "Can I see or pick up a recent print sample?" This is the ultimate test. You need to feel a transfer to judge its texture, stretch, and how vibrant the colors truly are. The proof is in the print.

- "Do you use a hot peel or cold peel film?" This is a technical detail that impacts your application process. Any professional shop will know the answer instantly and might even explain why they chose one over the other. For a deeper dive into different printing methods, see our guide on DTF vs DTG printing methods.

Taking the time to do this homework upfront will save you from the stress and expense of reprints down the line. It's how you find a partner who will consistently deliver flawless transfers.

Getting Your Artwork Ready for Perfect DTF Prints

The secret to a stunning final product almost always comes down to the quality of the digital file you hand over. I’ve seen it time and time again: even the best local DTF shop can't magically fix a blurry, low-resolution image. When you're searching for custom dtf transfers near me, getting the artwork right from the start is the most important step you can take.

Think of your digital file as the blueprint for your shirt. A shaky blueprint leads to a shaky final product. Let's walk through how to avoid those common mistakes that waste both time and money.

Nailing the Technical Details

First things first: your design absolutely must have a transparent background. This is probably the number one mistake beginners make. Unlike printing on paper, any white background left in your file will be printed as solid white ink on the final transfer. Unless a white box is an intentional part of your aesthetic, it needs to be completely removed for a clean, professional print that looks like it's part of the fabric.

Next up is resolution. The gold standard for any garment printing, including DTF, is 300 DPI (dots per inch). If you pull a 72 DPI image from a website and try to blow it up, you’re going to get a pixelated, fuzzy mess. Always start your design in a program like Adobe Photoshop or Affinity Designer at 300 DPI and at the exact size you want it to be printed. This ensures your lines are crisp and your colors pop. The best file formats for the job are PNG and TIFF, as they preserve both quality and that all-important transparency.

A Quick Pro Tip: If your design features very thin lines or delicate text, I'd recommend adding a subtle "stroke" or outline in your design software. Even a 1-2 pixel outline can make a huge difference. It gives the white adhesive powder a little more surface area to grab onto, which seriously improves the durability of those finer details after pressing.

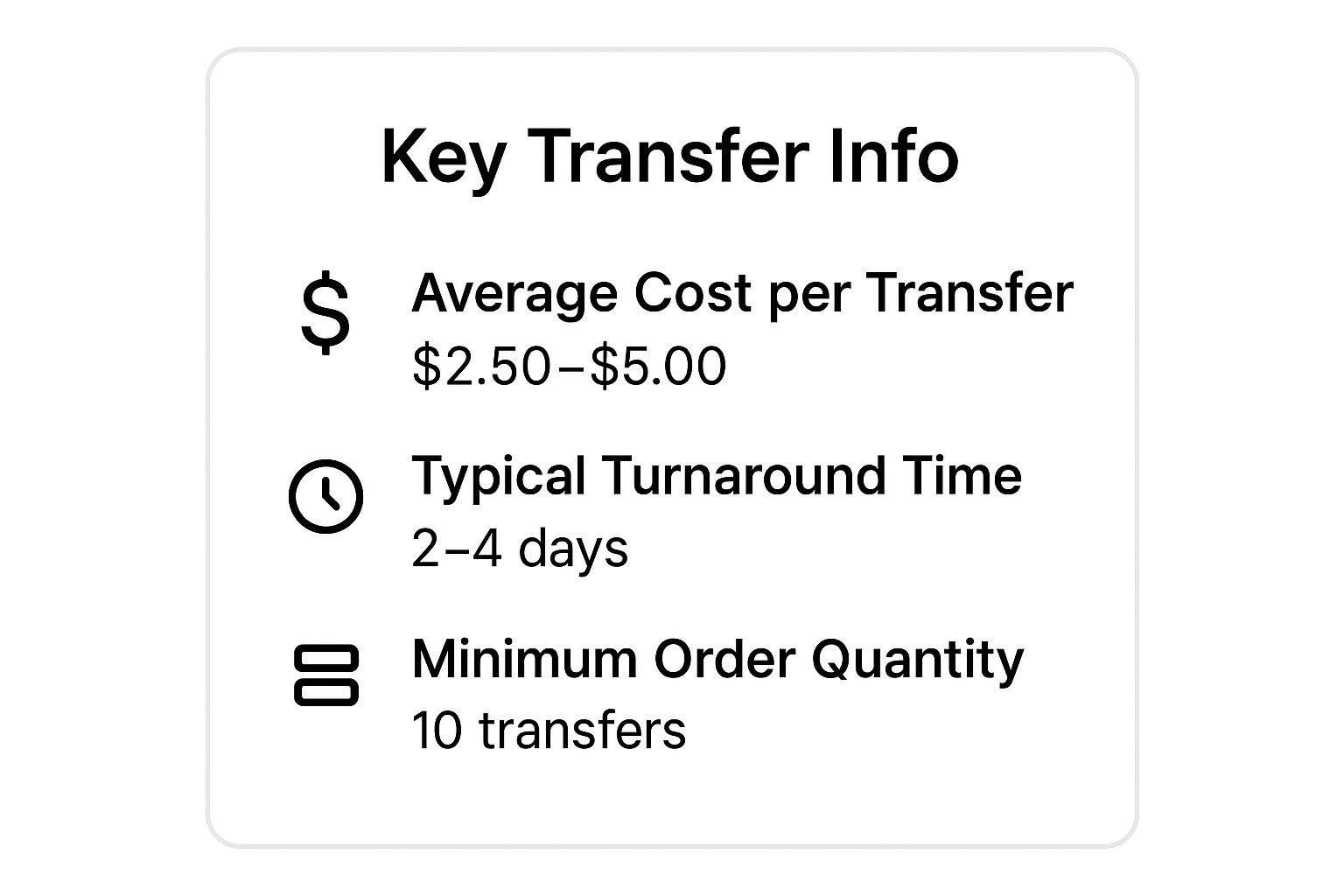

This graphic breaks down some key things to think about when you're planning a local DTF order, from typical costs to how quickly you can get your transfers.

As you can see, DTF is pretty accessible. Most local printers have low minimums, so it’s a great way to test out a new design without a huge investment.

The Artwork Submission Checklist

Before you attach that file to an email and hit send, take a few minutes to run through this checklist. Trust me, this little bit of prep work can save you from a lot of back-and-forth with your printer and avoid frustrating delays.

Artwork Submission Checklist

| Check | Requirement | Why It Matters |

|---|---|---|

| Transparency | Background is 100% transparent. | Prevents an unwanted white box from being printed around your design. |

| Resolution | File is 300 DPI at the final print size. | Ensures a sharp, high-quality print instead of a blurry, pixelated one. |

| File Format | Saved as a high-quality PNG or TIFF. | These formats support transparency and don't compress your file, preserving detail. |

| Clean Edges | Edges are clean and crisp (or intentionally feathered). | Avoids a hard "sticker" look on the garment unless that's the desired effect. |

Spending five minutes on this pre-flight check is the best way to guarantee a smooth process. It ensures you get a final product you’re genuinely excited about and proud to show off.

Bringing Your DTF Prints Home

Once you've handed off your artwork, the ball is in your local provider's court. The first thing you should get back is a digital proof, usually via email. Look it over very carefully. This is your final chance to spot a typo or a color issue before they hit the print button.

After you give them the thumbs-up, they'll queue up your job. Arranging for pickup is typically straightforward—a quick call or text exchange is all it usually takes to get your freshly printed transfers in hand.

The Magic Happens at the Heat Press

Now for the fun part. With your custom transfers ready, it's time to bring your designs to life. A successful application hinges on three critical factors: temperature, time, and pressure. These aren't one-size-fits-all settings; they need to be adjusted based on the specific garment you're printing on.

For a classic cotton t-shirt, a great starting point is often around 300-320°F for 10-15 seconds with medium pressure. But if you’re working with polyester or a blend, you'll need to be more careful. Those fabrics are sensitive to high heat, so you'll want to lower the temperature to avoid scorching the material.

Any good printer will know the ideal settings for their specific transfers. Don't be shy—ask them for their recommended recipe. They should have it ready for you.

There's one piece of information you absolutely must get from your provider: are their transfers hot peel or cold peel? This tiny detail changes everything about your application process and has a massive impact on the final look and feel. It’s a non-negotiable question.

Hot Peel vs. Cold Peel: What’s the Difference?

Getting a great result means understanding which type of film you're working with. The DTF world is largely split between two main types—cold peel film and hot peel film—each designed for different results and materials. It's a big part of what makes DTF so versatile. You can dig deeper into these DTF market film types on kbvresearch.com.

So, what's the practical difference for you?

-

Hot Peel Transfers: Just like it sounds, you peel the film away almost immediately after the heat press opens. It's a quick process that usually leaves a softer, matte finish that feels beautifully blended into the fabric.

-

Cold Peel Transfers: Patience is key here. You need to let the garment cool down completely before even thinking about peeling the film. If you rush it, you'll pull the design right off. The reward is a vibrant, slightly glossier finish known for being incredibly durable.

Knowing which one you have is the secret to a perfect press, every single time.

Your Top Questions About Local DTF Printing Answered

Even after you've found a promising local DTF shop, a few questions usually pop up. It's completely normal. Getting these details sorted out before you place an order is the best way to make sure your project is a success from the get-go.

Let's walk through some of the most common things people ask, so you can move forward with total confidence.

What's a Fair Price for DTF Transfers?

Pricing can definitely vary depending on where you are and how much you're ordering, but a good benchmark is somewhere between $5 to $10 per square foot for gang sheets. For smaller, one-off designs, you'll likely see them priced individually.

Always, and I mean always, ask for a detailed quote upfront. It's also smart to ask if they offer price breaks for larger orders—most local printers will give you a better deal on bulk buys. A good partner will be transparent about their costs, either on their website or by sending you a clear price list.

How Long Will a DTF Transfer Actually Last?

This is the question everyone wants to know, and the answer is one of the best things about DTF. When you use a quality transfer and apply it correctly with a real heat press, you can expect it to hold up for 50-100 washes. Honestly, it's not uncommon for the transfer to outlast the shirt itself.

What makes the difference? It all comes down to the quality of the transfer film, the ink, and the adhesive powder, plus a perfect heat press application. For a deeper dive, check out our complete guide on what determines DTF transfer durability.

Can I Just Use My Home Iron Instead of a Heat Press?

I get why people ask this—it seems like an easy shortcut. But the short answer is a hard no. A home iron just isn't built for this job; it can't provide the consistent, even pressure and exact temperature needed for the adhesive to cure properly into the fabric fibers.

If you try it with an iron, you're setting yourself up for disappointment. You’ll almost certainly see cracking and peeling after the first wash, and the design will feel stiff and cheap. For that soft-hand feel and professional quality that lasts, a heat press isn't just a recommendation—it's essential.

Ready to create amazing custom apparel with a partner you can count on? At Raccoon Transfers, we offer top-tier, ready-to-press DTF transfers with next-day shipping and local pickup options. Start your order today!