What Is the Real DTF Printing Meaning?

Share

So, what exactly is DTF printing? The acronym stands for Direct-to-Film printing, and it's a game-changer for anyone looking to put vibrant, long-lasting designs on fabric. The simplest way to think about it is like creating a high-quality, flexible decal for your clothing. First, a design is printed onto a special film, then it's prepped with an adhesive, and finally, it's heat-pressed right onto the garment.

What Is DTF Printing?

At its heart, DTF printing is a method that moves a design from a sheet of film to a piece of fabric using heat. But unlike some older techniques that leave a stiff, plastic-y feel, a DTF transfer becomes one with the material. It stretches and breathes with the fabric, so you don't have to worry about the design cracking or peeling after a few wears.

This technique really hits a sweet spot in the world of custom apparel. It gives you the full-color, photorealistic detail you'd get from Direct-to-Garment (DTG) printing but with the incredible versatility you find in screen printing. This means you can get brilliant, complex designs on almost any kind of fabric.

Essentially, DTF is a system for producing top-tier, full-color apparel with fantastic detail and durability. To get the job done, you need three key ingredients to work in harmony:

- Specialized Inks: These are the vibrant, water-based inks that bring your digital design to life on the film.

- Adhesive Powder: A crucial fine powder that acts as the "glue," bonding the ink securely to the fabric during the heat press stage.

- PET Transfer Film: This is the clear carrier sheet that holds the printed design and adhesive until it's transferred to the garment.

DTF printing blows the doors wide open when it comes to fabric choices. It neatly sidesteps the material limitations that plague other methods, letting you print on everything from 100% cotton and polyester blends to tricky synthetics and even leather. It’s a genuinely universal solution.

This incredible flexibility is what makes DTF such a go-to choice for everyone, from small Etsy shops working out of their garage to massive, commercial-scale printing operations.

How the DTF Printing Process Actually Works

To really get what DTF printing is all about, you need to follow the design's journey from a simple digital file to a finished piece of clothing. It's a surprisingly straightforward yet precise system, with each step building on the last to create a print that's both brilliant and tough.

The magic starts with a special printer and some unique materials. First, your digital design gets sent to a DTF printer, which is loaded up with specialized water-based inks. But here's the twist: instead of printing on the fabric, it prints the design backward onto a special sheet of PET (polyethylene terephthalate) film.

From Print to Powder

With the ink still wet on the film, we move to the most important part of the process. The entire print is generously coated with a fine, granular thermoplastic adhesive powder. Think of it like a special glue that only sticks to the wet ink, forming the bridge that will eventually lock your design onto the fabric. This very step is what makes DTF so versatile.

Next, the powdered film takes a quick trip through a heat source. The goal isn't to fully cook it, but to gently melt the adhesive powder until it forms a smooth, even layer over the ink. This creates a self-contained, ready-to-press transfer that can be used right away or stored for later. We dive deeper into the finished product in our guide on what a DTF transfer is.

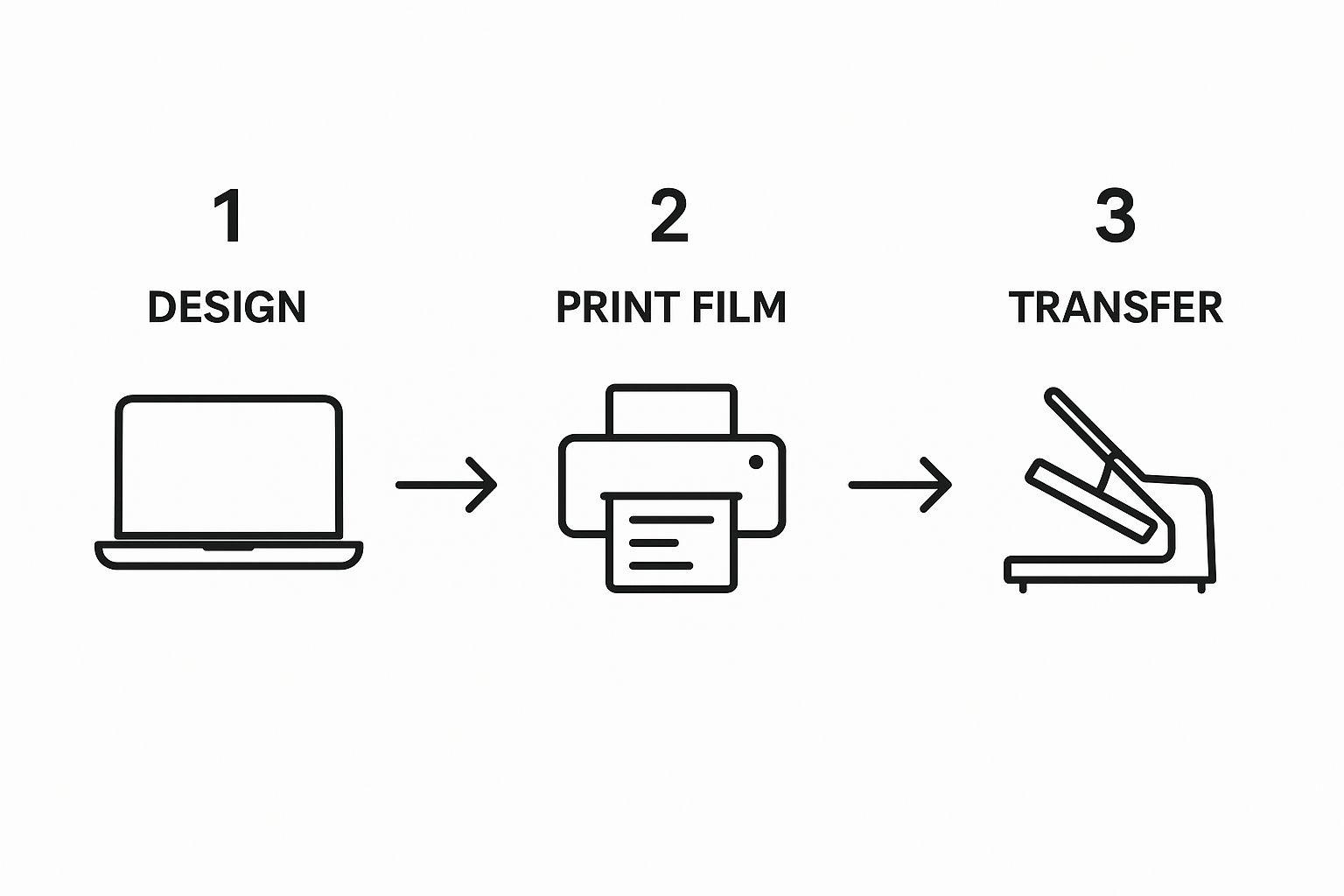

This graphic lays out the entire workflow, from the initial digital concept to the final, press-ready transfer.

As you can see, it’s a streamlined path for turning a great idea into something you can actually wear.

The Final Transfer

For the final step, the cured film is positioned exactly where you want the design on the garment. A heat press then applies the right amount of heat and pressure, which activates the adhesive and permanently fuses the ink into the fabric's fibers.

After a brief cooling period, the PET film is simply peeled away. What's left behind is a crisp, vibrant print that feels soft to the touch and stretches with the fabric.

This blend of quality and simplicity is what’s making the DTF market explode. Valued at roughly USD 667 million in 2025, the industry is projected to grow at a 5.2% CAGR through 2033, largely because so many small businesses are jumping on board for an affordable way to create custom apparel on demand.

The Key Advantages of Choosing DTF

The buzz around DTF printing is well-deserved. It’s not just another trend; it's a practical solution that solves real-world problems for everyone from small business owners to established brands. Simply put, DTF makes professional-grade custom apparel accessible in ways that older methods just can't match.

One of its standout features is its incredible versatility. Forget being locked into specific fabrics. While other techniques like sublimation demand polyester or specially coated surfaces, DTF breaks free from those limitations.

This flexibility opens up a massive creative runway. Suddenly, you can print vibrant, full-color designs on almost anything:

- Classic Cottons: The go-to for comfy t-shirts and hoodies.

- Performance Polyesters: Perfect for athletic apparel that needs to move and breathe.

- Versatile Blends: Handles popular cotton/poly blends with ease.

- Tougher Materials: You can even press designs onto denim, nylon, and leather.

This freedom means you never have to sacrifice your vision for the sake of your printing method.

Quality and Durability You Can Feel

Another huge win for DTF is the look and feel of the final product. The ink bonds to the surface of the fabric, rather than soaking into the fibers. The result is stunningly sharp detail and colors that truly pop, even on black or dark-colored garments.

You might expect a print that sits on top of the fabric to be thick or stiff, but it's surprisingly thin and flexible. It actually stretches with the garment, which prevents the cracking you see with older transfer methods. This toughness gives it serious staying power—with proper care, a DTF print can easily last through 50+ washes without fading or peeling.

The real magic of DTF is its unique balance. It offers the material freedom of screen printing and the full-color detail of DTG, but without the high setup costs or large order minimums.

This blend makes DTF a game-changer, especially for startups, independent designers, and anyone needing top-tier custom gear in small or medium quantities. It levels the playing field, allowing smaller creators to produce apparel with the same visual impact and longevity as major retail brands.

Seeing DTF Printing in the Real World

So, what does DTF printing really mean in practice? It's one thing to understand the mechanics, but the magic happens when you see how it’s being used by real creators and businesses. This isn't just another way to print t-shirts; it's a technology that’s leveled the playing field, making professional-grade custom products accessible to everyone. It's fueling a whole new generation of independent brands and side hustles.

Think about a local band getting its first merchandise line together. In the past, this meant a huge, risky order. With DTF, they can print stunning, durable designs on anything from soft cotton hoodies and denim jackets to tricky polyester hats. They can start small, producing high-quality gear that their fans will genuinely love and wear, without breaking the bank.

Empowering Small Businesses and Creators

That kind of flexibility is a game-changer. A small startup can easily create sharp, professional-looking uniforms for their team. An artist on Etsy can translate their intricate digital illustrations into full-color designs on tote bags. The applications go way beyond standard apparel.

Here are just a few real-world examples I've seen:

- Custom Sportswear: Local sports teams can get personalized jerseys—names, numbers, the works—printed directly onto modern performance fabrics that wouldn't work with other methods.

- Branded Workwear: I've seen construction companies and cafes use it to put their logos on heavy-duty work shirts and aprons that can withstand serious wear and tear.

- Artistic Merchandise: Independent artists can now reproduce their detailed paintings or digital art on canvas bags, hats, or jackets, preserving every color and nuance.

The rise of DTF has seriously shaken up the digital apparel world. It allows for quick, small-batch production runs without the messy, time-consuming setup of older methods like screen printing. This means businesses can jump on trends or fulfill personalized orders almost instantly, with minimal waste.

By knocking down the old barriers to entry, the dtf printing meaning has become synonymous with opportunity. It gives the little guy the power to go head-to-head with big brands on creativity and quality, not just on who can afford the biggest print run.

At the end of the day, DTF technology is democratizing the custom apparel market, one vibrant, incredibly durable print at a time.

Comparing DTF to Other Printing Methods

So, you know what DTF is, but how does it actually stack up against the other big players in the custom apparel world? It's a fair question. To really get a feel for what makes DTF special, it helps to see where it fits in with the old-school and new-school methods you might already be familiar with.

The best printing method always comes down to the job at hand—what you're printing on, how complex the design is, and how many you need to make.

DTF vs. The Competition

Let's break down the main contenders.

-

Direct-to-Garment (DTG): Think of this like your desktop inkjet printer, but for t-shirts. It sprays ink directly into the cotton fibers, which feels incredibly soft. It’s a dream for super-detailed, full-color photos on cotton, but it hits a wall with polyester and often needs a special pre-treatment on dark fabrics to make the colors pop. If you want a deep dive, we've covered the differences in our guide on DTF vs DTG printing methods.

-

Screen Printing: This is the tried-and-true workhorse of the industry, perfect for massive orders. It works by pushing ink through a stenciled screen onto the fabric, one color at a time. The result is a vibrant, incredibly durable print that can last for years. The catch? The setup is a real bear. Each color needs its own screen, so it gets expensive and time-consuming fast for small runs or designs with a lot of colors.

-

Heat Transfer Vinyl (HTV): This is your go-to for simple, bold graphics. Think names and numbers on the back of a sports jersey. You cut your design out of a sheet of colored vinyl and then use a heat press to apply it. It's fantastic for one-offs and simple text, but trying to create a complex, multi-color image with it would be a frustrating puzzle.

The reason DTF is making such waves is that it neatly sidesteps the biggest drawbacks of these other methods. It's no surprise the global Direct-to-Film printing market, valued at USD 2.72 billion in 2024, is projected to climb to USD 3.92 billion by 2030. Its killer combo of versatility and efficiency is what’s fueling that growth.

DTF Printing vs Other Methods

To really put things in perspective, let’s look at a head-to-head comparison. This table breaks down where each method shines and where it falls short.

| Feature | DTF Printing | DTG Printing | Screen Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|---|---|

| Fabric Compatibility | Excellent (Cotton, poly, blends, leather) | Good (Best on cotton, struggles with poly) | Good (Works on most fabrics) | Excellent (Cotton, poly, blends) |

| Feel of Print | Soft, flexible, slightly raised | Very soft, ink soaks into fabric | Varies, can be thick with many colors | Thicker, can feel like a sticker |

| Ideal Order Size | Small to large batches | Small to medium batches | Large batches (100+) | Small batches (1-25) |

| Color Complexity | Unlimited colors, photorealistic detail | Unlimited colors, photorealistic detail | Limited colors, costly for complex designs | Best for 1-3 solid colors |

Looking at the options side-by-side makes it clear. DTF printing bridges the gap perfectly, giving creators the freedom to print vibrant, full-color designs on almost any material without the steep setup costs of screen printing or the fabric limitations of DTG.

Common Questions About DTF Printing

Even after you understand the basics, a few practical questions always pop up when you're looking at a new printing method. Let's dig into some of the most common ones to give you a real feel for what DTF printing can do for you.

How Long Do DTF Prints Last?

This is probably the number one question we get, and for good reason. You want your designs to last. The good news is that DTF prints are incredibly durable. The ink and adhesive powder create a bond that's both strong and flexible, moving with the fabric instead of fighting against it.

With proper care, a quality DTF print can easily handle 50 or more washes without cracking, peeling, or losing its color. If you want to dive deeper into making your prints last as long as possible, our guide on how long DTF transfers last has all the details.

What Do They Feel Like on a Shirt?

Another big question is about the "hand feel." A well-made DTF transfer is surprisingly soft and light. It has a bit more body than a DTG print (which sinks right into the fibers), but it’s much thinner and more pliable than old-school heat transfer vinyl.

The result is a smooth design that feels like part of the shirt, not a stiff sticker sitting on top. It moves with you, so the garment stays comfortable to wear all day.

Is It Expensive to Get Started?

A lot of people assume getting into DTF printing requires a huge investment. While a full professional setup is a serious expense, getting started is actually quite affordable. The easiest way in is to simply order custom-printed DTF transfers from a service.

All you need on your end is a reliable heat press to apply them. This lets you get top-tier results without the massive upfront cost and learning curve of running your own specialized equipment.

It's a common mistake to think any old inkjet printer can handle DTF. That's a definite no. Your standard office printer isn't built for this. DTF requires a purpose-built printer that can handle textile inks and print onto the special PET film. Trying to use the wrong machine will only lead to frustration and a broken printer.

This is a key point for anyone considering a DIY setup. For most small businesses, designers, and hobbyists, working with a dedicated transfer provider is the smartest, most cost-effective route. You get all the benefits of DTF without the headache and expense of maintaining the gear.

Ready to bring your designs to life with unmatched color and durability? Raccoon Transfers offers premium, ready-to-press DTF transfers with next-day shipping. Start creating your custom transfers today!