DTF Transfers in Austin

Share

If you're searching for DTF transfers in Austin, you've come to the right place. The city's legendary mix of tech, art, and music has created the perfect storm for top-tier custom apparel printing, giving you access to incredible services for any project you can dream up.

Ready to get started with high-quality, vibrant prints for your next project? At Raccoon Transfers in Round Rock, we make it easy to bring your designs to life with our fast, reliable DTF printing service. Build your custom gang sheet and order your transfers today!

Why Austin is a Hotspot for Creative Printing

Austin is way more than just the live music capital. It's a buzzing ecosystem where creativity and technology collide, making it an ideal breeding ground for innovative printing methods like Direct to Film (DTF). This town just hums with an energy that demands custom, eye-catching merchandise.

Just think about all the creative ventures happening every single day. Local bands need merch for their next gig at The Continental Club. Tech startups are scrambling for branded swag before SXSW kicks off. Artists down on South Congress are always dropping new apparel lines.

All of them need a printing solution that's quick, vibrant, and can handle a variety of fabrics—which is exactly what DTF brings to the table.

A Culture Built on Customization

The "Keep Austin Weird" slogan isn't just a quirky saying on a bumper sticker; it's a way of life here, built on celebrating individuality. This cultural mindset creates a huge appetite for custom gear. People in Austin don't just want to buy off-the-rack stuff; they want to create and wear things that tell their unique story.

This deep-seated need for personalization has turned Austin into a magnet for printing technologies that put power back in the hands of creators. DTF transfers slot into this world perfectly.

- Full-Color Vibrancy: Designs explode with unlimited colors, which is perfect for detailed art and bold logos.

- Fabric Versatility: You can print on almost anything, from classic cotton tees for a band to polyester performance shirts for a 5K race.

- Accessibility: Low minimum orders mean small businesses and independent artists can get professional results without a huge upfront investment.

Searching for "DTF transfers in Austin" puts you right in the middle of this movement. It connects you to a community where pro-level tools are within reach, helping you turn a great idea into a real, high-quality product.

This environment didn't just happen overnight. Austin's journey from a sleepy college town to a major hub for tech and creative fields laid all the groundwork. The city's long history with semiconductors, software, and massive cultural festivals nurtured an economy that thrives on custom merchandise, making it a natural fit for advanced printing. If you're curious, you can learn more about Austin's evolution into an innovative powerhouse.

Ultimately, the demand for DTF transfers in Austin is a mirror of the city itself—creative, entrepreneurial, and proudly original. It's the place where your vision meets the technology that can bring it to life.

What Exactly Are DTF Transfers?

So, what are these DTF transfers everyone in Austin is talking about? Let's break it down without getting lost in technical jargon. The easiest way to think about it is like a modern, super-durable temporary tattoo, but for your clothes. It’s a brilliant method for putting custom, high-quality designs onto fabric.

Unlike some older printing methods that come with complicated setups or color limitations, Direct to Film (DTF) is refreshingly simple. First, your design is printed directly onto a special, clear film. This film is just the carrier, holding the ink perfectly in place until you're ready to press it.

Here’s where the real magic comes in. A fine adhesive powder is sprinkled over the wet ink on the film. Once it’s heated and cured, that powder melts into a smooth, even layer. Now your transfer is ready to be applied to a t-shirt, hoodie, or just about any other fabric with a heat press.

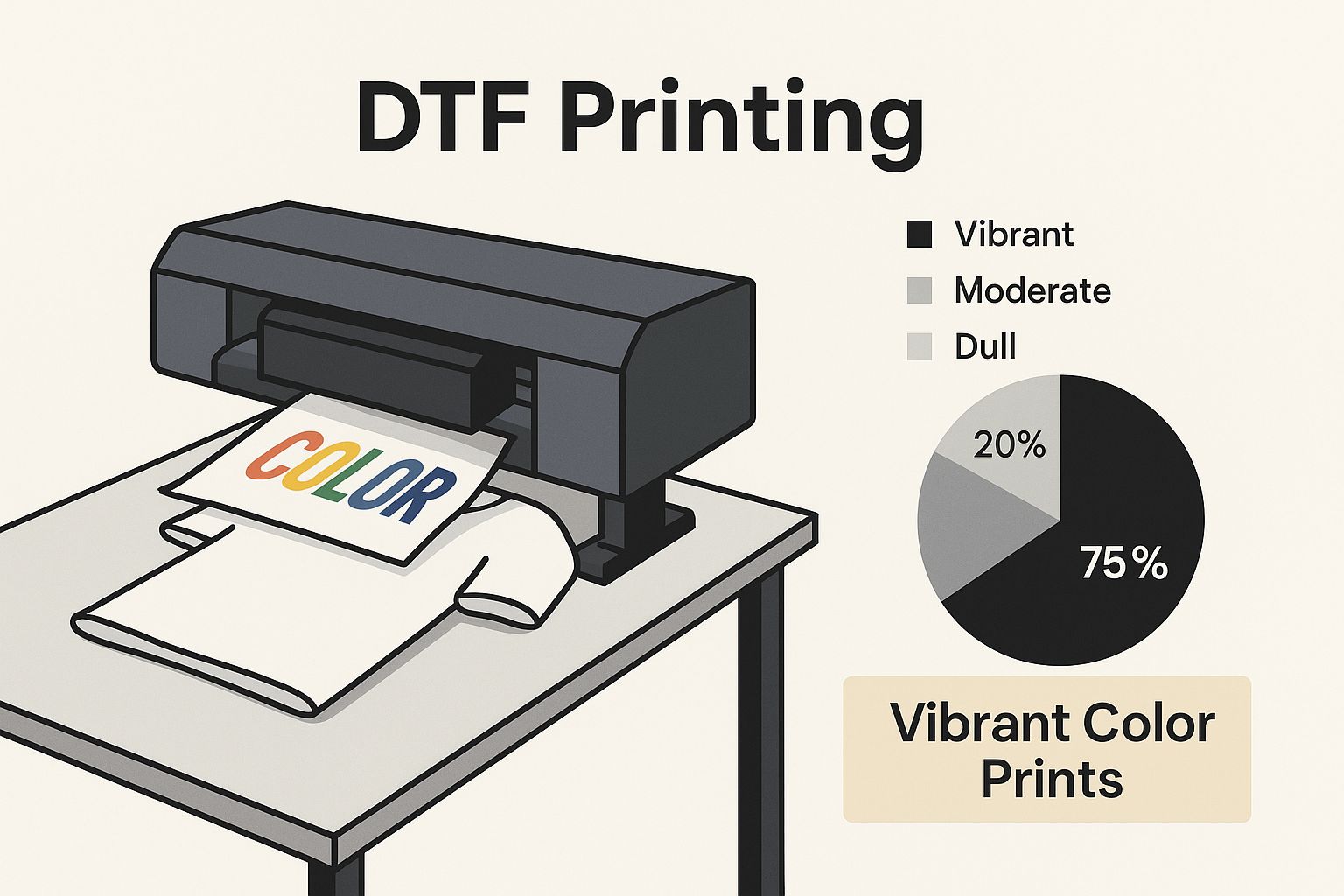

This image shows just how clean and vibrant the results are when a DTF transfer is applied.

You can see how the technology allows for incredibly intricate and colorful designs to be transferred seamlessly onto the shirt, making it a powerful choice for custom apparel.

Why This Method Is So Different

The true strength of DTF lies in its incredible versatility and the professional quality it delivers. Traditional screen printing is a workhorse for big jobs with simple graphics, but it gets expensive and tricky fast when you start adding more colors. On the other hand, heat transfer vinyl (HTV) is great for one-off names and numbers but can't really handle complex, multi-colored artwork.

DTF neatly fills that gap.

Because the design is printed onto a film first, it can capture photorealistic details and an unlimited spectrum of colors in a single pass. This film is then pressed onto the fabric, creating a design that feels soft, flexible, and surprisingly durable.

This is why DTF has caught on so quickly in Austin's creative community, from small Etsy shops to independent artists and brands. The ability to print gorgeous, long-lasting designs on almost any material—from cotton to polyester—without needing special pre-treatments has made it a local favorite.

Comparing DTF with Traditional Printing

To really see where DTF shines, it helps to put it side-by-side with the methods you might already know. Each has its place, but DTF opens up a lot of new possibilities.

| Feature | DTF Transfers | Screen Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|---|

| Color Capability | Unlimited colors, gradients, and fine details | Limited colors, each requiring a separate screen | Limited to solid colors, requires layering for multi-color |

| Fabric Versatility | Works on cotton, poly, blends, leather (light & dark) | Best on cotton, specialized inks needed for others | Works on cotton and polyester |

| Setup Costs | None; ideal for small orders and one-offs | High setup costs (screen creation) | Low setup, but material cost adds up per design |

| Feel on Fabric | Soft, lightweight, and flexible | Can be thick, especially with multiple colors | Can feel like a plastic layer, especially on large designs |

| Durability | Excellent; often outlasts the garment itself | Very durable | Good, but can crack or peel over time with improper care |

| Best For | Full-color photos, complex logos, small to large runs | Large runs of simple, one-to-three color designs | Names, numbers, and simple, single-color graphics |

This table makes it clear: if you need detailed, full-color designs on a variety of fabrics without ordering thousands of pieces, DTF is an incredibly powerful option.

Key Advantages You Need to Know

The benefits of using DTF transfers in Austin go beyond just vibrant colors and sharp details. Here’s a quick rundown of what makes this method so attractive for projects of any size:

- No Fabric Limitations: Seriously. You can press these onto cotton, polyester, leather, and all sorts of blends, whether the fabric is white or black.

- Exceptional Durability: When applied correctly, a DTF print can easily handle over 50 washes without showing signs of cracking, fading, or peeling.

- Cost-Effective for Small Runs: With no major setup fees, it’s completely affordable to print just one custom shirt or a few hundred. This is a game-changer for small businesses and personal projects.

This kind of flexibility is exactly why so many creators in Austin are making the switch to DTF. If you want to dive a bit deeper into the process, you might find our guide on understanding DTF printing for beginners really helpful.

Who Is Using DTF Transfers in Austin?

Walk around Austin on any given day, and you'll see DTF printing in action, even if you don't realize it. This isn't some obscure technique; it's the engine behind much of the custom apparel that gives our city its unique flair. From the creative heart of the city to its bustling business hubs, people are using DTF to bring their ideas to life on fabric.

Picture a local band getting ready for a gig at the Mohawk. They need some killer merch, but a massive order of screen-printed shirts is out of the question for a small run. With DTF transfers, they can get a batch of full-color, pro-quality tees that fans will actually be excited to buy. This story plays out all over Austin's legendary music scene.

Or think about the artists selling their work on South Congress. Suddenly, they can offer an entire clothing line without the huge upfront investment. All it takes is a heat press and their DTF transfers to turn intricate digital designs into wearable art, making their business far more viable.

Powering Brands and Startups

It’s not just the creative crowd, either. Austin's booming tech scene and vibrant small business community have fully embraced DTF transfers in Austin for all kinds of branding.

Every year, countless startups flock to the city for conferences and festivals. They need to look sharp, and that means high-quality swag. DTF is perfect for this, delivering incredibly detailed logos on tote bags, hoodies, and t-shirts that help them make a professional impression.

Local businesses, from your favorite coffee shop to that new fitness studio, use these transfers for everything from employee uniforms to retail gear. A cafe can press its complex logo onto aprons in minutes, and a yoga studio can sell branded performance apparel that holds up wash after wash.

The real power of DTF lies in its versatility. It gives Austin's creators and entrepreneurs a way to produce professional-grade custom apparel quickly and affordably, whether they need ten pieces or a thousand.

A City Built for Quality Merch

Honestly, the demand for great promotional gear is baked right into Austin's DNA. The city is packed with marketing, sales, and tech professionals who need branded items for campaigns, trade shows, and company events.

According to official data, the Austin-Round Rock area is home to thousands of marketing and sales managers—the very people who depend on compelling merchandise to build brand awareness. You can dig into the numbers yourself and see more about Austin's dynamic employment landscape from the BLS.

This professional demand, mixed with the city's independent creative spirit, creates the perfect ecosystem for DTF printing to flourish. It meets the needs of everyone, from a big company gearing up for a major event to an indie designer dropping their very first collection.

How to Choose the Right DTF Provider in Austin

Picking the right partner for your DTF transfers in Austin is a big deal. It's the step that turns your great idea into a real, wearable product. With so many local and national companies out there, it's easy to just look at the price, but that would be a mistake. Who you choose directly affects the quality of your final apparel, how quickly you get it, and how much of a headache the whole process is.

Think about it like hiring a caterer for a big party. You wouldn't just go with the cheapest option without tasting the food, right? You'd check reviews, see if they can handle your guest count, and make sure they'll show up on time. The same exact thinking applies here. A good DTF company is more than a supplier; they're a partner who makes sure your designs look fantastic and arrive when you expect them.

Evaluate Print Quality First

Nothing else matters if the print quality is bad. A low-quality transfer feels like a thick, plastic patch, cracks after one wash, and makes your colors look dull. It can completely ruin an otherwise great design. What you want is a transfer that’s vibrant, has a soft feel, and is built to last.

Here's how to check for quality:

- Request a Sample Pack: This is non-negotiable. Never place a big order without seeing and feeling the product yourself. Reputable companies, including services like Raccoon Transfers, will gladly send you a sample pack to test.

- Check Color Accuracy: Do their colors pop? A good provider uses professional-grade inks and printers to get the colors just right. You want to see deep, rich blacks and bright, vivid colors that match your artwork.

- Examine the Adhesive: Flip the transfer over. The white adhesive on the back should be a clean, even layer. If it looks clumpy or inconsistent, it’s a red flag for a poor press and future peeling.

Understand Their Pricing and Turnaround Time

Once you're confident in the quality, it's time to talk logistics. The cost and speed of delivery can be all over the map, so you need to know exactly what you’re paying for and when your transfers will land on your doorstep.

A common mistake is getting fixated on the cost per transfer sheet and ignoring the turnaround time. A slightly cheaper print that shows up a week late could cost you a client or make you miss an event deadline. Suddenly, that "deal" isn't such a good deal anymore.

Take a close look at their pricing model. Most services let you order "gang sheets," where you can place multiple designs on one large sheet (a common size is 22"x60"). This is the most cost-effective way to order. Compare prices for these sheets, but don’t forget to check their shipping options. Finding a provider that offers next-day shipping can be a true game-changer for those inevitable rush jobs.

Assess Customer Support and File Requirements

Finally, a great DTF provider should make your life easier, not harder. You want to work with a company that has responsive and genuinely helpful customer service. If you have a question about your file or the application process, you should be able to get a clear answer quickly.

Before you even think about ordering, find their artwork guidelines. Most shops will require a 300 DPI file with a transparent background (a PNG file is perfect for this). A good supplier will have this information laid out clearly on their website. Some, like Raccoon Transfers, go the extra mile with online tools that help you build your gang sheet right on their site. Choosing a company that invests in a smooth ordering process will save you a ton of time and frustration down the road.

Ordering and Applying Your DTF Transfers

Alright, you’ve got a killer design and you're ready to see it on a real shirt. This is where the magic happens—turning your digital art into a tangible, wearable product. It's a pretty straightforward path from artwork to finished garment, but paying close attention to the details is what separates a professional-looking shirt from an amateur one.

Think of your artwork file as the foundation of a house. If the foundation is shaky, the whole structure will be weak. It’s the exact same with DTF transfers in Austin; a low-quality file will always result in a blurry, pixelated print that looks cheap, no matter how nice the shirt is.

Preparing Your Artwork for Success

Before you even browse for a local printer, getting your artwork file in order is the most critical step you'll take. Honestly, a little bit of prep work here prevents a mountain of frustration down the road. This ensures your transfers come out looking sharp, vibrant, and just how you pictured them.

Here’s what you absolutely need to get right:

- High Resolution: Your design file needs to be at least 300 DPI (dots per inch). This is non-negotiable for crisp lines and clear details. Grabbing a small image off Google and blowing it up just won't cut it.

- Transparent Background: This is a big one. The background of your image must be transparent. Why? Because DTF printers print everything they see. If your logo has a white box around it in the file, you'll get a white box printed on your shirt. Save your file as a PNG to make sure the background stays clear.

- Correct Sizing: Size your artwork to the exact dimensions you want it to appear on the garment. If you try to make a small design larger after the fact, you'll lose quality and end up with a blurry mess.

Placing Your Order

With your file prepped and ready, ordering is usually a breeze. Most modern DTF shops have a slick online system where you can upload your art directly. A common practice is to create a "gang sheet," which is basically one large sheet of transfer film where you can place multiple designs.

This is a huge plus for anyone in Austin who wants to print different designs without being forced into a large order of just one. You can squeeze in a few chest logos, some sleeve prints, and maybe a couple of full-back designs all on a single sheet. It's an incredibly smart way to get more for your money.

Applying Your Transfer with a Heat Press

Now for the fun part—actually pressing the design onto your fabric. You might see some guides talking about using a home iron, but for DTF, I strongly advise against it. A good heat press is the only way to get the consistent, even pressure and temperature needed for the transfer's adhesive to properly bond with the fabric.

Here’s a simple, step-by-step walkthrough for a perfect application every time:

- Set Your Heat Press: First things first, preheat your press. The sweet spot is usually between 280-320°F (138-160°C). Always double-check the instructions from your transfer provider, as the ideal temp can change depending on your fabric.

- Pre-Press the Garment: Lay your shirt flat on the press and give it a quick 5-10 second press. This irons out any wrinkles and gets rid of hidden moisture, giving you a perfect canvas to work on.

- Position and Press: Carefully place your DTF transfer onto the shirt, design side up. Cover it with a Teflon sheet or parchment paper, and press down with firm pressure for about 10-15 seconds.

- Master the Cold Peel: This step is crucial. Once the timer goes off, take the garment off the press and let it cool down completely. Seriously, walk away for a minute. Once it’s cool to the touch, you can gently peel the film off. If you peel it while it’s hot, you'll pull the design right off with it.

- Final Cure: For maximum durability, I always recommend a final press. Just place the parchment paper back over the finished design and press for another 5-10 seconds. This really locks it in and ensures it lasts.

Sticking to these steps will give you a vibrant, durable print that has a soft feel and can withstand dozens of washes. The process shares some DNA with other heat transfer methods, but the specific temperature range and the all-important cold peel are unique to DTF. If you’ve worked with other materials, our guide on how to use heat transfer paper provides a great point of comparison.

Common Questions About DTF Transfers

Jumping into a new printing method always brings up a few questions. When you're looking to get DTF transfers in Austin, you want to feel confident you're making the right choice. Let's walk through some of the most common questions we hear, from cost and file types to what you can expect after the wash.

How Much Do DTF Transfers Cost in Austin?

The price for DTF transfers in Austin almost always boils down to the provider and how much you're ordering. Most services, including ours, price by the "gang sheet"—a large sheet of printable film (ours are typically 22x60 inches) where you can pack in as many designs as you can fit. This is, by far, the most cost-effective way to buy.

A single gang sheet usually lands somewhere between $15 and $25, which can drive your cost per individual design down to just pennies. While some shops might offer a per-piece price for tiny orders, buying by the sheet gives you the best bang for your buck. Plus, a huge advantage over screen printing is that most DTF printers have absolutely no setup fees.

By arranging different designs on one sheet, you can print a whole collection of merchandise at once—think chest logos, sleeve details, and full back graphics—all for one flat fee. It’s a smart way to maximize your budget and get creative.

What Kind of Artwork File Do I Need?

Your artwork file is the foundation for a great-looking print. For professional results, you need a high-resolution digital file with a 100% transparent background. Seriously, this is crucial. If your file has a white box around the logo, that white box is going to get printed right onto your shirt.

The best file formats to send your printer are:

- PNG: This is the go-to for most people. It handles high resolution and transparency perfectly.

- AI (Adobe Illustrator): The ideal choice for vector designs, as they can be scaled to any size without losing a drop of quality.

- PSD (Adobe Photoshop): A solid option for raster images, but you have to make sure it's set up correctly with a transparent layer.

The single most important technical requirement? Your file must have a resolution of at least 300 DPI (dots per inch). Grabbing a low-quality JPEG off a website will only lead to a blurry, pixelated transfer that cheapens the look of your final product.

How Long Will My DTF Transfer Last on a Shirt?

This is where DTF really shines. A quality DTF transfer that's been applied the right way is incredibly tough. It can easily handle 50 or more washes without cracking, peeling, or fading. It’s not uncommon for the print to actually outlast the t-shirt it's on.

Getting that kind of longevity is all about simple care. Just turn the garment inside out before washing, use cold water, and either tumble dry on low or hang it up. You'll also want to avoid harsh chemicals like bleach and fabric softeners, as they can break down the print's bond over time. For a much deeper dive, take a look at our complete guide on how long DTF transfers last and how to maximize their durability.

Can I Apply DTF Transfers with a Home Iron?

Look, I get the temptation. But if you want a professional-grade transfer that will actually last, using a home iron is a really bad idea. A heat press is an absolute must-have for DTF. It does two things an iron simply can't: deliver perfectly even pressure and hold a consistent, accurate temperature across the entire design.

An iron has hot spots and applies pressure unevenly, meaning the transfer's adhesive won't bond properly to the fabric. This pretty much guarantees the design will start peeling or cracking after just a wash or two. To get a durable, high-quality finish you can be proud of, a heat press isn't just a suggestion—it's a requirement.