A Guide to Fabric Printing Techniques

Share

Welcome to the world of fabric printing! Getting your design onto a piece of fabric might seem straightforward, but the method you choose is one of the most critical decisions you'll make. It affects everything: the look, the feel, the durability, and of course, the cost.

This guide will walk you through the most popular printing techniques out there today. We'll break down the pros and cons of each, so you can confidently pick the perfect match for your project.

Understanding the Printing Landscape

The textile printing industry is a fascinating mix of old-school craftsmanship and new-school tech. You have traditional methods that have been workhorses for decades, sitting right alongside digital printers that can create a photo-quality t-shirt in minutes. Each one has its place.

Screen printing, for example, is the undisputed king of large-scale production. Think concert tees, company uniforms, and brand merchandise. On the flip side, the boom in online stores and personalized everything has pushed digital printing into the spotlight, giving creators incredible flexibility for one-off and small-batch orders.

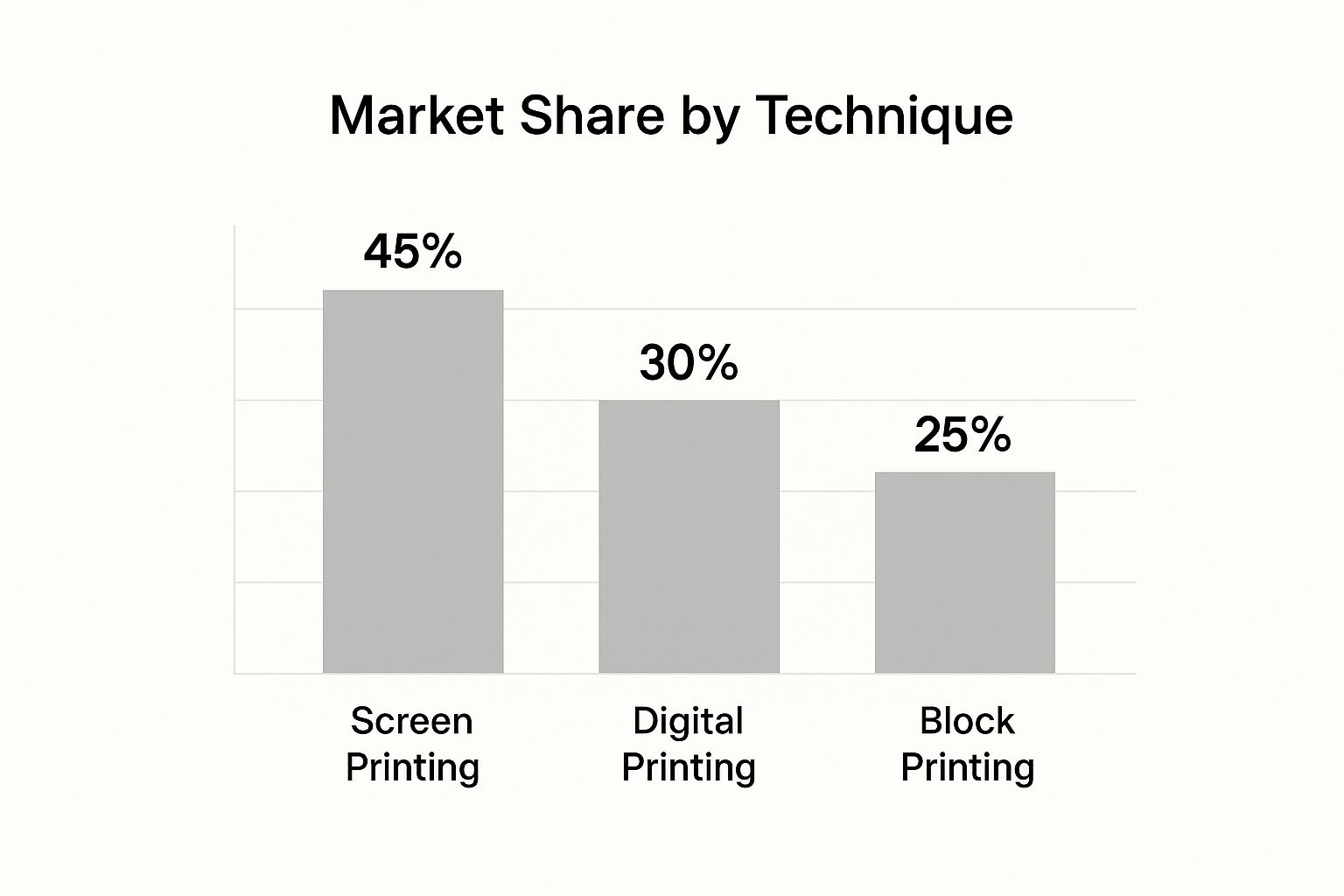

This chart gives you a quick snapshot of who's who in the market.

As you can see, screen printing still holds a massive 45% market share, but digital methods are catching up fast, proving they are a serious force in the industry.

Key Factors to Consider

Before we dive into the nitty-gritty of each technique, let's talk about what you need to think about first. The right choice for one project could be a complete disaster for another.

Keep these three things at the front of your mind:

- Fabric Composition: What is your item made of? Natural fibers like cotton behave very differently from synthetics like polyester. The ink has to be compatible with the material.

- Order Quantity: Are you making one special piece or a run of 1,000? Some methods have high setup costs that only make sense for bulk orders.

- Design Complexity: Is your design a simple, one-color logo or a complex, full-color photograph with subtle gradients? Not every technique can handle fine detail.

Thinking through these criteria first will save you a ton of headaches. It helps you instantly rule out the wrong options and zero in on the methods that will make your project a success.

To give you a bird's-eye view, here's a quick comparison of the most common methods we'll be covering.

Quick Comparison of Popular Fabric Printing Methods

| Technique | Best For | Fabric Compatibility | Feel on Fabric |

|---|---|---|---|

| Screen Printing | Large batches (100+) with simple designs (1-4 colors). | Cotton, blends, and most natural fibers. | Can feel slightly thick, a distinct layer of ink on top of the fabric. |

| Direct-to-Garment (DTG) | Detailed, multi-color designs in small quantities. | Best on 100% cotton; works on high-cotton blends. | Very soft and breathable, as ink soaks into the fibers. |

| Dye Sublimation | All-over, photo-realistic prints on light-colored synthetics. | 100% polyester is ideal; works on poly-blends. | No feel at all; the ink becomes part of the fabric itself. |

| Heat Transfer Vinyl (HTV) | Simple logos, names, and numbers on various items. | Works on almost any fabric: cotton, polyester, blends, nylon. | A smooth, plastic-like layer that sits on the fabric surface. |

| Direct-to-Film (DTF) | Vibrant, complex designs on any fabric type or color. | Cotton, polyester, nylon, leather—extremely versatile. | Soft and flexible, but you can feel a thin, rubbery layer. |

This table is just a starting point. As we explore each method in detail, you'll get a much clearer picture of how these differences play out in the real world.

The Enduring Art of Screen Printing

Screen printing, sometimes called silk screening, is one of the true OGs of the t-shirt world. For decades, it's been the go-to method for creating bold, vibrant designs that are built to last. If you’ve ever bought a band t-shirt that felt indestructible, chances are it was screen printed.

At its core, screen printing is a sophisticated stenciling technique. A special ink is pushed through a fine mesh screen directly onto the fabric. Each color gets its own screen, allowing for crisp, clean layers that create the final image.

How Does Screen Printing Actually Work?

The magic behind screen printing is beautifully simple. Think of it like painting with stencils, but with much more precision and specialized gear. To get a design from a digital file onto a shirt, a screen needs to be made for every single color in that design.

Here’s a look at the process, step by step:

- Screen Prep: A mesh screen is coated in a light-sensitive emulsion. The design for one color is printed onto a transparent film, placed on the screen, and exposed to bright light. The light hardens the emulsion everywhere except where the design is, creating a perfect stencil when the screen is washed out.

- Applying the Ink: The t-shirt is laid flat on a printing press, and the first screen is carefully aligned on top. A generous amount of thick plastisol or water-based ink is poured along one edge of the screen.

- The Squeegee Pass: Using a rubber squeegee, the printer pulls the ink across the screen with firm, even pressure. This forces the ink through the open areas of the stencil and onto the fabric below.

- Building the Design: For multi-color designs, the shirt is moved to the next station, and the process is repeated with a new screen and a new color. This is done for every color until the full image is assembled.

- Curing: The final, crucial step. The garment is sent through a conveyor belt dryer, where high heat cures the ink. This bonds it to the fabric fibers, making the print tough and flexible.

This hands-on, layered approach gives screen prints their classic, slightly raised feel. It’s a craft that demands a skilled operator to get those colors lined up just right.

The real superpower of screen printing is its color vibrancy. Because the ink sits on top of the fabric instead of soaking in, it produces incredibly bright and opaque colors. This is especially true for dark garments, where other methods can look faded or washed out.

The Good, The Bad, and The Inky

No printing method is the right tool for every single job, and screen printing is no exception. It absolutely shines when you need to print a lot of the same thing. Think uniforms for a company, merch for a music festival, or a massive run of promotional tees.

Why People Love Screen Printing:

- Insane Durability: Properly cured screen prints are legendary for their ability to withstand years of washing and wear without cracking or fading.

- Vibrant, Punchy Colors: It’s the best way to get bright, solid colors that truly pop, even on black or navy blue fabrics.

- Cost-Effective in Bulk: While setting up the screens takes time and money, the cost per shirt plummets as your order size goes up. It's the king of high-volume production.

But there are a few downsides. All that setup work makes it a poor choice for small orders or one-off custom prints—the costs are just too high. It also struggles with photorealistic images or designs full of subtle color gradients. For those, a digital method is usually a better fit. To see how it stacks up against a popular digital competitor, check out our guide on DTF vs. DTG printing.

Ultimately, screen printing is at its best with bold, graphic designs that use a limited number of solid colors.

Modern Precision with DTG Printing

If screen printing is the old-school workhorse of the apparel industry, think of Direct-to-Garment (DTG) printing as its younger, digital-savvy cousin. The concept is surprisingly simple: it’s like your home office inkjet printer, but supercharged to print directly onto fabric. Instead of paper, it sprays specialized water-based inks right into the cotton fibers of a t-shirt or hoodie.

This direct-to-fabric approach is what lets DTG create stunningly complex designs. We're talking millions of colors, photographic details, and gradients so smooth they look like they were painted on. It's the perfect method for bringing photorealistic images or intricate, colorful artwork to life in a way that would be a nightmare for traditional screen printing.

And because the whole process is digital, there are no setup costs. You don't have to burn screens for every color. This is a game-changer for anyone needing just one custom shirt, a small batch for an event, or running a print-on-demand shop.

How Does It Actually Work?

The DTG process is a neat blend of digital tech and textile science. First things first, the garment gets a pre-treatment. This is a crucial step where a special solution is applied, acting like a primer on a wall. It helps the ink grab onto the fabric fibers, ensuring the final print is vibrant and won't wash out after a few cycles. This works best on 100% cotton or high-cotton blends.

Next, the shirt is smoothed onto a flat plate, called a platten, and loaded into the printer. The machine then gets to work, jetting the ink directly onto the fabric with incredible precision. After the design is printed, the garment takes a quick trip through a heat press. This cures the ink, permanently locking the design into the fibers.

The result is a print that feels incredibly soft and flexible. Since the ink becomes part of the fabric instead of sitting like a thick layer on top, the shirt remains breathable and comfortable.

One of the biggest wins for DTG is the "soft hand" feel. That just means the print doesn’t feel stiff or heavy. It maintains the natural comfort and drape of the fabric, which is why it’s a top choice for high-quality retail apparel.

Is DTG Always the Right Choice?

DTG offers amazing creative freedom, but it's not a one-size-fits-all solution. You have to know its strengths and weaknesses to decide if it's the right tool for your specific project.

Where DTG Really Shines:

- Unlimited Colors: Want a full-color photograph on a shirt? No problem. DTG handles millions of colors and complex gradients without adding cost.

- Insane Detail: The inkjet technology can reproduce incredibly fine lines and sharp details that other methods just can't touch.

- No Minimums: Because there are no screens to make, printing a single shirt is just as easy as printing 20. This is fantastic for small businesses and creators.

- Super Soft Feel: The ink soaks right into the fabric, so the final print is lightweight and breathable.

But it’s not perfect. DTG works best on natural fibers, as its water-based inks have a tough time bonding with synthetics like polyester. For large runs, the per-shirt cost is also higher than screen printing, making it less economical for big bulk orders.

In fact, another modern technique, Direct-to-Film, is a powerful alternative that offers much more flexibility with fabrics. You can get the full rundown by reading our guide on what Direct-to-Film printing is.

At the end of the day, DTG is your go-to for high-detail, low-volume projects on cotton, delivering incredible quality for custom and on-demand apparel.

5. Dye Sublimation: A Tattoo for Your Fabric

When you want a print that’s truly permanent, nothing beats dye sublimation. This technique is a fascinating blend of chemistry and art. Instead of just laying ink on top of a garment like most methods, sublimation actually infuses the dye right into the fabric's fibers.

The best way to picture it is like a tattoo for fabric. The ink doesn't just sit on the surface; it becomes a genuine part of the material. This fusion is what gives sublimation prints their signature traits: they have absolutely zero feel and will last forever.

Because the dye is embedded in the fabric, you can't feel the design at all. Run your hand across the print, and it feels exactly the same as the rest of the shirt. This means the original soft, breathable feel of the garment is perfectly preserved, making it the go-to choice for performance wear where comfort is everything.

How Does It Actually Work?

The sublimation process is pretty cool and relies on some specific chemistry to pull it off. First, your design is printed onto a sheet of special transfer paper using sublimation inks. This paper just acts as a temporary carrier for the solid dye particles.

Next, you lay the transfer paper on your fabric and place both into a heat press. This is where the magic happens. The press applies intense heat—usually between 380-420°F—and firm pressure, which kicks off a unique reaction.

The heat causes the solid dye on the paper to skip the liquid phase entirely and turn straight into a gas (that's the "sublimation" part). At the same time, the high temperature opens up the pores of the polyester fibers, letting the gas sink deep into the material. As everything cools, the pores snap shut, trapping the dye inside the fibers for good.

The result is a print that's stunningly vibrant and photo-realistic. Since the dye is now part of the fabric itself, the design will never crack, peel, or fade, no matter how many times you wash it.

When to Go with Sublimation

Dye sublimation is the undisputed champ for certain jobs, especially when you need edge-to-edge printing or brilliant, long-lasting colors.

Sublimation is perfect for:

- All-Over-Print Apparel: If you want a design that covers an entire shirt, seam to seam, sublimation is the only way to get a flawless result with no texture.

- Performance Sportswear: Think cycling jerseys, running shirts, and athletic leggings. The process doesn't clog the fabric's pores, so it maintains its moisture-wicking and breathable properties.

- Promotional Items: Custom lanyards, mousepads, and trade show banners get their vibrant, durable branding from sublimation.

- Photographic Prints: It can reproduce images with incredible clarity and color, making it ideal for putting photos on fabric gifts like blankets or pillows.

The Fine Print: Limitations to Know

As powerful as it is, sublimation has a couple of non-negotiable rules. First, it only works on synthetic fabrics. You'll get the absolute best and brightest results on 100% polyester. It can work on poly-blends, but the colors will look more faded or "vintage" because the dye can only bond to the polyester fibers, not the cotton ones.

The second major limitation is color. Sublimation ink is transparent, so it can only be used on white or very light-colored fabrics. Trying to sublimate on a dark shirt is like using watercolors on black paper—the design just won't show up. Because of these constraints, dye sublimation is a highly specialized tool, but for the right project, it’s unbeatable.

A Look at Other Specialized Printing Methods

While screen printing, DTG, and sublimation tend to get most of the spotlight, the world of fabric printing is full of other specialized tools for very specific jobs. Techniques like Direct-to-Film (DTF) and Heat Transfer Vinyl (HTV) offer some really unique advantages, and old-school crafts like block printing bring an artisanal touch that modern machines just can't match.

Getting to know these alternatives can open up a ton of new creative doors. Whether you need something that works on literally any fabric, a quick way to slap bold logos on team gear, or a connection to a timeless art form, there's a perfect technique out there waiting for you.

Direct to Film: The Versatile Newcomer

Direct-to-Film, or DTF, is a clever hybrid method that gives you the full-color detail of digital printing but with incredible versatility. The best way to think of it is like creating a high-quality, durable sticker that becomes part of the fabric. The process starts by printing your design onto a special transfer film, applying an adhesive powder, and then using a heat press to bond it to the garment.

That two-step process is DTF's superpower: it works on almost anything. Since the design is transferred as a complete, self-contained unit, it doesn't really care what the fabric is made of.

- Cotton and Blends: You get vibrant, solid colors on both light and dark cotton fabrics without any trouble.

- Polyester and Synthetics: It’s a fantastic workaround for athletic wear that can't be sublimated.

- Leather and Nylon: DTF adheres beautifully to tricky materials that often make other inks peel or fade.

The final print feels soft and flexible, with a slight texture that’s much thinner and more comfortable than old-school vinyl. It really hits a sweet spot, offering the full-color freedom of DTG without being so picky about fabric types.

DTF effectively bridges the gap between other printing methods. It delivers the multi-color freedom of DTG, the broad fabric compatibility of screen printing, and the ease of a heat-press application, making it one of the most adaptable fabric printing techniques available today.

This adaptability makes DTF a phenomenal choice for small businesses and brands. You can print the exact same complex design across a whole range of products—from cotton t-shirts to polyester hoodies and even nylon tote bags—with consistent, high-quality results.

Heat Transfer Vinyl for Bold, Punchy Graphics

If you need crisp, bold, and simple graphics with a clean, professional look, Heat Transfer Vinyl (HTV) is your go-to. Ever seen the name and number on the back of a sports jersey? You’ve seen HTV in action. The process couldn't be more straightforward: a machine cuts your design from a sheet of colored vinyl, and then a heat press permanently bonds it to the fabric.

HTV shines where other methods struggle, especially for one-off customizations and simple, solid-color designs. It’s not built for photorealistic images or complex patterns, but for logos, text, and basic shapes, it’s incredibly effective. The result is a smooth, slightly raised design that sits right on top of the fabric.

This method is a huge hit with hobbyists and small businesses because the barrier to entry is pretty low. All you really need to get started producing high-quality custom gear is a good vinyl cutter and a reliable heat press.

The Timeless Craft of Block Printing

Long before digital printers and automated presses even existed, artisans were creating breathtaking textiles by hand using block printing. This ancient craft is beautifully simple: you carve a design into a block of wood, apply ink or dye, and press it firmly onto the fabric to transfer the image. By repeating the process, you can create wonderfully intricate patterns.

As one of the oldest fabric printing techniques known, block printing dates back to around 3000 BCE. It was a game-changer, allowing for the "mass production" of patterned fabrics long before machines came along, and was often used for cultural storytelling. You can dig deeper into these foundational innovations in this overview from Locofast.com.

While you won't find it in modern commercial apparel production, block printing is making a huge comeback among crafters and textile artists who cherish its unique, organic look. Each print is slightly different, carrying subtle imperfections that give it a character and charm that no machine could ever replicate.

To help you get a clearer picture of where these techniques fit, we’ve put together a handy comparison table.

Feature Breakdown of Printing Techniques

This table breaks down the key differences between DTF, HTV, and Block Printing, looking at factors like ideal order size, design complexity, and material compatibility.

| Technique | Ideal Volume | Design Complexity | Durability Rating (1-5) | Best Fabric Type |

|---|---|---|---|---|

| DTF | Small to Medium | High (Full Color) | 4 | Any (Cotton, Poly, Blends) |

| HTV | Small Batches | Low (Simple Shapes/Text) | 4 | Any (Cotton, Poly, Blends) |

| Block Printing | One-Off / Artisanal | Low to Medium | 3 | Natural Fibers (Cotton, Linen) |

Ultimately, exploring these different methods shows just how rich and varied the world of fabric printing is. Whether your project needs the modern flexibility of DTF, the graphic punch of HTV, or the handmade beauty of block printing, the perfect tool is out there to bring your vision to life.

How to Choose the Right Method for Your Project

Picking the right printing technique can feel like you're staring at a giant menu with too many options. But don't worry, it's actually pretty straightforward once you know what to look for. Think of it less like a test and more like a simple checklist.

By answering just a few key questions about your project, you can quickly zero in on the perfect method. Getting this right from the start means your final product will look, feel, and wear exactly how you want it to, saving you a ton of time and potential headaches down the road.

Consider Your Fabric Composition

First things first: what is the shirt or garment actually made of? This is the most critical question because different printing methods are chemically designed for specific fibers. Mismatching the ink and the fabric is a surefire way to get a print that cracks, fades, or washes out immediately.

- Natural Fibers (Cotton, Linen, etc.): For anything cotton-based, DTG printing is king. Its water-based inks soak right into the natural fibers, creating a soft, breathable print. Screen printing is also a classic, top-tier choice for cotton, known for its punchy colors and incredible durability.

- Synthetic Fibers (Polyester): If you're working with 100% polyester, especially for sportswear, dye sublimation is the undisputed champion. It dyes the fabric itself, leaving a permanent design with absolutely zero feel. For tricky poly-blends or dark-colored synthetics where sublimation won't work, DTF is the go-to solution, offering bright, stretchy prints on almost anything.

Evaluate Your Order Quantity

How many pieces do you need to make? This is where the economics of each method really come into play. Some techniques are built for mass production, while others are perfect for one-off custom jobs.

Let's say you need 500 shirts for a corporate event with a simple two-color logo. That’s a job practically screaming for screen printing. The upfront setup takes time, but once you're rolling, the cost per shirt becomes incredibly low.

But what if you just want one custom t-shirt for a birthday gift, or maybe a small run of ten for your band? The setup costs for screen printing would be way too high. In this case, DTG or DTF are the obvious choices because they have virtually no setup and are perfect for small orders.

Choosing a method based on quantity isn't just about price; it’s about efficiency. Using screen printing for a single shirt is like hiring a full catering team to make one sandwich—the tool simply doesn't match the scale of the job.

Analyze Your Design Complexity

Finally, take a good look at your artwork. A simple, bold logo has completely different requirements than a full-color photograph packed with gradients and tiny details.

If your design has just a few solid colors and sharp lines—think team logos or bold text—screen printing or heat transfer vinyl are fantastic, reliable options. But if you're trying to print a photorealistic image or an intricate illustration with tons of colors, DTG is the clear winner. It’s essentially an inkjet printer for fabric, capable of reproducing millions of colors with stunning precision.

For those who need that same level of detail but on a fabric that DTG can't handle (like polyester), DTF is an excellent alternative. And if you're just dipping your toes into heat press methods at home, this step-by-step guide on how to use heat transfer paper is a great place to start.

Answering Your Top Fabric Printing Questions

Diving into the world of custom apparel always brings up a few key questions. How long will the print really last? What's the most wallet-friendly option? Can I print on this specific type of fabric? Getting these answers right is the difference between a project you love and one that disappoints.

Let's clear up some of the most common questions I hear from people just starting out.

How Long Will My Print Last?

This is probably the number one concern, and for good reason! The answer really comes down to the printing method you choose.

- Screen Printing: When it comes to pure toughness, screen printing is the undisputed champ. That thick layer of ink cures into a durable, flexible finish that can easily handle hundreds of washes without giving up. It's the classic for a reason.

- Dye Sublimation: This method is in a league of its own for permanence. Since the ink literally becomes part of the polyester fibers, the design is there for good. It will last as long as the garment itself, with zero chance of peeling, cracking, or fading.

- DTG & DTF: Both of these modern digital methods offer great durability. With proper care, you can expect them to hold up well for 50+ washes. The trick is to follow the care instructions—like turning the shirt inside out before washing—to get the most life out of the print.

What Is The Most Cost-Effective Printing Method?

"Cost-effective" is all about context, specifically your order size. There’s no single cheapest method; the best choice depends entirely on how many pieces you're making.

If you're doing a large bulk order (think 50 pieces or more), screen printing is almost always the way to go. Yes, there are initial setup costs for creating the screens, but the price per shirt plummets as your quantity goes up. For big runs, it's the most economical option by a long shot.

On the other hand, for small orders or one-of-a-kind custom pieces, DTG and DTF are your best friends. They have zero setup fees, which means you can print a single, full-color design without feeling the financial sting.

The most expensive mistake you can make is picking a method that doesn't fit your order volume. Screen printing one shirt is a waste of money, just as using DTG for a 1,000-shirt order would be needlessly expensive.

Can I Print On Any Type Of Fabric?

Definitely not, and this is a crucial detail to get right. The fabric's material content is a huge factor in deciding which printing technique will actually work.

- Cotton & Natural Blends: DTG was practically made for 100% cotton. Its water-based inks are designed to absorb beautifully into natural fibers. Screen printing also works exceptionally well on cotton and its blends.

- Polyester & Synthetics: Dye sublimation is the specialist here—it only works on polyester. Try it on cotton and you'll get nothing. For those tricky dark polyesters or other synthetics, DTF is often the perfect, versatile solution.

- Pretty Much Any Fabric: When you're stuck, DTF is the ultimate problem-solver. It’s incredibly versatile and can adhere to cotton, polyester, nylon, and even trickier materials like leather.

Ready to bring your vibrant, full-color designs to life on almost any fabric? Raccoon Transfers specializes in high-quality DTF transfers that are durable, easy to apply, and perfect for any project size. Learn more and get started with your own transfers today.