Find Custom DTF Transfers Near Me - A Practical Guide

Share

Find Custom DTF Transfers Near Me - A Practical Guide

When you find yourself Googling "custom DTF transfers near me," you're not just looking for a close address. You're making a smart move for speed, hands-on quality control, and a level of service you just can't get from a massive online-only operation. Going local means you can ditch the shipping delays entirely, often getting your transfers the same or the very next day.

Why Choose a Local DTF Printer for Your Project

Let's be real—when you're on a tight deadline, waiting for a package to travel across the country is a non-starter. Working with a local shop turns that stressful waiting game into a quick trip across town. It gives you an incredible amount of control over your project's timeline and offers a few key advantages that big, national suppliers just can't compete with.

The Power of Proximity and Partnership

The most immediate win is access. Instead of just approving a digital proof on your screen, you can actually walk into the shop and see physical print samples. There's a world of difference between seeing a color on a monitor and holding a transfer in your hand, feeling its texture and seeing the true vibrancy of the ink.

This kind of direct interaction also helps build a real relationship. Got a design with intricate details or a tricky color gradient? You can have a conversation about it with the person who will actually be running the printer. This ensures nothing gets lost in translation and your vision comes out exactly as you planned.

A good local printer isn't just a supplier; they become part of your team. You get personalized advice based on their direct, hands-on experience with their specific machines and materials.

Tangible Business Advantages

Choosing local goes way beyond just being convenient; it brings some serious strategic perks to the table that can directly impact your final product and your bottom line.

- Faster Turnaround Times: By taking shipping completely out of the picture, you can often get your transfers in a fraction of the time it would take an online company.

- Zero Shipping Costs: This one is simple. Picking up your order means no shipping fees, which can really add up, especially on larger orders.

- Real-Time Problem Solving: If there's a problem with your art file, a local printer can give you a quick call to get it sorted out immediately, preventing frustrating and costly production delays.

This local-first approach is part of a booming industry. The global market for DTF printing was valued at USD 2.72 billion in 2024 and is expected to grow to nearly USD 3.92 billion by 2030. This growth is fueled by people just like you who need high-quality, on-demand custom apparel. You can read the full research about DTF market growth to see where the industry is headed.

Local DTF Provider vs National Online Supplier

So, when does it make sense to go local versus ordering from a large national company? It really comes down to your priorities. Here's a quick breakdown to help you decide what's best for your specific project.

| Feature | Local DTF Provider | National Online Supplier |

|---|---|---|

| Turnaround | Often same-day or next-day pickup | 2-3 business days plus shipping time |

| Cost | No shipping fees; may have higher per-transfer cost | Often lower per-transfer cost; shipping fees apply |

| Support | Face-to-face interaction and direct problem-solving | Email/chat support; can be slower to resolve issues |

| Quality Control | Can inspect physical samples before a full run | Rely solely on digital proofs and user reviews |

| Minimums | Often lower or no minimum order requirements | May require higher minimum order quantities |

Ultimately, if your project values speed, hands-on control, and personalized support, a local provider is almost always the superior choice. For massive bulk orders where the absolute lowest per-unit cost is the only factor, a national supplier might be a consideration, but you'll be sacrificing the significant benefits of working with a local expert.

How to Find and Vet the Best Local DTF Printers

When you're searching for custom DTF transfers near me, a basic Google search will only get you so far. To really zero in on the best local shops, you have to think like a seasoned pro and get specific with your search terms.

Try phrases like "DTF gang sheet printing in [your city]" or "custom apparel transfers [your zip code]." These targeted searches help you cut through the noise and find printers that specialize in exactly what you're looking for.

Don't just stop at search engines, though. Your local community can be a treasure trove of information. Dig into local business directories or join Facebook groups dedicated to crafting and apparel in your area. You'd be surprised how often you can get a solid recommendation just by asking employees at your local fabric or craft supply store.

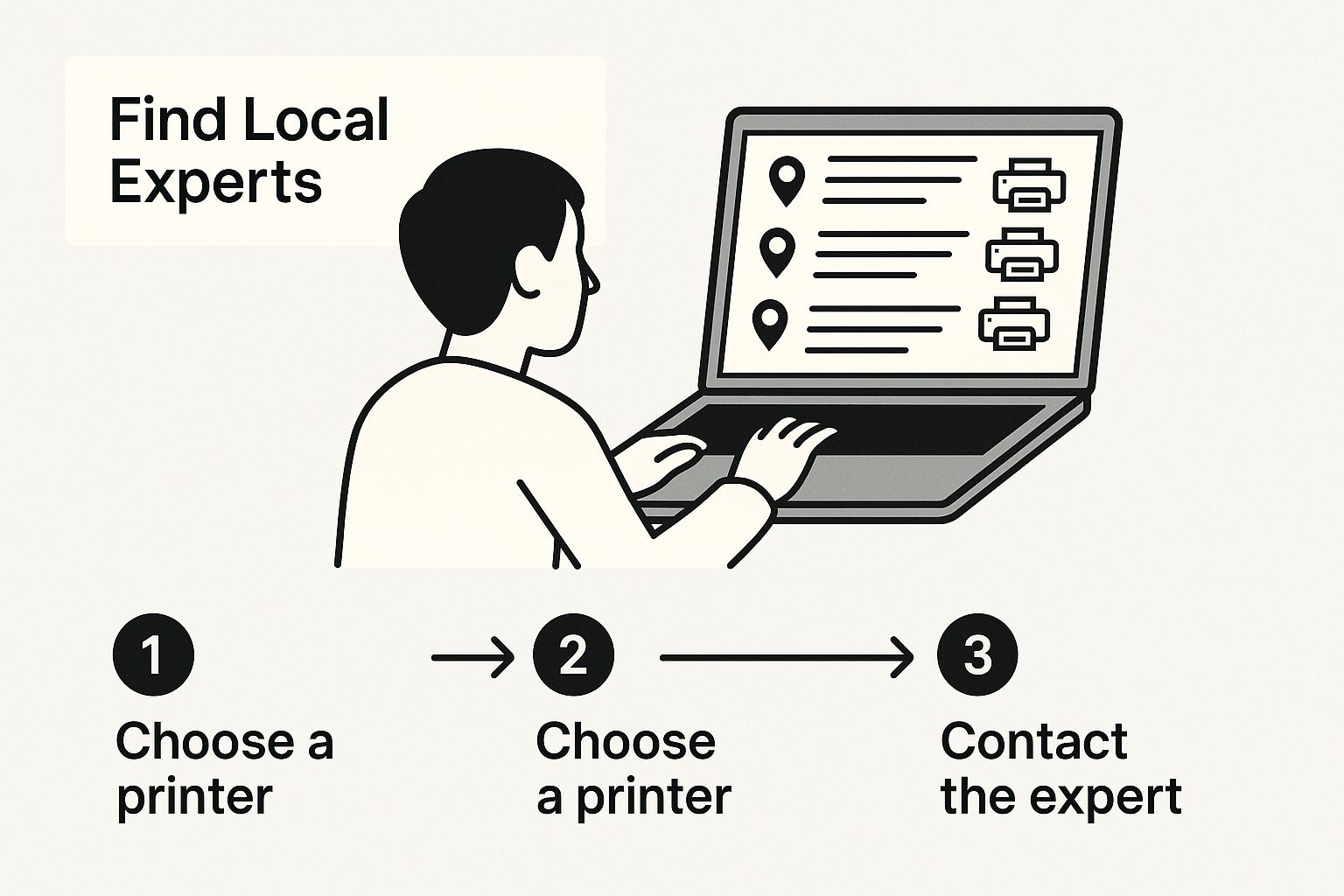

This graphic breaks down the typical online search process, starting with a broad search and narrowing it down to find the real local experts.

The trick is to move beyond general searches and tap into those specific directories and community groups. That's how you find the most relevant and reliable local printers.

Key Questions to Ask Before You Order

Okay, so you've got a shortlist of potential printers. Now comes the most important part: vetting them. A little homework now can save you from the headache of bad prints and missed deadlines later on.

First, do a quick digital background check. A professional printer should have a clean, modern website with a portfolio showcasing their actual work—not just generic stock images.

Next, it's time to reach out and ask some direct questions. Here's what I always ask:

- Can you send me a physical sample? Any printer worth their salt will be happy to let you see and feel a sample. This is your chance to check the texture, stretch, and color vibrancy before committing to a full order.

- What's your real-world turnaround for local pickups? Forget the advertised estimates. You want to know how quickly you can realistically expect your order to be ready.

- Do you have a minimum order quantity (MOQ)? This is a deal-breaker if you're a small business or just starting out and don't need hundreds of transfers.

- What are your artwork file requirements? A pro will ask for a 300 DPI PNG file with a transparent background. If they don't have clear specs, it might signal a lack of experience.

Pay close attention to how they communicate. If a shop is slow to email you back or gives you vague, one-word answers, that's a huge red flag. It's a preview of the customer service you can expect when you're on a tight deadline.

At the end of the day, go with your gut. A great local partner will be just as excited about your project as you are, offering helpful advice and being transparent about their process.

For a deeper dive, check out our complete guide on how to find custom DTF transfers near me for even more pro tips on vetting printers.

Getting Your Artwork Ready for Perfect DTF Prints

The single biggest factor separating a stunning, professional-looking print from a disappointing dud often comes down to one thing: the quality of your artwork file. Before you even start searching for a local DTF shop, prepping your design is the most important step you'll take.

Your printer isn't a magician. They can only work with the quality you give them. So, what's the gold standard? A high-resolution file. You absolutely need to aim for 300 DPI (dots per inch). This ensures your final print is crisp and sharp, not a blurry, pixelated mess.

The best file format for DTF, hands down, is a PNG with a transparent background. This is non-negotiable. Using a transparent background means only your design gets printed—no weird white or black box framing it on the final garment.

How to Make Your Artwork Truly Print-Ready

Think of your design file as the blueprint for your final product. A shoddy blueprint leads to a shoddy outcome. I've seen a few common, easily avoidable mistakes sink an otherwise fantastic design.

- Steer Clear of Super-Fine Lines: Any text or design elements that are only a few pixels thin are a recipe for trouble. There just isn't enough surface area for the DTF adhesive powder to grab onto, so they might not transfer completely.

- Keep an Eye on Opacity: Designs using semi-transparent effects or low opacity don't play well with DTF. The necessary white underbase will likely show through, leaving a milky, washed-out look instead of the subtle transparency you were going for.

- Double-Check Your Colors: Always work in the RGB color mode, as this is what DTF printers are calibrated for. If you design in CMYK, don't be surprised if the colors on your finished shirt look a bit off from what you saw on your screen.

Use a Gang Sheet to Get the Best Bang for Your Buck

Want to get the most value out of your order? You need to get familiar with gang sheets. This is simply the process of arranging multiple designs—or many copies of the same one—onto a single, large transfer sheet. Instead of paying per design, you pay for the whole sheet, which is a much smarter and more economical way to order.

This image gives you a good idea of how gang-run printing, the core concept behind gang sheets, works by combining different jobs to save space and cost.

By cleverly arranging your chest logos, sleeve prints, and larger back designs all onto one sheet, you can slash your per-print cost. Most local printers even have online tools that make building your own gang sheet a breeze.

My Two Cents: When you're building a gang sheet, always leave about a quarter-inch of breathing room around each individual design. This little bit of space will be a lifesaver when you're cutting them apart, preventing you from accidentally nicking the design next to it.

How DTF Pricing and Ordering Actually Work

When you start looking for custom DTF transfers near me, you'll find that pricing can feel a bit all over the place. Don't worry, it's usually simpler than it looks. Most local print shops stick to one of two pricing models.

The most common—and often most cost-effective—is per-sheet pricing. This is where you buy a "gang sheet," a large, standardized sheet (say, 22x60 inches), and you get to cram as many of your designs onto it as you can. This is the secret to getting your per-print cost way down, especially for smaller logos or designs.

The other option is straightforward per-transfer pricing. This is great for a single, one-off design, but it can get pricey if you have a bunch of different graphics. Before you commit, always ask about hidden costs like setup fees or rush charges—they can catch you by surprise.

At the end of the day, your final price tag really boils down to two things: the size of your transfers and how many you're ordering. Bigger prints and small-batch orders will always cost more per piece than tiny designs ordered by the hundreds.

Walking Through the Order Process

So, you've picked a local printer. Awesome. Placing the order itself is usually a breeze. It really just starts with you sending them your files and telling them what you need.

Here's a breakdown of what to expect:

- Sending Your Art: You'll start by uploading your artwork. Make sure it's a 300 DPI PNG file with a transparent background. You'll also need to tell them the exact dimensions and how many transfers you need.

- Getting the Quote: The printer will review your request and send back a quote. Comb through this for any weird fees or charges you didn't discuss.

- The Digital Proof: This is critical. You'll get a digital mockup of your transfer sheet. Check it very carefully. This is your last chance to spot a typo or a color issue before it goes to print.

- Payment & Confirmation: Once you give the proof the green light, you'll pay for the order to get it into the production queue.

- Pickup Time: Your printer will give you a solid turnaround time so you know exactly when your transfers will be ready to grab.

Getting a handle on pricing is key, especially when you consider that dedicated Direct to Film printers are on track to pull in revenues of around USD 1.31 billion by 2025. That kind of growth shows just how much people want high-quality prints that last. You can learn more about the durability of DTF transfers in our detailed guide.

This whole industry boom is really being fueled by our collective love for custom gear. If you're interested in the numbers behind it, you can find more insights on the booming DTF market on grandviewresearch.com.

Turning Your DTF Transfers into Professional Apparel

You've sourced your transfers from a great local printer, but getting those designs onto your garments is where the real magic happens. Proper application is the final, crucial step that separates a homemade-looking shirt from a retail-quality piece that stands up to wear and washing.

The absolute must-have for this job is a good heat press. I know it's tempting to think a household iron will do the trick, but it's a recipe for disappointment. An iron just can't deliver the consistent, even heat and pressure needed for the DTF adhesive to properly fuse with the fabric fibers. You'll end up with hot spots, uneven application, and prints that start peeling or cracking after the first wash.

Nailing the "Big Three": Temperature, Time, and Pressure

Every successful DTF application comes down to getting three things right: temperature, time, and pressure. Think of it as a recipe—if one ingredient is off, the final product won't be right. While your printer will give you the recommended settings, here are some solid starting points I use all the time.

- For 100% Cotton: I typically set my press to 320°F (160°C) and press with medium pressure for a full 15 seconds.

- For Polyester & Blends: You need to be more careful here. Drop the heat to around 300°F (150°C) and shorten the press time to 10-12 seconds. This helps prevent that dreaded shiny, scorched look on synthetic fabrics.

Here's a pro-tip that saves a lot of headaches: Always pre-press your garment for 3-5 seconds. This quick step irons out any wrinkles and, more importantly, removes hidden moisture from the fabric. A dry, smooth surface is the key to a perfect bond.

Another critical piece of information from your printer will be the peel type. Is it a "hot peel" or a "cold peel"? A hot peel means you'll pull the carrier film off immediately after the press opens. For a cold peel, you need to be patient and let the garment cool down completely before peeling the film—rushing it will ruin the transfer.

If you ever run into problems like transfers not sticking or cracking later on, nine times out of ten, the issue can be traced back to incorrect temperature, time, or pressure. It takes a bit of practice, but once you get the feel for it, you'll be producing amazing quality.

For a deeper dive into the whole process, you can learn exactly how to heat press for flawless custom apparel in our complete guide. It's packed with tips to help you get vibrant, durable results every single time.

Common Questions We Hear About DTF

Even when you've pinpointed the right local printer, a few questions might still be bouncing around in your head. That's completely normal! Let's walk through some of the most common things people ask, so you can place your order feeling totally confident.

How Do DTF Transfers Hold Up Against Screen Printing?

This is a big one. High-quality DTF transfers are impressively durable, easily lasting 50-100 washes when you press them right and follow the care instructions.

In terms of pure longevity, they're right on par with traditional screen printing. Where they really pull ahead, though, is in their stretchability and resistance to cracking. This makes them a fantastic modern choice, especially for those detailed, multi-color designs that would be a headache to screen print.

Can I Just Use My Home Iron to Apply These?

I get why people ask, but I have to strongly advise against it. A home iron just isn't built for this job—it can't deliver the consistent, even pressure or the stable temperature needed for the transfer adhesive to properly cure into the fabric fibers.

To get those professional, long-lasting results that won't peel or fade after a few wears, a quality heat press is non-negotiable. It's the only way to do it right.

What Kind of Fabrics Can I Use DTF On?

This is where DTF truly shines. Its versatility is incredible, and it works beautifully on a huge range of materials. We're talking:

- 100% Cotton

- Polyester

- Cotton/Poly Blends

- Tri-Blends

- Even tougher stuff like Canvas and Denim

This flexibility makes it a much better option than methods like sublimation, which really only works on high-polyester content fabrics.

When it comes to complex, full-color designs, DTF is almost always a better choice than heat transfer vinyl (HTV). You get photorealistic prints in a single press without any of that tedious weeding or layering. The finished print also has a much softer, more natural feel than most HTV.

This incredible adaptability is a key reason the global Direct to Film printing market is on track to hit an estimated USD 4.15 billion by 2032. As more and more people want custom apparel, the need for a do-it-all printing solution just keeps growing. You can discover more insights about the DTF market and see the data behind its growth for yourself.

Ready to Get Started?

Ready to see your designs come to life with prints that are vibrant, durable, and a breeze to apply? At Raccoon Transfers, we specialize in premium quality DTF transfers with next-day shipping available for any project.

Build your gang sheet and get started today!