UV DTF vs. Traditional UV Printing: A Comparative Study for Informed Printing Choices

Share

In the dynamic landscape of custom decoration and industrial marking, Ultraviolet (UV) printing has long been celebrated for its ability to produce vibrant, durable prints on a wide array of rigid substrates. For businesses in Austin, Texas, grappling with diverse printing needs, understanding these distinctions is crucial for making informed decisions that optimize quality, efficiency, and cost-effectiveness.

This comprehensive comparative study will dissect the fundamental differences between UV DTF printing and traditional UV printing (specifically UV flatbed printing). We will analyze their respective printing processes, delve into the nuances of durability, assess their cost-effectiveness for various volumes, compare material compatibility, and evaluate overall print quality. Our goal is to provide a clear, actionable guide to help you determine which printing method is best suited for your specific projects and business goals.

Comparative Analysis: UV DTF vs. Traditional UV Printing

Let's break down the critical factors for comparison:

1. Durability

- Traditional UV Printing: Highly durable. Once cured, the ink forms a robust layer on the surface, resistant to scratches, water, and fading. Its durability depends significantly on the substrate's surface and whether pre-treatment was optimal.

- UV DTF Printing: Exceptional durability, often surpassing direct UV prints, especially on challenging surfaces. The cured ink and adhesive system create a very strong bond that is highly resistant to abrasion, chemicals, and scratching. The optional top varnish layer adds an extra layer of protection. This durability makes it ideal for high-wear items.

2. Cost-Effectiveness

- Traditional UV Printing:

- Setup Costs: Can have higher initial setup costs due to the need for jigs and precise alignment for each unique product shape.

- Per-Unit Cost: Generally more cost-effective for high-volume, consistent runs of the same item where direct printing efficiency is maximized.

- Labor: Less labor-intensive per unit once setup is complete for high volumes, as the printer handles the direct application.

UV DTF Printing:

- Setup Costs: Very low setup costs as designs are printed onto film rolls, eliminating the need for complex jigs or individual item alignment.

- Per-Unit Cost: Highly cost-effective for short runs, one-off customizations, and varied items. Eliminates waste from misprints on expensive products.

- Labor: Application can be manual, potentially more labor-intensive per unit for very high volumes compared to fully automated direct printing lines, but very efficient for small batches.

3. Material Compatibility

- Traditional UV Printing: Excellent compatibility with a wide range of flat or slightly curved rigid materials (acrylic, metal, wood, glass, PVC, ceramic tiles). However, optimal adhesion often requires primers for certain challenging surfaces. Can struggle with highly irregular or deeply curved objects.

- UV DTF Printing: Unparalleled material compatibility for rigid, hard surfaces, regardless of shape or texture. Adheres strongly to virtually any non-porous material, including those difficult for direct UV printing (e.g., heavily textured plastics, complex curves, finished wood, rubber, silicone). The adhesive layer ensures strong bonding without pre-treatment in most cases.

4. Print Quality and Finish

- Traditional UV Printing: Produces high-resolution, vibrant prints with excellent detail. Can achieve a flat, glossy, or matte finish depending on ink/curing.

- UV DTF Printing: Delivers equally high-resolution and vibrant full-color prints with excellent opacity (due to the white ink layer). A key differentiator is the ability to easily add a tactile, raised, or embossed effect through the varnish layer, giving products a premium, unique feel that direct UV printing might require multiple passes or specialized techniques to achieve. The finish is typically glossy from the varnish.

5. Application Ease & Flexibility

- Traditional UV Printing: Requires the physical product to be placed on the printer. Once printed, the design is permanent.

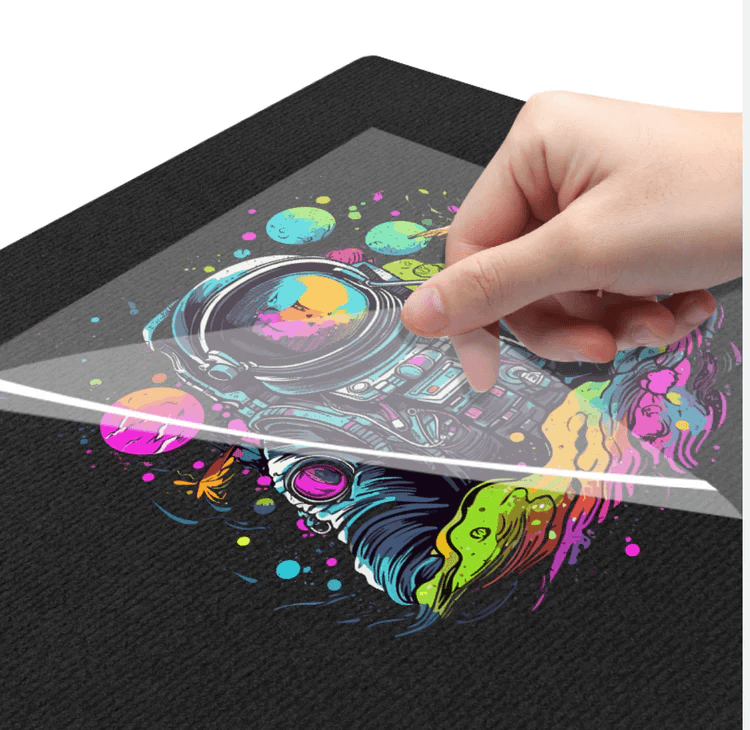

- UV DTF Printing: Offers incredible flexibility. Transfers can be printed, stored, and applied later, on-demand, by simply peeling and sticking. This simplifies inventory management for blanks and finished products, allowing for just-in-time customization. The application process itself is very quick and requires no specialized machinery.

Comparative Overview Table: UV DTF vs. Traditional UV Printing

| Feature | UV DTF Printing | Traditional UV Printing (Flatbed) |

|---|---|---|

| Methodology | Indirect transfer (print to film, then apply) | Direct print onto substrate |

| Best For | Curved, irregular, small, complex shapes; short runs, custom items | Flat, rigid items; high-volume, consistent runs |

| Material Versatility | Almost any rigid, hard, non-porous material (incl. textured, curved) without pre-treatment | Wide range of flat/slightly curved rigid materials (some require primer) |

| Durability | Exceptional; high resistance to scratches, water, chemicals, abrasion | Very good; resistant to scratches, water, fading |

| Print Finish | Vibrant, opaque, often with tactile/raised (varnish) effect | Vibrant, opaque; flat/glossy/matte (no tactile by default) |

| Cost-Effectiveness | Excellent for low to medium volumes, custom, one-off jobs | Excellent for high volumes, consistent product runs |

| Application Time | Very quick "peel-and-stick" application (after transfer printed) | Direct print time varies by coverage and printer speed |

| Pre-treatment | Generally not required | Often required for optimal adhesion on certain materials |

| Flexibility | Print transfers, store, apply on-demand | Direct production; print and finished immediately |

Informed Choices: When to Use Which Printing Method

Understanding these distinctions allows businesses to strategically select the most appropriate printing method for their specific needs.

Choose UV DTF if:

- You need to customize items with irregular shapes, curves, or textures that are difficult to fit or print directly on a flatbed printer.

- Your primary need is for short-run customization, personalized items, or prototyping.

- You require extreme durability and scratch resistance on high-wear products.

- You want to add a premium, tactile (raised) finish to your designs.

- You need the flexibility to print transfers in bulk and apply them on demand to various items.

- You want to avoid the need for pre-treatment on most non-porous hard goods.

Choose Traditional UV Printing if:

- You are primarily printing on flat, rigid items in high volumes.

- You have a consistent product line where you can maximize efficiency with direct printing setups.

- You need to print directly onto very large flat surfaces (e.g., signs, large panels).

- Your existing workflow is already optimized for direct-to-substrate printing.

Often, the two technologies can complement each other within a single business, expanding overall customization capabilities. Businesses in Austin, TX, with diverse client bases might find significant value in integrating both for maximum versatility.

Conclusion

The choice between UV DTF printing and traditional UV printing is not about one being definitively "better" than the other, but rather about selecting the optimal tool for the specific job. Both technologies offer incredible capabilities, but their unique strengths cater to different applications, volumes, and material requirements. Understanding this comparative landscape is vital for any business or print professional aiming to deliver high-quality, durable, and cost-effective custom products.

At Raccoon Transfers, we are experts in cutting-edge printing technologies, specializing in delivering superior UV DTF transfers. We understand the nuances of both direct and indirect UV applications and are committed to providing the transfers that best suit your unique product and business needs. Whether you're looking for the unparalleled versatility and durability of UV DTF or need guidance on integrating it into your existing printing workflow, we are your trusted partner for high-quality, long-lasting custom solutions. Partner with us to make informed printing choices that drive your business forward.

Ready to elevate your product customization with the right UV printing solution? Explore the endless possibilities with Raccoon Transfers' high-quality UV DTF transfers. Contact us to discuss your project and discover the perfect fit for your printing needs!

Frequently Asked Questions (FAQs) -

What is the main difference in how UV DTF and traditional UV printing apply ink?

The main difference is the application method. Traditional UV printing applies ink directly onto the product and cures it instantly. UV DTF printing applies ink onto a special transfer film first, which is then transferred (peeled and stuck) onto the final product.

Which printing method offers better durability for custom products?

Both methods offer good durability, but UV DTF prints often exhibit superior durability, especially regarding scratch, abrasion, and chemical resistance. The layered ink and adhesive system, along with an optional top varnish layer, provides a robust bond to the substrate.

Is UV DTF printing more cost-effective than traditional UV printing for all types of jobs?

UV DTF is generally more cost-effective for short runs, one-off customizations, and jobs involving multiple different items or irregular shapes, due to minimal setup time and no need for jigs. Traditional UV printing tends to be more cost-effective for high-volume, consistent runs of the same flat items.

Which method has broader material compatibility, especially for curved or textured items?

UV DTF printing offers significantly broader material compatibility, adhering to virtually any hard, rigid, or even highly irregular/curved non-porous surface (e.g., textured plastics, rubber, silicone) without the need for pre-treatment. Traditional UV printing is best suited for flatter, rigid items.

Can UV DTF printing achieve special effects like raised textures?

Yes, a distinct advantage of UV DTF printing is its ability to easily incorporate a clear varnish layer on top of the design. This varnish creates a noticeable tactile, raised, or embossed effect, adding a premium feel and visual depth that is more challenging or costly to achieve with traditional direct UV printing.