What is DTF Transfer? Discover the Game-Changing Printing Method

Share

Direct-to-Film, or DTF, is a pretty clever way to get detailed, full-color designs onto fabric. Instead of printing directly on the garment, we first print your design onto a special transfer film. Then, a powdered adhesive is applied and melted, and the whole thing is heat-pressed onto the final item.

What you're left with is a stunning, durable graphic that feels like part of the fabric itself. It’s a technique that opens up a world of possibilities for all sorts of materials.

Your Quick Guide To DTF Transfers

Let's say you want a really complex, photorealistic image on a black polyester jacket. With some older methods, that would be a real headache. But with DTF, it's not a problem at all.

Think of it like a souped-up, professional-grade iron-on. The difference is, these transfers are incredibly soft, flexible, and tough enough to handle dozens and dozens of washes without cracking or fading. That’s where the real magic lies.

The biggest advantage of DTF is its incredible versatility. We're not just limited to cotton t-shirts here. It works beautifully on almost anything you can think of.

- Cotton & Natural Fibers: Perfect for getting bright, sharp designs on classic tees and hoodies.

- Polyester & Synthetics: Bonds flawlessly to athletic apparel and performance wear.

- Blends & More: It even works on tricky surfaces like denim, nylon bags, and even leather.

This "print on anything" capability makes it a favorite for custom apparel businesses. The process starts by printing your digital artwork onto a sheet of PET film, using a special white ink layer to make the colors pop. After that, we apply the adhesive powder, melt it to create a smooth backing, and your transfer is officially ready to press.

A Growing Force In Customization

It's no secret that people love personalized gear, and that demand has pushed DTF printing into the spotlight. The global market was valued at USD 2.72 billion and is expected to keep growing, thanks to how affordable and high-quality the results are. You can dig into more of the numbers on this market trend over at Grand View Research.

For a quick reference, here’s a simple breakdown of what makes DTF transfers tick.

DTF Transfer at a Glance

| Characteristic | Description |

|---|---|

| Print Quality | Full-color, high-resolution prints with unlimited color options. |

| Material Versatility | Works on cotton, polyester, blends, denim, leather, and more. |

| Feel & Durability | Soft, lightweight feel on the fabric. Highly durable and wash-resistant. |

| Best For | Complex, multi-color designs, photorealistic images, and small to large batch orders. |

| Setup Costs | No screen setup required, making it ideal for on-demand and small runs. |

This table shows why DTF has become such a go-to choice—it's flexible, high-quality, and efficient.

At its core, what is a DTF transfer? It's the bridge between a digital idea and a tangible, wearable piece of art. It removes creative barriers, allowing for unlimited colors and intricate details without the high setup costs of screen printing.

For everyone from growing businesses to weekend hobbyists, this means you can produce a single, unique t-shirt just as easily as you can a batch of 100. The end product is always a vibrant, long-lasting graphic that feels fantastic, cementing DTF's place as a true game-changer in the world of custom apparel.

The Innovation Behind DTF Printing

While Direct-to-Film printing might feel like it came out of nowhere, its roots go back decades. The technology didn't just pop into existence; it was built on a foundation laid by earlier breakthroughs, especially in digital design and inkjet printing. If you think back to the 1990s, that's when digital tools really started giving creators incredible control over their art.

This digital shift was the crucial first step. As designers could suddenly create incredibly complex, vibrant graphics on their computers, the pressure was on to find a printing method that could actually bring them to life. Old-school methods like screen printing were reliable, sure, but they often fell short with fine details, had steep setup costs, and were picky about fabrics. The industry needed something new.

Solving Old Printing Problems

The challenge was clear: how could the apparel world take a detailed digital design and put it on a huge range of fabrics, all without the hassle of screen printing or the fabric limitations of Direct-to-Garment (DTG)? DTG, for instance, really only loves high-cotton fabrics, which left a big hole in the market for all the popular synthetic blends.

This is where the cleverness of DTF really started to take shape. Direct to Film (DTF) transfer technology first appeared in the early 2000s, born from a need for a more versatile and affordable option. It smartly adapted the advancements from inkjet printing, which had become incredibly precise through the '90s. This allowed specialized inks to be printed perfectly onto a new medium: the transfer film.

DTF was created to solve a problem. It answered the call for a method that could give you the color freedom of digital printing and the apply-it-to-anything flexibility of a transfer, all while being simple and affordable. The solution was a step-by-step process that hit all those marks.

The Key Technical Breakthroughs

Making DTF printing a real-world, reliable workhorse wasn't about a single invention. It was the result of several crucial components coming together and working in perfect harmony.

- Specialized DTF Inks: These are nothing like the ink in your office printer. They are engineered to be incredibly flexible and tough, so the final design can stretch right along with the fabric without ever cracking or peeling.

- Hot-Melt Adhesive Powder: This fine powder is the real magic behind the scenes. It melts under heat and acts like a super-strong glue, bonding the ink directly to the fabric's fibers for a permanent hold.

- Advanced PET Film: The transfer film is another critical piece of the puzzle. It’s specially coated to hold the wet ink in place without letting it bleed, keeping the design crisp until it’s released cleanly onto the garment with a heat press.

These three elements combined to create a process that solved the biggest headaches of older methods. For anyone just starting out, our guide offers a deeper dive into the nuts and bolts of how it all works; you can check out our guide on understanding DTF printing for beginners. At the end of the day, DTF isn't just another trend—it's the natural evolution of textile printing, built on years of progress.

How Your Custom Design Becomes a DTF Transfer

Ever wondered how that design on your screen actually becomes a vibrant, durable graphic on a t-shirt? It’s a fascinating process, one that we’ve perfected over the years. Turning a digital file into a professional DTF transfer isn't magic, but it does involve a precise, multi-step workflow.

Let's pull back the curtain and walk through exactly how your vision comes to life, step by step.

Step 1: Prepping and Printing the Artwork

It all starts with your design file. Before a single drop of ink is used, we load your artwork into specialized RIP (Raster Image Processing) software. This is a critical first step. The software translates your design's colors (the CMYK) for our printers and, more importantly, it generates the white ink base layer that's essential for making colors pop on any garment.

With the file prepped, our dedicated DTF printer gets to work. Instead of paper, it prints your design directly onto a special PET (polyethylene terephthalate) film. This isn't just any plastic sheet; its unique coating is designed to hold the wet ink in place, ensuring every line is razor-sharp with no bleeding. In a single, efficient pass, the printer lays down both the color layer and the crucial white underbase.

Step 2: Applying the Magic Powder

Once the design is printed on the film, it’s on to what I consider the most critical part of the process: applying the adhesive. The ink is still wet, so the film is immediately coated with a hot-melt adhesive powder.

Think of it like breading chicken—the fine, granulated powder clings only to the wet ink, perfectly outlining your design. Any excess powder is shaken off, leaving a clean, precise layer of adhesive. This powder is the powerful glue that will permanently fuse your design to the fabric in the final step.

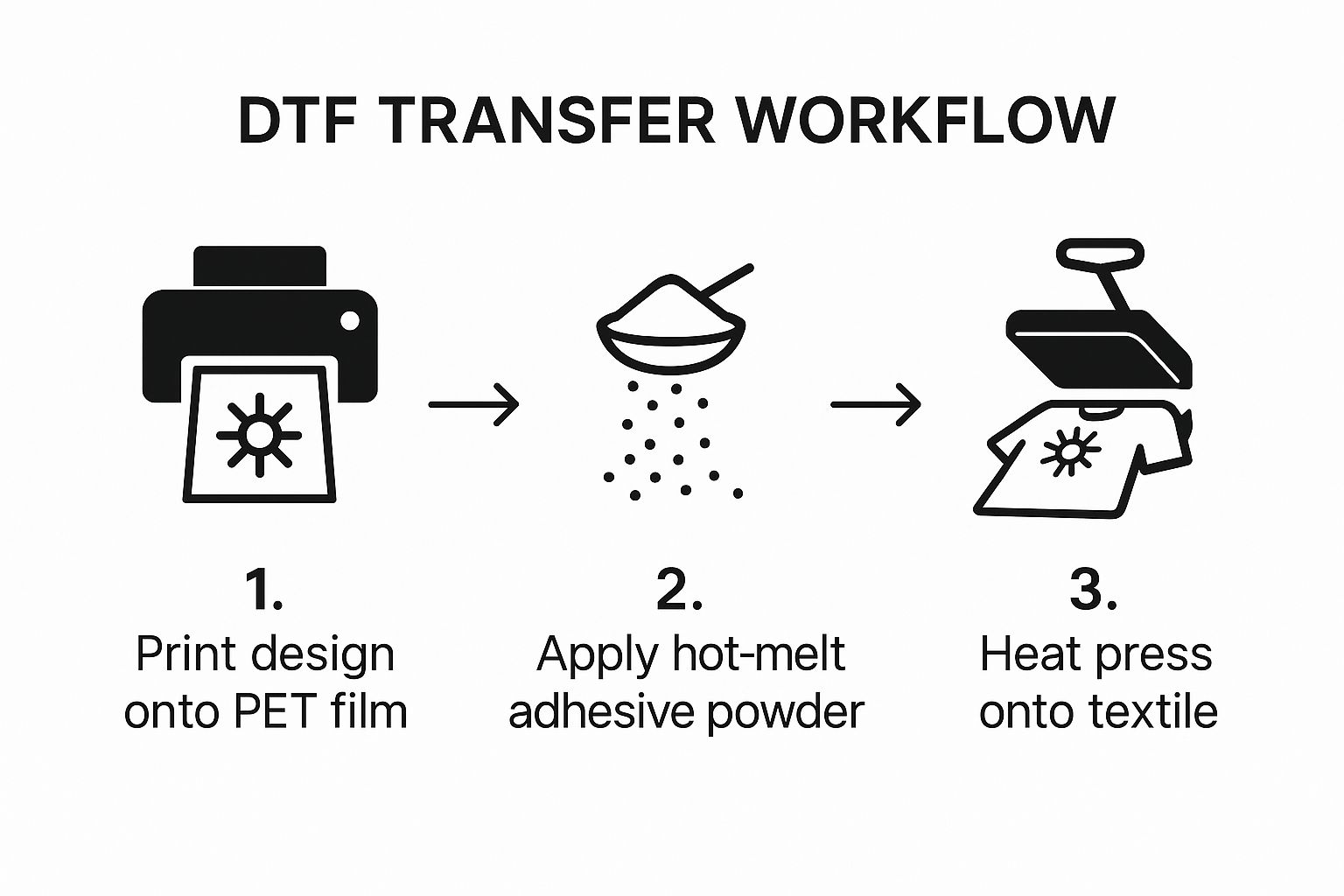

This simple infographic gives you a great visual of the core workflow.

It really boils the process down to its three key actions, showing how we get from a printed film to a ready-to-press transfer.

Step 3: Curing and Applying to the Garment

The powdered transfer still needs one more thing: heat. The film moves through a curing oven where the adhesive powder is melted, transforming it from a grainy layer into a smooth, solid sheet of glue on the back of the ink. After it cools, the DTF transfer is officially complete and ready for application.

Now for the fun part—pressing it onto a garment. This involves a few key actions:

- First, we pre-press the garment itself to smooth out any wrinkles and remove moisture.

- Next, we carefully position the DTF transfer on the fabric.

- Finally, we heat press the transfer at a specific temperature (usually around 280-320°F for cotton) and pressure.

The heat from the press reactivates the adhesive, melting it deep into the fibers of the fabric. We then let it cool down completely for what’s called a "cold peel." Once it's cool, the PET film peels away smoothly, leaving just the soft, brilliant design bonded to the apparel. A quick final press with a protective sheet locks it all in, guaranteeing a design that lasts.

Choosing the Right Print Method for Your Project

The best way to truly grasp what makes DTF transfers so special is to see how they measure up against the other big names in custom apparel. Direct-to-Film wasn't just invented on a whim; it was engineered to fix the real-world headaches that other methods couldn't.

By comparing it to the classics—screen printing, Direct-to-Garment (DTG), and Heat Transfer Vinyl (HTV)—you can figure out exactly which one is the perfect match for what you're trying to create. Each technique has its own moment to shine. It all comes down to the specifics of your job: the size of your order, how complex your design is, the fabric you're using, and even the feel you want the final print to have.

A Head-to-Head Comparison

To make a smart choice, you really have to look at these methods side-by-side. The "right" answer almost always depends on the details. Are you printing a single, photorealistic masterpiece on a polyester jacket, or are you running 500 T-shirts with a simple one-color logo? That single question changes everything.

Let's dive into a clear comparison to help you make your decision.

DTF vs Screen Printing vs DTG vs Vinyl

When you're starting a custom apparel project, the printing technology you choose will make or break your final product. Below is a detailed look at the four most popular methods, comparing them on the factors that matter most to creators and businesses.

| Feature | DTF Transfer | Screen Printing | DTG Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|---|---|

| Best For | Small-to-medium runs, full-color designs, diverse fabrics. | Large bulk orders (100+ items) with simple designs. | One-off prints on 100% cotton, high-detail photos. | Simple text, numbers, and solid-color graphics. |

| Fabric | Cotton, polyester, blends, leather, nylon (any color). | Best on cotton and blends, less effective on synthetics. | Primarily 100% cotton, struggles with dark polyester. | Works on cotton, polyester, and blends. |

| Feel | Soft, flexible, and lightweight on the garment. | Can be heavy, especially with multiple color layers. | Very soft, as ink soaks into the fabric fibers. | Thicker, plastic-like feel that sits on top of fabric. |

| Durability | Excellent; rated for 50+ washes without cracking or fading. | Very durable, can last the lifetime of the garment. | Good, but can fade over time with repeated washing. | Good durability, but can peel or crack if not applied well. |

This table makes it clear that while every method has its place, DTF has carved out a unique space as a versatile, high-quality solution for the modern creator. It handles the jobs that other methods just can't.

Where Each Method Wins

As you can see, each technique has its own sweet spot. DTF really stands out as a powerful all-rounder, borrowing the best features from the other methods.

DTF excels where other methods force you to compromise. It gives you the full-color freedom of DTG, the fabric versatility that surpasses both DTG and screen printing, and a much softer feel than traditional vinyl—all without the crazy setup costs.

For an even deeper dive, especially between the two leading digital methods, be sure to read our complete guide on DTF vs. DTG and which printing method suits your needs.

To put it simply, here’s when you should pick each one:

- Choose DTF for vibrant, detailed designs on almost any material, especially for orders under 100 pieces. It's your go-to for flexibility and quality.

- Choose Screen Printing when you have a large order (think hundreds of items) with just a few colors. This is your workhorse for bulk jobs where cost-per-shirt is key.

- Choose DTG for one-of-a-kind, super-detailed prints on light-colored, 100% cotton shirts. Nothing beats its soft feel for photographic images.

- Choose HTV for straightforward jobs like names and numbers on team jerseys or simple, bold logos.

By weighing these pros and cons, you can confidently pick the printing method that will deliver the exact quality, cost, and feel your project truly deserves.

The Real-World Benefits of Using DTF Transfers

It's one thing to understand the technical side of DTF, but what really matters are the practical advantages you get. These are the benefits that solve the real-world headaches creators and businesses face with other printing methods every day.

First off, let's talk about versatility. This is where DTF really shines. Unlike other digital printing techniques that are notoriously picky about fabrics, DTF transfers stick to almost anything. You can press incredible designs onto cotton, polyester, nylon, leather, and even tricky blends—whether the material is light or dark. This unlocks a whole new world of products beyond the basic t-shirt, letting you create custom hoodies, hats, bags, and jackets with confidence.

Basically, your creativity gets to lead the way, not the limitations of your printing equipment.

Superior Quality and Durability

Two of the biggest questions people have about any printed garment are: "How does it feel?" and "How long will it last?" DTF transfers deliver fantastic answers to both. The finished print feels surprisingly soft and light, becoming part of the fabric rather than sitting on top like a thick, plastic-y decal. This means even large graphics won't compromise the comfort of the shirt.

The durability is just as impressive. The specialized ink and adhesive powder fuse together to form a bond that can handle whatever you throw at it.

When applied properly, a quality DTF transfer can survive 50+ wash cycles without cracking, fading, or peeling. It stretches right along with the fabric, keeping its original look and feel for an impressively long time.

This toughness is a huge selling point for anyone creating products that are meant to be worn and loved. If you want to dive deeper into making them last, check out our guide on DTF durability and care instructions.

Efficiency and Cost-Effectiveness

In business, time and money are always a factor, and DTF offers major savings on both fronts, especially for small-to-medium-sized print runs. The process is smarter, cutting out the most frustrating steps from older methods.

- No Setup Fees: Forget screen printing, where every single color in your design requires its own custom screen and associated cost. DTF prints the entire design, with unlimited colors, all at once. This makes it affordable to run small batches or even single custom pieces.

- No Weeding Required: Anyone who has worked with heat transfer vinyl (HTV) knows the pain of weeding. DTF completely eliminates this tedious task. There is absolutely no weeding needed because the adhesive only sticks where the ink is printed. You can say goodbye to hours spent picking tiny pieces of vinyl out of complex designs.

- Photorealistic Detail: Because it’s a digital process, DTF can reproduce incredibly sharp lines, fine text, and smooth color gradients. You can print actual photographs and intricate art with a level of clarity that other methods simply can't achieve.

When you put it all together, DTF transfers are a powerful and practical solution. They give you the vibrant, long-lasting quality your customers want, with the speed and affordability your business needs to grow.

Your Top Questions About DTF Transfers, Answered

You've seen what DTF can do, but you might still have a few questions rolling around in your head. That's perfectly normal! Let's clear up some of the most common ones so you can feel confident about getting started.

How Well Do DTF Transfers Hold Up in the Wash?

This is the big one, right? You’ll be happy to know that DTF transfers are incredibly durable. When you press them correctly, they’re engineered to last through 50+ washes without showing signs of cracking, peeling, or fading. It all comes down to the flexible, water-based inks and the powerful adhesive that literally melts into the fabric fibers.

To get the most life out of your prints, we always tell people to wash the garment inside-out with cold water. Tumble dry on low, or better yet, just hang it up to dry.

Can I Just Use a Home Iron to Apply These?

Technically, you could, but we really, really don't recommend it. For a transfer to work properly, it needs two things: perfectly even heat and consistent, firm pressure. A professional heat press is built to deliver exactly that, ensuring the adhesive cures properly and bonds permanently to the material.

An iron, on the other hand, has hot spots and cool spots, and you can never apply even pressure by hand. This almost always results in a weak bond, with corners that peel up and a design that starts to look rough after the first wash.

Think of it this way: a heat press gives you a professional, permanent result. An iron gives you a temporary, frustrating one. That consistent heat and pressure is the secret sauce for a transfer that looks and feels great for years.

Is There a Limit to How Many Colors I Can Use?

Absolutely not! This is one of the most exciting things about DTF. Traditional screen printing gets expensive and complicated fast because you need a separate screen for every single color. DTF completely changes the game.

Because it's a digital printing process, you can go wild with your designs. We're talking unlimited colors, smooth gradients, intricate details, and even full-color photos—all printed in one go with no extra setup fees. Your creativity is the only limit.

What Do DTF Transfers Actually Feel Like on a Shirt?

Forget those old, stiff, plastic-feeling transfers from back in the day. Modern DTF transfers have a remarkably soft, lightweight, and flexible feel. They're much thinner than the bulky heat transfer vinyl you might be used to and feel way smoother on the shirt.

The finished design really integrates with the fabric, so it stretches and moves with you instead of feeling like a heavy sticker. The result is a comfortable garment you'll actually want to wear.

Ready to see—and feel—the difference for yourself? At Raccoon Transfers, we specialize in top-quality, ready-to-press DTF transfers that ship out the next day. Let's bring your designs to life. Start your custom order today!