What is Direct to Film Printing? Complete Guide & Benefits

Share

You've probably seen those super-vibrant, detailed T-shirt designs and wondered how they're made. A lot of the time, the answer is Direct-to-Film, or DTF, printing. It’s a game-changing method for putting custom graphics onto all sorts of fabrics.

The simplest way to think about it is like creating a high-end, custom sticker for your clothes. But unlike a sticker, a DTF transfer is incredibly flexible, brilliantly colored, and tough enough to handle plenty of wear and tear. It truly merges the precision of digital printing with a straightforward, reliable transfer process.

What Exactly Is Direct To Film Printing?

DTF printing isn't just a fleeting trend—it's a seriously powerful technique that has cemented its spot in the custom apparel world. It stands out because it works on a huge range of materials, from cotton and polyester to blends and even nylon, which other methods can't always handle.

So, how does it work?

- Print: First, a special DTF printer lays down your design onto a sheet of polyethylene terephthalate (PET) film. This isn't just any old plastic sheet; it’s a specific film designed to hold the ink and then release it cleanly. A crucial layer of white ink is printed first, which makes the colors on top pop, even on dark fabrics.

- Powder: While the ink is still wet, a fine, hot-melt adhesive powder is sprinkled over the design. The powder sticks only to the ink, creating the glue that will eventually bond the graphic to the garment.

- Press: Finally, the film is placed onto the fabric and put into a heat press. The heat and pressure activate the adhesive, permanently transferring the entire design from the film to the material. You peel off the film, and you’re left with a crisp, full-color graphic that feels great.

The growth here is no surprise. The global DTF market is on track to jump from $2.72 billion to more than $3.9 billion by 2030. That’s all thanks to people like us wanting unique, personalized gear.

The real magic of DTF is how three simple things work together: the special film acts as the carrier, the adhesive powder creates the bond, and the heat press makes it all permanent. It’s a simple yet incredibly effective formula.

For a deeper dive into the specifics, our comprehensive guide to understanding DTF printing is a perfect resource for anyone getting started.

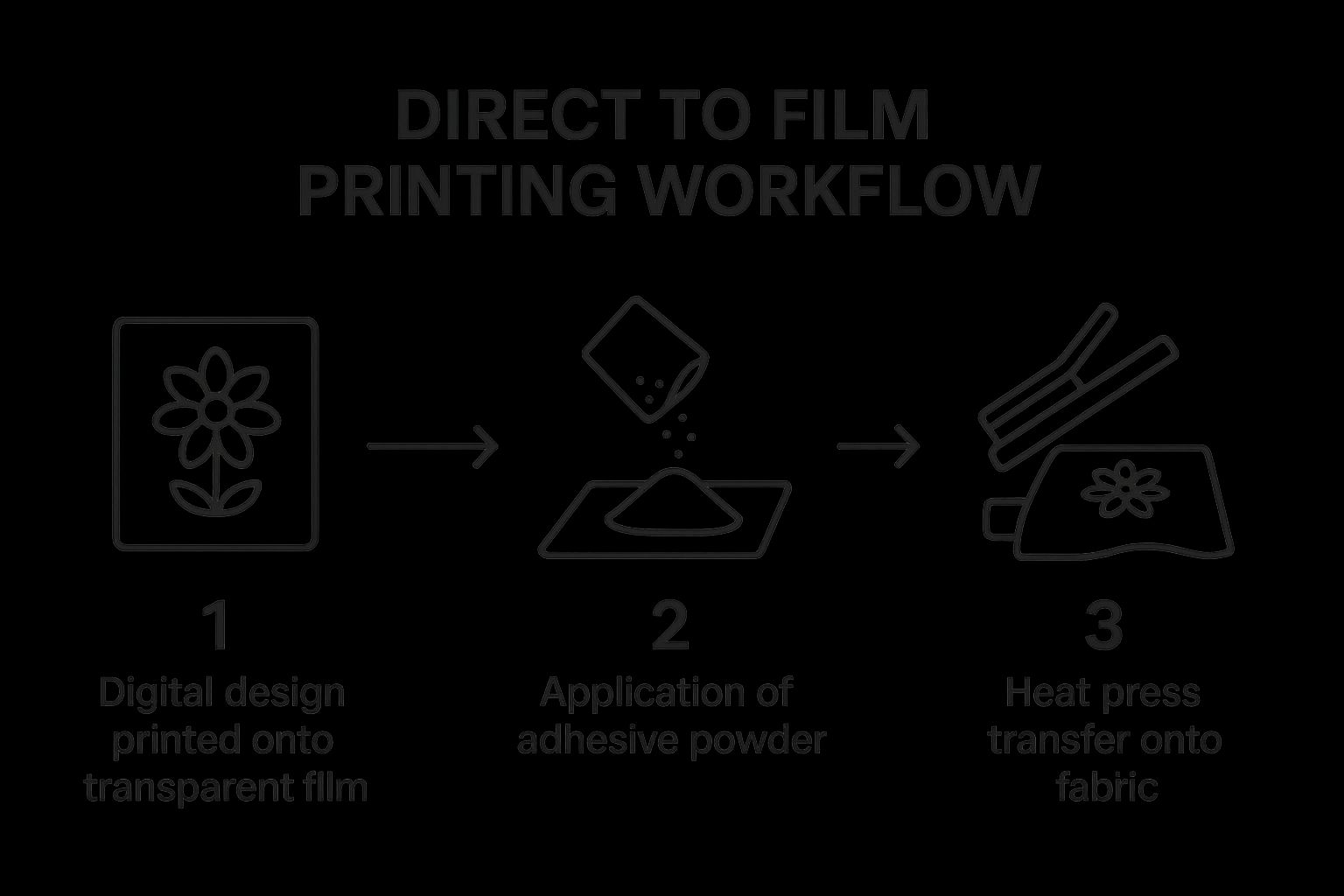

To quickly recap the key elements, here's a simple breakdown of the process.

DTF Printing at a Glance

| Component | Role in the Process |

|---|---|

| PET Film | The special carrier sheet that the design is printed onto and later peeled away from. |

| DTF Inks | Pigment-based inks, including a vital white ink base, that create the vibrant, opaque design. |

| Adhesive Powder | A hot-melt powder that sticks to the wet ink and acts as the bonding agent. |

| Heat Press | The machine that uses heat and pressure to activate the adhesive and transfer the design. |

Each part plays a critical role, and when they come together, they produce durable, high-quality prints that can be applied to almost any fabric.

How the DTF Printing Process Unfolds

So, we've covered the essential gear. Now, let's walk through how all those pieces—the printer, inks, film, and powder—actually work together to create a finished shirt. The magic of direct-to-film printing happens in just three main stages, each one building on the last to turn a digital file into a vibrant, durable graphic.

The entire workflow is surprisingly straightforward. This simple visual breaks it down nicely, from the initial print to the final press.

As you can see, it's a logical path from the computer screen to the clothing rack.

Stage 1: Printing on the Film

Everything starts with your digital design file. You send it to the DTF printer, which gets to work printing directly onto a special PET transfer film.

First, the printer lays down all the colors (the CMYK layer). Then, in a critical second pass, it prints a layer of bright white ink directly on top of the color. This white underbase is the secret sauce; it ensures your design looks solid and pops with color, even when you press it onto a black or dark-colored garment.

Stage 2: Adding and Curing the Adhesive

While the ink is still wet on the film, it’s time for the adhesive. The printed film gets an even coating of a fine, granulated hot-melt adhesive powder.

This powder is designed to stick only to the wet ink, leaving the blank areas of the film clean. After a good shake to remove any excess, the film moves through a small curing oven. This melts the powder, transforming it from a grainy layer into a smooth, solid adhesive sheet that will act as the glue for your design.

Key Takeaway: It's the combination of the white ink base and the targeted adhesive powder that gives DTF its power. This duo is why you can get brilliant, long-lasting prints on almost any fabric type or color.

Stage 3: The Final Heat Press

With the transfer cured and ready, the final step is to apply it. You place the film precisely where you want it on the garment—a t-shirt, a tote bag, you name it—and put the whole thing into a heat press.

A specific combination of heat, pressure, and time activates that adhesive layer, permanently bonding the ink into the fabric’s fibers. After the timer goes off, you let it cool for a moment and then peel back the film. What’s left behind is just the design itself—crisp, vibrant, and ready to wear.

The Essential DTF Toolkit: What You'll Need

To get started with direct-to-film printing, you need more than just a great design. Having the right equipment and materials on hand is what makes the magic happen. Each piece of the puzzle plays a specific, critical role in turning a digital file into a vibrant, wearable print.

At the center of any DTF operation is the DTF printer itself. This isn't your average office printer. It’s a purpose-built machine engineered to work with special textile inks and, most importantly, to print a layer of white ink. This white base is the secret sauce that makes your colors pop on dark or colored fabrics.

The Core Materials That Make It Work

Beyond the printer, a few key consumables are essential for producing high-quality transfers. Think of these as the ingredients in your printing recipe; the quality of each one directly affects the final result.

-

DTF Pigment Inks: These aren't just any inks; they're specially formulated water-based pigments designed for fabric. This gives the final print excellent flexibility and the ability to withstand washing. The standard CMYK inks create the color, but the white ink is what provides the opaque foundation.

-

PET Transfer Film: This is the special sheet your design is printed onto. It has a unique coating that grips the ink during printing but is designed to release it perfectly onto the garment when heat is applied.

-

Hot-Melt Adhesive Powder: This fine, granulated powder acts as the glue. After printing, this powder is applied to the wet ink on the film. It's the key to bonding the design to the fabric fibers once it's melted.

It's hard to overstate how much the quality of these consumables matters. Better film means a cleaner transfer, and a premium adhesive powder ensures the print feels soft and lasts for the long haul, resisting cracks and peeling.

Finally, the whole process is brought together with a quality heat press. You absolutely need one. This machine delivers the consistent heat and even pressure required to melt the adhesive powder and permanently fuse your design onto the fabric. It’s the final, crucial step that makes the print last.

DTF vs DTG vs Screen Printing Compared

When you're ready to bring a design to life, picking the right printing method can feel like a huge hurdle. Let's break down how direct-to-film printing measures up against the two other heavyweights in the apparel world: Direct to Garment (DTG) and classic Screen Printing. Each one has its own sweet spot, and the best choice really comes down to what you're making.

The Lay Of The Land: DTG and Screen Printing

For decades, screen printing has been the go-to for big jobs. Think concert tees or company-wide staff shirts. It’s fantastic for large bulk orders with simple designs that don't use a ton of colors. The catch? It gets expensive and complicated fast if you only need a few shirts or have a super detailed, photorealistic image, since every single color requires its own custom screen.

Then there's DTG. This method prints ink right onto a garment, much like your home office printer prints on paper. The result on cotton fabrics is amazing—the ink soaks right into the fibers, leaving an incredibly soft feel. The big limitation here is that DTG really only loves cotton. On polyester or dark-colored fabrics, the colors can look dull and faded.

This is exactly where DTF comes in and changes the game. For a deep dive into how these two modern methods compare, our guide on DTF vs. DTG printing methods is a great resource.

Where DTF Fits In

Direct-to-film really is the best of both worlds. It gives you the full-color, photographic detail you can get with DTG, but with the versatility to print on almost any fabric, just like a traditional transfer. It’s no wonder so many creators are making the switch. In fact, a recent direct to film printing market analysis found that global production hit over 7.2 billion DTF prints in a single year, marking a nearly 30% jump. That’s not just growth; it's a massive shift in the industry.

To help you see the differences at a glance, we've put together a simple comparison table.

Key Insight: Your final choice almost always boils down to three factors: the fabric you're using, the complexity of your design, and the number of items you're ordering. DTF often hits the perfect sweet spot right in the middle.

Printing Method Comparison: DTF vs DTG vs Screen Printing

This table lays out the core strengths and weaknesses of each method, helping you align the technology with your project's specific needs.

| Feature | Direct to Film (DTF) | Direct to Garment (DTG) | Screen Printing |

|---|---|---|---|

| Fabric Versatility | Excellent (Cotton, Polyester, Blends, Leather) | Limited (Best on Cotton) | Good (Most Fabrics) |

| Color Vibrancy | Excellent on all colors | Good on light fabrics, muted on darks | Excellent but complex |

| Feel of Print | Soft, flexible layer on top of fabric | Very soft, ink soaked into fabric | Can be thick with many colors |

| Best For | Small to large orders, complex designs | Small orders, simple designs on cotton | Large bulk orders, simple designs |

| Durability | High, resists cracking and peeling | Good, but can fade over time | Very high, extremely durable |

Ultimately, having a clear picture of these trade-offs makes it much easier to decide. DTF provides a robust, flexible option that handles modern demands for vibrant color on diverse materials without requiring massive order quantities.

Why Creators Are Choosing DTF Printing

The massive shift we're seeing toward direct-to-film printing isn't just a trend; it's a practical solution to many of the headaches that have plagued apparel decorators for years. Both seasoned creators and emerging brands are making the switch because DTF hits a sweet spot, delivering an impressive blend of quality, versatility, and efficiency that other methods just can't match.

One of the biggest wins for DTF is its incredible material versatility. Forget being stuck with just cotton. Direct-to-film transfers adhere beautifully to a whole spectrum of fabrics, which is a massive advantage over methods like DTG.

This opens up your product catalog to include:

- Cotton and all sorts of cotton blends

- Polyester and other synthetic performance fabrics

- Tricky materials like nylon and even leather

This means you can print the exact same design and press it onto a classic cotton tee, a polyester sports jersey, or a nylon jacket without changing your process. That kind of flexibility is a game-changer for streamlining production.

Unmatched Vibrancy and Lasting Power

The print quality is another area where DTF really shines. You get stunning, full-color graphics with crisp details and razor-sharp lines. Because the ink is laid down on the film first—not directly onto porous fabric—the colors stay true to the original design. A solid white ink base layer makes sure the entire graphic is opaque, so your colors pop, even on the darkest garments.

The result is a print that feels surprisingly soft and pliable. It moves and stretches with the fabric, which means you don't get that cracking and peeling you often see with older, stiffer transfer methods.

This durability is a huge selling point. When customers buy custom apparel, they expect it to look good for a long time. The resilience of these prints is a major reason why creators feel so confident in the products they sell. To see just how well these transfers stand up to real-world use, our guide to DTF durability breaks down what you can expect from repeated washing and wearing. It's this one-two punch of brilliant visuals and rugged performance that makes DTF a go-to for professional-quality gear.

Common Questions About DTF Printing

As you dig into what direct-to-film printing is all about, you're bound to have some questions. It’s a new technology for many people, so that’s completely normal. Let’s tackle some of the most common ones I hear from people trying to figure out if DTF is the right move for them.

Do DTF Prints Feel Heavy or Plastic-Like on a Shirt?

This is probably the number one concern, and for good reason. Anyone who remembers the thick, iron-on transfers of the past is wary of anything that feels like a plastic shield on their chest.

The good news is that a quality DTF print feels surprisingly light and soft. While it is a layer that sits on top of the fabric, the materials are engineered to be flexible. A good transfer moves and stretches right along with the shirt, so you don't get that stiff, uncomfortable feeling. The final feel is closer to a premium screen print—smooth, but much lighter and more flexible, which helps it avoid the cracking that can happen with thicker, heavier prints.

How Durable Are DTF Transfers Really?

This is where DTF really shines. When you apply a transfer correctly with a good heat press, the adhesive creates an incredibly strong bond with the fabric fibers. The result is a graphic that can take a real beating.

DTF prints are built to last through wash after wash. They can handle dozens of cycles without the fading, peeling, or cracking you might see with other types of heat transfers. A big part of this is the elasticity of the inks. Since the design can stretch with the garment, it’s much less likely to break down over time. In our own testing, we've found they hold their color and integrity exceptionally well.

Key Insight: Durability isn’t just about the ink. It’s the whole system working together—the specialized ink, the quality of the adhesive powder, and the right heat press settings. When all those elements are right, you get a bond that’s made for commercial-grade apparel.

Can I Use My Regular Inkjet or Laser Printer for DTF?

I get this question a lot, and the simple answer is no. Your standard office or home printer just isn't equipped for the task, and trying to make it work will only lead to frustration.

Here’s a breakdown of why you need a dedicated DTF printer:

- Specialized Inks: DTF uses unique, water-based textile inks designed to stick to the film properly. The ink in your desktop printer would just pool and slide right off.

- White Ink Channel: Printing a solid layer of opaque white ink is non-negotiable. This white underbase is what makes your colors pop on dark-colored shirts. Standard printers don't have this feature.

- Film Handling: DTF printers are built to carefully guide the PET film through the machine without smearing the wet ink layers.

Honestly, attempting this with a regular printer would just create a huge mess. The entire process depends on the specific hardware and supplies that were designed to work in sync.

Ready to see the quality and versatility of DTF for yourself? At Raccoon Transfers, we make it easy to get professional, ready-to-press prints delivered right to your door. Upload your designs and see the difference today.