What Is DTF Printing and How Does It Work?

Compartir

Have you ever wondered how those incredibly vibrant, detailed designs get onto t-shirts, hats, and even leather jackets? One of the most exciting methods taking the custom apparel world by storm is Direct to Film (DTF) printing.

Simply put, DTF involves printing a design onto a special film, which is then heat-pressed onto a garment. The result is a brilliant, long-lasting graphic with a feel that's remarkably similar to a high-end screen print. It's a fantastic solution for printing on fabrics that other methods just can't handle well.

Understanding The Basics Of Dtf Printing

Think of DTF printing like creating a high-quality, ready-to-apply sticker for fabric. Instead of printing directly onto the shirt, the magic happens on a sheet of PET film first. This two-step process—print then press—is the secret to its incredible versatility.

This flexibility has made DTF a go-to for everyone, from Etsy shop owners to major fashion brands. The numbers don't lie, either. The global DTF market hit an impressive USD 2.56 billion in 2023 and is on track to nearly double within the next decade.

So, what’s the big deal? What really sets DTF apart is its unique approach:

- Fabric Freedom: It’s not picky. DTF works beautifully on cotton, polyester, leather, nylon, and all sorts of blends.

- Stunning Detail: It's perfect for creating photo-realistic images and complex, full-color designs with crisp lines.

- No Pre-Treatment Needed: Unlike other methods, most fabrics don't need a chemical pre-treatment, which saves a ton of time and hassle.

DTF effectively bridges the gap between the flexibility of a heat transfer and the premium quality of printing directly on the garment. It’s an accessible yet incredibly powerful way to create professional custom apparel.

For anyone new to the scene, it helps to view DTF as an all-in-one solution for a huge range of printing projects. To get a better handle on the fundamentals, check out our comprehensive guide to understanding DTF printing. It's the perfect starting point to see why so many creators are making the switch.

A Look Inside the DTF Printing Process

So, how does a digital file on a computer screen become a vibrant, wearable print? The journey from pixel to product in DTF printing is a fascinating one, blending digital precision with a physical, hands-on application. Each step is vital to getting that soft, durable finish that feels great and lasts wash after wash.

The process actually starts on a special PET film, not on the garment itself. A dedicated DTF inkjet printer gets to work, first laying down all the colors of your design (CMYK). Then, it prints a solid layer of white ink directly on top. This white ink is the secret sauce—it serves as a base so the colors really pop on dark fabrics, and it also creates the foundation for the adhesive that comes next.

From Powder to Permanent Print

With the ink still wet, the real magic begins. A fine adhesive powder is sprinkled evenly across the entire design. Think of this powder as the "glue" that will permanently bond your artwork to the fabric fibers. Any extra powder is shaken off, leaving only the ink-covered areas perfectly coated.

Next, the powdered film goes into a curing oven or under a heat press that hovers just above the surface. This quick blast of heat melts the adhesive powder, transforming it into a smooth, almost rubbery layer that seals in the ink. This step is absolutely crucial; it prepares the transfer for its final home.

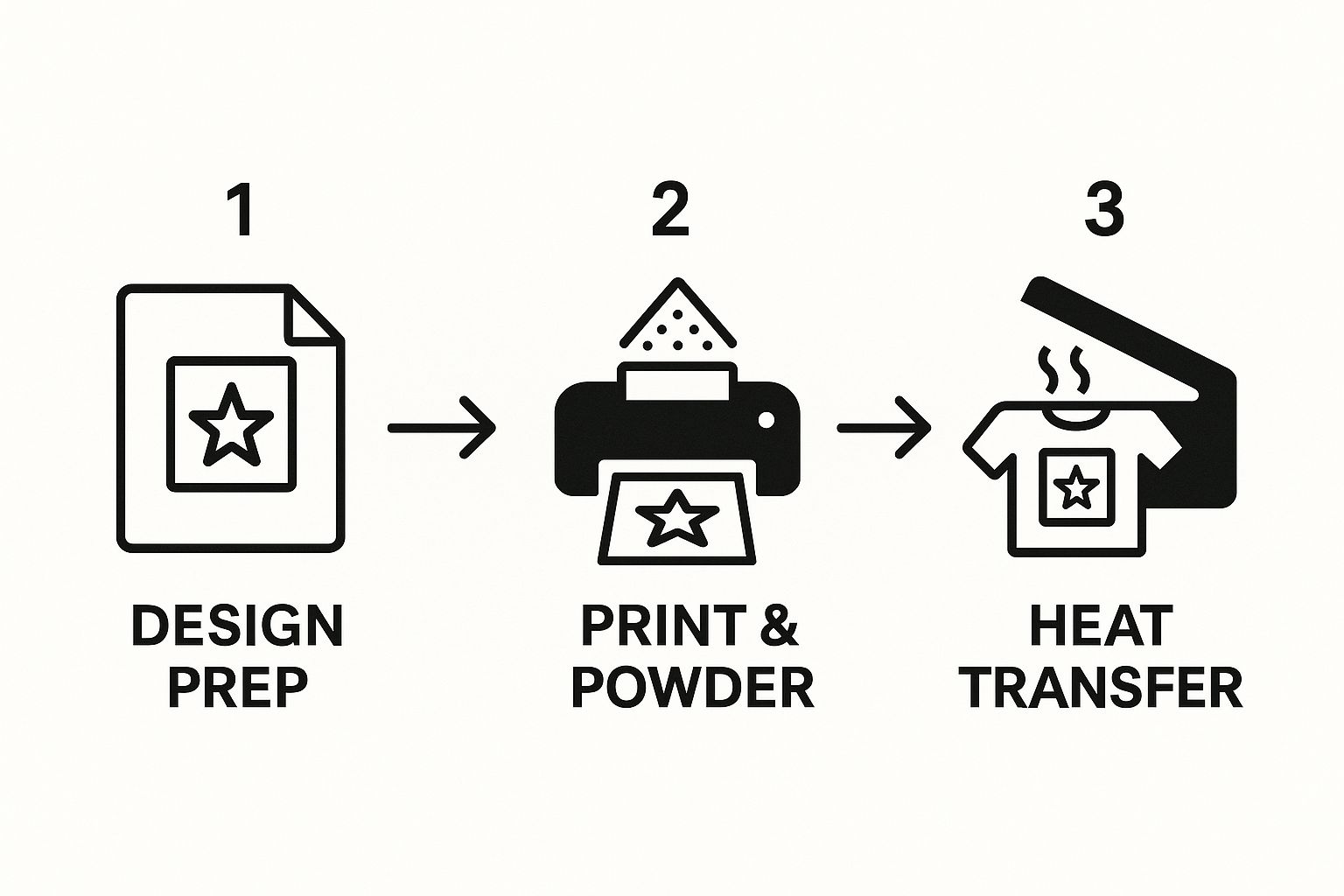

This visual guide breaks down the core workflow into its three main stages.

As you can see, the entire process flows seamlessly from the digital printer to the finished garment.

The final step is the most satisfying: the heat transfer. The cured film is positioned on the t-shirt or hoodie, and a heat press applies just the right amount of heat and pressure. This is what permanently fuses the design into the fabric.

After it cools down, the PET film is peeled away, revealing a brilliant and flexible design left behind on the garment. The highly specialized inkjet printers that deposit these inks are what make such complex, colorful results possible with amazing consistency. And with options like hot or cold peel films, the process gives printers a ton of flexibility. If you want to dive deeper into the market and technology, this in-depth DTF intelligence report is a great resource.

How DTF Stacks Up Against Other Methods

So, you know what DTF printing is. That's the easy part. The real trick is knowing when it’s the right tool for the job. In the world of custom apparel, DTF isn’t your only option; it’s constantly competing with Direct-to-Garment (DTG) and old-school screen printing.

Choosing the right method really comes down to what you’re trying to create. A single, super-detailed photo on a polyester jersey has a totally different answer than 200 one-color logos for a corporate event. You have to weigh things like your order size, the fabric you're using, and how complex your design is.

DTF's biggest selling point is its insane versatility. It works on just about anything you can think of—from cotton to nylon and even leather. On the other hand, DTG gives you that super-soft feel by printing directly into cotton fibers, while screen printing is still the undisputed champ for big, simple bulk orders where cost is king.

DTF Versus DTG Printing

The most common showdown is DTF vs. DTG. Picture DTG as a dye process: the ink soaks right into the fabric, leaving almost no "hand," or feel, on light-colored shirts. It's fantastic for that buttery-soft finish on 100% cotton. The problem is, DTG gets picky. It doesn't play well with polyester and can look faded on dark garments unless you use a pricey pre-treatment.

DTF takes a different approach. Instead of soaking in, it lays a bright, solid layer of ink right on top of the material. This is why it works beautifully on cotton, synthetics, and blends of any color. You get punchy whites and vivid colors that DTG just can't reproduce on those tougher fabrics. For a more detailed look, check out our guide on DTF vs DTG printing. The trade-off? DTF prints have a slight feel to them, but modern transfers have gotten so thin and flexible you’ll barely notice.

The key takeaway is simple: For soft, breathable prints on light-colored cotton, DTG is a strong contender. For vibrant, durable designs on literally anything else—especially synthetics and dark fabrics—DTF is the more reliable choice.

DTF Versus Screen Printing

Screen printing is the seasoned veteran of the industry, famous for its durability and low cost on large orders. The process uses a stencil (a "screen") to push ink onto a garment, one color at a time. That means every new color adds another screen, driving up the setup time and cost. It’s just not practical for small jobs or photorealistic designs.

This is exactly where DTF comes in and changes the game. Since it's a completely digital process, it has zero setup cost per design.

- Small Batches: Perfect for printing just one shirt or a small run of 20-50.

- Full-Color Designs: A complex photograph costs the same to print as a simple one-color logo.

- Perfect Consistency: Every single print is a perfect clone of the first one.

Screen printing only starts making financial sense when you’re ordering over 100 items with just a few colors. For small businesses, brands just starting out, or anyone needing detailed prints in low quantities, DTF is a much friendlier and more affordable way to get professional results.

DTF vs DTG vs Screen Printing at a Glance

Still on the fence? Sometimes seeing it all laid out helps clarify which method is the best fit for your specific project. This table breaks down the core differences.

| Feature | DTF Printing | DTG Printing | Screen Printing |

|---|---|---|---|

| Best For | Full-color on any fabric, small to medium runs | Soft-feel prints on 100% light-colored cotton | Large bulk orders (100+) with simple designs |

| Fabric Type | Cotton, poly, blends, leather, nylon (versatile) | Primarily 100% cotton; struggles with synthetics | Most fabrics, but ink may vary |

| Design Complexity | Unlimited colors, photos, gradients | Unlimited colors, but less vibrant on dark fabrics | Limited by the number of colors (each adds cost) |

| Feel of Print | Soft, flexible layer on top of fabric | Very soft, breathable, no feel on light garments | Thicker, durable layer on top of fabric |

| Durability | Excellent; rated for 50+ washes | Good, but can fade faster than DTF or screen prints | Excellent; the most durable option for workwear |

| Cost | Low setup, affordable for small runs | Moderate cost per print, best for one-offs | High setup cost, but very cheap per print on large runs |

Ultimately, there’s no single "best" method—just the best one for you. DTF has carved out its place by offering a powerful, flexible solution that bridges the gap between DTG’s material limitations and screen printing’s volume requirements.

The Real-World Advantages of DTF Printing

So, beyond all the technical talk, what’s the big deal with DTF printing? Why are so many creators and businesses getting excited about it? It really comes down to a few game-changing benefits that solve some of the oldest headaches in the custom apparel world.

The first, and maybe biggest, advantage is its incredible material versatility. If you've ever worked with DTG printing, you know it's pretty much a cotton-only club. DTF blows those limitations wide open. You can press these transfers onto cotton, polyester, nylon, leather, and all sorts of tricky blends without having to mess with special chemical pre-treatments. Suddenly, you're not just making t-shirts; you can brand team jerseys, tote bags, hats—you name it.

Stunning Quality and Durability

Another area where DTF really shines is the sheer quality and toughness of the prints. This method is fantastic for producing designs with photo-realistic detail and colors that pop, even on black or dark-colored fabrics.

And these prints are built to last.

- Excellent Stretchability: The transfer is flexible and moves with the fabric, so you don't get that awful cracking effect after a few wears.

- Superior Wash Resistance: When cared for properly, a DTF print can handle 50+ washes without fading or peeling away.

- Soft Hand-Feel: Forget those thick, plastic-y prints from the past. Modern DTF transfers feel surprisingly soft and lightweight on the garment.

When you combine that vibrant look with serious durability, you get a product that not only looks incredible off the press but stays that way. That's how you create real value for your customers.

Finally, let's talk about the money. DTF offers a serious economic edge, especially if you're doing small-to-medium-sized runs. The process is efficient, cutting down on both production time and the cost for each item. For many projects, it just makes more financial sense than older methods. As more and more people want unique, personalized gear, DTF's low setup costs and efficiency are a big reason it's taking off. A recent global shift towards DTF technology confirms just how much momentum it's gaining worldwide.

Putting DTF Printing into Practice

It's one thing to talk about how a technology works, but it's another to see what it can actually do. This is where DTF printing gets really exciting. Its power to work with almost any material unlocks a massive range of creative and commercial projects, pushing way beyond the classic cotton t-shirt.

DTF really comes into its own when you throw a tricky job at it—the kind of thing that makes other printing methods stumble. Need to put a vibrant team logo on a slippery polyester jersey? No problem. Or how about a detailed, multi-color design on a tough canvas tote bag or a uniquely shaped hat? DTF handles these with ease, creating a perfect bond where a DTG printer would simply fail.

Unlocking New Creative Possibilities

The possibilities are really only limited by your imagination. Since the whole process is digital, printing a complex, full-color photograph is just as straightforward as a simple one-color logo. This opens the door to a huge variety of products.

Here are just a few real-world examples:

- Custom Apparel: Think vivid graphics on denim jackets, cozy hoodies, and stretchy leggings.

- Branded Workwear: Durable logos that stand up to tough conditions on high-visibility vests and heavy-duty work shirts.

- Promotional Goods: Crisp, clean branding on canvas bags, aprons, and bandanas.

- Niche Items: Detailed designs on things you might not expect, like leather patches, nylon windbreakers, or even custom sneakers.

The real magic of DTF is its incredible versatility. It lets you put a high-quality, long-lasting print on a massive variety of surfaces without ever sacrificing detail or color.

This "print-on-anything" flexibility makes DTF a fantastic tool for any business looking to offer more to its customers. Whether you're a small startup launching a new apparel line or a company creating unique promotional gear, DTF gives you a reliable and affordable way to get professional results on almost any fabric you can think of. It’s no surprise it's being adopted so quickly—it just works.

Your Essential DTF Starter Toolkit

Thinking about bringing DTF printing into your own shop? Awesome. To get started, you’ll need a few key pieces of gear that all work in concert to create those vibrant, professional-grade transfers. Getting a handle on what each piece does is your first step to making a smart investment.

The star of the show is, without a doubt, the DTF printer. This isn't your average desktop printer. It’s a specialized beast built to handle textile inks, and most importantly, it has dedicated channels for white ink. That white ink is non-negotiable—it’s what allows your designs to pop on dark-colored fabrics.

Once you have the printer sorted, you'll need the right consumables. Each one plays a crucial part in the magic that makes DTF transfers stick.

Your Core Supplies List

- DTF Inks: You can't just use any old ink. These are specially formulated textile inks with a bit of stretch, so they move with the fabric. You'll need the standard CMYK colors plus a good white ink.

- PET Film: This is what you print on. It's a special coated film sheet that holds your design perfectly until it's ready to be pressed.

- Adhesive Powder: This is the secret sauce. After printing, you coat the wet ink with this fine "hot melt" powder. It acts as the glue, bonding your design permanently to the garment.

The last piece of the puzzle is the heat press. Your printer might create the beautiful design, but it’s the heat press that makes it a permanent part of the shirt. It applies the exact heat and even pressure needed to melt the adhesive powder and fuse the design to the fabric fibers.

Getting this step right is everything. You can learn way more by mastering heat press settings for DTF in our in-depth guide.

Take it from me: cutting corners on any of this, especially your printer or heat press, is a recipe for frustration, failed transfers, and wasted materials. A solid toolkit is the foundation for getting consistent, sellable results every single time.

Got Questions? We've Got Answers

To wrap things up, let's tackle a few of the most common questions that pop up when people first discover DTF printing. Getting these details straight will help you see exactly where this technology fits into the world of custom apparel.

How Well Do DTF Prints Actually Hold Up?

This is the big one, right? You want to know if the final product will last. The good news is that DTF prints are incredibly durable. You can expect them to handle 50+ washes before you see any significant cracking or fading.

While screen printing has a long-standing reputation for being tough, DTF has a unique advantage: elasticity. The print stretches right along with the fabric, which is a huge plus for activewear or stretchy garments where other inks might start to break down over time.

Can I Just Use My Home Printer?

It's a tempting thought, but unfortunately, no. You can't use a standard office inkjet or desktop printer for DTF.

The whole process relies on a specialized setup. DTF printers are built to handle thick, water-based textile inks and, most importantly, have a dedicated channel for white ink which is essential for vibrant colors on dark fabrics. Your everyday printer simply isn't equipped for the specific inks or the PET film this method requires.

A bonus for many brands is that DTF is often seen as a more sustainable choice than screen printing. It creates far less water waste because there are no screens to wash out between jobs. Plus, the eco-friendly, water-based inks help reduce the environmental footprint, making it a solid option for environmentally conscious businesses.

Ready to bring your vibrant, durable designs to life on any fabric? At Raccoon Transfers, we make it easy. Upload your artwork and order your custom DTF transfers today!