What Is DTF Printing on Shirts? Complete Guide & Benefits

Compartir

If you’ve ever wanted to take a brilliant, full-color digital design and put it on almost any shirt, you've stumbled upon the magic of Direct-to-Film (DTF) printing. Think of it as creating a high-end, custom "sticker" of your artwork that's then permanently bonded to the fabric with heat.

This method has become a massive hit in the apparel world because it produces stunning, vibrant graphics that are tough enough for daily wear but also surprisingly flexible. It's a fantastic solution for printing on all sorts of materials, from classic cotton and polyester to tricky blends.

Unlocking Custom Apparel: The Power of DTF Printing

So, what is DTF printing on shirts really about? It elegantly sidesteps the limitations of older printing methods, giving decorators a unique blend of quality, versatility, and speed that's tough to beat. It’s quickly become a go-to choice for creating custom apparel.

Unlike techniques that dye the fabric directly, DTF printing is a different beast altogether. The process creates a self-contained graphic layer that sits on top of the garment. This is the key to its incredible adaptability—it doesn't matter if you're working with a black cotton hoodie, a sleek white polyester jersey, or even a rugged denim jacket. The results are consistently brilliant.

A New Standard in Fabric Decoration

This technology has caught on like wildfire for a few simple but powerful reasons. It just works, solving common printing headaches while delivering a premium finish that both creators and customers love.

Here’s why it’s become so popular:

- Fabric Freedom: Got a tricky fabric? No problem. DTF transfers stick to a massive range of materials, including many that are a nightmare for other methods like DTG (Direct-to-Garment). This blows the doors wide open for creative projects.

- Vibrant, Detailed Prints: The process is a dream for reproducing complex designs with razor-sharp lines and a huge spectrum of colors. Since the ink is printed on the film first, its pop and vibrancy aren't dulled down, even on the darkest fabrics.

- Cost-Effective for Small Runs: DTF has very little setup, making it perfect for one-off jobs and small batches. This empowers solo entrepreneurs and small brands to launch professional merch without the risk of ordering in bulk.

You could say DTF printing is like a high-tech tattoo for fabric. It gives you the incredible detail of a digital print combined with the durability and stretch needed for clothes that get worn, washed, and loved.

This unique mix of benefits makes DTF more than just another option—it’s now a core tool for any modern garment decorator. To really get into the nitty-gritty, you can learn more about what is DTF printing and its technical side in our complete guide.

The DTF Printing Process From Start to Finish

To really get what DTF printing is all about, it helps to walk through the entire process, from a simple digital file to a finished, wearable shirt. It’s a fascinating sequence where each step builds on the last to create a design that's bright, tough, and feels great. Forget what you know about traditional printing—this is more like making a high-tech, custom decal for fabric.

The whole thing starts not on the shirt itself, but on a special sheet of PET (polyethylene terephthalate) film. This is a clear, flexible material that acts as the temporary home for your design. A purpose-built DTF printer, loaded with special textile inks, prints the artwork directly onto this film.

Here’s the clever part: the printer lays down all the colors first, then finishes with a solid layer of white ink on top. This white base is key, as it makes sure the colors look bold and vibrant, no matter if the shirt is black, white, or any color in between.

From Film to Adhesive Powder

After printing, the design is just wet ink sitting on a piece of plastic. To get it to stick to a shirt, it needs an adhesive. This is where the real magic comes in. The wet print is covered with a fine layer of thermoplastic adhesive powder. Imagine sprinkling fine sugar over a wet painting—the powder sticks only to the ink.

Any extra powder is shaken off, leaving the adhesive only on the printed areas. This step is absolutely critical. This powder is the glue that will eventually melt and lock the design into the fabric fibers. Without it, you just have a pretty picture with no way to attach it.

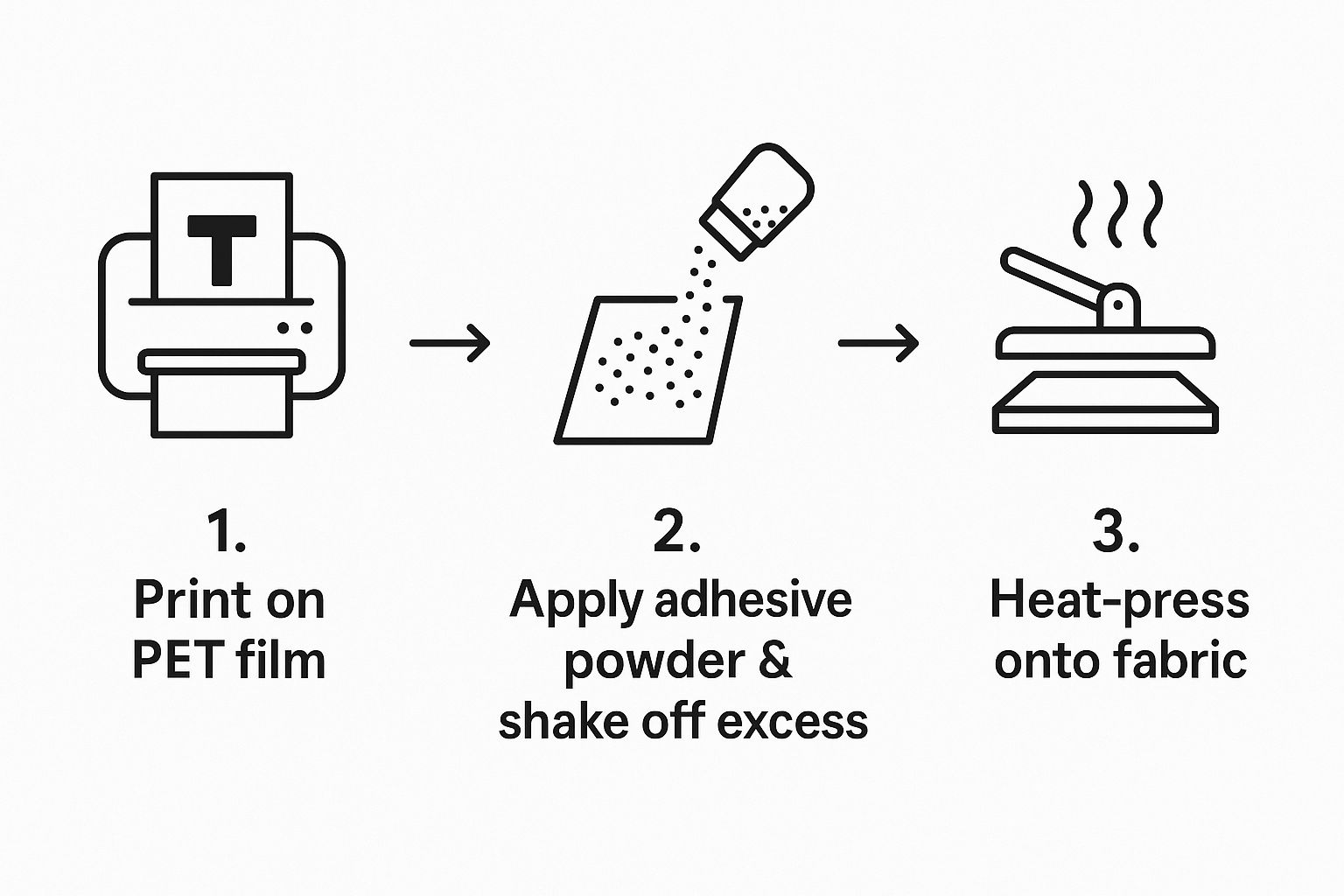

This visual breaks down the core three-step workflow of DTF printing, from the initial print to the final press.

As you can see, the journey is straightforward: print, powder, and press. The result is a custom garment ready to go.

Curing and Final Application

With the powder perfectly coated on the ink, the film is sent through a curing oven or placed under a heat press that hovers just above the surface. This quick "baking" step melts the powder, turning it from a grainy layer into a smooth, solid sheet that locks in the ink. Now you have a stable, ready-to-use transfer.

The curing phase is arguably the most important. It's where the ink and adhesive fuse into a single, durable entity. Rushing this step can lead to a weak bond, but getting it right ensures the final print is built to last through countless washes.

Finally, it's time to bring it all together. The cured transfer is placed exactly where you want it on the shirt. Using a heat press, high heat and firm pressure are applied for about 10-15 seconds. This heat reactivates the adhesive, causing it to melt right into the weave of the fabric.

After a brief moment to cool down, the PET film is peeled away. What's left behind is just the graphic, now permanently bonded to the shirt. You get a print that’s not only vibrant and sharp but also has a soft feel and incredible durability.

What Makes DTF Such a Big Deal for Custom Apparel?

If you're wondering what is DTF printing on shirts, the best way to understand its buzz is to look at the real-world problems it solves. DTF didn't just appear as another option; it showed up with clear answers to challenges that have bugged garment decorators for years.

The single biggest win for DTF is its incredible versatility. Forget being locked into one type of fabric. While methods like DTG are pretty much cotton-only, DTF doesn't care what you're printing on. Cotton, polyester, nylon, leather, tricky synthetic blends—it handles them all with the same great results.

This opens up a massive creative playground. You can suddenly take that one awesome, full-color design and press it onto a classic cotton tee, a sleek polyester jersey, and a rugged denim jacket, all using the exact same process. For any brand that wants to offer a diverse product line, that’s a game-changer.

Print Quality You Can See and Feel

DTF is a powerhouse when it comes to producing prints that pop. The colors are incredibly vibrant and the details are razor-sharp. Why? Because the design is printed on a transfer film first, the ink sits right on top of the garment instead of soaking into the fibers. This keeps colors bright and true to your digital file, even on black or dark-colored shirts.

But it’s not just about looks. The prints have a fantastic, soft feel to them. They're flexible and move with the fabric, which means no more of that stiff, plastic-y feeling that leads to cracking and peeling. It’s that perfect combination of brilliant color and a lightweight finish that makes for a premium product people actually want to wear.

Think of it this way: DTF builds the entire graphic on a separate film—every color, every tiny detail. This ensures nothing gets lost when it's transferred to the shirt, giving you a flawless, retail-quality look every time.

Built to Last Through Wash and Wear

A great-looking print doesn't mean much if it falls apart after a few washes. This is another area where DTF shines. These prints are seriously durable. The special adhesive powder creates a powerful bond with the fabric that can handle dozens of wash cycles without fading, cracking, or peeling.

This toughness makes DTF a perfect match for all kinds of apparel, including:

- Workwear: Uniforms and branded gear that get washed constantly.

- Athletic Apparel: Jerseys and sportswear that need to stretch and withstand abuse.

- Everyday Fashion: Your favorite go-to tees and hoodies that see a lot of use.

If you want to get into the nitty-gritty of its longevity, our guide on how long DTF transfers last breaks it all down.

DTF Printing vs Other Methods: A Quick Comparison

To put it all in perspective, let's see how DTF stacks up against the other big players in the custom apparel world. Each method has its place, but DTF fills a unique and powerful niche.

| Feature | DTF Printing | Screen Printing | DTG Printing |

|---|---|---|---|

| Best For | Small to large runs, full-color designs | Large bulk orders (100+ items) | Small runs, on-demand, detailed prints on cotton |

| Fabric Type | Cotton, polyester, blends, leather, nylon—virtually anything! | Best on cotton, can work on blends | Primarily cotton and high-cotton blends |

| Color Capability | Unlimited colors, gradients, and photo-realistic prints | Limited colors per screen (costly for more) | Unlimited colors, excellent for photos |

| Setup Costs | Very low; no screens or color separations needed | High; requires screen creation for each color | Low; digital file is sent directly to the printer |

| Feel of Print | Soft, flexible, and lightweight on the shirt | Can be thick, especially with multiple colors | Very soft, ink soaks into fabric fibers |

| Durability | Excellent; rated for 50+ washes | Excellent; very durable and long-lasting | Good, but can fade faster than other methods |

As you can see, DTF's ability to handle any fabric with full color and low setup costs makes it an incredibly versatile and cost-effective solution for modern apparel businesses.

The Smart Choice for Today's Market

Finally, let's talk money. DTF makes fantastic financial sense, especially for small-to-medium-sized orders. With traditional screen printing, the high setup costs make it a non-starter for just a handful of items. DTF has virtually zero setup, making it profitable to print just one shirt or one hundred.

This is why DTF has become the go-to for the personalized apparel market. T-shirts alone account for roughly 41% of the market revenue for DTF printing. That growth is fueled by the massive demand for custom graphic tees, which DTF serves perfectly by empowering small businesses and e-commerce shops to produce short runs without breaking the bank.

Real-World Applications for DTF Technology

Any new printing tech is only as good as what you can actually do with it. This is where Direct-to-Film really shines. Its sheer flexibility has made it a go-to for creative entrepreneurs, small businesses, and even established brands, shaking up how custom apparel gets made and sold.

One of the biggest wins has been for the merchandise industry. Artists, YouTubers, and musicians can now drop top-quality merch without gambling on a huge upfront order. DTF lets them produce small, highly profitable runs of t-shirts, hoodies, and tote bags whenever they need them.

Empowering Small Businesses and Creators

For smaller shops, DTF is a game-changer. It completely tears down the high barrier to entry you see with old-school methods like screen printing, which demand massive minimum orders. A local coffee shop can now easily whip up 20 branded aprons, or a new clothing startup can test a design on a handful of shirts before going all-in.

The demand for small-batch, custom runs is exploding. People want low-minimum, high-margin products, and DTF's lack of setup fees directly answers that call. It's pouring fuel on the fire for the creator economy and micro-brands that win by being nimble and unique.

Pushing Beyond T-Shirts

T-shirts might be the first thing that comes to mind, but DTF’s versatility goes way beyond that. The technology works beautifully on items that are traditionally a nightmare to print on, opening up a whole new menu of product ideas.

Here are just a few places where DTF is making a huge difference:

- Headwear: Getting vibrant, detailed logos onto hats and beanies is tough because of their shape and texture. DTF handles it with ease.

- Sportswear: It's perfect for applying flexible, tough designs to polyester jerseys and athletic gear that need to stretch and take a beating.

- Outerwear: You can decorate jackets, hoodies, and even tricky materials like leather with crisp graphics that hold up against the weather.

This adaptability makes it the clear winner in a lot of situations. To see a head-to-head comparison, check out our guide on DTF vs. DTG printing.

And it doesn't stop there. The industry is already moving on to exciting new things like UV DTF printing, which lets you apply these transfers to hard surfaces like glass, plastic, and metal. This is opening the door for custom tumblers, phone cases, and signs, proving that DTF technology is really just warming up.

The Future of DTF in Custom Garment Decoration

Direct-to-Film printing isn't just a passing fad; it's a fundamental shift in how we think about and produce custom apparel. From where I'm standing, its trajectory points toward even greater influence, pushed forward by rapid tech improvements and what customers are asking for. The future of DTF isn't just about tweaking a process—it's about completely reshaping the garment decoration game.

We're already seeing innovations that are making DTF printers faster and more automated, capable of handling bigger jobs without skipping a beat on quality. Ink chemistry is getting better, giving us transfers with more stretch and durability in the wash. At the same time, the software is getting smarter, making the whole workflow smoother. These changes are making it easier for anyone to get started, empowering more creators to launch professional-looking products from a small shop or even a spare room.

Aligning with Modern Market Demands

The timing for DTF's rise couldn't be better. It fits perfectly with major shifts in how people buy and sell things today. Take the creator economy, for example. It runs on unique, on-demand merchandise, and DTF is the perfect tool for influencers, artists, and small brands to offer top-notch apparel without sinking money into a huge inventory. It’s the direct answer to what modern shoppers want: personalization and something that feels genuine.

The numbers back this up. The global Direct-to-Film printing market was valued around USD 2.72 billion and is expected to hit USD 3.92 billion by 2030. That steady growth is all about the increasing demand for custom gear and the fact that DTF is simply more cost-effective than older methods for many applications. You can explore detailed market analysis and revenue forecasts on globenewswire.com to see the full picture.

Looking ahead, DTF is poised to become the backbone of on-demand manufacturing for textiles. Its ability to produce a single shirt just as efficiently as a small batch makes it essential for a future where customization isn't a luxury—it's the standard.

The Push Toward Sustainability

Another big piece of the puzzle for DTF's future is sustainability. As the tech matures, manufacturers are putting real work into developing more eco-friendly inks and adhesive powders. The process itself uses far less water and creates less waste than a massive screen printing run, which lines up perfectly with the growing demand from both customers and companies for more environmentally responsible products.

When you combine the constant innovation, the perfect market fit, and the green-friendly potential, it's clear that understanding what is DTF printing on shirts is crucial for anyone serious about the future of custom apparel. It’s quickly becoming a non-negotiable tool in the modern decorator's toolkit.

Common Questions About DTF Printing

As you dive into the world of DTF printing for shirts, a few questions always pop up. Getting these sorted out really shows why this technique has caught on so quickly in the garment industry.

How Durable Are DTF Prints?

This is probably the number one question I get asked. The durability is honestly impressive. A quality DTF print is rated to handle 50+ washes before you'll see any significant cracking or fading.

The magic is in the thermoplastic adhesive that melts and bonds directly with the fabric fibers. It creates a connection so strong that the design essentially becomes part of the shirt, making it just as tough as the garment itself.

Does DTF Work on Dark Garments?

Absolutely, and this is one of its biggest selling points. The secret is the layer of brilliant white ink that's printed first, acting as an underbase for the colors.

This base layer makes sure your design pops with full opacity and vibrancy, whether it's on a jet-black hoodie or a plain white t-shirt. No more dull, muted colors on dark fabrics.

What Kind of Artwork Files Do I Need?

For a sharp, professional-looking print, your file quality is everything. You'll want to work with high-resolution formats like PNG, PDF, or EPS, as they handle the fine details and transparent backgrounds that DTF requires.

As a rule of thumb, always aim for a resolution of at least 300 DPI. This is the industry standard for a reason and ensures your final print is crisp, not blurry.

Is DTF an Eco-Friendly Option?

People are more conscious about their environmental impact than ever, and printing is no exception. While no method is perfect, DTF is certainly a step in a greener direction.

Compared to traditional methods, DTF printing is a more eco-friendly choice. It relies on water-based inks and creates far less waste and water pollution than a typical screen printing operation.

This makes it a solid choice for any brand or creator looking to produce great products while keeping their environmental footprint as small as possible.

Ready to bring your designs to life with vibrant, durable, and versatile prints? At Raccoon Transfers, we make it easy to get professional-quality DTF transfers with next-day shipping. Upload your artwork and create your custom transfers today!