Your Guide to the Best Paper for Heat Transfer

Share

The best paper for your heat transfer project really boils down to what you're making and the gear you have. If you're a hobbyist working with a home inkjet printer and light-colored cotton shirts, Inkjet Paper for Light Fabrics is your go-to. For a small business owner who needs a tougher finish that works on any color, Laser Paper for Dark Fabrics gives you fantastic washability. And for the pros chasing those super vibrant, permanent designs on polyester, Sublimation Paper is in a league of its own.

Finding Your Perfect Heat Transfer Paper Match

Stepping into the world of heat transfer paper can feel a bit overwhelming, but picking the right one is the most critical step for getting results you'll be proud of. It's like choosing the right tires for your car—the slick set you use for city driving would be useless off-road. The same logic applies here: your paper has to be compatible with your printer, your fabric, and the look you're trying to achieve.

The demand for custom gear is exploding, and that's pushing the technology forward. In 2023, the global heat transfer paper market was already valued at a whopping USD 523.2 million, and it's projected to hit nearly USD 700 million by 2033. This isn't just a niche hobby anymore; it's a massive industry driven by people who want to create unique, personalized items.

If you're just starting out, this comprehensive guide to iron-on transfer paper is a great place to build your foundational knowledge. Getting the basics down first will make all the other choices much easier.

Heat Transfer Paper Quick Comparison Guide

Before we dive deep into the technical weeds, let's start with a simple overview. This table gives you a quick side-by-side look at the most common types of paper. Think of it as your cheat sheet for narrowing down the options.

| Paper Type | Best For | Feel on Fabric | Durability | Printer Needed |

|---|---|---|---|---|

| Inkjet Paper | Beginners, cotton fabrics, craft projects | Soft, but a noticeable layer | Good (5-15 washes) | Standard Inkjet |

| Laser Paper | Small businesses, cotton & blends, durability | Slightly thicker, very smooth layer | Excellent (25-50+ washes) | Laser Printer |

| Sublimation | Professionals, polyester fabric, vibrant photos | No feel at all (ink dyes fabric) | Permanent (lasts as long as fabric) | Sublimation Printer |

Use this table as your starting point. It helps you quickly filter your choices based on the equipment you already own and the results you're after. For instance, if you're working with a standard inkjet printer from your home office, you can immediately focus on inkjet transfer papers. Your next step is simply choosing the right one for your light or dark fabric.

How Heat Transfer Paper Actually Works

Ever wondered what’s really going on when a printed design becomes part of a t-shirt? It's not magic, but it is some clever chemistry. The simplest way to think about heat transfer paper is as a high-tech sticker, engineered specifically for fabric.

Each sheet has a special polymer coating that acts as the perfect vehicle for your printer's ink. When you print, the ink sits right on top of this layer, waiting for the next step. At this point, it’s just ink on paper. The real transformation happens when you bring in the heat.

The Science Behind the Bond

When you apply heat and pressure with a press or an iron, that polymer coating melts for a few crucial seconds. This is where the process gets fascinating.

As the polymer turns to liquid, it does two things at once. First, it releases the ink it was holding onto. Second, this molten polymer seeps into the tiny nooks and crannies between the fabric's fibers. As it cools down almost instantly, it solidifies, permanently locking the ink onto the garment. It's like you've created a custom, ultra-thin film that holds your design tight.

Key Takeaway: Heat transfer creates a physical bond. The polymer carrier melts, weaves itself into the fabric, and then hardens, creating a durable new layer that displays the ink. It isn't just staining the cloth.

Additive vs. Subtractive: A Tale of Two Transfers

This whole process is what we call an additive transfer. The design is a new layer that sits on top of the fabric. This is why you can often feel the design on the shirt—a quality that pros call its "hand."

It's also the reason you need a different paper for dark fabrics. That paper comes with a built-in opaque white base layer. Without it, your vibrant colors would get swallowed up by the dark background of the shirt.

The alternative is a subtractive process like sublimation, which works completely differently. Sublimation ink turns into a gas under heat and actually dyes the polyester fibers. There's no added layer at all, so the design has zero "hand" and feels just like the original fabric. Each method has its pros and cons, but understanding this core difference is the first step to picking the right one for your project.

To see this process broken down even further, you can learn more about how transfer paper works in our detailed guide.

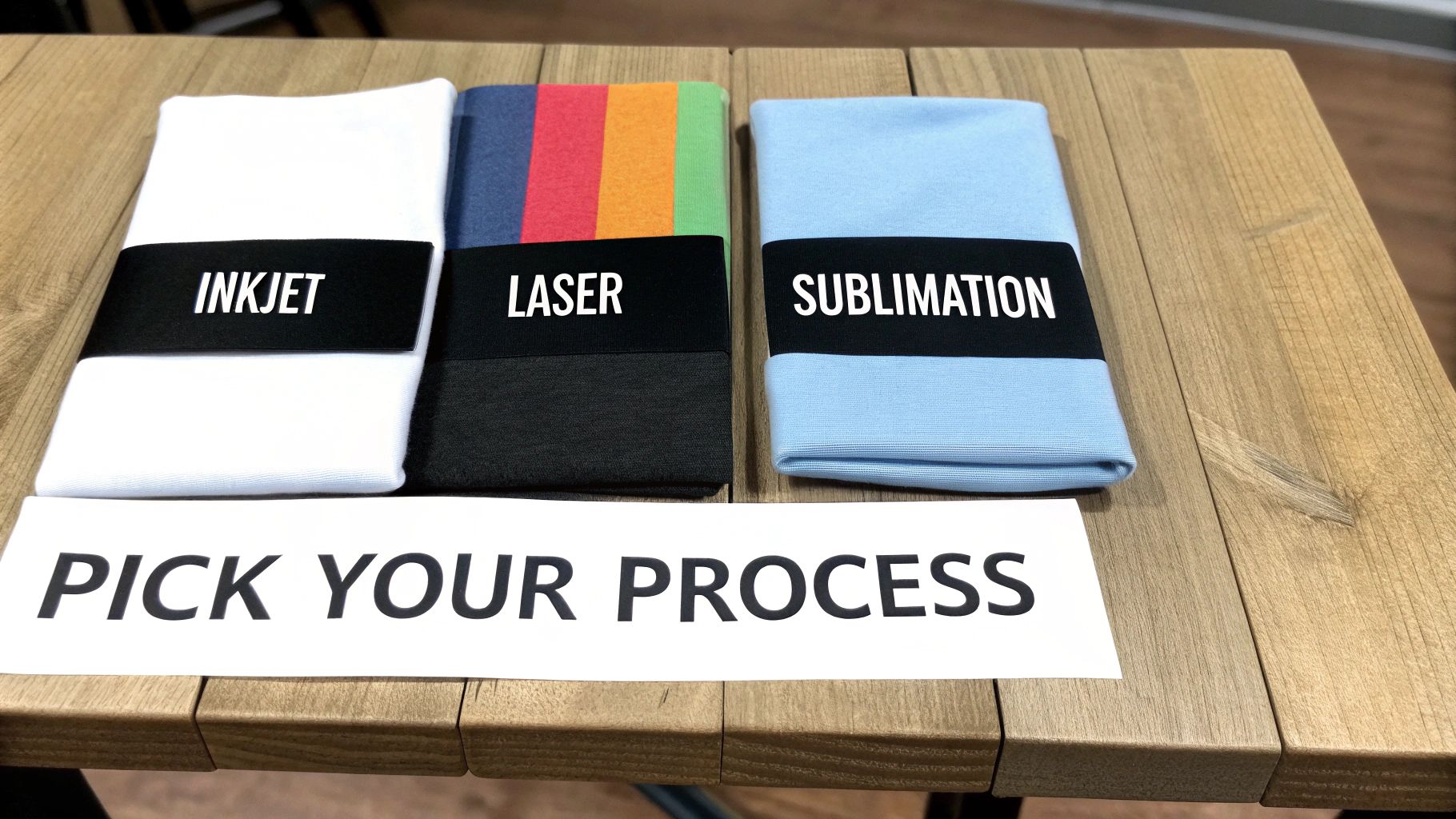

Choosing Between Inkjet Laser and Sublimation

Picking the right transfer method is the first and most critical decision you'll make. It sets the stage for everything else—your printer, your paper, and even the types of fabrics you can use. I like to think of it like painting: inkjet and laser are like acrylics, where you're adding a distinct layer of color on top of a surface. Sublimation, on the other hand, is like a watercolor stain that literally becomes one with the paper.

This choice goes far beyond just the paper. You're really investing in an entire creative ecosystem. Your decision will shape your startup costs, the learning curve, and the final look and feel of every single product you make. Let's dig into the three main technologies to help you figure out the best paper for heat transfer for your specific goals.

Inkjet Transfer Paper The Accessible All-Rounder

For most people just dipping their toes into custom apparel, inkjet transfer paper is the go-to starting point. It’s designed to work with the standard inkjet printer you probably already have at home, making it incredibly affordable and easy to get started with. If your printer takes liquid ink cartridges, you're good to go.

The main thing to understand about inkjet paper is that it comes in two flavors:

- For Light Fabrics: This paper has a clear polymer film. When you press it, the transparent backing essentially melts into the shirt, so any unprinted areas of your design just show the fabric's natural color.

- For Dark Fabrics: This type has a solid, opaque white backing. That white layer acts as a primer, giving your colored inks a bright base to sit on so they look vibrant and don't get swallowed up by the dark fabric.

Inkjet transfers are a fantastic match for cotton and cotton-blend materials. They deliver bright, punchy colors and a relatively soft feel, though you can definitely feel the design as a thin layer on the shirt. It’s the perfect method for one-off gifts, personal projects, or anyone just starting their creative journey.

Laser Transfer Paper The Professional Workhorse

If inkjet is the beginner's best friend, laser transfer paper is the logical next step for small businesses or anyone who needs their creations to last. Made specifically for laser printers (the ones that use toner instead of liquid ink), this paper gives you a serious upgrade in durability. Your designs can often handle 50 or more washes without showing signs of cracking or fading.

A huge advantage of laser systems is the "no-cut" or self-weeding paper. This is usually a two-paper process that cleverly transfers only the toner to the shirt, leaving all the negative space behind. This completely eliminates the tedious task of cutting around intricate designs, saving a massive amount of time and producing a clean, sharp finish that looks a lot like professional screen printing.

Laser paper provides a more durable, professional-grade finish. Its self-weeding capability is a game-changer for businesses that need to produce high-quality, complex designs efficiently and at scale.

Sublimation The Magic of Ink Infusion

Sublimation isn't just a different type of paper—it's a whole different ballgame based on chemistry. With this method, you print your design using special sublimation ink on sublimation paper. Then, under high heat and pressure, that solid ink turns directly into a gas and permanently infuses itself into the polyester fibers of your item.

The result is truly amazing: a transfer with absolutely zero feel or "hand." The design is in the fabric, not on top of it. This means it will never crack, peel, or fade, period. The colors are stunningly vibrant and photographic in quality.

So, what's the catch? Sublimation only works on light-colored, 100% polyester garments or hard-surface items (like mugs and phone cases) that have a special polymer coating. The ink simply won't bond with natural fibers like cotton. This makes it the champion for performance apparel, sportswear, and promotional products. The growing demand for durable, polymer-based methods is clear, with the broader heat transfer market projected to hit USD 2,107.5 million by 2033. You can explore more on the heat transfer market growth to see just how big this industry is becoming.

Now that we've covered the basics, let's put these three methods side-by-side to see how they really stack up on the technical details.

Feature Deep Dive Inkjet vs Laser vs Sublimation

| Feature | Inkjet Transfer | Laser Transfer | Sublimation |

|---|---|---|---|

| Printer Type | Standard Inkjet Printer | Laser Printer (OKI white toner recommended for darks) | Dedicated Sublimation Printer (e.g., Sawgrass, Epson with special ink) |

| Ink/Toner | Pigment or Dye-Based Ink | Toner Cartridges (CMYK + White) | Sublimation Ink |

| Fabric Compatibility | Cotton, poly-blends, canvas. Best on light or dark fabrics (with specific paper). | Cotton, poly-blends. Excellent on lights and darks (especially with white toner). | 100% Polyester (or high-poly blends) and polymer-coated hard surfaces. Light colors only. |

| Feel of Transfer | A soft, flexible film on the fabric surface. Can feel slightly heavy on darks. | Can range from very light (self-weeding) to a thin film. Generally smoother than inkjet. | Zero feel. The ink becomes part of the fabric itself. |

| Durability & Washability | Good. Typically lasts 20-30 washes before noticeable fading or cracking may occur. | Excellent. Often rated for 50+ washes with minimal degradation. Highly durable. | Permanent. Will not crack, peel, or fade. Lasts the lifetime of the garment. |

| Best For | Hobbyists, personal gifts, startups, full-color photos on cotton. | Small businesses, intricate text/logos, high-volume production, durable workwear. | Performance apparel, sportswear, mugs, phone cases, photo-realistic designs on polyester. |

| Key Advantage | Low startup cost and high accessibility. | Durability and the time-saving "self-weeding" feature. | Unmatched vibrancy, permanence, and a professional, no-feel finish. |

This table should give you a much clearer picture of the trade-offs. Each method shines in different areas, so the "best" one truly depends on what you plan to create and for whom.

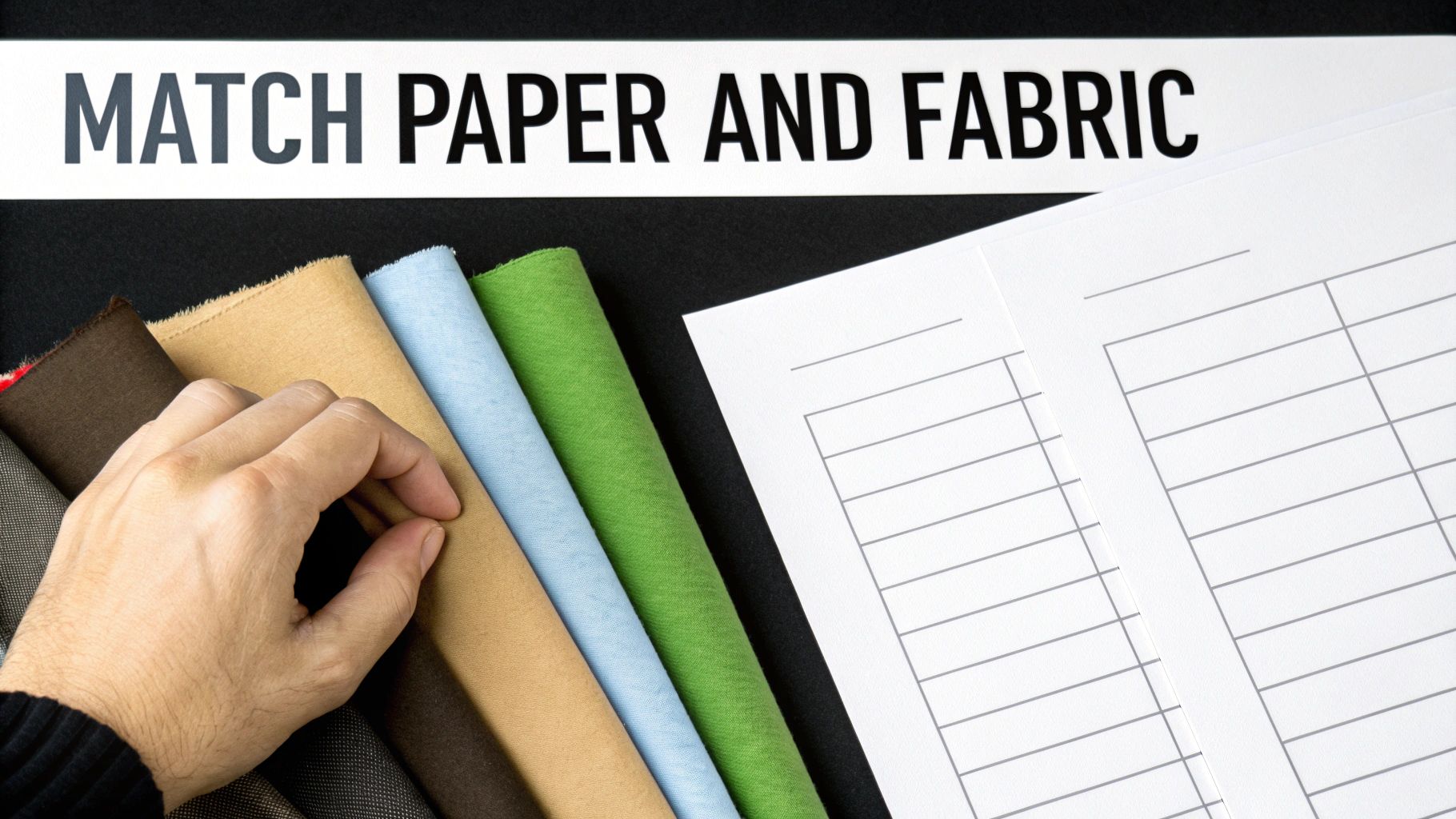

Pairing Your Paper With The Right Fabric

Choosing the right paper is only half the battle. The real magic—or disaster—happens when you pair that paper with a fabric. You can have the best design and the best paper, but if you press it onto the wrong material, you’re just setting yourself up for a cracked, peeling, or faded mess.

Think of it like cooking. You wouldn’t use delicate pastry flour to make a hearty, rustic bread, would you? It’s the same logic here.

Each type of heat transfer paper is engineered to bond with specific fibers. Inkjet and laser papers, for instance, are made to work with cotton and cotton-poly blends. Their polymer coating literally melts and grabs onto the natural fibers, creating a solid physical bond.

Sublimation, on the other hand, is a whole different ballgame. It's a chemical reaction where the ink turns into a gas and fuses directly into polyester fibers. Trying to sublimate on 100% cotton is like trying to dye a glass of water with an oil-based paint—the color has nothing to bond with and will just wash away.

Matching Your Materials: A Quick Guide

Getting this match right is the key to creating designs that are not just vibrant but can actually survive the washing machine. You also have to think about the fabric's weight and texture. If you want to get into the weeds on that, this is a great resource for understanding fabric GSM.

For a simpler approach, just follow this checklist:

- 100% Cotton or High-Cotton Blends: Stick with inkjet or laser transfer paper. They are made for this exact purpose and will give you the strongest adhesion.

- 50/50 Cotton-Polyester Blends: This is a flexible middle ground. Most inkjet and laser papers perform really well, giving you a nice balance of feel and durability.

- 100% Polyester or High-Poly Blends (Light Colors Only): This is sublimation's home turf. It’s the only way to get that permanent, soft-to-the-touch finish that performance wear is known for.

This isn’t just some niche hobbyist trick; it’s the foundation of a huge industry. The global market for thermal transfer paper—a close cousin in the specialty printing world—hit USD 1,587 million in 2024. That growth is fueled by people demanding precise, reliable results, which all starts with matching the right tech to the right material.

Pro Tip: Always, always, always check the garment's tag before you press. It’s a simple two-second step that can save you from the frustration of ruining a perfectly good shirt because you thought it was cotton when it was actually a blend.

Once you nail down how different papers and fabrics interact, you stop guessing and start creating professional-quality work every time. For a deeper look into fabrics themselves, you can check out our guide on the best fabric for t-shirts.

Decoding Paper Features for Better Results

Once your paper, printer, and fabric are in sync, the real craftsmanship lies in the details. These subtle specs can transform an adequate transfer into a standout piece, affecting everything from color vibrancy to long-term durability.

Think of it like choosing a car. Two models might cover the same distance, but one delivers a more refined ride, sharper handling, and superior comfort. In heat transfers, it’s the hidden features that make the final product truly shine.

Opacity And Fabric Color

Opacity matters most when you’re working with bold or dark garments. Transfer paper for light fabrics has a clear polymer backing that lets the shirt color peek through unprinted areas. Against a dark background, this transparency can mute your design and leave it looking flat.

By contrast, paper made for darker fabrics includes an opaque white underlayer. It acts as a primer, ensuring your hues remain crisp and vibrant no matter the shirt’s shade. Mixing up these paper types is one of the most frequent—and heartbreaking—errors newcomers face.

Defining The Hand And Feel

The hand describes how a completed transfer feels against the skin. Is it soft and barely noticeable, or does it register as a thick, stiff layer?

A softer hand often means a more comfortable fit, perfect for fashion-forward tees. Heavier transfers might feel less flexible, but they can indicate a design built to withstand rougher wear—ideal for work uniforms or gear that takes a beating.

Durability And Performance Under Pressure

A stunning print is just the beginning. You’ll want your design to weather washes and stretches without cracking, peeling, or fading. Keep these three metrics in mind:

-

Washability: Tracks how many machine washes and dries a transfer can survive. Budget papers might handle 10-15 washes, while top-tier laser options often last 50+ washes. Always check the specs—and nail your application steps. For optimal settings, consult our Heat Press Temperature Guide.

-

Stretchability: Measures how much the print can flex with the fabric. Athletic wear and fitted garments demand high stretchability; anything less will show stress lines and cracks almost immediately.

-

Ease Of Use: Some papers force you to trim closely around each graphic, which adds time and effort. Self-weeding laser papers only transfer the toner—no cutting required. That “no-cut” perk can be a lifesaver when you’re churning out dozens of shirts.

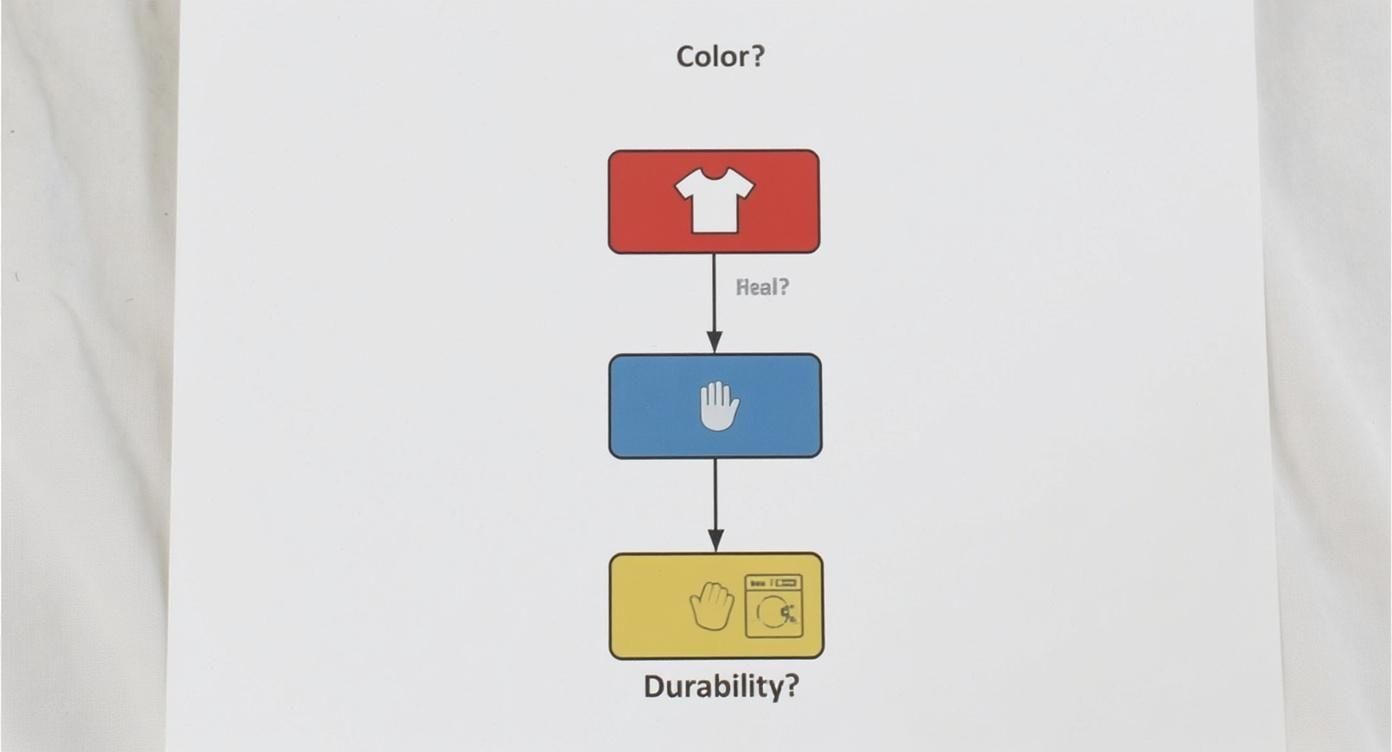

Your Heat Transfer Paper Selection Checklist

Alright, let's pull everything together. With all the options out there, it can feel like a lot, but picking the right paper really boils down to answering a few straightforward questions. Think of it as a simple checklist to guide you straight to the perfect paper for your project, saving you from any guesswork or expensive do-overs.

Before you add anything to your cart, just run through these key points.

- First, what kind of printer are you working with? Is it an inkjet, a laser printer, or a sublimation setup?

- Next, look at your garment. Is it a light-colored fabric, or are you printing on a dark shirt?

- What's the material made of? Are we talking 100% cotton, polyester, or a poly-cotton blend?

- Finally, what's the end goal for the finished product? Do you want a transfer with a super soft feel (what we call "hand"), or is top-notch durability through countless washes the most critical factor?

This decision tree infographic is a great way to see how these questions lead you to the right choice. It really simplifies the whole process.

As you can see, the fabric color is always the first fork in the road. From there, your priorities for how the transfer should feel and hold up will narrow down the options even further.

Final Selection Questions

So, to lock in your choice, just have the answers to these four questions ready:

- What is my printer? (Inkjet, Laser, or Sublimation)

- What is my fabric material? (Cotton, Polyester, or a Blend)

- What is my fabric color? (Light or Dark)

- What is my priority? (Soft Feel, Durability, or Vibrancy)

Once you have these answers, you've got a clear roadmap. You know your equipment's capabilities, what your fabric needs, and the look and feel you're aiming for. This ensures you buy the right paper to get a perfect press the very first time.

Got Questions? We've Got Answers.

Even when you've picked out the perfect heat transfer paper, things can still go sideways. It happens to everyone. Let's walk through some of the most common questions and frustrations to get you back on track and creating awesome stuff.

Why Did My Design Crack After Just One Wash?

It's a classic, gut-wrenching moment: you pull your newly decorated shirt from the laundry, only to find your masterpiece is cracked and flaking. This almost always comes down to one of three things: not enough heat, not enough pressure, or simply a low-quality paper.

Think of it like trying to iron on a patch. If your iron isn't hot enough or you don't press down hard enough, the adhesive never really melts into the fabric. The same principle applies here. The polymer coating on the paper needs the right amount of heat and a whole lot of pressure to properly fuse with the fibers of the garment.

- Heat & Time: First things first, go back and double-check the instructions for your specific paper. Being off by even 10-15 degrees can be the difference between a design that lasts and one that doesn't.

- Pressure: This is the most common mistake, by far. You need to apply serious, even force to push that melted polymer deep into the fabric's weave. That’s what creates the strong, lasting bond.

- Paper Quality: Let's be honest, not all papers are created equal. Cheaper options often use thinner, less durable coatings that are just more prone to breaking down when washed.

Can I Just Use My Home Iron Instead of a Heat Press?

Absolutely! Using a home iron is a fantastic way to dip your toes into the world of heat transfers without shelling out for more equipment. But, you have to know its limitations. The biggest hurdles with an iron are getting the heat and pressure completely even across the whole design.

A heat press is a beast. It clamps down with hundreds of pounds of perfectly distributed force and holds a rock-solid temperature. An iron, on the other hand, relies on your own strength and guesswork. This often leads to spotty results—one part of your design might be perfectly bonded while another spot is barely hanging on, just waiting to peel off.

When an Iron is Fine: It’s great for smaller, simple designs or one-off craft projects where you aren't too worried about long-term durability.

When to Get a Heat Press: If you're starting a business, working with large or intricate designs, or just want that professional, wash-proof finish, a heat press is a must-have.

What's the Real Difference Between Paper for Lights and Darks?

This is one of those foundational things you just have to get right. The difference is all in the backing of the paper.

Paper for light fabrics has a clear polymer backing. When you press it, any part of the paper you didn't print on becomes transparent, letting the shirt's color show through. Try this on a black shirt, and your design will look muddy and practically invisible.

Paper for dark fabrics has a solid white, opaque backing. This white layer acts like a coat of primer before you paint a dark wall—it gives your ink a bright white base to sit on, making the colors pop. If you use this on a white shirt, you’ll end up with a noticeable white box around your image, which probably isn't the look you’re going for.

At Raccoon Transfers, we focus on top-tier Direct-to-Film (DTF) transfers that give you incredible vibrancy and washability on any fabric, light or dark. Ready to skip the trial and error? Check out our custom transfers.