DTF vs DTG Printing A Head-to-Head Comparison

Share

When you're trying to decide between DTF vs DTG printing, it boils down to one fundamental question: are you printing directly onto the shirt, or are you creating a transfer to press onto it? That's the core difference right there.

DTF, which stands for Direct-to-Film, involves printing a design onto a special film and then heat-pressing it onto a garment. In contrast, DTG, or Direct-to-Garment, applies ink directly into the fabric's fibers. This single distinction impacts everything from material compatibility to the final feel of the print.

DTF vs DTG Printing An Executive Summary

Choosing the right printing method isn't just a technical decision; it’s a business decision. Your choice between Direct-to-Film (DTF) and Direct-to-Garment (DTG) printing really depends on what you plan to sell and the kind of quality your customers expect.

Think of DTG printing like an advanced office printer, but for clothes. It uses water-based inks that soak right into the fabric. The result is an incredibly soft, breathable print that feels like it's part of the shirt itself. This makes it perfect for detailed, photorealistic designs, especially on 100% cotton t-shirts.

DTF printing takes a different approach. Your design is first printed on a special PET film. A powdered adhesive is applied and melted onto the back of the ink, creating a ready-to-press transfer. This transfer is then applied to the product with a heat press, forming a durable layer that sits on top of the fabric.

The real game-changer with DTF is its versatility. Because you're pressing a transfer onto the surface, it works on almost anything—polyester, nylon, leather, blends, and even hard goods. This opens up a massive range of products you can offer, far beyond just cotton tees.

So, while DTG gives you that premium, soft-hand feel that's hard to beat, DTF offers incredible flexibility and toughness across a huge variety of materials. Understanding this trade-off is the key to picking the right tech for your shop.

To make things a bit clearer, here's a quick side-by-side comparison of their main differences.

Quick Look DTF vs DTG Key Differences

This table gives you a snapshot of the most important distinctions between the two methods, helping you see where each one shines.

| Feature | DTF (Direct-to-Film) | DTG (Direct-to-Garment) |

|---|---|---|

| Fabric Versatility | Excellent. Works on cotton, polyester, blends, nylon, and leather. | Limited. Best results are on 100% cotton or high-cotton blends. |

| Print Hand Feel | A slightly thicker layer that sits on top of the fabric. | Extremely soft and breathable as the ink is absorbed into the fibers. |

| Ideal Production Scale | Efficient for both small and large batches; transfers can be pre-made. | Best for one-off prints and small runs, ideal for print-on-demand. |

| Initial Investment | Generally lower, with more affordable entry-level equipment. | Significantly higher, requiring a larger upfront capital investment. |

As you can see, the "best" method really isn't a simple answer. It's all about aligning the technology's strengths with your specific goals and product lineup.

Understanding DTG: The Direct-to-Garment Method

Think of Direct-to-Garment, or DTG, printing as a specialized inkjet printer, but for clothes instead of paper. It works by spraying water-based inks directly onto the fabric, allowing the design to soak right into the garment’s fibers.

This direct application is what gives DTG prints their signature soft feel. The ink becomes part of the shirt, not just a layer sitting on top. The result is a vibrant, breathable design that won’t crack or peel over time, making it a top-tier choice for high-quality custom apparel.

The DTG Printing Process Step-by-Step

Getting from a digital file to a finished shirt isn't as simple as just hitting "print." The DTG process involves a few crucial steps to guarantee a great-looking, long-lasting design, especially when you're working with dark-colored fabrics.

First up is pre-treatment. A special liquid solution is applied to the garment, which acts as a primer. This helps the water-based inks bond correctly to the fibers for maximum vibrancy and wash durability. After the solution is applied, the shirt is heat-pressed to create a perfectly smooth printing surface.

With the prep work done, the garment is carefully loaded onto the DTG printer's platen. The machine then gets to work, often laying down a white ink base on dark garments to make sure the final colors really pop. The last step is curing, where the printed shirt is run through a heat tunnel or press one more time to permanently set the ink.

Where DTG Excels: Materials and Applications

DTG technology really comes into its own on natural fibers. It performs best on 100% cotton, as the material’s absorbency is perfect for locking in those water-based inks and creating super crisp, detailed images. It also works well on high-cotton blends, though you might notice the vibrancy dip a bit as the synthetic content goes up.

This makes DTG the ideal method for specific kinds of jobs:

- Photorealistic Prints: Its ability to handle fine details and smooth color gradients is perfect for printing photographs directly onto shirts.

- Complex Graphics: Designs with tons of colors, intricate lines, or soft, painterly effects are reproduced with incredible clarity.

- Print-on-Demand: Setup is fast and easy for each new design, making DTG incredibly efficient for one-off orders and small batches—the bread and butter of the print-on-demand world.

The real magic of DTG is how it merges the art directly with the fabric. If your goal is a soft, retail-quality feel on cotton apparel, there’s really no digital method that can touch it.

This specialization in natural fibers is a huge factor in the DTG vs. DTF printing conversation. While DTF can print on almost anything, DTG delivers a superior feel and seamless integration on its chosen canvas. It’s a significant player in the global textile printing market, which was valued at around USD 1.92 billion and is expected to climb to nearly USD 3.9 billion by 2030, with cotton apparel being a major growth driver.

DTG is just one of many ways to customize apparel today. To see how it compares to other methods, you might find our complete guide to different fabric printing techniques helpful. Understanding the full picture makes it easier to see exactly where DTG shines.

Exploring DTF: The Film Transfer Revolution

While DTG printing soaks ink directly into a garment's fibers, Direct-to-Film (DTF) printing takes a completely different route. It’s an indirect process that creates a vibrant, tough transfer that can be applied to almost any surface you can think of. That’s the secret to its rising popularity—its sheer adaptability.

The whole thing starts with printing a design onto a special polyethylene terephthalate (PET) film. A DTF printer meticulously lays down the CMYK colors first, then follows up with a perfectly registered layer of white ink. This white layer is crucial; it’s the foundation that makes the design pop on dark fabrics and also the surface the adhesive will stick to.

From Powder to Powerful Print

Here’s where the magic really happens. Once the design is printed, the still-wet ink gets a dusting of a hot-melt adhesive powder. This stuff is a fine polymer that clings only to the ink. Give it a good shake, and all the excess powder falls away, leaving the design perfectly coated.

Next, the film goes through a curing oven or under a heat press that hovers just over the surface—no touching. This melts the powder, turning it into a smooth, even adhesive layer that locks the ink together. What you’re left with is a ready-to-press transfer that you can store and use whenever you need it.

To finish the job, you just place the transfer on your product and press it with heat. The heat activates the adhesive, forming a solid bond with the fabric. Let it cool for a moment, peel off the PET film, and you've got a crisp, full-color graphic that feels great.

The core strength of DTF lies in its separation of printing and application. By creating a transferable layer, it bypasses the chemical limitations of fabric dyes, allowing it to adhere to surfaces where DTG ink simply cannot.

This process is fundamentally different from DTG. If you want a deeper dive, our comprehensive guide answers the question "What is DTF printing?" and breaks down the technology even further.

Unmatched Versatility Across Materials

When you get into the DTF vs DTG printing debate, the conversation about materials is where DTF really shines. Because the design is an applied transfer, not ink that needs to soak in, DTF isn't picky about substrates. This throws the door wide open for product customization.

DTF works beautifully on a huge range of fabrics and surfaces:

- Polyester and Blends: Finally, a great solution for athletic wear, jerseys, and performance gear where DTG often fails.

- Nylon and Leather: Perfect for custom jackets, bags, and unique accessories.

- Cotton of Any Color: Handles cotton just as well as synthetics, and you don't need to pre-treat it.

- Hard Surfaces: You can even press these onto materials like wood and canvas for unique promotional items.

This incredible flexibility is what's fueling its explosive growth. Global production for DTF has already hit over 7.2 billion prints a year, which is a nearly 30% jump from the previous year. This isn't just a niche method anymore; it’s becoming a mainstream solution, largely because it works on so many different materials. You can learn more about these market trends and read the full research about apparel decoration.

A Detailed Comparison of DTF vs DTG

When you’re weighing DTF vs DTG printing, you have to look past the spec sheets and think about how these technologies actually perform in the real world. The right choice really comes down to what you want to create—from the feel of the finished print to the kinds of fabrics you plan to use.

Let's break down the key differences that will matter most to your business.

Print Quality and Feel

The first thing anyone notices is how a print feels on the shirt. This single factor can be a deal-breaker, especially for retail brands where comfort is king.

DTG printing is famous for its soft-hand feel. Because the water-based ink soaks right into the cotton fibers, the design literally becomes part of the fabric. You get a breathable, lightweight finish you can barely feel, which is exactly what you want for premium apparel.

DTF, in contrast, creates a transfer that sits on top of the material. The result has a bit more substance, often described as a very thin, flexible layer similar to a modern screen print. While today's DTF transfers are incredibly soft and flexible, they don't quite merge with the fabric in the same seamless way.

If you're targeting the high-end cotton apparel market where a barely-there feel is non-negotiable, DTG is still the clear winner. But for jobs where a durable, slightly raised print is acceptable or even desired, DTF offers a practical and vibrant alternative.

Durability and Washability

A beautiful print means nothing if it cracks or fades after a few washes. This is where DTF really pulls ahead, thanks to its adhesive-based application.

The DTF process uses a hot-melt adhesive powder that bonds the ink to the fabric with incredible strength. This bond is built to last, holding up against cracking, peeling, and fading through dozens of wash cycles. That’s why it’s a go-to for workwear, athletic jerseys, and anything else that needs to take a beating.

DTG prints can be durable, but their lifespan is heavily tied to getting the pre-treatment and curing process just right. Any misstep can lead to fading over time. A well-made DTG print holds up nicely, but DTF is generally more forgiving and consistently robust across the board. If you want to dive deeper, our guide on how long DTF transfers last gives a thorough breakdown of its wash performance.

Material and Fabric Versatility

Here’s where the DTF vs DTG printing conversation gets a little lopsided. DTF’s biggest advantage is its incredible versatility—it works on almost anything. Since the design is pressed onto the surface, the fabric type doesn't really matter.

DTF is a true all-rounder:

- Cotton & Blends: Handles all cottons and poly-cottons beautifully.

- Polyester & Synthetics: Perfect for performance wear and athletic apparel.

- Nylon, Leather, & More: Unlocks printing on jackets, bags, hats, and other unique items.

- Hard Surfaces: With the right technique, you can even apply it to non-garment items like wood.

DTG, on the other hand, is a specialist. It’s at its best with 100% cotton or blends with a high cotton content. Its water-based inks need natural fibers to bond with. On polyester and other synthetics, the results are often faded and blotchy. While DTG has a stronghold on the premium cotton market, DTF is perfectly positioned to dominate the rapidly growing polyester and performance-wear segment.

To provide a clearer picture, let's look at a head-to-head comparison of their core features.

Detailed Feature Showdown DTF vs DTG

This table offers a comprehensive breakdown, comparing the technical specifications, performance, and practical applications of both printing methods.

| Comparison Point | DTF (Direct-to-Film) | DTG (Direct-to-Garment) | Key Takeaway |

|---|---|---|---|

| Feel | Sits on top of the fabric; thin, flexible layer | Soaks into the fabric; soft, breathable feel | DTG feels softer and more integrated into the garment. |

| Durability | Excellent; highly resistant to cracking and peeling | Good, but relies heavily on perfect pre-treatment | DTF is generally more durable and forgiving. |

| Fabric Compatibility | Extremely versatile: cotton, polyester, nylon, leather, blends | Limited: best on 100% cotton or high-cotton blends | DTF is the clear choice for printing on diverse materials. |

| Color Vibrancy | Exceptionally bright and opaque, especially on darks | Bright, but can be slightly muted by fabric absorption | DTF often appears more vibrant due to its solid white base. |

| Best For | Batch production, diverse materials, workwear, merch | One-off prints, print-on-demand, premium cotton apparel | Your business model dictates the best technology. |

| Workflow | Print now, press later; great for stocking transfers | Direct printing; ideal for unique, on-the-spot orders | DTF offers more flexibility for future applications. |

This showdown highlights that the "better" method truly depends on the job at hand. Each technology has a clear purpose and excels in different scenarios.

Color Vibrancy and Opacity

Both methods can produce incredible, full-color graphics, but they get there in different ways—especially on dark-colored garments.

To print on a black shirt, a DTG machine first lays down a layer of pre-treatment, then a base of white ink, and finally the CMYK colors. This process works well, but because the ink absorbs into the fabric, the final vibrancy can sometimes be a touch muted.

DTF also uses a white ink base, but it’s printed onto the transfer film behind the color layer. This creates a completely opaque foundation that stops the garment's color from bleeding through. The entire graphic is then transferred as a single unit, which is why DTF prints often look exceptionally bright and seem to pop right off the fabric.

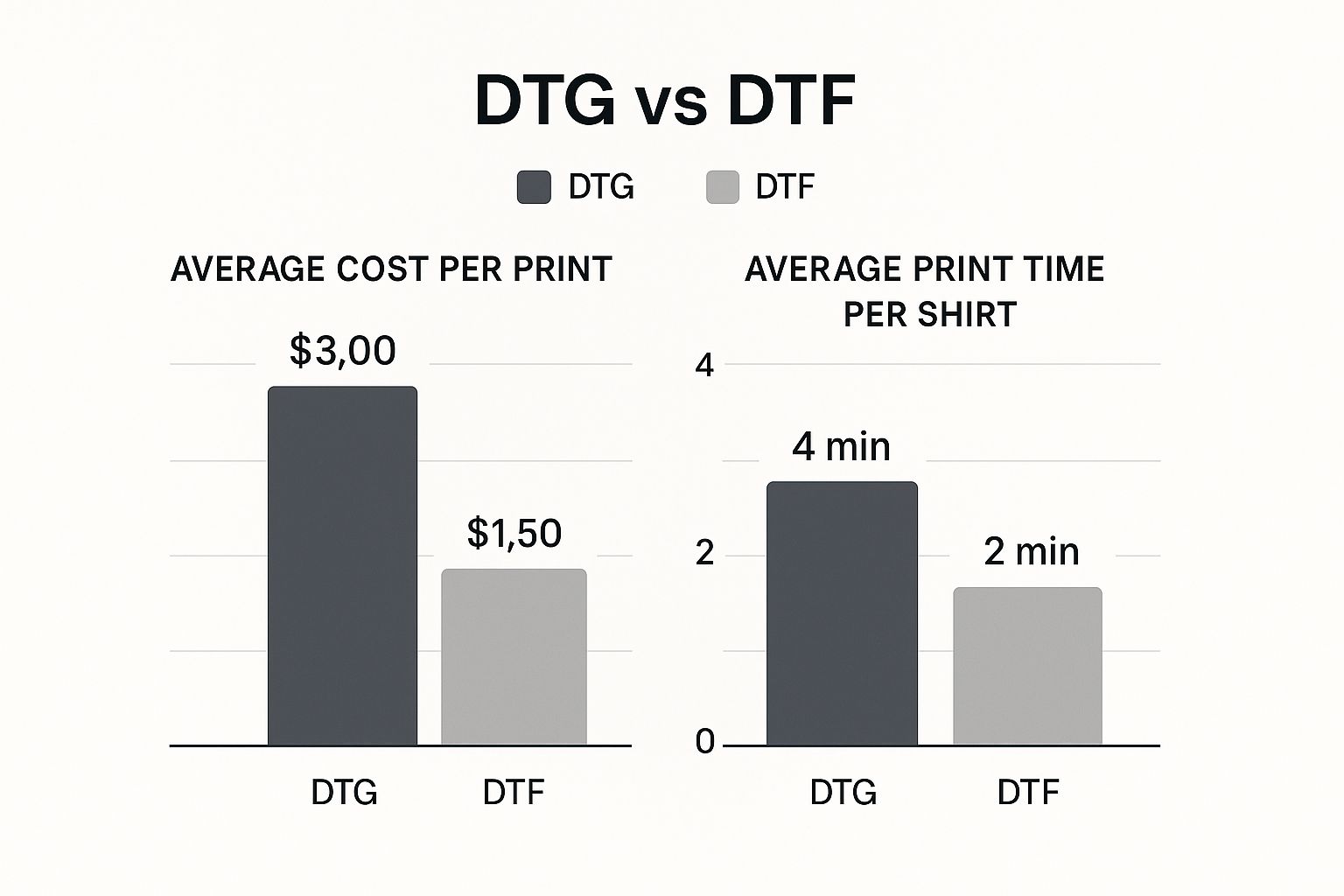

This infographic really drives home the efficiency differences between the two methods.

As you can see, DTF not only costs less per print but also gets the job done faster.

Production Speed and Workflow

From a workflow perspective, one isn't necessarily "faster" than the other; they're just built for different things.

DTG is a dream for one-off custom jobs. You load the shirt, hit print, and you’re done. There’s almost no setup time between designs, making it the undisputed champion for print-on-demand businesses where every single order is different.

DTF, however, is built for efficiency at scale. You can "gang" dozens of different designs onto a single roll of film and print them all in one go. Once printed, these transfers can be pressed onto garments immediately or stored for months. This "print now, press later" model gives you incredible flexibility to build up an inventory of popular designs without tying up a single t-shirt.

Breaking Down the Costs: DTF vs. DTG Printing

When you're trying to decide between DTF vs DTG printing, money talks. It really boils down to two things: how much it costs to get started and how much you'll spend on every single print. Let's be honest, this is often the deciding factor for any shop looking to turn a profit. These two methods are worlds apart when it comes to their financial footprint, and each one fits a different kind of business.

The Upfront Investment

The initial barrier to entry is probably the starkest difference between the two. Getting into DTG printing requires a serious chunk of change. You’re looking at $15,000 to over $30,000 for a professional-grade DTG printer. And that’s just the printer—you still need to budget for essential gear like pre-treatment machines and conveyor dryers, which can easily add thousands more to the bill.

DTF, on the other hand, is a much easier pill to swallow financially. You can get a complete, entry-level DTF system—printer, powder shaker, and curing oven—for under $5,000. This makes it a fantastic starting point for new businesses or for established shops wanting to add new services without draining their bank accounts.

Unpacking the Per-Print Cost

Once your equipment is up and running, your long-term profitability hinges on the cost of each print. This is where the numbers get really interesting, and DTF often pulls ahead as the more economical choice for day-to-day production.

With DTG, the big variable is ink, especially the expensive white underbase needed for dark garments. A single print on a black t-shirt can easily run you $2.00 to $4.00 in ink and pre-treatment fluid. This can make it tough to keep your margins consistent, particularly if you're printing large designs with heavy ink coverage.

Don’t just look at the printer's price tag. The true cost of ownership includes everything: equipment, consumables, labor, and maintenance over the long haul. DTF’s lower consumable costs often mean you’ll see a return on your investment much faster, especially if you’re running medium-to-high volume jobs.

DTF’s running costs are not only lower but also more predictable. For an average-sized design, the combined cost of the film, adhesive powder, and ink typically lands somewhere between $0.75 and $1.50. That’s a huge difference per unit, and it adds up quickly to impact your bottom line.

To put it in perspective, here’s a quick cost breakdown for a standard chest logo:

| Cost Component | DTF Printing | DTG Printing |

|---|---|---|

| Ink Cost | ~$0.50 - $1.00 | ~$1.50 - $3.50 |

| Consumables | ~$0.25 (Film & Powder) | ~$0.50 (Pre-Treatment) |

| Estimated Total Per Print | ~$0.75 - $1.25 | ~$2.00 - $4.00 |

The table makes it pretty clear: DTF has a solid edge on consumable costs. While DTG is king for one-off, on-demand jobs thanks to its simpler workflow, DTF's cost-efficiency makes it a powerhouse for batch production and scaling your business. Ultimately, the right financial choice depends entirely on your production volume and the types of products you sell.

DTF vs DTG: Which One Is Right for You?

So, how do you decide between DTF and DTG? Forget the technical jargon for a moment. The best choice really comes down to what you want to create and who you're selling to.

Instead of getting bogged down in specs, think about your business goals. Are you building a premium apparel brand focused on the softest cotton t-shirts? Or do you need the flexibility to print on just about anything your customers can dream up? The answer to that question will point you in the right direction.

Go with DTG If Your Business Is All About:

Direct-to-Garment printing is a master of its craft, but it's a very specific craft. If your business model lines up with the points below, DTG is probably the way to go.

-

Premium Cotton Apparel: Your brand is all about high-quality, 100% cotton shirts and hoodies. For you, the feel of the final product is everything—you want a print that’s soft, breathable, and feels like it’s part of the fabric itself.

-

Print-on-Demand Simplicity: You specialize in one-off orders and custom designs. Speed and efficiency for single-item jobs are critical, and you need to get a design from the computer to a finished shirt with almost no setup time.

-

Complex, Photorealistic Art: Your designs are packed with intricate details, color gradients, or high-resolution photos. DTG’s ability to replicate this kind of artwork directly onto a garment with incredible precision is essential for your products.

If the customer experience hinges on the absolute softest feel on a premium cotton shirt, DTG is still the king. It produces that retail-quality finish that’s indistinguishable from what you’d find in a high-end store.

Go with DTF If Your Business Needs:

Think of Direct-to-Film as the versatile all-rounder. It gives you incredible flexibility to pivot and expand your product catalog. If your strategy is built on variety and toughness, DTF is your perfect match.

-

Material Versatility: You want to print on more than just cotton. Your product ideas include polyester athletic wear, nylon jackets, canvas tote bags, hats, or even leather goods. DTF doesn't care about the material—it just works.

-

Serious Durability: You're making gear that has to last, like workwear, team jerseys, or merch for active brands. These items will be washed and worn hard. The tough, adhesive-backed DTF transfers are built to resist cracking and fading wash after wash.

-

Batching and Stocking Designs: You handle bulk orders or sell at events where you need inventory on hand. With DTF, you can print hundreds of transfers ahead of time. This creates a "print-on-demand" inventory of designs that you can press onto any item whenever you need to, which is a massive workflow advantage.

Ultimately, the choice between DTF and DTG printing is a strategic one. DTG is the specialist for premium cotton, while DTF is the flexible workhorse that lets you print on practically anything. Take a hard look at your products, your customers, and your production needs, and the right choice will become clear.

Frequently Asked Questions

Even after a side-by-side comparison, it's natural to have a few more questions when you're on the fence between DTF and DTG. Let's dig into some of the most common queries to help you nail down the right choice for your projects.

Can You Feel the Print on the Shirt?

You can, but how it feels is a major difference between the two. This is one of the most important distinctions in the DTF vs DTG printing conversation.

A DTG print feels almost like nothing at all. The water-based inks soak directly into the garment's fibers, so the design becomes a part of the fabric. This gives you that super soft, breathable feel you'd expect from high-end, retail-quality shirts.

On the other hand, DTF transfers sit on top of the fabric. While modern transfers are impressively thin and flexible, they do create a noticeable layer. The best comparison is that it feels a lot like a high-quality, soft-hand screen print transfer.

Which Printing Method Is More Environmentally Friendly?

Honestly, both have their pros and cons when it comes to being green. DTG gets points for using water-based, non-toxic inks. The downside is the pre-treatment process, especially for dark shirts, which uses chemicals and water. DTG printers also tend to be more power-hungry per print.

DTF creates a different kind of waste, mainly the used PET film and leftover adhesive powder. But looking at the bigger picture, the process uses significantly less water and energy than something like traditional screen printing, making it a solid step up from older techniques.

In the end, neither method is perfectly "green," but they are both improvements over old-school, high-waste printing. The decision really comes down to whether you're more concerned with chemical usage or physical material waste.

Do I Need Special Software?

Yes, for both DTF and DTG, you absolutely need special software to get professional results. The key piece of the puzzle is a Raster Image Processor, better known as RIP software.

You can't really get by without it. RIP software is what manages the complex ink layers, especially the white underbase needed for printing on dark colors.

Here’s what it does:

- Controls Ink Layers: It tells the printer exactly where to lay down the white ink so your CMYK colors on top come out looking bright and vibrant.

- Manages Color: It ensures the colors you see on your monitor are the colors you get on the final shirt by using proper color profiles.

- Optimizes Ink Usage: A good RIP can also fine-tune how much ink is used, which helps cut down on waste and reduces your cost per print.

How Does Printer Maintenance Differ?

Printer upkeep is a big deal for both, but DTG printers are famously high-maintenance. The water-based inks they use are prone to clogging the printheads, so you have to stick to a strict daily and weekly cleaning schedule. You'll be wiping printheads, running nozzle checks, and even controlling the room's humidity to avoid expensive clogs and repairs.

DTF printers still require care—you’ll be cleaning printheads and maintaining the powder system—but they’re generally less fussy. Because the ink is printed onto film in a more contained system, you tend to run into fewer of those sudden, print-stopping clogs that can plague DTG operators.

Ready to see what the versatility and durability of DTF can do for you? At Raccoon Transfers, we make it simple to get your designs on practically any material. Upload your artwork and create your custom gang sheet today!