Finding Good Heat Press Brands A Buyer's Definitive Guide

Share

When you start looking for a good heat press, you'll quickly realize the "best" brand really just depends on what you need it for. If you're a hobbyist, names like Cricut and Siser probably come to mind for their ease of use. For small businesses that need something dependable, Hotronix is a go-to. And for the big guys running industrial-level production, brands like Geo Knight and HIX are the undisputed workhorses.

Finding The Right Heat Press Brand For You

Picking out a heat press is a lot more than just buying a piece of equipment. You're really investing in the heart of your business or creative outlet. The machine that's perfect for a weekend crafter making t-shirts for family is completely different from what a small business needs to crank out dozens of DTF transfer orders every single day. The right choice has to line up with your goals—from how much you plan to produce to what materials you'll be using, not to mention your budget and how much space you have.

The market is crowded, but you'll see the same names pop up again and again. The competitive field is made up of about 10–15 key manufacturers, with Geo Knight & Co., Stahls’/Hotronix, HIX Corporation, Siser, and Cricut consistently leading the pack. It's clear from looking at the market that brand loyalty shifts by user type; home crafters often go for the simplicity of a Cricut, while professionals are willing to pay for the longevity of a premium, heavy-duty press. You can learn more about the leading players in the heat press market to get a broader view.

To give you a head start, I've broken down the top brands by who they're for, what they do best, and what you should expect to pay.

Top Heat Press Brands At A Glance

This quick comparison table breaks down the leading heat press brands, helping you see where each one fits in terms of its ideal user, main selling points, and general price. Think of it as a starting point to narrow down which brands align with your needs before we get into the nitty-gritty details.

| Brand | Ideal User | Primary Strengths | Price Range |

|---|---|---|---|

| Hotronix (by Stahls') | Small Businesses & Professionals | Precision controls, durability, interchangeable platens | $800 - $4,000+ |

| Geo Knight & Co. | High-Volume & Industrial Producers | Unmatched durability, heavy-duty construction, USA-made | $700 - $5,000+ |

| Siser | Hobbyists & Small Businesses | User-friendly digital controls, great value, vibrant colors | $300 - $900 |

| Cricut | Hobbyists & DIY Crafters | Simplicity, compact design, seamless ecosystem integration | $150 - $400 |

This simple breakdown makes that first decision much easier. A hobbyist will likely gravitate toward the affordability and straightforwardness of a Siser, while a growing business will immediately see the long-term value in a Hotronix machine's reliability and advanced features. Getting this initial match right is the first step toward buying a press you'll be happy with for years to come.

How to Evaluate a Heat Press Like a Pro

When you're trying to figure out which heat press brands are worth your money, it helps to know what to look for under the hood. It’s not just about the brand name; the real quality of a heat press comes down to its core components and how they actually perform. Learning to spot these differences is what will help you invest in a machine that gives you consistent, reliable results for years.

The single most important part of any heat press is its platen. That's the heated upper surface that does all the work. Nine times out of ten, a bad press job comes down to a shoddy platen, which means wasted transfers and a lot of frustration.

Cheaper presses often use a simple X-pattern for the heating element, which is a recipe for disaster. It creates major hot and cold spots across the surface. This means one corner of your transfer could be getting scorched while another part isn't even sticking. The good stuff? Premium brands use a winding, snake-like coil pattern that distributes heat evenly across the entire surface, giving you a perfect press every time.

Key Takeaway: A heat press is only as good as its platen. For professional-grade results, especially with something as specific as DTF transfers, a thick, evenly heated platen isn't just nice to have—it's non-negotiable.

Platen Construction and Heat Retention

It’s not just the heating element inside that matters; the platen's material and thickness are just as critical. A high-quality press will have an upper platen that's at least ¾-inch thick. Think of that thickness as a heat reservoir. It holds a stable temperature even after you've opened and closed it a few times.

The thin platens you find on budget models lose heat the second you open them. This forces you to wait for the machine to get back up to temperature, which kills your workflow and leads to inconsistent results when you're trying to knock out a batch of shirts.

When you're looking at a platen, here’s what to check for:

- Heating Element Spacing: Make sure the internal heating coils are no more than two inches apart. Any wider and you'll get cold spots.

- Temperature Accuracy: Look for models with an RTD probe. These are accurate to about ±2°F, which is way better than the old-school bimetallic thermometers that can be off by as much as 10°F.

- Material Quality: A solid steel or coated aluminum platen is a good sign. It means durability and excellent heat conduction, which is exactly what you need for consistent performance.

Getting a feel for the mechanics of a heat press is one thing, but understanding the wider principles of thermal efficiency in industrial heating systems can offer some great insights into heat management that apply across different industrial applications.

Precision in Temperature and Pressure Control

Okay, so you've found a press with a solid platen. The next thing to look at is the controls. Having precise control over temperature, time, and pressure is what really separates the amateur stuff from professional-quality products.

Modern digital controllers are pretty much standard now, letting you dial in exact temperatures and times. But the real game-changer in professional machines is digital pressure control.

A lot of presses still rely on a manual knob and pure guesswork—you'll see settings like "light," "medium," or "firm." That’s just not going to cut it for DTF transfers, which need very specific pressure to get the right adhesion and feel. A digital pressure readout gives you an exact PSI (pounds per square inch) number, so you can repeat your results perfectly on every single item in an order. If you want to go deeper on this, check out our guide on the best heat press machine for shirts.

Build Quality, Warranty, and Support

Finally, take a step back and look at the machine's overall construction and the company that made it. A sturdy, steel frame tells you it's built to last. Flimsy plastic parts? That’s a sign it won't be around for long. Another tell-tale sign of quality is an over-the-center pressure adjustment, which ensures pressure is applied evenly from edge to edge.

Just as important is the manufacturer's warranty and customer support. When your press breaks down, you're losing time and money. The best brands offer comprehensive warranties, have tech support you can actually reach, and keep replacement parts in stock. That support system is a huge part of your investment, giving you peace of mind that someone has your back when things go wrong.

A Detailed Comparison Of Leading Heat Press Brands

Let's be clear: there's no single "best" heat press brand. The right machine for a hobbyist making a few shirts for family is a world away from the workhorse a small business needs to crank out orders all day. The key is to match the brand and model to what you’re actually doing.

If you look at the market, this becomes obvious. Apparel and textile applications drive over 40% of heat press demand, with small-to-medium businesses making up about half of all sales. This is why you see beginners flocking to user-friendly brands like Cricut, while print shops invest in heavy-duty equipment from specialists like Hotronix or Geo Knight.

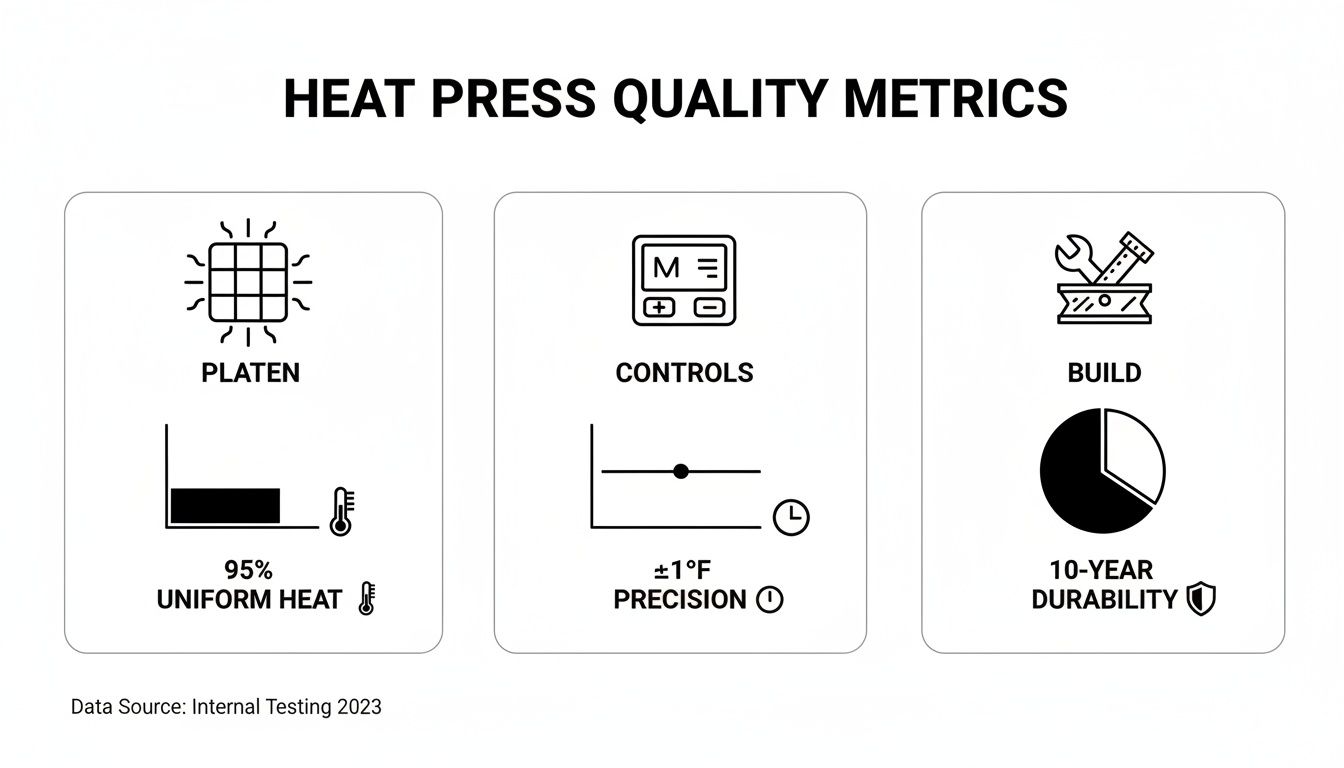

The real difference comes down to three things: consistent platen heat, precise controls, and a durable build.

As you can see, professional presses are engineered from the ground up for repeatable, consistent results. That’s what you pay for.

For The Hobbyist: Cricut vs. Siser

If you're just starting out, your search will almost certainly lead you to two major names in the craft space: Cricut and Siser. Both make great, compact machines for home use, but they come at it from different angles.

Cricut is all about the ecosystem. Their EasyPress and AutoPress models are designed to work seamlessly if you already own one of their cutting machines. The AutoPress, in particular, is built for simplicity—it handles the pressure for you, taking a lot of the initial guesswork out of the equation.

Siser comes from the world of professional materials, and their hardware reflects that. The Siser Craft Heat Press is a small clamshell that operates like a miniature version of a professional press. It gives you manual control over the pressure, which is a fantastic way to actually learn the feel of the process.

The Bottom Line: Cricut is about automation and fitting into its own universe of products. Siser offers a more hands-on, traditional heat press experience that teaches you the fundamentals. If you want a "set it and forget it" process, go Cricut. If you want to learn the craft from the ground up, Siser is a great starting point.

For The Small Business: Hotronix vs. Geo Knight

Once you start selling your creations, your needs shift dramatically. Now, it's all about reliability and getting the same perfect result every single time. That’s the territory of American-made powerhouses like Hotronix and Geo Knight.

Hotronix is the innovator. Their Fusion IQ and Auto Clam presses are loaded with tech, featuring digital screens for time, temp, and—critically—pressure readouts. When you're working with delicate transfers like DTF, knowing your exact pressure is a game-changer for quality control. Their quick-change platen system is also a huge plus for anyone pressing more than just t-shirts. If you need a versatile machine that can handle a demanding workload, a premium heat press with these features is what you should be looking for.

Geo Knight is the tank. Their machines, like the legendary DK20S swing-away, are built for one thing: survival. People in the industry joke that a Geo Knight will outlive everything else in your shop, and they’re not wrong. While they have modern digital controls, the brand’s soul is in its bulletproof mechanical engineering.

This kind of evaluation isn't unique to heat presses. When you're investing in any serious equipment, you weigh similar factors, just like someone researching the best commercial refrigerator brands would compare durability against modern features.

So, who wins? If your business thrives on versatility, varied products, and a tech-forward workflow, Hotronix is probably your brand. But if you need a simple, indestructible machine to handle high-volume, repetitive jobs day in and day out, a Geo Knight is an investment that will pay for itself for years to come.

For High-Volume Production: HIX vs. Ricoma

When you're running a full-scale production line, efficiency is everything. Operator fatigue becomes a real cost, and automation isn't a luxury—it's a necessity. This is where industrial brands like HIX and Ricoma come in.

HIX Corporation is an industry institution, famous for its beastly air-operated automatic presses. These machines hook up to an air compressor to apply perfect, consistent pressure with the push of a button. This is crucial for eliminating human error and fatigue during multi-shift, thousand-piece runs.

Ricoma is a big name in embroidery, but they also produce high-end heat presses designed to slot right into an automated shop. They offer multi-station presses that can seriously boost throughput, and a key benefit is their focus on a complete equipment ecosystem. If you already run Ricoma gear, adding their presses means streamlined support from a single vendor.

At this level, your choice often hinges on your shop's existing setup. A facility with an established pneumatic system might naturally gravitate toward the power of a HIX. A business already deep in the Ricoma ecosystem will appreciate the seamless integration. Both brands deliver the hardcore, industrial performance needed for true mass production.

Matching The Right Brand To Your Business Goals

Technical specs are important, but they don't tell the whole story. The best heat press brands aren't just selling machines; they're solving problems for specific kinds of creators. They build features that align with your real-world needs and business dreams. So, picking a brand isn't just about features—it's a strategic move that affects your workflow, product quality, and how easily you can scale up.

This decision couldn't come at a better time. The global heat press market hit around USD 1.2 billion in 2024 and is on track for a major surge by the early 2030s. This growth is fueled by people just like you—custom apparel makers and small print-on-demand businesses. As you can explore in more detail about the growing market, grabbing the right gear now puts you in a prime position to ride that wave.

Let's get past the spec sheets and look at how this plays out in the real world.

For The Etsy Seller Launching A T-Shirt Store

Let's say you're finally launching that Etsy shop you've been dreaming about. You're working from your home office, focused on creating killer designs, getting your listings perfect, and handling those exciting first orders. What you need is a press that's easy to use, doesn't take over your entire room, and delivers consistent results without draining your bank account.

This is the perfect scenario for a brand like Siser. Their digital clamshell presses, like the Siser Craft Heat Press, are a fantastic starting point. They're incredibly straightforward to operate and give you precise digital controls, which is a huge leap from basic craft machines. It’s the perfect way to master the fundamentals of time, temperature, and pressure—the skills you'll rely on as your business grows.

Why it's a strategic fit: Siser gives you professional-level results in a small, affordable package. You can start making high-quality, sellable products from day one, building a solid reputation without the overwhelming cost or complexity of industrial machinery.

For The Established Print Shop Adding DTF Services

Now, picture a different scene: you run a busy screen printing or embroidery shop. Business is good, you have a solid client base, but you want to add Direct-to-Film (DTF) to your services. You need a machine that can handle a ton of different products—not just full-chest designs on shirts, but custom hats, tote bags, and everything in between.

This is where a brand like Hotronix really shines. Their Fusion IQ series, with its swing-away and draw press design, gives you a heat-free workspace, which is a godsend for getting transfer placement just right. But the real game-changer is their system of quick-change interchangeable platens. This single feature is a massive strategic advantage.

One minute you're pressing a standard 16"x20" design, and a few minutes later, you've swapped in a 6"x10" platen for sleeves or a 4" round platen for a left-chest logo. That kind of adaptability means you can say "yes" to more unique and profitable jobs, which directly impacts your bottom line. Add in the precise digital pressure readout, and you’ve got a recipe for perfect DTF applications every time.

For The High-Volume Decorator Fulfilling Large Orders

Finally, imagine a production floor pumping out thousands of pieces for a corporate client or a major sports team. In this world, the only things that matter are speed, consistency, and keeping your team from burning out. Manual pressing is completely off the table. You need an absolute workhorse.

For this kind of heavy lifting, Geo Knight is the undisputed champion. Their industrial-grade presses, especially air-operated automatic models like the DK20SP, are built for one thing: relentless, repetitive work. Hooked up to an air compressor, these machines deliver the exact same, perfectly even pressure with just the push of a button. It completely eliminates the physical strain and guesswork of manual pressing.

Their tank-like construction, from the over-the-center pressure systems to the heavy-duty steel frames, is designed to handle multi-shift production schedules without breaking a sweat. For a business where every second counts and quality can't be compromised, a Geo Knight press isn't just a tool—it's the engine driving your entire production line.

Nailing the Perfect Press with DTF and UV-DTF Transfers

Newer transfer technologies like DTF and UV-DTF have completely changed the game, but they are far less forgiving than old-school vinyl. These transfers work because of a precise chemical reaction between the ink, the adhesive, and the fabric—a reaction that demands very specific conditions to succeed. This is where your heat press moves from being just a tool to being the single most important factor in your success.

A cheap press with a patchy heating element will kill a beautiful DTF transfer before it even has a chance. If you have cold spots on your platen, you'll get weak adhesion, and parts of your design will lift or peel after a single wash. On the flip side, hot spots can burn the transfer film or, even worse, cause dye migration on polyester fabrics, leaving you with a discolored, blurry mess.

Crucial Insight: Let's be clear: for DTF and UV-DTF, a quality heat press isn't a "nice-to-have," it's a requirement. The durability and professional finish of your products are directly tied to your machine’s ability to deliver consistent, accurate heat and pressure across the entire surface, every single time.

Why Precision Isn't Optional

The science behind a DTF transfer is simple enough: the heat melts the adhesive powder evenly, and the pressure forces it to bond with the garment fibers. But for that bond to be permanent, the conditions have to be just right. A small deviation can ruin everything.

Think of it this way: if your temperature is off by just a few degrees, you might pull a transfer that looks perfect at first glance, only to have it fail on the customer later. This is exactly why it pays to invest in one of the good heat press brands known for using accurate RTD temperature probes and thick, heat-retaining platens.

A solid machine gives you the control you need to dial in your settings for different materials, ensuring you get those bright, vibrant colors and a soft-hand feel that people expect from professional gear.

Your Checklist for a Perfect DTF Press

Getting consistent results with DTF means being methodical. If you follow a set process every time, you can quickly spot what went wrong if a press fails—whether it was the machine, the settings, or the transfer itself.

Here’s a simple step-by-step routine to make sure every press is a winner:

- Verify Your Settings: Always start by confirming the recommended temperature, time, and pressure for the specific transfers you're using. Our guide on heat press settings for DTF is a great resource to get you started.

- Pre-Press the Garment: Press the blank item for 5-10 seconds. This is a critical step that removes moisture and smooths out wrinkles, giving the transfer a flat, dry surface to bond to.

- Ensure Even Pressure: You can test this before your press even heats up. Put a piece of paper in each of the four corners, lock it down, and try to pull them out. If any of them slide out easily, your pressure is uneven and needs to be adjusted.

- Use a Protective Sheet: Always place a Teflon sheet or a piece of parchment paper over the transfer. This acts as a barrier, protecting both the design and your platen from scorching.

- Follow Cooling Instructions: Pay close attention to whether your Raccoon Transfers are a "hot peel" or "cold peel." Peeling at the wrong temperature is probably the most common mistake and the fastest way to ruin a good print.

Making this checklist a habit is what separates the pros from the hobbyists. This disciplined approach ensures your investment in high-quality transfers and equipment actually pays off with durable, fantastic-looking products.

Common Questions We Hear About Choosing a Heat Press

Diving into the world of heat presses can feel overwhelming. Even after you’ve compared a few models, some nagging questions usually pop up right before you’re ready to buy. We get it. You're about to make a big investment, and you want to get it right.

Let's walk through some of the most common questions we hear from other creators. Think of this as a final gut-check to make sure you’re covering all your bases and picking a machine that will actually help you grow.

Is a Cheap Heat Press From Amazon a Good Starting Point?

It’s tempting, I know. You see a press on Amazon for a couple of hundred bucks and think, "What a steal!" But from my experience, those deals almost always come with hidden costs. These no-name machines are infamous for uneven heating across the platen, which is an absolute deal-breaker for getting professional-looking results, especially with DTF transfers. You'll end up wasting more money on ruined shirts and transfers than you saved on the machine itself.

On top of that, their temperature gauges are often wildly inaccurate. You can't build a business on guesswork. For anyone serious about this, even as a hobby, an entry-level press from a trusted brand like Siser is a much smarter move. You get reliability and support for a little more money, but the peace of mind is priceless.

Expert Insight: A reliable entry-level press from a known brand is always a better investment than a top-of-the-line model from a generic, unsupported one. Consistency is the foundation of any successful apparel business, and that starts with your equipment.

What's the Real Difference Between a Clamshell and a Swing-Away Press?

The main distinction is pretty simple: it’s all about how the top platen opens. A clamshell press opens up on a hinge, kind of like a clam's shell. It’s a compact design, which makes it a go-to for people just starting out or working in a small space.

A swing-away press, however, moves the hot platen completely off to the side. This simple difference creates a wide-open, heat-free workspace, which offers some huge advantages:

- Safety: It dramatically cuts down on the risk of accidentally burning your hands or arms as you work.

- Precision: You get a crystal-clear, unobstructed view when laying down your garment and transfer.

- Versatility: They’re much better at handling thicker items like hoodies or plaques because the pressure is applied more evenly.

For most professional shops where safety and accuracy are top priorities, a swing-away is easily the better choice.

How Important is a Digital Pressure Readout?

Honestly, for any kind of professional work, a digital pressure readout isn't just a nice-to-have; it's a must-have. With manual presses, you're left guessing based on feel, using vague terms like "medium" or "firm." That approach is inconsistent at best and impossible to replicate perfectly every time.

DTF transfers are especially picky about pressure—it’s crucial for getting the adhesive to bond properly with the fabric. A digital readout gives you a hard number, a quantifiable PSI (pounds per square inch) setting that you can repeat over and over. This is the key to ensuring every single item in an order gets the exact same application for consistent quality and durability.

Do I Really Need Interchangeable Platens?

If you ever plan on printing more than just t-shirts, then yes, you absolutely do. A standard 16"x20" platen is great for shirts, but it's clumsy and ineffective for anything smaller or oddly shaped.

Using a platen that actually fits the print area is a game-changer. It lets you isolate the surface you're pressing and avoid problems from seams, zippers, or collars that get in the way of even pressure. This is where brands like Hotronix and Geo Knight really shine, with quick-change systems for all sorts of platens:

- Sleeves and pant legs

- Hats and caps

- Tote bags and shoes

- Youth apparel and onesies

This kind of versatility turns your heat press from a one-trick pony into a full-blown decoration powerhouse, opening up a ton of new products you can offer.

Ready to create stunning, professional-quality custom apparel and products? With Raccoon Transfers, you get vibrant, durable DTF transfers that apply perfectly every time. Take the guesswork out of your production and achieve flawless results by visiting us at https://raccoontransfers.com today.