Sublimation and Heat Transfer: Key Differences

Share

When you're trying to figure out the best way to get a design onto a product, you'll almost always run into two main contenders: sublimation and heat transfer. The best choice really boils down to what you're making. Sublimation permanently dyes the very fibers of polyester, leaving a finish you can't even feel, while heat transfer lays a design on top of the fabric, which opens the door to a much wider range of materials. This guide will walk you through the differences so you can pick the right method for your project.

Choosing Your Customization Method

Deciding between sublimation and heat transfer is one of the first and most important calls you'll make for any custom apparel or product. Each has its own set of strengths, and the right fit depends on the fabric you're using, how long you need the design to last, and what you're willing to spend upfront. Nailing this choice is the key to creating professional-looking products that hold up.

The demand for personalized gear is exploding. The market for sublimation equipment alone was valued at USD 2.5 billion in 2023 and is on track to hit USD 4.8 billion by 2032. This isn't just a trend; it's a massive shift in how people shop, making it more important than ever for creators to get their printing techniques right.

Sublimation vs Heat Transfer At a Glance

To make things simple, let's start with a high-level look at what sets these two methods apart. The table below breaks down the core differences in a nutshell.

| Feature | Dye Sublimation | Heat Transfer (Vinyl/Paper) |

|---|---|---|

| Process | Ink becomes a gas that bonds directly into the material's fibers. | A layer of material (vinyl or printed paper) is pressed onto the surface. |

| Feel | Absolutely no texture. The design is literally part of the fabric. | You can feel a distinct layer sitting on top of the material. |

| Durability | Permanent. It won’t crack, peel, or fade, ever. | Good, but can eventually show wear, crack, or peel after many washes. |

| Fabric Type | Works best on light-colored, high-polyester-count fabrics. | Very versatile. Works on cotton, polyester, blends, canvas, and more. |

| Color Limit | Only effective on white or very light-colored materials. | Works well on both light and dark-colored fabrics. |

This table gives you a solid starting point. While sublimation and heat transfer cover a lot of ground, you can always explore other fabric printing techniques to see what else is out there. Getting familiar with customization methods for specific items like Greek stoles can also help you understand how different processes are used for unique, niche products.

How Each Printing Process Really Works

To pick the right method between sublimation and heat transfer, you first have to get a feel for the science behind each one. While both use heat, how they apply it and the results they produce are worlds apart. This difference is what dictates the final product's feel, longevity, and overall look.

Let's break down the distinct workflows for each process.

The Sublimation Workflow

Sublimation is a neat bit of chemistry where solid ink turns directly into a gas, completely skipping the liquid phase. It’s a lot like how dry ice creates fog. This unique transformation is the secret to creating those permanent, super-vibrant designs you literally can't feel on the fabric.

The whole thing happens in a few careful steps:

- Printing: First, you print your design onto a special sublimation transfer paper using sublimation inks. Critically, the image has to be mirrored before you print it.

- Preparation: The item you're printing on, like a white polyester shirt, needs to be perfectly clean. Even a tiny speck of lint will absorb the ink gas and leave a permanent blue dot on your finished product.

- Pressing: Next, the printed paper is positioned on the item and placed in a heat press. You’ll apply high heat (usually around 400°F) and firm pressure, which triggers the ink to vaporize. This gas then seeps into the now-open pores of the polyester fibers.

- Bonding: As the item cools down, the polyester pores close up, trapping the ink inside the fabric for good. The design isn't just sitting on top of the material; it’s become part of it.

Sublimation is pure science in action. The gaseous ink bonds at a molecular level with polyester coatings, resulting in a print that is as durable as the fabric itself—it will not crack, peel, or fade.

The Heat Transfer Workflow

Heat transfer, on the other hand, is a more straightforward mechanical process. You're basically applying a physical layer of material onto the surface of an item. Think of it as a sophisticated, ultra-durable sticker that’s bonded to the fabric with heat and pressure. This method's biggest advantage is its versatility—it works on cotton, blends, and even dark-colored garments where sublimation is a no-go.

When using heat transfer vinyl (HTV), a popular choice, the workflow is quite different:

- Cutting: A vinyl cutter slices your design out of a sheet of HTV, following a digital outline. After it's cut, you have to remove all the excess vinyl, a process called "weeding."

- Positioning: The vinyl design, which is stuck to a clear carrier sheet, is placed exactly where you want it on the garment.

- Pressing: A heat press applies heat and pressure for a set amount of time. This activates the adhesive on the back of the vinyl, fusing it securely to the fabric.

- Peeling: Once it’s pressed, you peel away the carrier sheet (this can be done hot or cold, depending on the vinyl). All that’s left behind is your design, bonded to the item.

Getting a handle on these core differences is the first real step to making the right choice for your project. If you want to dive deeper, you can explore other resources that compare heat transfer and sublimation printing in more detail. Each method has its place, and understanding the mechanics helps you match the process to what you're trying to achieve.

When you're deciding between sublimation and heat transfer, it really boils down to three things: how the final product looks, how it feels, and how long it's going to last. Both methods can give you fantastic custom gear, but they get there in completely different ways, and the results reflect that. Knowing these differences is key to picking the right process for your project.

This is especially true in the custom apparel world, which has just exploded. The global dye sublimation market alone hit USD 15.22 billion in 2025 and is expected to jump to USD 25.52 billion by 2030. With clothing making up over 62% of that pie, the push for prints that look great and last a long time is stronger than ever.

How Durable Are The Prints?

When it comes to durability, sublimation is in a league of its own. The process literally infuses the ink into the polyester fibers, so the design becomes a permanent part of the fabric. It simply won't crack, peel, or fade, no matter how many times you wash it. This makes it the clear winner for items that take a beating, like sports jerseys, swimwear, and performance gear.

Heat transfer vinyl (HTV) and other modern transfers are tough, too, but in a different sense. A well-applied transfer forms a solid bond on top of the fabric. But because it's a layer sitting on the surface, it's more exposed to wear and tear. Over time and many wash cycles, you might eventually see some cracking or peeling, especially if you don't follow the care instructions. You can explore a detailed guide on how long DTF transfers last to get a better sense of how modern methods hold up.

Key Takeaway: For a print that's truly permanent and will never show wear, sublimation is your best bet. For great durability across a wider variety of fabrics, a quality heat transfer is a very solid option, though it might show its age after years of use.

The Feel of The Final Product

The "hand" or feel of a printed shirt is another major point of difference. A sublimated design has zero texture. You can run your hand over it and feel nothing but the fabric itself. It’s completely soft, flexible, and breathable, which is non-negotiable for athletic apparel where comfort is everything.

On the other hand, a heat transfer adds a distinct layer you can feel. The texture and thickness can range from super thin and soft to thicker, more substantial materials used for effects like glitter or flock. This extra layer will naturally reduce a bit of the fabric’s breathability right where the design is.

Color Vibrancy and Limitations

Both printing styles can produce incredibly bright colors, but they shine in different situations.

Sublimation is king for creating stunning, photo-quality images. It excels at smooth gradients and a massive range of colors. The ink is translucent, so it blends beautifully with the white or light-colored polyester beneath it, resulting in images that are unbelievably vibrant and crisp.

Heat transfer, however, is your solution for bold, opaque colors, especially on dark-colored garments. Since you're applying a solid layer of color, you can get brilliant whites, neons, and other vivid shades to pop on a black t-shirt—something sublimation just can't do. While some transfer types can handle gradients, they generally can't replicate the seamless, photographic detail you get from sublimation.

Understanding Material and Fabric Limitations

One of the biggest distinctions between sublimation and heat transfer boils down to the materials they work with. This isn't some minor technicality—it's a fundamental difference that will likely guide your entire decision. The product you want to create will often dictate the printing method for you.

Sublimation's Specific Requirements

Sublimation works at a molecular level. The process requires synthetic polymers for the ink to permanently bond with the material. This scientific constraint means sublimation is almost exclusively for high-content polyester fabrics or hard-surface items treated with a special polymer coating.

This is exactly why sublimation is the top choice for performance athletic wear, which is almost always 100% polyester. It’s also fantastic for items like ceramic mugs, metal tumblers, and specialty tiles designed for this process.

But here’s the catch. Sublimation has two major limitations: it simply won't work on natural fibers like 100% cotton, and the ink is transparent, so it's useless on dark-colored substrates.

The All-Around Versatility of Heat Transfer

This is where heat transfer really comes into its own. Instead of infusing ink into the material, it applies a design layer right on top of the surface. Because of this, its compatibility is much, much broader. Heat transfer vinyl (HTV) and transfer papers work beautifully on a huge range of substrates.

This flexibility makes it the go-to method for many of the most popular custom products out there. You can apply heat transfers to just about anything:

- Natural Fibers: Perfect for 100% cotton, canvas, and linen.

- Synthetic Blends: Works great on popular cotton/polyester mixes.

- A Rainbow of Colors: Heat transfer performs equally well on both light and dark garments.

- Diverse Hard Goods: It can even stick to untreated surfaces like wood or leather.

The market for these materials is massive and growing. The global industry for heat transfer paper and vinyl is expected to hit USD 2.27 billion by 2034, largely because it’s so cost-effective and useful for everything from small crafts to large textile runs. The popularity and accessibility of these methods for creators are undeniable. You can dive deeper into the trends of the heat transfer paper and vinyl market to see where it's headed.

Key Takeaway: If you're printing vibrant, full-coverage designs on performance wear or polyester promotional items, choose sublimation. For custom cotton tees, branded canvas totes, and any design going on a dark garment, heat transfer is the clear winner.

Ultimately, the material you're working with is your first checkpoint. If you’ve got cotton or dark fabrics, heat transfer is your only real option. If you’re focused on white or light-colored polyester apparel and coated hard goods, sublimation delivers quality and durability that’s hard to beat. This one factor often makes the choice between the two methods surprisingly simple.

Breaking Down the Costs and Equipment Needs

When you look at the financials, sublimation and heat transfer are two completely different beasts. Your budget, how much you plan to produce, and what you’re making will really determine which one makes more sense for your bottom line. Getting this right from the start can save you a ton of headaches and cash later on.

The barrier to entry for heat transfer vinyl (HTV) is noticeably lower, which is why so many hobbyists and new small businesses gravitate towards it. The list of must-have equipment is short and relatively inexpensive.

The Accessible Path of Heat Transfer

Getting an HTV operation off the ground won't break the bank. You really only need two core pieces of equipment to start cranking out custom shirts and other products.

- Vinyl Cutter: This is the machine that precisely cuts your designs out of HTV sheets. You can find solid, entry-level cutters starting at just a few hundred dollars.

- Heat Press: A good heat press is non-negotiable for getting the even heat and pressure needed for a lasting application. There are clamshell and swing-away models to fit different budgets and workspaces.

This low upfront cost makes HTV a fantastic way to dip your toes in the water or launch a side hustle without a massive financial risk. The costs are easy to track and scale directly with every order you fulfill.

Investing in a Sublimation Setup

Sublimation, on the other hand, requires a more significant initial investment because the equipment is more specialized. While the per-item cost for vibrant, full-color designs can be lower once you're running at volume, the startup price tag is a real factor to consider.

A basic sublimation starter package will typically include:

- Dedicated Sublimation Printer: You can't just use any old inkjet printer. You need a specific model, like an Epson F170, built to handle sublimation inks.

- Sublimation Inks and Paper: These are specialized consumables that cost more than their standard office-supply counterparts.

- A Reliable Heat Press: This is the one major piece of gear both methods have in common. For sublimation, it's absolutely essential for the chemical reaction to work.

The initial outlay for a full sublimation setup can be a hurdle. Beyond the direct purchase price, exploring various options for equipment financing loans can help manage the initial investment for your sublimation setup.

Here’s a quick look at how the initial and ongoing costs stack up.

Startup Cost and Consumables Comparison

While sublimation requires a bigger initial check, the long-term consumable costs can be more efficient for high-volume, full-color printing. Conversely, HTV's startup costs are low, but material costs can add up on complex, multi-color jobs.

| Cost Factor | Sublimation | Heat Transfer Vinyl (HTV) |

|---|---|---|

| Primary Equipment | Sublimation Printer, Heat Press | Vinyl Cutter, Heat Press |

| Initial Cost | Higher (Dedicated printer is a significant cost) | Lower (Entry-level cutters are affordable) |

| Ongoing Consumables | Sublimation Ink, Sublimation Paper, Blanks | Heat Transfer Vinyl (by the roll/sheet) |

| Per-Print Cost | Can be very low for full-color images | Varies based on vinyl usage and colors |

Ultimately, the math depends on your business model. If you’re doing large runs of photographic prints on polyester apparel, sublimation’s per-print cost eventually becomes more attractive. But if you’re doing one-off custom text or simple logos, the cost of an HTV project is tied directly to the vinyl used, which is often more economical for simpler designs. You really have to calculate your expected volume and design complexity to see which method wins out in the long run.

Making the Final Call for Your Project

So, which one is right for you? Honestly, there’s no single "best" method. The choice between sublimation and heat transfer really boils down to what you want to create, the materials you're working with, and your overall business plan. Forget a simple pros and cons list—let's think about this in terms of real-world results to make sure you pick the right tool for the job.

The trick is to match the technology to your vision. Let's say you're launching a line of high-performance sportswear with those incredible, full-wrap, vibrant designs. In that case, sublimation is the only way to go. The ink becomes one with the polyester fibers, meaning the design will never crack, peel, or fade. Plus, you can't feel the print at all, so the fabric stays breathable and comfortable—exactly what an athlete needs.

On the flip side, maybe you're starting an Etsy shop focused on custom cotton t-shirts with funny quotes or simple graphics. Here, a heat transfer setup makes a ton of sense. The startup costs are much lower, and it works beautifully on the cotton and dark-colored shirts that are so popular online.

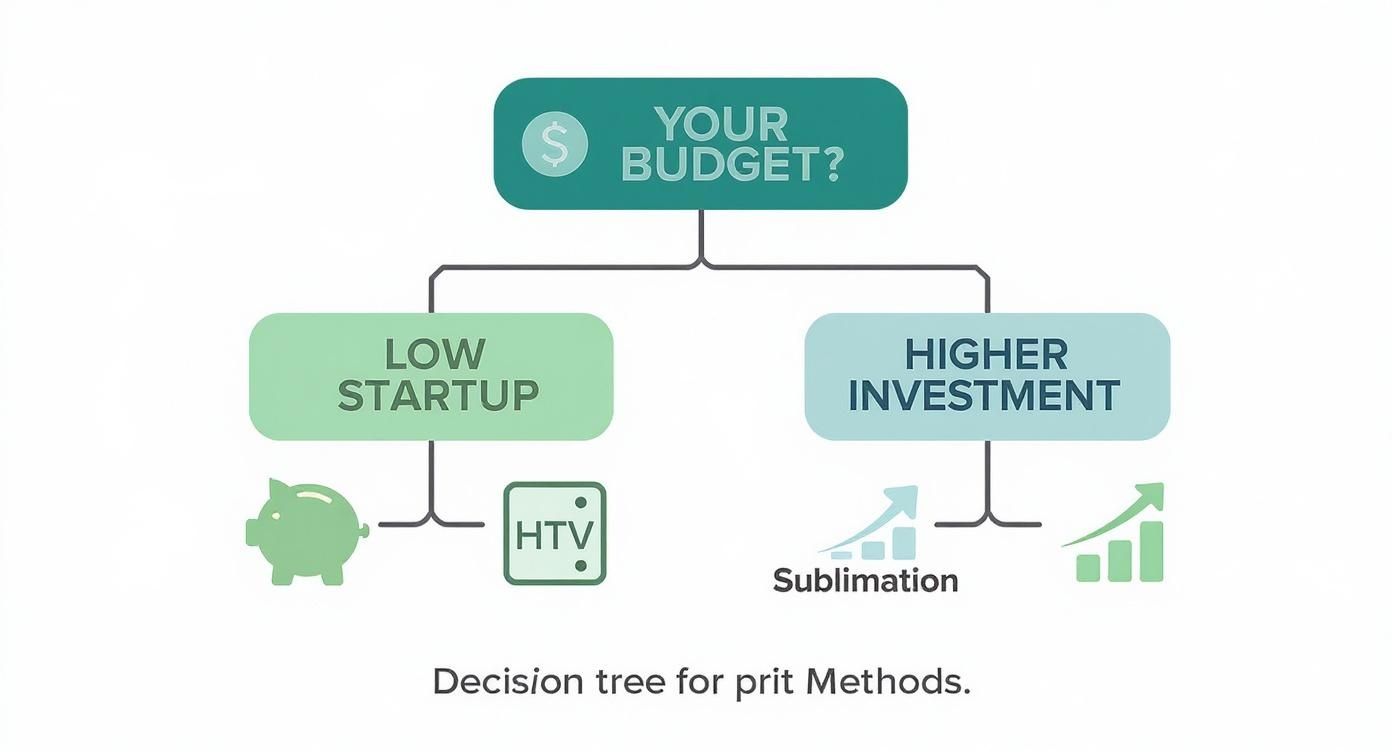

This decision often starts with your budget. The initial investment required for each setup can point you in the right direction from the get-go.

As you can see, a smaller startup budget naturally leads you toward HTV, while a more significant initial investment is needed for sublimation. This difference really comes down to the specialized printers and inks sublimation requires.

When to Use Which Method

To make it even clearer, let's look at a few specific scenarios. For each of these projects, there's a clear winner.

-

Photographic Mugs and Tumblers? Go with sublimation, no question. It creates those flawless, photo-quality images that wrap seamlessly around hard surfaces. The final product is durable and even dishwasher-safe.

-

Bold Logos on Dark Cotton Hoodies? You need heat transfer for this. The opaque vinyl layers sit on top of the fabric, ensuring that bright colors like white and yellow pop against a dark background, something sublimation just can't do on cotton.

-

Small Batches or One-Off, Multi-Color Designs? Heat transfer is usually more cost-effective here. Since your cost is tied to the amount of vinyl you use for a single design, it's perfect for small runs without the setup of other methods.

Think about your main product first. If you're all about polyester activewear, sublimation is your path. If you're building a brand around cotton promo items, heat transfer is the most practical and profitable choice.

Got Questions? Let's Get Them Answered.

When you're weighing sublimation against heat transfer, a few questions pop up time and time again. Getting straight answers to these is key to making the right call for your projects and avoiding headaches later on.

How Well Do The Designs Hold Up In The Wash?

Sublimation is the undisputed champion of washability. Because the ink actually becomes part of the polyester fibers, the design is permanent. It won't crack, peel, or fade, even after a hundred washes. This is why it's the go-to for performance wear and athletic jerseys that see a lot of action and a lot of laundry.

Heat transfer, on the other hand, is still incredibly durable, but the science is different. A good quality heat transfer vinyl (HTV) fuses to the surface of the fabric. It can handle tons of washes, but since it's a layer on top, it might eventually show tiny cracks or signs of wear after a few years of heavy use.

Why Can't I Use Sublimation On Dark Shirts?

This is a big one. Sublimation ink is transparent. The best way to think about it is like a wood stain—it soaks in and tints the material, but you can still see the wood grain (or in this case, the fabric color) underneath. If you try to sublimate a design onto a black shirt, the dark fabric color will completely overwhelm the transparent ink, and you won't see a thing.

This is a fundamental difference you have to plan for. If you want vibrant, popping colors, sublimation must be done on white or very light-colored polyester. For any design going on a dark cotton or poly-blend shirt, heat transfer is your only real option.

What's The Bare Minimum Equipment I Need To Start?

The startup kits for these two methods look quite different, and the entry cost reflects that.

- For Heat Transfer Vinyl (HTV): You can get started with just two key pieces of gear: a vinyl cutter to slice out your designs and a heat press to apply them. It's generally the more straightforward and budget-friendly way to get into the game.

- For Sublimation: This process requires a more specialized setup. You'll need a dedicated sublimation printer (you can't use a regular one) loaded with special inks, sublimation paper to hold the design, and a heat press.

Ready to create stunning custom apparel? Raccoon Transfers delivers top-tier Direct-to-Film transfers that bring together brilliant, full-color designs and amazing durability for almost any fabric. Check out our simple, effective solutions at https://raccoontransfers.com.