Sublimation Printing vs Heat Transfer The Right Choice

Share

When it comes to putting a custom design on a t-shirt, mug, or just about anything else, you'll almost always run into two main options: sublimation and heat transfer. At first glance, they seem similar since both use a heat press. But the way they work is fundamentally different, and that difference affects everything from the feel of the final product to how long it will last.

The core distinction is simple. Sublimation dyes the actual fibers of the material, while heat transfer lays a design on top of the fabric. Picking the right one means understanding what you're making and what you value most—longevity and vibrancy, or material flexibility.

What’s Really Happening During the Process?

Sublimation is a pretty neat bit of chemistry. Under high heat and pressure, special sublimation ink turns from a solid directly into a gas, skipping the liquid phase entirely. This gas then infuses into polyester fibers or polymer-coated surfaces, bonding with them at a molecular level. The result is a print that has no feel, or "hand," at all. It's literally part of the material, so it will never crack, peel, or fade.

Heat transfer, on the other hand, is a more direct application. You print your design onto a special transfer paper or cut it from Heat Transfer Vinyl (HTV). Then, you use a heat press to essentially bond that layer onto the surface of the item. It sits on top of the fabric, which means you can feel it. This is also why it works on a much wider range of materials, like 100% cotton and dark fabrics, where sublimation just isn't an option.

Think of it this way: Sublimation is like a tattoo for your fabric—it’s permanent and becomes one with the material. Heat transfer is more like a high-quality, durable sticker applied to the surface.

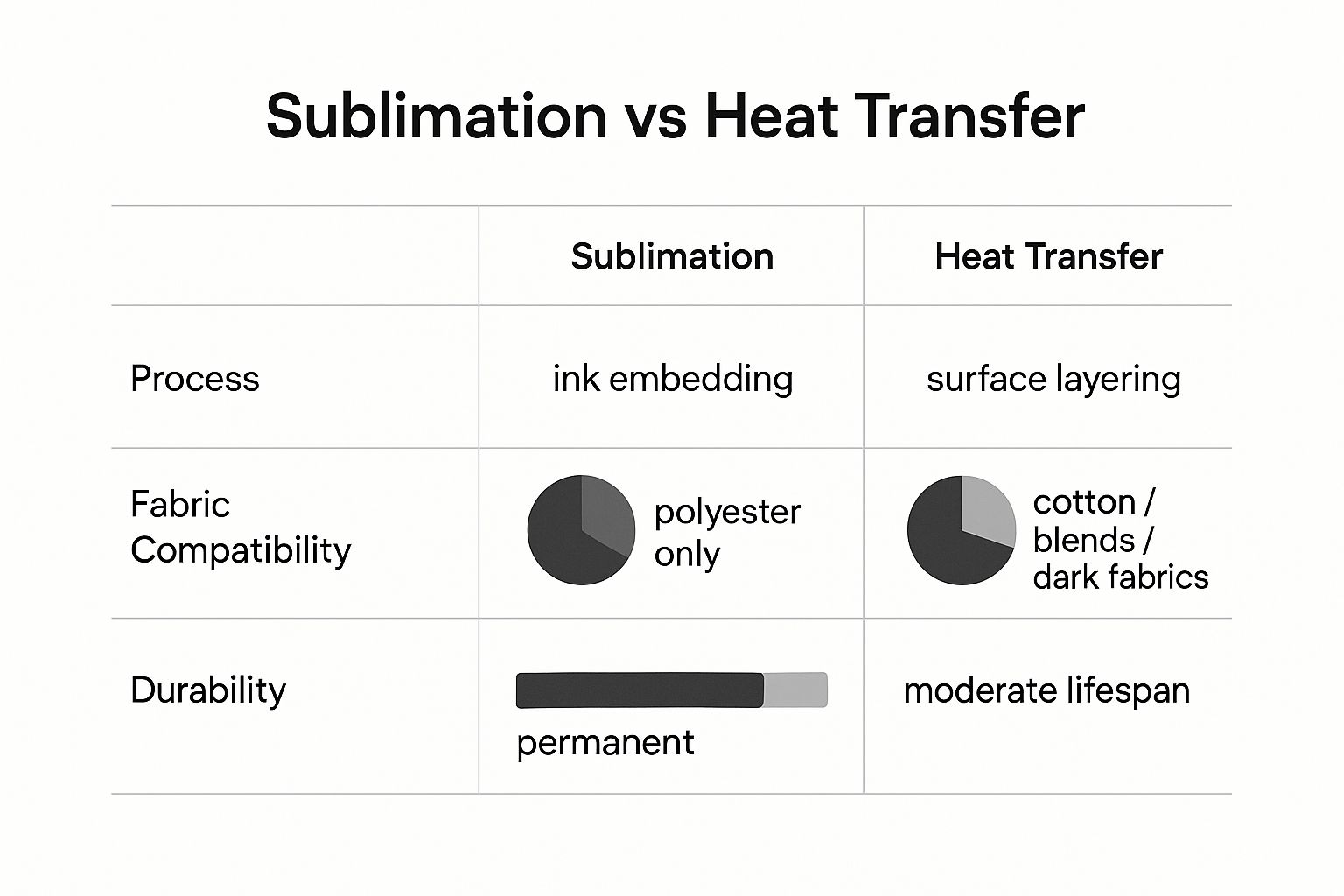

Sublimation vs Heat Transfer At a Glance

To make the choice clearer, it helps to see the core differences side-by-side. This quick breakdown highlights where each method shines and where it falls short.

| Attribute | Sublimation Printing | Heat Transfer |

|---|---|---|

| Process | Ink turns to gas and fuses into the fabric fibers. | A layer of material (vinyl, paper) is applied to the fabric surface. |

| Feel | No "hand" or feel; the print is part of the fabric. | A tangible layer sits on top of the fabric; can be stiff or flexible. |

| Durability | Permanent; will not crack, peel, or fade over time. | Less durable; can crack or peel with repeated washing and wear. |

| Fabric Type | Requires polyester or polymer-coated items. | Works on cotton, polyester, blends, and more. |

| Fabric Color | Best on white or very light-colored fabrics only. | Works on any color fabric, including black and darks. |

| Color Vibrancy | Excellent, photorealistic quality with vibrant colors. | Good to excellent, depending on the transfer material quality. |

As you can see, the decision often comes down to the trade-offs between durability and material compatibility. You get a permanent, professional finish with sublimation, but you're limited in what you can print on. Heat transfer gives you freedom with fabrics, but the design's lifespan isn't quite as long.

Ultimately, your project's needs will steer you in the right direction. If you're decorating a polyester performance tee, sublimation is the clear winner for a permanent, breathable print. For a run of black cotton shirts, heat transfer is your go-to method.

These two methods are just part of a bigger world of customization. If you're curious about where they fit in, you can explore other fabric printing techniques to get a full picture of the available options. And for those interested in broader printing comparisons beyond just apparel, understanding the distinctions between digital printing vs offset can also provide some useful context.

Understanding The Core Process of Each Method

To really get to the heart of the sublimation vs. heat transfer debate, you have to look at how each one works from start to finish. While both use a heat press to get a design onto an item, their core mechanics are completely different. One method actually dyes the fabric, while the other applies a layer on top.

This single distinction is a big deal—it impacts everything from the gear you need to buy to how the final product feels and holds up over time. Walking through these workflows will make it crystal clear why one might be perfect for a specific project and the other not so much.

The Sublimation Printing Workflow

Sublimation is where art and science really shake hands. It’s a fascinating chemical process that turns solid ink directly into a gas, which then bonds permanently with polymer fibers.

First, you print your design onto special sublimation transfer paper. This requires a dedicated sublimation printer loaded with sublimation inks—not your everyday office printer ink. These are formulated to react specifically to high heat.

Next, you place the printed paper onto a polyester or polymer-coated item, like a t-shirt or a coffee mug. A heat press clamps down, applying intense heat (usually 380-400°F) and pressure. This is where the magic happens: the solid ink on the paper vaporizes into a gas, skipping the liquid phase entirely.

This gas sinks into the open pores of the polyester fabric or coating. As everything cools, the gas turns back into a solid and becomes chemically locked into the material. Your design is now part of the substrate, not just sitting on top of it.

Key Takeaway: With sublimation, you're dyeing the fabric at a molecular level. The final print has zero feel to it—it’s completely smooth—and because it’s infused into the material, it will not crack, peel, or fade.

The Heat Transfer Workflow

Heat transfer is more of an umbrella term for methods that apply a material onto an item's surface. The two most popular players in this space are Heat Transfer Vinyl (HTV) and printable heat transfer paper.

Your workflow will change depending on which path you take.

-

Heat Transfer Vinyl (HTV): Here, you start by cutting a design from a colored sheet of vinyl using a cutting machine. After the machine does its thing, you have to "weed" away all the excess vinyl, leaving just your graphic on its clear carrier sheet. You then position this on your garment and use a heat press to activate the adhesive on the back of the vinyl, bonding it to the fabric.

-

Printable Heat Transfer Paper: For full-color graphics, this is a common route. You print a design onto a special sheet of transfer paper using a standard inkjet or laser printer. Once printed, you trim it out, place it on the garment, and press it. The heat activates an adhesive coating, which transfers the printed layer from the paper to the fabric. If you want to dive deeper into how this works, check out our guide on what heat transfer printing is.

Unlike sublimation, heat transfer always adds a physical layer you can feel on top of the fabric. The thickness and texture of this layer really depend on the quality and type of vinyl or paper you're working with.

Core Differences in Equipment and Labor

The tools and effort involved for each method are quite different, which directly affects your initial investment and how complex your production will be.

| Aspect | Sublimation Printing | Heat Transfer Printing |

|---|---|---|

| Printer | Requires a dedicated sublimation printer. | Can use standard inkjet/laser printers (for paper) or none (for HTV). |

| Inks/Media | Specialized sublimation inks and transfer paper. | Standard inks; Heat Transfer Vinyl (HTV) or printable transfer paper. |

| Tools | A quality heat press is essential for consistent results. | A heat press is required, plus a vinyl cutter for HTV methods. |

| Labor | Involves printing, aligning, and pressing. No weeding is necessary. | Involves printing/cutting, weeding vinyl, and pressing. Weeding can be very time-consuming for intricate designs. |

At the end of the day, sublimation requires a more specialized setup geared toward dyeing polymer-based materials. Heat transfer, especially with vinyl, is about adding a physical layer to a much wider range of fabrics and demands different tools like a cutter and weeding picks to prep the design for pressing.

Analyzing Print Quality, Durability, And Feel

When you get right down to it, the real difference between sublimation and heat transfer isn't just the process—it's what the final product looks, feels, and how long it lasts. This is where the two methods really start to show their distinct personalities. How a design actually sits on the fabric is a huge deal, affecting everything from appearance to how it holds up in the wash.

Ultimately, your choice here directly impacts how customers feel about your brand's quality. One method gives you a print you can't even feel, completely fused with the material. The other offers incredible versatility but leaves a tangible layer on the surface. Let's break down what that means for you.

Color Fidelity and Visual Impact

Sublimation is king when it comes to jaw-dropping color and detail. Because the ink turns into a gas and becomes one with the fabric fibers, you get these beautiful, seamless gradients and photorealistic images without any harsh edges. This is why it’s the go-to method for complex photos, detailed patterns, or any design that needs to cover the entire garment.

Heat transfer, especially HTV (heat transfer vinyl), is more at home with bold, solid graphics—think logos, text, and simple shapes. While you can use printable transfer paper for full-color images, it often falls short of the vibrancy and fine detail you get with sublimation. The final print can sometimes look more like a high-quality sticker applied to the shirt, rather than being part of the fabric itself.

Key Differentiator: Sublimation absolutely shines with photorealistic, all-over prints using unlimited colors. Heat transfer is the champ for simpler, block-color designs where a layered feel is perfectly fine, or even part of the look.

The All-Important Feel or "Hand"

In the printing world, "hand" is what we call the feel of the print on the fabric. And this is arguably the single biggest difference you'll notice between these two methods.

A sublimated print has absolutely no hand. Zero. You can't feel it at all because the ink is infused into the fibers, not sitting on top of them. The garment stays just as soft, light, and breathable as it was before it was printed. This makes sublimation ideal for performance sportswear and high-end fashion where comfort is everything.

Heat transfer, by its very nature, adds a layer on top of the fabric. You can feel it. The texture can vary quite a bit:

- Heat Transfer Vinyl (HTV) can be thin and flexible or sometimes thick and a bit stiff, depending entirely on the type of vinyl you're working with.

- Printable Transfer Paper typically leaves a thin, almost film-like layer on the surface. This can feel a little heavier and make the fabric less breathable in that spot.

That added layer is a major consideration. While modern transfer materials have come a long way, they will never give you that "zero-hand" feel that makes sublimation so unique. If you want to dive deeper into these distinctions, check out our guide that further compares heat transfer and sublimation printing.

Unpacking Print Durability and Longevity

When it comes to durability, sublimation is in a league of its own. Because the design is chemically bonded with polyester fibers, it's permanent. A sublimated print won't crack, peel, or fade, no matter how many times you wash it. The design will literally last as long as the shirt itself, staying just as vibrant as the day it was made.

This incredible staying power is why sublimation has become such a powerhouse. The global dye sublimation market was valued at around USD 14.9 billion in 2024 and is expected to hit USD 28.0 billion by 2030. That growth is fueled by people wanting personalized gear that looks amazing and lasts forever—which is exactly what sublimation delivers. You can see more on the sublimation market growth on GrandViewResearch.com.

Heat transfer prints, on the other hand, have a more finite lifespan. That bonded layer on the surface is exposed to friction from wearing and washing, making it vulnerable over time. Eventually, these prints can start to crack, the edges can begin to peel, or the colors can fade. A high-quality HTV might get you 25-50 washes, but it simply can’t compete with the permanence of sublimation.

The lifespan of a heat transfer print really hinges on a few things:

- Quality of the material: Premium vinyls and papers last way longer than the cheap stuff.

- The application process: Nailing the right temperature, pressure, and time is critical for a solid bond.

- How you care for it: Simple things like washing inside-out on a gentle cycle can make a big difference and extend the print's life.

Comparing Material And Fabric Compatibility

The success of your entire project often boils down to one critical question: will your printing method actually work with your chosen material? This is where sublimation and heat transfer take dramatically different paths. One offers incredible durability but is famously picky about materials, while the other is the flexible workhorse of the apparel world.

Getting this right isn't just a suggestion; it’s the line between a vibrant, professional product and a pile of expensive, useless blanks. When you're weighing sublimation printing vs. heat transfer, the fabric you start with often makes the decision for you.

The Sublimation Mandate: Polyester and Polymers Only

Sublimation isn't just a printing method; it's a chemical reaction. The gaseous ink needs polymer fibers to bond with permanently. Without them, the process simply fails. This is a hard-and-fast rule.

For apparel, this means you're locked into fabrics with a high polyester count. You’ll get the absolute best, most vivid results from 100% polyester. You can get away with blends, but be warned: the lower the polyester content, the more faded and "vintage" your print will look because the ink has fewer fibers to latch onto.

Crucial Insight: Sublimation ink is transparent. It dyes the fabric itself instead of sitting on top as a separate layer. Because of this, it only works on white or very light-colored materials. Trying to sublimate on a dark shirt is like using a highlighter on black paper—the design completely disappears.

This polymer-only rule isn't just for clothes. It’s also why sublimation works so well on hard goods, as long as they have a special polymer coating applied first.

- Ceramic Mugs: A classic for a reason; the coating allows for stunning, permanent images.

- Phone Cases: You can create tough, scratch-resistant designs that won't peel off.

- Mouse Pads: The polyester fabric top makes them an ideal canvas for sublimation.

- Metal Tumblers: The secret to those vibrant, full-wrap tumbler designs is a sublimation-ready coating.

The Versatility Champion: Heat Transfer

If sublimation’s strict rules sound limiting, you’ll love the freedom of heat transfer. Its biggest selling point is its incredible versatility. Since you're applying a layer of material on top of the fabric rather than dyeing it, you can use it on almost anything.

This is your go-to method for the classic 100% cotton t-shirt. Both heat transfer vinyl (HTV) and printable transfer papers stick perfectly to natural fibers like cotton, a feat sublimation can never achieve. This flexibility opens the door to a huge range of products.

- Cotton: By far the most popular use for heat transfer.

- Polyester: Works just as well as it does on cotton.

- Cotton/Poly Blends: The go-to for custom hoodies and sweatshirts.

- Canvas: Perfect for tote bags, aprons, and other accessories.

- Denim and Leather: With the right specialty vinyl, you can even decorate tougher materials.

Even better, the color of the garment is no obstacle. You're adding an opaque layer, so putting a bright white design on a black t-shirt is simple and effective—something that's physically impossible with sublimation. This blows your creative doors wide open, letting you pair any design color with any fabric color.

Ultimately, your material dictates your method. Need that permanent, no-feel finish on a polyester performance shirt? Go with sublimation. Need to print a bold, multi-color logo on a classic black cotton tee? Heat transfer is your only real choice.

Breaking Down Costs and Scalability for Businesses

Choosing between sublimation and heat transfer isn't just about the final look—it’s a serious business decision that shapes your budget, profit margins, and how easily you can grow. Both can create incredible custom products, but their financial models and potential for scaling are night and day. One path requires a bigger investment upfront but pays off with lower costs per print down the line. The other is famous for its low barrier to entry but can become a real grind as your orders pile up.

Heat transfer, especially with Heat Transfer Vinyl (HTV), is the hands-down winner for anyone on a tight budget. You can get a solid setup going with a decent vinyl cutter, a heat press, and your first few rolls of vinyl without breaking the bank. A lot of crafters and small business owners already have a cutting machine, which drops the startup cost even further.

This accessibility makes HTV a fantastic starting point for hobbyists, Etsy shop owners, and businesses that thrive on small, one-off custom orders. For simple designs, the process is quick and lets you turn around single items fast.

Analyzing Initial Investment Costs

The moment you start pricing out equipment, the financial differences really hit home. A sublimation setup requires specialized gear right out of the gate, which means a higher initial cost.

- Sublimation Setup: You’ll need a dedicated sublimation printer loaded with special sublimation inks, the right kind of transfer paper, and a quality heat press. You can't just use your home office inkjet, so this first purchase is a big one.

- Heat Transfer (HTV) Setup: The essentials here are a vinyl cutter, rolls of HTV, and a heat press. While high-end professional cutters cost a pretty penny, there are plenty of affordable entry-level models perfect for getting your feet wet.

Sublimation’s higher initial cost is really an investment in future efficiency and top-tier quality for certain products. Heat transfer’s lower startup cost is an investment in versatility and getting your business off the ground today.

Once you’ve got a handle on your equipment and supply costs, you need a plan for effectively pricing your custom-printed items to make sure you're actually turning a profit. This is where your creative hobby becomes a real business, no matter which printing method you land on.

Comparing Per-Print Costs and Scalability

While HTV is cheaper to start, the story completely flips when you start looking at the cost per print for more complex jobs and the reality of scaling up. A simple, one-color vinyl logo? Incredibly cost-effective. But what about a design with four or five colors? Now you’re layering multiple pieces of vinyl, which skyrockets your material costs and, more importantly, your time. Each color means another layer to cut, weed, and press.

This is exactly where sublimation’s strengths come into play. The cost to sublimate a print is the same whether it's a single black letter or a full-color, high-resolution photograph. Your cost is based on the ink and paper you use, not how complicated the artwork is. This makes sublimation vastly more economical and easier to scale for those detailed, vibrant, all-over prints that are so popular.

You can see this shift playing out in the market. The global heat transfer paper market—which includes supplies for both methods—was valued at roughly USD 550 million in 2023 and is expected to almost double by 2033. Sublimation paper is the driving force behind that growth, thanks to its amazing print quality and its fit with the booming textile industry. It's a clear signal that the industry is leaning into the efficiency and quality that sublimation delivers at scale.

So, if you’re building an apparel brand focused on premium, photorealistic designs for performance wear, sublimation gives you a clear runway to scale up without your labor costs exploding. But if your business is all about custom cotton t-shirts with bold, simple logos, heat transfer will likely be a perfectly profitable and manageable model for you.

When to Choose Sublimation vs. Heat Transfer

So, how do you make the final call in the sublimation printing vs heat transfer debate? It's not really about one being universally "better" than the other. Instead, think of it as choosing the right tool for a specific job. Your decision hinges on what you’re printing on, how complex your design is, and just how tough you need the final product to be.

Let's move past a simple summary and dive into some real-world situations. Seeing where each method truly shines will help you match your project's vision with the right technology and sidestep some common frustrations.

Scenarios Where Sublimation Is the Clear Winner

Sublimation is your go-to when you need absolute vibrancy, permanence, and a professional finish you can't even feel. Because the ink becomes a part of the material itself, it's the premium choice for certain applications where quality is paramount.

You’ll want to choose sublimation for projects like these:

- Custom Sportswear and Performance Apparel: Think about athletic jerseys, leggings, or any moisture-wicking gear. Breathability is everything. Sublimation has a zero-hand feel, meaning the print doesn't clog the fabric's pores, so the garment performs exactly as it was designed to. Plus, the design is permanent—it won't crack or peel after intense use and countless washes.

- All-Over-Print Fashion Items: If you have a bold design that needs to cover an entire garment seamlessly, from edge to edge, sublimation is really the only practical way to pull it off. It’s the secret behind those eye-catching, continuous patterns you see on modern apparel.

- Personalized Photo Gifts: When you're putting a high-resolution photo on something like a ceramic mug, a phone case, or a metal tumbler, sublimation is unbeatable. It delivers stunning color accuracy and a glossy, durable finish that’s dishwasher-safe and resists scratches.

Pro Tip: If your product is going to face heavy use, frequent washing, or a lot of sun, sublimation is the most reliable choice. Its permanence ensures the design stays vibrant for the long haul.

When to Opt for Heat Transfer

Heat transfer is the versatile workhorse of the two. It’s perfect when you need flexibility with materials and want to keep costs in check. The fact that it works on a huge range of fabrics—especially cotton and dark-colored items—opens up a ton of creative doors.

Go with heat transfer in these cases:

- Branding Dark-Colored Garments: This is where heat transfer really pulls ahead. Since you're applying an opaque layer of material on top of the fabric, you can easily put a bright white logo on a black cotton hoodie. That's something you simply can't do with sublimation.

- Small Runs of Cotton T-Shirts: If you're a small business or a hobbyist making classic cotton tees with simple logos or text, Heat Transfer Vinyl (HTV) is incredibly efficient. The startup costs are low, and the process is straightforward.

- Quick and Cost-Effective Event Merchandise: Need 50 shirts for a one-day event? Heat transfer is a fast, affordable way to produce promotional gear on a tight budget without a big investment in equipment.

The growing dominance of sublimation in textiles is hard to ignore. Globally, the annual volume of sublimation-printed fabric has already hit 2.7 billion square meters and is expanding at 10–12% per year—a pace far outstripping most heat transfer methods. You can learn more about the growth of dye sublimation paper on Burgo.com.

Looking at these scenarios side-by-side really helps clarify the decision.

Ideal Use Cases: Sublimation vs. Heat Transfer

To make it even simpler, this table breaks down common projects and points you toward the best method. Think of it as a quick-reference guide for your next creation.

| Project Type | Recommended Method | Why It's a Good Fit |

|---|---|---|

| Full-Color Sports Jerseys | Sublimation | Permanent, breathable, and vibrant on polyester. |

| Black Cotton Hoodies with Logo | Heat Transfer | Works on dark cotton; opaque layer provides contrast. |

| Photographic Mugs | Sublimation | Creates a durable, photorealistic, and glossy finish. |

| Charity Event T-Shirts (Small Batch) | Heat Transfer | Low startup cost and fast for simple designs. |

Ultimately, understanding the strengths and limitations of both sublimation and heat transfer will empower you to choose the right process, ensuring your final product looks and feels exactly how you envisioned it.

Frequently Asked Questions

When you're trying to pick between sublimation and heat transfer, a few questions always pop up. Let's get them answered so you can skip the trial-and-error and invest in the right setup for what you want to create.

Here are the answers to the most common questions I hear from people just starting out.

Can You Use a Regular Printer for Sublimation?

That's a hard no, and it's probably the most important thing to get right. You absolutely need a dedicated sublimation printer loaded with special sublimation inks. Your standard office inkjet just won't work.

The whole magic of sublimation is turning a solid ink into a gas that permanently dyes polyester fibers. Regular printer ink isn't designed for that kind of chemistry. If you try it, your design will either fail to transfer or just wash right out of the fabric. You have to commit to the specific gear for this process.

Which Method Is Better for a Small Business?

Honestly, it really depends on what you're planning to sell. Heat transfer is usually the go-to for new businesses because the startup cost is so much lower. If your game plan is selling custom cotton tees with text or simple graphics, especially on dark colors, heat transfer gives you a ton of flexibility without a big upfront investment.

On the other hand, if you're building a brand around high-end, full-color products—think performance jerseys or personalized mugs and tumblers—sublimation is where the money's at. The initial equipment cost is higher, but your per-print cost for those intricate, vibrant designs is actually lower. Plus, the premium, permanent finish means you can charge a higher price.

Key Insight: Heat transfer is perfect for startups needing versatility on a tight budget. Sublimation is the smarter long-term play for brands that want to scale with premium, full-color products that last.

Can You Sublimate on 100 Percent Cotton?

This is another one where the answer is a definite "no." The science just doesn't work. Sublimation requires the gaseous ink to form a chemical bond with polymer (polyester) fibers. Natural materials like cotton simply don't have the right structure for the ink to grab onto.

Try to sublimate on a 100% cotton shirt, and you'll get a disappointingly faded, muddy-looking image right off the press. It gets worse: the design will wash away almost completely in the first laundry cycle because there's nothing for the ink to permanently bond with. If you want to print on cotton, you have to use heat transfer.

At Raccoon Transfers, we specialize in cutting-edge DTF (Direct-to-Film) transfers that combine the versatility of heat transfer with the vibrant, full-color quality you need. Skip the equipment investment and get professional, ready-to-press transfers delivered right to your door. Explore our DTF transfers today!