Finding Wholesale Blank Apparel Suppliers

Share

Before you even think about Googling wholesale blank apparel suppliers, you need to do some serious homework. Trust me, the most important work happens right at your own desk, long before you start sending out emails. It’s the difference between a targeted, successful search and a chaotic, time-wasting mess.

First Things First: What Do You Actually Need?

Jumping into a list of suppliers without a crystal-clear idea of what you want is like walking into a grocery store hungry with no shopping list. You’ll end up with a cart full of stuff you don't need and a big bill. To avoid that, you need to build a detailed spec sheet for your ideal blank garment. This is way more than just saying, "I need some t-shirts."

Let's get specific. What's the fabric? Are you after that ultra-soft, premium feel of 100% ring-spun cotton, or do you need the durability and stretch of a poly-blend for athletic wear? The fabric choice affects everything—the print, the feel, the price. If you're still weighing your options, our guide to the best blank t-shirts for printing is a great place to start digging into materials.

The Devil is in the Details

Now, let's talk about weight. A lightweight 150 GSM (Grams per Square Meter) tee feels totally different from a beefy 220 GSM heavyweight shirt. One is perfect for a breezy summer collection, while the other gives you that classic, durable streetwear vibe. What you choose signals a lot about your brand.

Color is another big one. Don't just ask for "blue." One factory's navy is another's royal blue. To get exactly what you envision, use Pantone codes. This ensures the color is perfectly consistent, whether you're ordering today or six months from now.

Pro Tip: A detailed spec sheet or "tech pack" is your secret weapon. It eliminates guesswork and shows suppliers you’re a serious professional who knows their stuff. This single document can save you from a world of headaches.

Find a Supplier That Fits Your Brand's Vibe

Think about where your brand sits in the market. Are you building a high-end, sustainable brand? Then you should only be talking to suppliers who offer things like GOTS-certified organic cotton. This immediately filters out 90% of the noise and connects you with partners who share your values.

On the flip side, if your brand competes on price and volume, you'll be looking for a completely different set of qualifications, prioritizing cost-effective materials and massive production capacity.

It's also smart to know the lingo. Understanding the difference between OEM and ODM manufacturing models helps you communicate your needs more clearly. The apparel market is huge, and knowing where you fit in helps you find the right manufacturing partner. Taking the time to map all this out ensures that every supplier you reach out to is a real contender, saving you from dead-end conversations and samples that are just plain wrong.

Where to Find Your Ideal Wholesale Apparel Partner

Alright, you’ve got your wishlist dialed in. Now comes the fun part: finding a wholesale blank apparel supplier who can actually deliver on it. A quick Google search will give you a ton of results, but the real gems are often found a little deeper. To find a partner that truly gets your brand’s quality and budget, you need to cast a wider net.

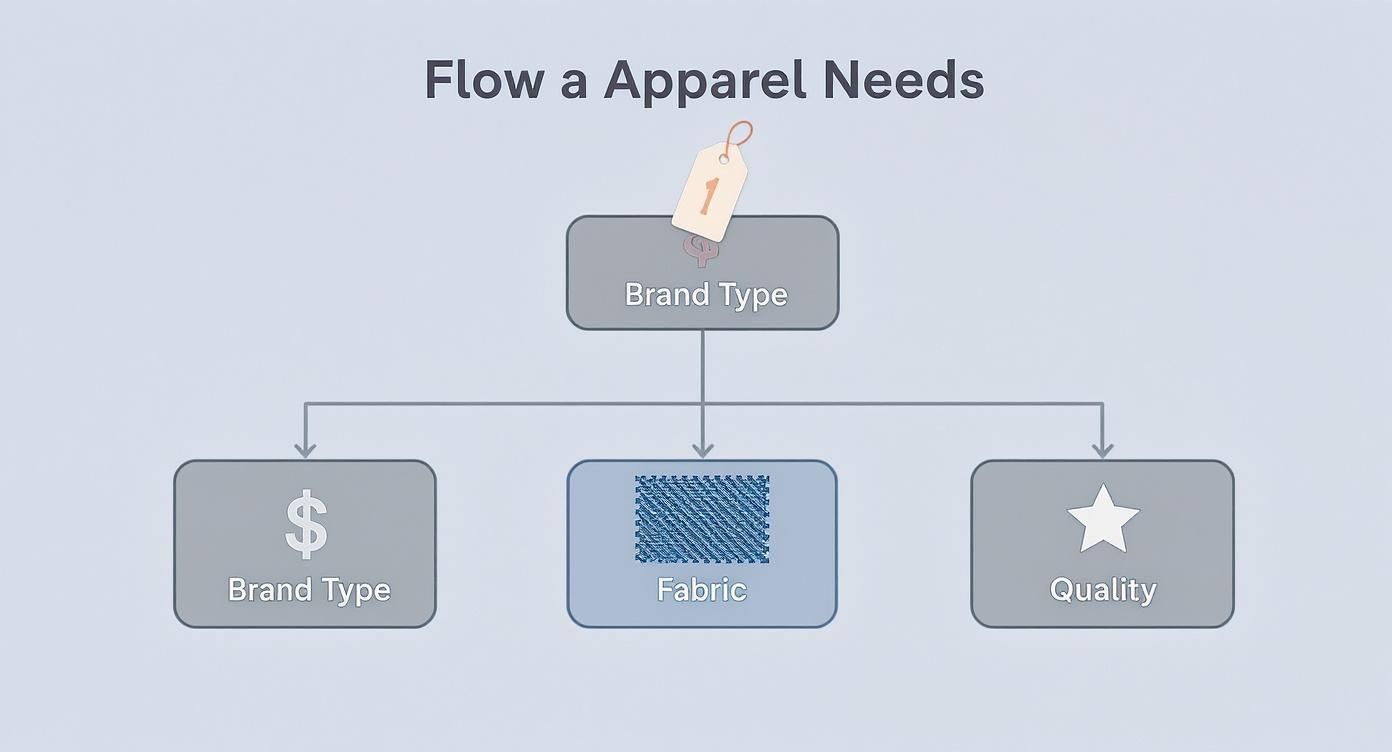

This flowchart breaks down how your brand's identity—from its market position to fabric choice—should steer your sourcing strategy.

As you can see, locking down your brand type first makes the whole process smoother. It immediately helps you filter for the right fabric and quality, saving you a ton of time.

To give you a clearer picture, let's break down the most common sourcing channels. Each one has its own set of pros and cons, especially for a growing apparel brand.

Comparing Apparel Sourcing Channels

| Sourcing Channel | Best For | Pros | Cons |

|---|---|---|---|

| B2B Marketplaces | New brands looking for variety and competitive pricing. | Huge selection of global suppliers; transparent pricing and reviews. | Can be overwhelming; MOQs can be high; communication barriers. |

| Industry Trade Shows | Brands wanting to build relationships and assess quality in person. | Feel fabrics firsthand; build personal connections; spot new trends. | Requires travel budget and time; can be intimidating for newcomers. |

| Industry Communities | Anyone seeking honest, unfiltered feedback and hidden gems. | Candid reviews from peers; find niche or local suppliers. | Information can be subjective; requires active participation. |

Ultimately, a mix-and-match approach often works best. Start with a marketplace to get a feel for the landscape, then use trade shows and communities to vet your shortlist and build stronger relationships.

Hitting the B2B Online Marketplaces

For most new brands, digital marketplaces are the first port of call. Think of them as massive online directories where you can connect with thousands of wholesale blank apparel suppliers from all over the world.

Alibaba is the undisputed giant here. You’ll find a massive network of international manufacturers, often with unbeatable prices. The catch? Navigating it can be a beast. You’re often dealing with high Minimum Order Quantities (MOQs) and pretty long lead times.

If you’re aiming for a more curated, boutique feel, a platform like Faire might be more your speed. Faire focuses on linking independent brands with suppliers and retailers, usually offering lower MOQs and simpler terms. Expect to pay a bit more per piece, but the trade-off in convenience can be worth it.

The global apparel manufacturing industry is enormous, with around 459,000 businesses pulling in an estimated $507.9 billion in revenue. Digital platforms are the glue holding this fragmented market together, making it possible for small brands to find their footing. You can dig into more data on the apparel manufacturing landscape on IBISWorld.

The Power of In-Person Trade Shows

There's just no substitute for seeing and touching fabrics in person. Industry trade shows like MAGIC in Las Vegas or Texworld in New York are perfect for this. In a single afternoon, you can walk the floor and meet dozens of potential suppliers face-to-face.

This direct contact is a game-changer. It lets you:

- Instantly Judge Quality: Feel the hand of a garment, inspect the stitching, and compare materials right there on the spot.

- Forge Real Relationships: Putting a face to a name can lead to better communication and more flexible terms later on.

- Spot Emerging Trends: You get a firsthand look at what other brands are creating and which new fabrics are making waves.

Yes, attending takes time and money. But the connections you forge can become foundational to your brand's growth.

Tapping into Your Industry Network

Never, ever underestimate the power of a good recommendation from a fellow entrepreneur. Online communities—think specialized Facebook groups or subreddits for apparel brand owners—are pure gold. This is where people share the unvarnished truth about their experiences with suppliers, both good and bad.

You can ask direct questions and get the kind of honest feedback you’ll never find on a supplier's website. Someone might tip you off to an amazing local manufacturer you'd never discover otherwise, or warn you away from a big name whose quality control is slipping.

This multi-pronged strategy—combining digital research, face-to-face networking, and community intel—is your best bet for building a solid list of potential partners. Once you lock in the right supplier, you can confidently find the perfect blank shirts for your custom projects and start bringing your vision to life.

How to Properly Vet Potential Suppliers

So, you've got a list of potential wholesale suppliers. Now the real work starts. This is where you separate the solid partners from the ones that will cause you endless headaches down the line. Vetting isn't just a formality; it's a crucial process that protects your brand, your money, and your reputation.

Trust me, rushing this part is the single biggest—and most expensive—mistake I see new brands make. You're not just buying a box of t-shirts. You're building the foundation of your supply chain. A thorough vetting process is your best defense against shoddy quality, blown deadlines, and surprise costs.

Making a Professional First Impression

How you first approach a supplier sets the tone for your entire relationship. You need to come across as a serious buyer, not just someone window-shopping. A vague email like "Do you sell shirts?" will probably get ignored or a generic, unhelpful reply. Be specific, be professional, and get straight to the point.

Here’s a simple email template I've adapted over the years. It works because it’s clear and shows you mean business.

Subject: Inquiry for Wholesale Blank Apparel – [Your Brand Name]

Hello [Supplier Contact Name],

My name is [Your Name] from [Your Brand Name], an apparel company based in [Your City/State]. We're currently sourcing a new supplier for premium blank t-shirts for our upcoming collection.

We're looking for a 100% ring-spun cotton, heavyweight tee around 220 GSM in black, white, and one custom Pantone color. Our initial order would be around 250 units across sizes M, L, and XL.

Could you please provide some information on:

- Your pricing tiers for this style.

- Your Minimum Order Quantity (MOQ).

- The process and cost for ordering samples.

- Your typical production lead time for an order of this size.

Thanks for your time. I look forward to hearing from you.

Best,

[Your Name]

[Your Brand Name]

[Your Website]

This isn't just an email; it’s your first move. It tells the supplier you know what you want and positions you as a valuable potential client, which usually gets you a much better response.

The Art of the Sample Order

I’ll say this as clearly as I can: Never, ever place a bulk order without getting a physical sample first. Website photos can be deceiving. A sample is the only way to know what you’re really getting. It’s where their marketing claims meet cold, hard reality.

When the samples arrive, don’t just give them a quick look. Put them through their paces. This is your chance to really dig in before you commit serious cash.

Here's what to look for on your inspection checklist:

- Fabric Hand-Feel: Does it actually feel premium? Is the texture right for your brand? Feel it, stretch it, hold it up to the light.

- Stitching and Construction: Flip it inside out. Check the seams on the collar, sleeves, and hem. Are the stitches tight and straight? Any loose threads or sloppy work is a bad sign.

- Color Accuracy: Compare the fabric color to your Pantone swatches. Look at it in different lighting—sunlight, office light—to see if the color shifts.

- Fit and Sizing: Try it on yourself or get a fit model. Does it match their size chart? Sizing consistency is everything for keeping customers happy.

The All-Important Wash Test

This is the moment of truth. A t-shirt can look perfect right out of the box but turn into a shrunken, twisted mess after one trip through the laundry. This test reveals the garment's true quality.

Here’s how to do it right:

- Measure Before: Lay the shirt flat and measure the chest width (pit to pit), body length (collar to hem), and sleeve length. Write it down.

- Wash and Dry: Follow the care label. To really push it, use a warm wash and a medium-heat dry cycle.

- Measure After: Remeasure the same points. High-quality fabric shouldn't shrink more than 5%. Anything above that is a major red flag.

- Inspect for Changes: Did the color fade? Did the side seams twist? A well-made garment will hold its shape and color.

A sample that fails the wash test is an instant disqualification. No exceptions. This one simple step can save you from a customer service nightmare. For brands just starting out, it helps to know how the pros handle quality control. You can get a feel for this in our guide about finding great custom shirt services near you, which covers similar principles.

By combining professional outreach with a meticulous, hands-on sample evaluation, you’ll build a vetting process you can count on. It's this diligence that ensures you find a partner who can deliver the quality your brand and your customers deserve.

Navigating Pricing, MOQs, and Payment Terms

Once you've given the green light on samples, the conversation pivots to what really matters for your bottom line: money. This is where a good partnership becomes a great one. The pricing and terms you lock in now will directly shape your brand's profitability and cash flow for the foreseeable future.

Understanding the Numbers Game

Most suppliers live by a tiered pricing model. It's simple: the more you buy, the less you pay per piece. For a small brand, this can feel like you're on the back foot, but it also gives you a clear roadmap for improving margins as you scale.

For instance, a supplier might quote $6.00 per shirt for 50 units, but that could drop to $5.25 for 250 units and even $4.50 for 1,000 units. This isn't arbitrary; it's directly tied to their Minimum Order Quantity, or MOQ. The MOQ is the smallest batch a factory will run to cover their own costs for materials, machine setup, and labor.

How to Negotiate MOQs Without Walking Away

A high MOQ can feel like a brick wall for a new brand. Taking a gamble on 500 units of a single style right out of the gate is a huge financial risk. But if a supplier's MOQ seems out of reach, don't give up just yet. If you've built a solid, professional rapport, there’s almost always some wiggle room.

Here are a few tactics I’ve seen work wonders:

- Pitch a Trial Order. Ask if they’d be open to a smaller, one-time run, even if it’s at a slightly higher per-unit cost. Frame it as a way for you to "test the market" with their product before you commit to their standard MOQ on your next order.

- Split the MOQ Across Variations. Find out if the MOQ is per style or for the total order. Many suppliers will let you meet a 300-unit MOQ by ordering 100 units of three different colors, which is a much easier pill to swallow.

- Show Them Your Vision. Share your business plan or realistic sales projections. If you can paint a clear picture of future, larger orders, they’re far more likely to be flexible with your first one.

Don't Get Blindsided by Hidden Costs

One of the costliest mistakes I see new brand owners make is getting fixated on the per-unit price. To really know if you're making money, you have to calculate your total landed cost—the final, all-in price to get that garment from their factory to your door.

Your landed cost is much more than the sticker price. It includes:

- The per-unit cost of the apparel

- Shipping fees (air freight is fast but expensive; sea is slow but cheaper)

- Customs duties and import taxes

- Insurance or brokerage fees

That shirt that looks like a steal at $4 from an overseas supplier can easily end up costing you over $7 by the time it’s actually in your hands.

Pro Tip: Never move forward without a detailed quote that estimates shipping and duties. This simple step prevents sticker shock down the road and lets you calculate your true cost of goods sold (COGS) from day one.

Mastering Payment Terms for Better Cash Flow

Finally, let’s talk about how you actually pay. For new customers, the industry standard is often 100% payment upfront. This makes sense for the supplier, but it can be a massive drain on a small business’s cash flow.

A much better, and often negotiable, arrangement is a 50/50 split: 50% upfront to kick off production and the final 50% when the goods are ready to ship. This is a common and fair compromise, especially after you've approved a sample order. It proves you're a serious buyer while letting you hold on to half your cash until the product actually exists.

As you build a solid track record of on-time payments, you can often negotiate even better terms, like Net 30 (payment due 30 days after you receive the goods). Exploring options like supply chain finance can also help bridge payment gaps, creating more stability for both you and your supplier. Getting your financial strategy right is every bit as important as the quality of the tees themselves.

Streamlining Your Production and Logistics Workflow

Okay, you’ve placed the order. That's a huge step, but the work isn't over yet. The real secret to making good money and keeping your sanity is nailing down a smooth, predictable workflow for production and logistics. This is the part that separates brands that scale from those that get stuck in a cycle of expensive mistakes and delays.

It all starts with crystal-clear communication, way before a single yard of fabric is cut. Any gray area in your instructions is just asking for trouble. This is why a detailed technical specification sheet—what we call a "tech pack"—is absolutely non-negotiable.

The Power of a Perfect Tech Pack

Your tech pack is the official blueprint for your apparel. It’s a document that leaves zero room for guessing, telling the supplier everything they need to produce your blanks exactly how you want them. Vague requests get you inconsistent products. A solid tech pack gets you uniform quality across every single piece.

Think of it as your ultimate instruction manual. A good one should always include:

- Detailed Garment Sketches: Front, back, and side views showing every seam and detail.

- Exact Measurements: A full spec sheet with grading for all sizes (chest, length, sleeve opening, etc.).

- Fabric Specs: Composition (100% combed cotton, for example), weight (GSM), and specific color codes (Pantone is the standard).

- Construction Details: Stitch types (like a double-needle stitch), thread color, and any special finishing touches.

- Labeling Info: Where you want your neck labels or care tags, and what kind.

A well-crafted tech pack does more than just prevent errors—it signals to wholesale blank apparel suppliers that you are a professional who knows the game. This builds instant credibility and sets the stage for a much smoother partnership.

A clear tech pack is your insurance policy against misinterpretation. To make sure you're covering all your bases, here's a sample checklist of what should be in your technical specifications.

Sample Technical Specification Checklist

This table breaks down the critical details you need to provide. The more specific you are, the less chance there is for costly errors.

| Specification Category | Key Details to Include | Example |

|---|---|---|

| Garment Overview | Style Name/Number, Garment Sketch (Front/Back/Side), Description | Style #H101, "Heritage Heavyweight Tee," Classic fit, crew neck. |

| Fabric | Composition, Weight (GSM), Weave/Knit, Color (Pantone Code) | 100% Combed Ringspun Cotton, 240 GSM, Jersey Knit, Color: Pantone 19-4052 TCX. |

| Measurements | Point-of-Measure (POM) chart with full grading for all sizes | Chest (1" below armhole), Body Length (HPS), Sleeve Length. Graded for S-XXL. |

| Stitching & Seams | Stitch Type (SPI - stitches per inch), Thread Color, Seam Type | Double-needle stitching on hem and sleeves, 10 SPI, matching thread color. |

| Labels & Tags | Type (woven, screen printed), Placement, Dimensions, Artwork | Woven neck label, 1.5" x 2.5", centered 0.5" below collar seam. |

| Finishing & Packaging | Wash Instructions, Folding Method, Polybag Size, Carton Specs | Garment washed for softness. Folded once, packed in individual 10"x12" polybags. |

Treat this like a contract. If it's not in the tech pack, you can't expect the factory to produce it.

Smart Strategies for Cost Optimization

Once your blank apparel arrives, it's time for customization. How you handle this can make or break your profit margins. For brands using Direct-to-Film (DTF) printing, one of the smartest cost-saving moves is to use gang sheets.

Instead of printing one design at a time, a gang sheet lets you cram multiple designs onto a single large transfer film. You can mix and match—different designs, same design in different sizes, you name it. Services like Raccoon Transfers have online builders that make this super simple. By filling the sheet, you use every square inch of the material, which can easily cut your printing cost per graphic by 50% or more.

This is perfect for things like:

- Front Chest and Sleeve Logos: Pair a big back graphic with smaller chest logos and sleeve hits on the same sheet.

- Fulfilling Small Orders: Group designs for a few different customer orders together to hit your print minimums without waste.

- Creating Neck Tag Transfers: Throw your branded neck tags onto the sheet with your main designs and avoid a separate print run.

Navigating the World of Logistics

Finally, you have to get the goods from the factory to your door. This last leg is all about logistics, and your choices here will directly impact your timeline and your budget.

When you're working with overseas suppliers, you're usually choosing between two main shipping methods:

- Air Freight: The fast option, typically taking 5-10 days. This is great for small, urgent orders or for getting your first samples quickly. That speed comes at a price, though—it's much more expensive.

- Sea Freight: This is way cheaper, especially for big, heavy shipments. The trade-off is time. Sea freight can take anywhere from 30 to 60 days, so you have to plan your inventory carefully to avoid selling out.

Don't forget about customs. Every country has its own rules, taxes, and duties for imported goods. A good supplier or a freight forwarder can help you estimate these, so your "total landed cost" is accurate. Factoring these steps in is crucial for setting realistic launch dates and keeping your customers happy. This is also a huge deal in growing markets like secondhand apparel, which is projected to hit $260.24 billion by 2025. Those businesses thrive on having a dialed-in supply chain, and you can read more about trends shaping the wholesale industry on Bankvogue.

Got Questions About Sourcing Wholesale Apparel?

Diving into the world of wholesale blank apparel can feel like you're trying to read a foreign language. It's totally normal to have questions, especially when you've got your own money and brand reputation on the line. Let's walk through some of the biggest hurdles I see new brand owners face.

These aren't just hypothetical problems. They're the real-world roadblocks that can stop a great idea in its tracks. Getting these things right from the start will make your journey from a cool concept to a finished product so much smoother.

What’s a Realistic Budget for a First Wholesale Order?

This is the big one, but the honest answer is: it depends. Your budget is tied directly to your supplier's minimum order quantity (MOQ) and the quality of the garments you've chosen. There isn't a single magic number, but we can definitely break it down into realistic starting points.

If you're working with a domestic supplier that has a friendly, low MOQ—say, in the ballpark of 24 to 50 pieces—you could get your first run off the ground with a budget between $500 and $1,500. This is a smart way to test the waters without taking a massive financial plunge.

On the other hand, if you’re sourcing internationally to get a better per-piece price, the game changes. Their MOQs are often much higher, frequently starting at 100 units or more. For an order that size, you should be prepared to invest anywhere from $2,000 to $5,000. And remember, that figure doesn't even include the cost of shipping and customs.

Pro Tip: Always, always set aside a separate budget of $100-$300 just for ordering samples. On top of that, add a 20% buffer to your main order budget. You'll be glad you did when you have to cover unexpected shipping hikes or customs fees.

How Do I Make Sure Quality Stays Consistent on Future Orders?

Getting one perfect batch of tees is great. Getting consistent quality order after order is what builds a real brand. The secret is establishing a clear standard right from the beginning. Your most powerful tool here is what we call a "golden sample."

This isn't just any sample. It's the one physical, approved garment that you and your supplier agree is the absolute benchmark for your product. It's the gold standard.

From that point on, you need to reference this golden sample in every single purchase order you send. This makes it a binding part of your agreement. For larger runs, especially from overseas factories, it's often worth hiring a third-party inspection service. They can physically check your inventory before it ships, catching problems at the source. For smaller domestic orders, a thorough spot-check when the boxes arrive usually works just fine.

Ultimately, a strong relationship is your best defense. A supplier who wants to keep your business is going to be invested in getting it right every time.

Should I Use a Domestic or International Supplier?

There's no single right answer here. It all boils down to what you value most for your brand right now: speed, cost, or simplicity.

- Domestic Suppliers: You're going to get much faster shipping, way easier communication (no 3 AM calls to a different time zone!), and typically lower MOQs. The trade-off? A higher cost per garment.

- International Suppliers: The main draw here is the significantly lower cost per piece, which is why brands looking to scale their margins go this route. But this comes with a price of its own: long shipping times, potential language barriers, and the headache of customs clearance.

A lot of new brands find a sweet spot with a hybrid model. Start with a domestic supplier to get your first products out fast and build some momentum. Once your sales volume is strong enough, you can make the move to an international partner to improve your profit margins.

What Are the Biggest Mistakes New Brands Make?

Learning from someone else's expensive mistake is the cheapest education you can get. The most common pitfall I see is brands skipping the sample phase entirely. They see a nice photo on a website, get excited, and place a huge order. It almost never ends well.

Another classic error is underestimating the "total landed cost." It's easy to get fixated on a low per-unit price, but many first-timers forget to account for shipping, customs duties, and taxes. These can easily add 30-50% to your final bill, completely wrecking your budget.

Finally, vague instructions are a one-way ticket to disappointment. Your tech pack needs to be painfully specific. Every detail matters—fabric GSM, stitch type, Pantone colors, exact measurements. The more specific you are, the less room there is for your supplier to guess, and the more likely you are to get exactly what you paid for.

Ready to bring your designs to life on some high-quality blanks? At Raccoon Transfers, we specialize in vibrant, durable DTF transfers that make customization simple and cost-effective. Build your gang sheet online, get next-day shipping, and see why brands trust us for their printing needs. Start creating your custom transfers today!