The Best Blank T Shirts for Printing in 2024

Share

If you've ever printed a killer design only to have it ruined by a cheap, scratchy t-shirt, you know that the blank you choose is everything. When people ask me for the best blank t shirts for printing, I usually point them toward 100% ringspun cotton for its incredibly smooth printing surface. Think of brands like the Bella+Canvas 3001—it’s a workhorse for a reason. But for a softer, more vintage vibe, a high-quality blend can be perfect.

Ultimately, the "best" shirt isn't a one-size-fits-all answer. It’s a careful balance between the fabric, how the shirt is built, and the brand's track record.

Your Guide to the Best Blank T Shirts for Printing

Choosing the right blank is the bedrock of any custom apparel project. A phenomenal design printed on a subpar garment will always look and feel cheap, which tanks customer satisfaction and hurts your brand's reputation. This guide will walk you through the essential factors that separate a great blank from one that’s just... okay.

We're going to get practical, focusing on how your choice directly impacts popular printing methods like DTF (Direct to Film). Getting these fundamentals right from the start will save you a ton of headaches and help you make smart decisions that elevate your apparel line.

Key Factors for Selecting Print-Ready Blanks

The demand for quality blank tees is massive—the global industry is valued at roughly $330 billion. That number tells you just how much the t-shirt is relied on as the ultimate canvas for creativity. The most popular options are 100% cotton and cotton-polyester blends, with cotton leading the pack because it just prints so well and feels great. If you want to dig deeper, you can explore more apparel industry trends and statistics to see just how big this market is.

To cut through the noise, let's simplify your selection process by focusing on three core criteria:

- Fabric Composition: This is the big one. The material dictates how well ink or adhesive sticks, the final texture of your print, and how the shirt feels against the skin.

- Garment Construction: How a shirt is sewn together matters more than you'd think. It affects fit, durability, and whether it feels like a premium retail product or a cheap promo item. Side seams, for example, make a world of difference.

- Brand Reputation & Consistency: Working with a reliable brand means you get consistent sizing, color, and quality from one order to the next. This is non-negotiable for building a serious apparel business.

For printers, consistency is currency. A t-shirt that prints perfectly one time but inconsistently the next is a liability. Choosing a reputable brand known for tight quality control is non-negotiable for scaling your operations.

To help you get started, I've put together a quick cheat sheet. This table breaks down what to look for in each of these areas and gives you a clear framework for the more detailed comparisons we'll get into later.

Quick Guide to Selecting T-Shirts for Printing

| Selection Factor | What to Look For | Why It Matters for Printing Quality |

|---|---|---|

| Fabric Composition | 100% ringspun cotton for crisp detail; 50/50 blends for a vintage feel; Tri-blends for a soft, heathered look. | A smooth, tight-knit surface ensures ink adheres evenly and details remain sharp. Polyester content can affect ink bonding and may require special transfers. |

| Shirt Construction | Side-seamed construction for a retail-quality, structured fit; tear-away tags for easy rebranding. | A well-constructed shirt provides a better canvas for printing. Tubular shirts can twist after washing, distorting the print. |

| Brand Reputation | Brands known for consistent sizing, colorfastness across dye lots, and reliable stock levels. | Consistency ensures that a design printed today will look the same on a shirt ordered six months from now, protecting your brand's quality standards. |

Think of this table as your starting point. As you evaluate different blanks, keep coming back to these three pillars—fabric, construction, and brand—and you’ll be well on your way to choosing a shirt that makes your designs shine.

Choosing the Right Fabric for Flawless Prints

The fabric of a blank t-shirt is the foundation for everything. It dictates the print quality, how the final garment feels against the skin, and how long it holds up. Think of it as the canvas for your art—picking the right one ensures your design looks exactly as you envisioned and survives countless wash cycles.

This decision is about more than just "cotton or poly." It's about understanding how different fibers and weaves interact with the adhesives and inks in your transfers. A smooth, tightly knit fabric gives you a perfect surface for razor-sharp details, whereas a looser weave might be just what you need for a vintage, lived-in vibe. This is a key principle that extends beyond just printing; as guides on how to select apparel for photoshoots explain, the material fundamentally shapes the final look.

The Industry Standard: 100% Cotton

When it comes to printability, 100% cotton is still king, especially for detailed DTF transfers. But here’s the thing: not all cotton is the same. The real difference is in how the raw cotton fibers are processed before being spun into thread.

-

Carded Open-End Cotton: This is your basic, budget-friendly option. The fibers are shorter and less uniform, creating a slightly rougher texture. It's fine for promotional giveaways or simple, bold prints, but it doesn't have that premium feel or the super-smooth surface you need for high-end retail apparel.

-

Ringspun Cotton: This is the gold standard, and for good reason. The cotton fibers are twisted and thinned into a very fine, strong, and incredibly soft rope. This process results in a much smoother and more consistent surface, allowing DTF transfers to adhere perfectly for crisp, detailed prints with a soft hand-feel.

For any brand serious about quality, ringspun cotton is a must. Its ultra-smooth surface means DTF adhesives get a perfect bond, capturing every tiny detail of your design without the fabric's texture interfering.

The Polyester Problem: Dye Migration

On paper, 100% polyester is perfect for athletic and performance wear thanks to its moisture-wicking ability and durability. It makes colors pop and has a modern, sleek look. But printing on it comes with a major hurdle: dye migration.

During heat pressing, the heat can cause the dyes in the polyester fabric itself to turn into a gas. This gas can then seep into your transfer's ink and permanently stain it. Suddenly, your crisp white design on a red shirt turns a blotchy pink. To stop this, you absolutely must use DTF transfers made with a special dye-blocking layer. This barrier stops the fabric dye from bleeding through, keeping your print's colors true. To dig deeper, a good best fabric for t-shirts guide can offer more on this.

Finding the Sweet Spot with Blends

Blended fabrics are where you often find the perfect balance of feel, function, and cost. They combine the best traits of different materials and are extremely popular for their versatility, making them some of the best blank t-shirts for printing.

Here’s a quick rundown of the most common blends you'll encounter:

-

50/50 (Cotton/Polyester): The classic workhorse. This blend gives you the softness of cotton and the durability and wrinkle-resistance of polyester. It's a cost-effective choice that prints well, but keep in mind that dye migration can still be a risk on darker-colored shirts.

-

CVC (Chief Value Cotton): These are usually a 60% cotton and 40% polyester mix. CVC fabrics feel significantly softer than a standard 50/50. They hit that sweet spot between comfort and performance, making them a fantastic option for retail brands wanting to offer something better than a basic tee.

-

Tri-Blends (Cotton/Polyester/Rayon): This is the peak of softness and comfort. The rayon adds a unique, drapey quality and a slightly heathered, vintage look. While they feel amazing, the mixed texture can give prints a slightly faded or retro look right off the press—which is often exactly the desired effect.

How T-Shirt Weight and Construction Affect Quality

Fabric type is just the start. If you really want to understand a t-shirt's quality, you need to look at its weight and construction. These two factors are what truly define how a shirt feels, how it hangs on the body, and ultimately, how your customers perceive its value.

Getting this right is what separates the pros from the beginners. It's about moving past the simple "soft" or "heavy" descriptions and digging into the specs that actually dictate performance. Let's break down what fabric weight and construction really mean for your prints.

Decoding Fabric Weight: GSM and Ounces

Fabric weight is simply a measure of the material's density. In the U.S., you'll see it measured in ounces per square yard (oz/yd²), while the rest of the world uses grams per square meter (GSM). The higher the number, the heavier and thicker the shirt.

This single metric tells you a lot, from how opaque the shirt is to how substantial it feels. A heavier shirt feels more premium and is less likely to be see-through—a must-have for high-end streetwear or brand merch.

Here’s a practical way to think about the different weight classes:

-

Lightweight (Under 5 oz / ~140-160 GSM): Think soft, breathable, and drapey. These shirts are perfect for a fashion-forward, retail fit. They're great for summer lines, but they can be a bit tricky. You'll need a lighter touch with the heat press to avoid scorching the thinner material.

-

Midweight (5-6 oz / ~160-200 GSM): This is the sweet spot for most brands. It's the workhorse category, offering a fantastic balance of durability, substance, and comfort. A shirt like the classic Gildan Heavy Cotton provides a solid, stable surface that’s practically made for DTF printing—it handles heat well and holds up to endless washing.

-

Heavyweight (Over 6 oz / ~200+ GSM): These are built to last. Heavyweight tees are thick, sturdy, and have that classic, structured look popular in workwear, skate brands, and streetwear. The dense fabric gives you an amazing canvas for big, bold graphics that really pop. We explore this in our deep dive into the Gildan Heavy Cotton t-shirt, which is a true benchmark for this category.

When choosing a shirt's weight, always think about your customer and your design. A heavy, boxy tee is perfect for a loud graphic aimed at the streetwear crowd. On the other hand, a soft, lightweight shirt is a much better fit for a subtle, minimalist design for a lifestyle brand.

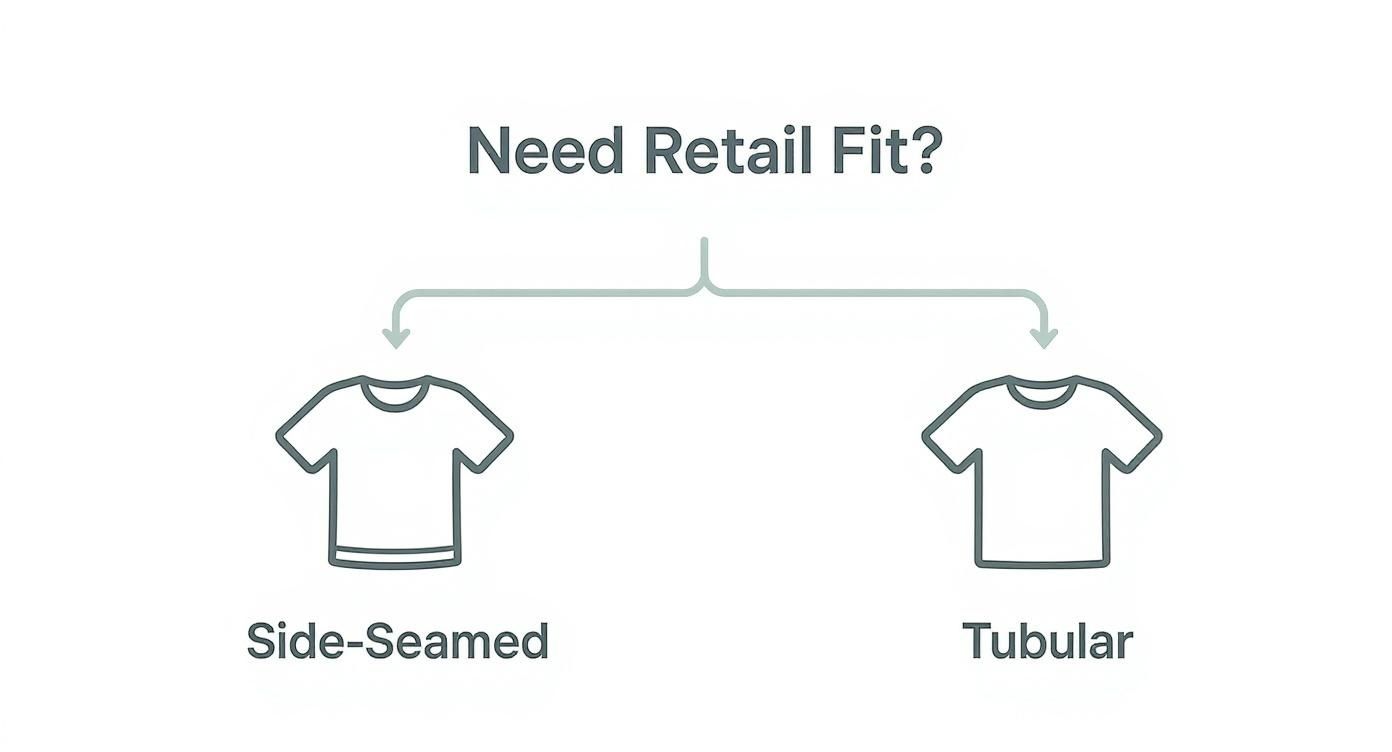

The Construction Debate: Side-Seamed vs. Tubular

How a t-shirt is put together is just as important as what it's made of. There are two ways to do it, and the difference in fit and quality is night and day.

Tubular Construction

This is the fast and cheap method. A machine knits a single "tube" of fabric, which is then cut to length, with sleeves and a collar sewn on. It’s efficient and creates less waste, which keeps costs down.

But that cost-saving comes at a price. Tubular shirts have a generic, boxy fit that doesn't follow the shape of a human body. Worse, they have a nasty habit of twisting after a few washes, which can completely distort your print. They’re fine for one-off promotional events, but not for a brand that cares about quality.

Side-Seamed Construction

This is how proper retail garments are made. The front and back panels are cut separately and then sewn together along the sides.

This construction method results in a significantly better, more tailored fit that hangs correctly. For printers, the stable structure of side seams is a game-changer; your design stays perfectly straight and centered, even after dozens of washes. Yes, they cost a little more, but the superior fit and durability make side-seamed tees the best blank t shirts for printing for any serious apparel line. It’s a non-negotiable for building a reputable brand.

Comparing the Top T-Shirt Brands for Printing

Picking the right blank t-shirt brand is about more than just the shirt itself. It's a strategic move that affects your quality, consistency, and bottom line. A supplier that can deliver the same size and color shade with every single order is just as critical as the softness of the fabric.

This breakdown gets into the nitty-gritty of the industry's most trusted names: Bella+Canvas, Next Level, Gildan, and Comfort Colors. We'll look at them through the lens of a print shop owner, focusing on fabric smoothness, color reliability, fit consistency, and overall value. The goal is to help you zero in on the best blank t-shirts for printing, whether you're launching a premium clothing line or knocking out a massive promotional order.

Bella+Canvas: The Retail-Quality Standard

Bella+Canvas has cemented its reputation as the brand of choice for anyone chasing that premium, fashion-forward feel. Their flagship tee, the Bella+Canvas 3001, is a legend in the industry for its incredibly soft touch, modern fit, and a staggering color palette of over 100 options.

Their secret sauce is the 100% Airlume combed and ringspun cotton. This process creates a super smooth, tight-knit surface that’s an absolute dream for DTF transfers. You'll capture even the finest details with stunning clarity. All their solid color shirts feature a side-seamed construction, giving them a structured, retail-ready fit that lets you charge a higher price. It also stops the shirt from twisting after a wash, a common problem with cheaper, tubular-knit tees.

Of course, this level of quality comes with a higher price tag. It's the perfect choice for established brands and high-end merch, but the cost might be a tough pill to swallow if you're competing on volume or targeting the promotional market.

Next Level Apparel: The Versatile Contender

Next Level occupies that sweet spot right in the middle, offering a fantastic mix of quality, comfort, and value. Think of them as a direct competitor to Bella+Canvas, but often at a slightly more wallet-friendly price. Their wildly popular Next Level 3600 is a favorite for its soft ringspun cotton and slightly more athletic cut.

But where Next Level really shines is with its fabric blends. Their CVC (chief value cotton) and tri-blend tees are exceptionally soft and deliver that perfect vintage, heathered look that's so popular with lifestyle and fitness brands. Their solid consistency in sizing and quality makes them a reliable workhorse for growing businesses.

While their fabric is great for printing, some veterans in the industry might argue that Bella+Canvas has a marginally smoother print face on its core cotton styles. The difference is subtle, but if your designs rely on ultra-fine lines, it’s something to consider.

Situational Recommendation: If your brand is all about a modern, athletic fit and you need access to high-quality, soft blends without paying top-dollar, Next Level Apparel strikes the perfect balance.

Gildan: The Workhorse for Volume

When it comes to sheer volume, Gildan is an absolute powerhouse. Known for durability, affordability, and being available pretty much everywhere, it's the default choice for promotional products, large events, and workwear. The Gildan 5000 (Heavy Cotton) is a classic—a sturdy, reliable canvas for printing.

These shirts are built for cost-effectiveness, using carded open-end cotton and a tubular knit. The trade-off is a less-than-retail fit and a fabric surface that isn't as smooth as its ringspun competitors. You might lose some of the finer details in your designs, but for bold graphics, text, and logos, they perform perfectly fine.

The main selling point here is the price. For bulk orders where the budget is the number one concern, Gildan delivers a dependable product that gets the job done without draining your bank account. Their consistency across massive production runs is another major plus.

This diagram helps visualize the fundamental choice between a fashion-focused fit and a more basic, cost-effective one.

The image makes it clear: if a tailored, modern silhouette is a must-have for your brand, you absolutely need to go with a side-seamed construction.

Comfort Colors: The Niche for Vintage Aesthetics

Comfort Colors has totally cornered the market on garment-dyed apparel. By dyeing the shirt after it’s been sewn together, they achieve a soft, broken-in feel and a subtly faded, vintage color palette that you just can't get with standard dyeing methods.

Their shirts, like the fan-favorite Comfort Colors 1717, are typically heavyweight and made from ringspun cotton. This gives you both a substantial feel and a good print surface. They are the perfect blank for brands aiming for that relaxed, coastal, or retro vibe. In fact, their unique colors and textures can become a signature element of a brand's identity.

The key thing to remember with Comfort Colors is their specific niche. The color palette is intentionally muted, not bright and poppy like other brands. The fit is also generally more relaxed and boxy. This makes them a poor choice for corporate or athletic wear, but an absolute slam dunk for boutique brands with a strong visual theme.

To wrap it all up, let's put these brands head-to-head.

Feature Comparison of Popular Blank T-Shirt Brands

Here’s a side-by-side look at how these leading brands stack up based on what matters most for your printing business. This table should help you quickly see the strengths and weaknesses of each one.

| Brand | Best For | Fabric Quality & Feel | Printability (DTF/UV-DTF) | Price Point |

|---|---|---|---|---|

| Bella+Canvas | Premium retail & fashion brands | Exceptional. 100% Airlume combed & ringspun cotton. Very soft, tight weave. | Excellent. The super-smooth surface holds fine details beautifully. | Premium |

| Next Level | Lifestyle, fitness & mid-tier brands | Great. Very soft ringspun cotton and popular blends (CVC, tri-blends). | Very Good. Smooth surface, great for most designs. Slightly less refined than Bella+Canvas. | Mid-Range |

| Gildan | Promotional, events & budget-focused orders | Good. Durable and sturdy carded open-end cotton. Not as soft. | Good. Best for bold graphics and text. Not ideal for hyper-detailed artwork. | Budget |

| Comfort Colors | Boutique, vintage & niche lifestyle brands | Excellent. Soft, heavyweight ringspun cotton with a unique broken-in feel. | Very Good. The ringspun surface prints well, but the garment-dye can affect colors. | Mid-to-Premium |

Ultimately, the "best" brand really depends on who you're selling to, your design style, and your budget. There's no substitute for getting your hands on the real thing. Ordering samples from each is the single most effective way to decide which will become your go-to blank.

Perfecting Your Printing Workflow from Prep to Press

Picking out the perfect blank t-shirt is a great start, but it's only half the journey. The real magic, the thing that turns that quality blank into a sellable, professional product, happens in your workflow. This is where you build consistency and sidestep the common mistakes that can ruin a batch of shirts.

A disciplined process, from how you store your shirts to the final press, is what separates the pros from the hobbyists. Let's walk through the practical steps that will ensure you get top-notch results every single time.

Pre-Production Garment Prep

Your workflow kicks off the second those boxes of blanks arrive. Proper storage is something a lot of printers overlook, but it's crucial. Keep your t-shirts in a dry, climate-controlled space to stop them from absorbing moisture. Humidity is the absolute enemy of a good DTF application.

This brings us to the most critical prep step of all: the pre-press. Before you even think about laying down a transfer, press the blank shirt by itself for 5-10 seconds. This simple move zaps out any lingering moisture and flattens wrinkles, creating a perfect canvas for the transfer's adhesive to grab onto. Skipping this is the number one reason I see for transfers peeling later on.

Once your shirts are prepped, it's time to think about working smart, especially if you're using gang sheets.

- Maximize Your Film: Group designs for different jobs onto one sheet. A well-planned gang sheet is a game-changer for reducing your cost per print.

- Leave Room for Cutting: Don't jam designs right up against each other. Give yourself enough of a border to easily cut each graphic out without accidentally nicking the one next to it.

- Organize by Job: If you can, keep all the graphics for one order in the same area of the sheet. It makes production so much smoother and helps prevent mix-ups.

Dialing in Your Heat Press Settings

The heat press is where it all comes together, but winging your settings can lead to disaster. Temperature, pressure, and time have to be calibrated for the exact fabric you're working with. The settings for a 100% cotton tee will scorch a delicate tri-blend in a heartbeat.

A huge mistake I see people make is using a one-size-fits-all approach to pressing. Always start with the settings recommended by your transfer supplier. From there, do a few test presses on scrap fabric to fine-tune them for your specific shirt and even the conditions in your shop that day.

Here are some good starting points, but always double-check with your transfer provider:

- 100% Cotton: These can take the heat. You're usually looking at 300-320°F (149-160°C) for about 10-15 seconds with medium-to-firm pressure.

- Polyester & Blends: Much more sensitive. Back the temperature down to 260-280°F (127-138°C) for 8-12 seconds with medium pressure. This helps you avoid scorching and dreaded dye migration.

- Tri-Blends: Handle these with care. Go low and slow: around 250-270°F (121-132°C) for just 7-10 seconds with light-to-medium pressure.

Getting to know the quirks of your own equipment is essential. For a deep dive, our guide on how to properly heat press transfers breaks down the process for different materials in detail.

Post-Press Quality Control and Wash Testing

After you've pressed the transfer and peeled the film, you're not quite done. Do a final post-press for 3-5 seconds with a protective sheet (parchment paper works great). This extra step helps lock the design into the fabric fibers, making it more durable and giving it a softer, more matte finish.

The last thing to do is a solid quality check. Scan the shirt for any peeling edges or discoloration. But the real proof is in the wash.

A true quality test isn't just one wash cycle. Throw a sample shirt through at least 5-10 washes—inside out, cold water—to see how the print really holds up over time. This is the only way to be totally confident that you're shipping a durable product that will have customers coming back for more. This kind of rigorous testing is what confirms you've truly found the best blank t-shirts for printing and have perfected the process to match.

Common Questions About Printing on Blank T-Shirts

When you're getting into apparel, you're bound to have questions. It's totally normal, especially when your brand's quality and consistency are on the line. Getting straight answers is the best way to dodge expensive mistakes and pick your blanks with confidence. This section cuts through the noise to answer the most common questions we hear about choosing and printing on tees.

We'll cover the real-world advice you need to get over those initial hurdles—from finding the right fabric for your specific project to understanding how a shirt's color can completely change your final print. Think of this as your go-to guide for troubleshooting and dialing in your process.

What Is the Absolute Best Fabric for DTF Printing?

Everyone wants to know the "best" fabric, but the real answer always comes down to what you're making. For retail-quality prints with sharp details, 100% ringspun cotton is king. Its smooth, tight knit is the perfect canvas for DTF adhesives, letting you capture incredibly fine lines and crisp edges. If you’re aiming for a premium feel, you can’t go wrong with it.

But the right choice shifts depending on the garment's purpose. For activewear that needs to handle sweat, 100% polyester is the obvious winner. The catch is you'll need DTF transfers made with a special dye-blocking layer. Without it, the fabric’s color will bleed right into your design during pressing—a costly mistake.

And if you’re chasing that soft, vintage vibe? Tri-blends are fantastic. They create a comfortable, lived-in feel right off the bat. Just know that the print will take on a slightly heathered, retro look, which is usually exactly what designers are going for with this fabric.

The key takeaway is to align your fabric choice with your product's function and your brand's identity. The best blank t shirts for printing are the ones that perfectly serve the end customer's needs.

Do I Need to Pre-Treat Shirts Before DTF Printing?

Nope. And that's one of the biggest reasons people love Direct to Film (DTF). It's a huge step up in efficiency from older methods like Direct to Garment (DTG) printing, where pre-treating the fabric with a liquid solution is a mandatory, messy step.

With DTF, the magic happens on the film, not the shirt. Your design is printed onto a special transfer film, and the adhesive powder is applied directly to the ink.

From there, you just press the finished transfer onto the t-shirt. This completely cuts out the pre-treatment stage, which means less labor, fewer chemicals, and a much faster workflow from start to finish.

How Does T-Shirt Color Affect Print Quality?

A shirt’s color is a huge factor in how your final print looks, affecting everything from vibrancy to technical issues like dye migration. DTF printing gets a major assist from its white underbase, which is what allows you to put bright, solid graphics on any color garment, even jet black.

The real challenge comes from dark polyester or poly-blend fabrics. When you apply heat, the dye in the fabric can turn to gas (a process called sublimation) and stain the ink in your transfer. That crisp white print on a red poly shirt can turn pink in a matter of seconds.

To stop this, you have to use DTF transfers made with a dye-blocking or anti-migration layer. This creates a barrier that stops the fabric dye from bleeding through. On light-colored cotton shirts, dye migration isn't a problem, so you can expect the most vibrant, color-true results.

Beyond the technical side of printing, many creators want to know how to turn their work into a business. For those ready to sell their products, there are many expert tips for selling clothes online that can help you get started.

What Are the Most Common Mistakes to Avoid?

When you're choosing blanks, a few common slip-ups can sabotage a great design and damage your brand's reputation. Getting this part right is crucial for long-term success.

Here are the mistakes we see most often:

- Choosing Price Over Quality: A cheap, flimsy shirt feels cheap, no matter how cool your design is. It leads to prints that peel, poor durability, and unhappy customers who won't be back.

- Mismatching Fabric to Function: Putting a streetwear design on 100% cotton is perfect. Using that same shirt for a marathon run? Not so much. The fabric has to make sense for how the customer will use it.

- Ignoring Construction: A cheap, boxy "tubular" tee saves a few cents but fits poorly and twists after washing. A shirt with side seams hangs better, looks more professional, and holds its shape.

- Skipping the Test Phase: Never, ever go straight to a bulk order without testing a sample first. You need to print it, press it, wash it, and wear it to make sure it holds up and meets your standards.

At Raccoon Transfers, we provide premium DTF transfers that make your designs shine on any garment. Our easy-to-use gang sheet builder and next-day shipping help you bring your creative vision to life without delay. Get your custom DTF transfers today!