Your Guide to the Gildan T-Shirt Heavy Cotton 5000

Share

When you hear someone mention a Gildan t-shirt heavy cotton, they're almost certainly talking about the Gildan 5000, which is arguably the most popular shirt in the market. It’s an absolute staple in the custom apparel world, and for good reason. Think of it as the reliable, go-to canvas for countless creators, especially when working with Direct-to-Film (DTF) transfers.

Why the Gildan 5000 is a Creator's Favorite

Ever bought a t-shirt from a local band, a small business, or a community event? Chances are, you were wearing a Gildan 5000. This shirt didn't become an industry workhorse by accident. It nailed the perfect formula: quality construction, a budget-friendly price point, and fantastic printability.

The Gildan Heavy Cotton T-Shirt 5000 is a dominant force in both print-on-demand (POD) and bulk custom apparel businesses. Its blend of durability, comfort, and affordability is tough to beat. The shirt’s build, featuring 100% preshrunk cotton and reinforced with double-needle stitching, means it can handle wear and tear, which ultimately leads to happier customers. You can dig deeper into why the Gildan 5000 is such a market leader.

To give you a clearer picture, here’s a quick rundown of what makes this shirt so well-suited for printing projects.

Gildan 5000 Heavy Cotton Key Features

This table breaks down the essential specifications that make the Gildan 5000 a top choice for custom printing projects.

| Feature | Specification | Benefit for DTF Printing |

|---|---|---|

| Fabric Weight | 5.3 oz. | Substantial enough to feel durable but not overly heavy, providing a premium feel. |

| Material | 100% Preshrunk Cotton | Creates a smooth, consistent surface for the DTF adhesive to bond securely. |

| Construction | Classic Fit | A universally flattering silhouette that appeals to a wide range of customers. |

| Reinforcement | Taped Neck & Shoulders | Prevents stretching around the collar, maintaining the shirt's shape after many washes. |

| Label | Tear-Away Tag | Allows for easy rebranding with your own custom labels without damaging the shirt. |

These features combine to create a reliable and consistent blank that you can count on for every order.

The Ideal Fabric for Printing

The real magic is in the fabric itself. The Gildan 5000 is made from 5.3 oz preshrunk 100% cotton. That specific weight is the sweet spot—it feels solid and high-quality in your hands but is still breathable enough for comfortable, everyday wear.

For DTF printing, this material is a dream to work with. The tight, smooth weave of the cotton allows the transfer’s adhesive to create a strong, even bond. The result? Vibrant colors, sharp lines, and designs that truly pop and last.

Key Takeaway: The 5.3 oz cotton weight hits the perfect balance. It’s sturdy enough for a premium feel and durable print, yet its smooth surface ensures your DTF transfers apply flawlessly without cracking or peeling.

Built for Consistency and Durability

Beyond the fabric, the shirt’s construction is all about reliability. Its classic fit is a comfortable, familiar shape that works for just about everyone, which makes it a safe and smart choice when you're stocking inventory.

You'll also notice a few key details that contribute to its longevity:

- Taped Neck and Shoulders: This is a small but crucial feature that reinforces the seams, helping the shirt keep its shape over time.

- Double-Needle Stitching: Look at the sleeves and bottom hem—that extra stitching adds resilience where garments experience the most stress.

- Tear-Away Label: This is a huge plus for anyone looking to build their own brand, as you can easily remove the Gildan tag and add your own custom one.

These thoughtful construction details ensure your final product doesn't just look amazing right off the press but also holds up to real-world use. It’s this solid foundation that makes the Gildan t-shirt heavy cotton the right canvas for your creations.

Choosing the Right Color and Blend

Picking the right Gildan Heavy Cotton t-shirt is about more than just the design you plan to press on it. The shirt's color and material are the foundation, and they play a huge role in how your final DTF transfer looks and feels.

Sure, classic white is a foolproof option, but the Gildan 5000—probably the most popular blank tee on the market—comes in a massive range of colors that can really make your designs pop.

Think about contrast. A bright, colorful transfer is going to look incredible on a black or navy shirt. On the other hand, a more delicate, single-color graphic might stand out better on a lighter color like Carolina Blue or Sand. The trick is to get the shirt and the transfer to complement each other, not fight for attention.

How Fabric Blends Affect Your Press

While the Gildan 5000 is known for being 100% cotton, some specific colors are actually blended fabrics. This is a critical detail because different materials need slightly different heat press settings. Getting this right is the key to consistent, pro-level results every single time.

- 100% Cotton (Most Colors): This is the gold standard for DTF. Cotton takes heat like a champ and gives you a great surface for the transfer to adhere to. I usually start my press around 300-325°F for these.

- Ash Grey (99% Cotton, 1% Polyester): With just 1% polyester, you can treat this one just like a 100% cotton shirt. Your standard settings should work perfectly fine.

- Heather & Safety Colors (50% Cotton, 50% Polyester): Now this is where you need to pay attention. A 50/50 blend is much more sensitive to heat. If you go too hot, you risk scorching the polyester fibers. I recommend dropping your temperature to the 280-300°F range to play it safe.

If you're new to this and want to get the basics down, our guide on understanding DTF printing for beginners is a great place to start.

Sizing and Inventory Strategy

There's a reason the Gildan Heavy Cotton line has been a go-to for so long: the sizing is incredibly inclusive. The classic Gildan 5000 runs from Adult Small all the way up to 5XL, which means you can cater to just about everyone.

Over the years, they've also expanded their color options to 36 standard colors, making it a staple for anyone running a t-shirt business. You can see just how extensive the options are by checking out more details on Gildan's color and size availability.

Pro Tip: When you're buying inventory, don't try to stock every size equally. The data doesn't lie: Large (L) and Extra Large (XL) are almost always the top sellers, with Medium (M) and 2XL right behind them. Focusing your budget on these core sizes is a smart way to manage your stock and keep your customers happy.

How to Prep Your Shirt for a Perfect Press

A truly professional-looking shirt starts well before the transfer even touches the fabric. The prep work you do now is what makes the difference between a homemade look and a high-quality, sellable product. This is especially true for the Gildan 5000—it's a fantastic, reliable canvas, but you have to treat it right.

The first thing you absolutely must do is the pre-press. I know it’s tempting to skip, but don't. Every Gildan t-shirt heavy cotton has a surprising amount of hidden moisture trapped in its fibers, plus all those little wrinkles from being folded and shipped. If you press a transfer onto a damp, wrinkled shirt, the heat creates steam, and that steam is the enemy of good adhesion. It can lead to an uneven press and a transfer that starts peeling after the first wash.

A quick 5–7 second pre-press at your regular application temperature is all it takes. This simple step forces out moisture, flattens the fibers, and gives you a perfectly smooth surface to work with.

Nailing the Placement Every Time

Okay, the shirt is flat and dry. Now comes the moment of truth: placement. Just "eyeballing it" is a recipe for disaster. We've all been there—you finish a press only to realize the design is crooked or sitting way too high. It's a frustrating and costly mistake.

Luckily, there are a couple of tried-and-true tricks to get it right.

- The Three-Finger Rule: This is my go-to for quick chest placements. Just lay your hand flat below the collar seam. The spot just under your pinky is usually the sweet spot for the top of your design. It's fast, easy, and consistent.

- Use a Placement Guide: If you need absolute precision, nothing beats a t-shirt alignment tool or a simple ruler. These guides take all the guesswork out of finding the center line, ensuring your graphic is perfectly straight and centered every single time.

Taking just a minute to prep correctly ensures your DTF custom transfers look sharp and professional, giving you a result you can be proud of.

Mastering Your Heat Press Settings for DTF

Alright, this is where the magic happens—turning that blank Gildan Heavy Cotton T-shirt into a piece of custom apparel. Getting your heat press dialed in perfectly is the single most important factor for a DTF transfer that not only looks great but also lasts. Let’s get into the specific numbers and techniques I use for the Gildan 5000.

The fabric on these shirts is a solid 5.3 oz, 100% cotton, which is a fantastic canvas for DTF. I've found the sweet spot for temperature is right around 315°F. You have a little wiggle room, so aim for a range between 300-325°F (149-163°C).

For the timer, set it for 10-15 seconds. Pressing for too long can scorch the cotton, and going too short means you won't get a solid bond.

Dialing in the Perfect Pressure

We've all seen the vague "medium pressure" instruction, but what does that feel like? Here’s my rule of thumb: you should have to use a bit of muscle to close and lock the press, but you shouldn't be fighting it. It’s a firm, confident clamp down.

Consistent pressure is non-negotiable. If it's too light, the edges of your design might peel up later. If you go too heavy, you risk squishing the ink into the fabric, which can make your vibrant colors look dull. A quick check is to try and slide a piece of paper under the corner of the locked platen—if it slides out easily, you need more pressure.

The Art of the Cold Peel

Now for the part that requires a little patience: the cold peel. Unlike other transfer types, you absolutely cannot peel a DTF transfer while it's still warm. If you do, you're asking for lifted ink and a ruined shirt. It's the most common mistake I see people make.

Pro Tip: Seriously, just walk away. Let the shirt cool down to room temperature before you even think about touching the film. Go prep the next tee or grab a coffee. This cooling-off period allows the adhesive to fully set and bond to the cotton fibers, giving you that perfect, clean peel every time.

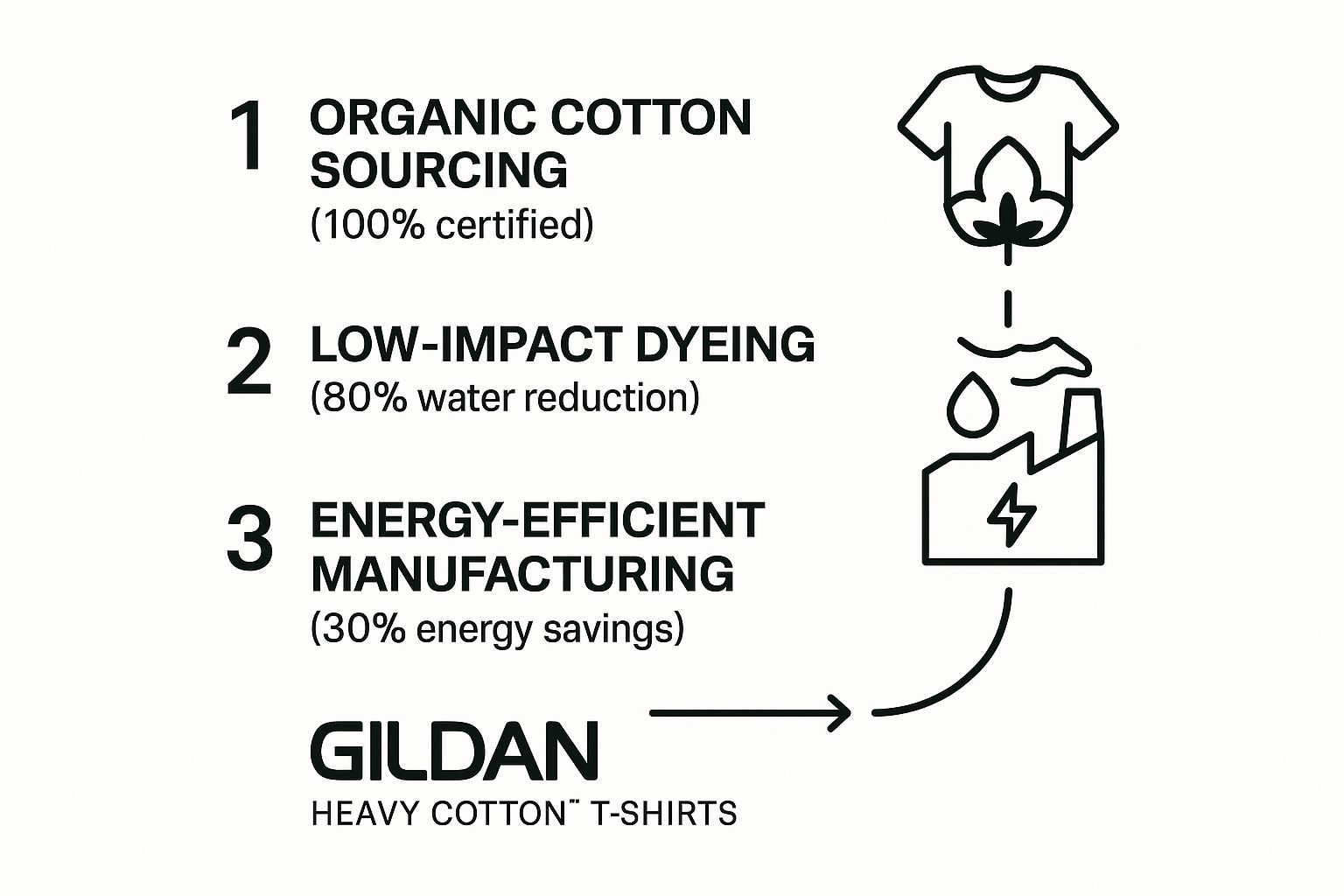

This graphic gives a great overview of how Gildan focuses on sustainable manufacturing for their heavy cotton tees.

It really breaks down their commitment to an eco-friendly process. If you want to get even more granular with settings for different fabrics, check out our complete guide on heat press settings for DTF.

Finishing and Caring for Your Printed Shirt

After the cold peel, your shirt is looking sharp, but we're not quite finished. There's one last step that truly separates a good print from a great one: the finishing press. Don't skip this—it makes a world of difference in the final feel and durability.

Just lay a sheet of parchment paper over the design and give it another press for about 5-7 seconds at the same temperature. This quick press accomplishes two key things. First, it knocks back any shine from the transfer, leaving a beautiful matte finish. Second, it pushes the ink even deeper into the fabric's fibers.

This simple trick seriously boosts the washability and gives the shirt a much more professional, screen-printed feel.

Long-Lasting Aftercare Instructions

You’ve just made a fantastic, durable Gildan T-Shirt Heavy Cotton, and the final piece of the puzzle is making sure it stays that way. Giving your customers (or yourself!) simple care instructions is a pro move that protects the design from cracking and fading.

Here are the essential tips I always share:

- Turn It Inside Out: This is non-negotiable. Washing the shirt inside out protects the print from rubbing against other clothes and the inside of the machine.

- Stick to Cold Water: Hot water is a print's worst enemy. It can fade colors and weaken the transfer over time. Cold water on a gentle cycle is the way to go.

- Go Easy on the Detergent: Harsh chemicals and bleach will break down the ink. Always recommend a mild, color-safe detergent.

- Hang Dry if Possible: High heat from the dryer is rough on DTF transfers. If you must use a machine, tumble dry on the absolute lowest setting. For maximum longevity, though, nothing beats air drying.

By taking a few extra seconds for a finishing press and passing along these care tips, you're ensuring every custom Gildan 5000—arguably the most popular shirt on the market—looks vibrant and feels great for years to come.

Working Through Common DTF Printing Hiccups

Even when you've done everything right, sometimes things just go a bit sideways. It happens. While starting with a solid, reliable blank like the Gildan T-Shirt Heavy Cotton is a huge advantage, DTF printing has its own unique personality. Let’s walk through a few common problems and how to fix them.

Why Is My DTF Transfer Peeling on a Gildan Heavy Cotton?

This is probably the most frustrating issue, but the fix is almost always simple. If your design is peeling or cracking, the culprit is usually one of three things: heat, pressure, or forgetting the final press. The Gildan 5000 is a thick, sturdy shirt, and that means the DTF adhesive needs enough heat and solid, even pressure to really work its way into those cotton fibers.

First, check your heat press settings. Are you in that sweet spot between 300-325°F? More importantly, did you do the second press? After your cold peel, you absolutely must cover the design with parchment paper and press it again for another 5-7 seconds. This is the step that melts the design into the fabric, giving it that soft feel and ensuring it lasts wash after wash.

Think of the second press as the final cure. It’s what separates a good-looking print from a great-feeling, long-lasting one. Don’t skip it!

Can I Get Away With Using a Home Iron on a Gildan 5000?

I get it, especially if you're just starting out or doing a one-off project. But for a professional result on a Gildan T-Shirt Heavy Cotton, a home iron just isn't going to cut it. The problem is that an iron can't provide the two things DTF needs most: consistent, even temperature across the entire design and heavy, uniform pressure.

What you end up with is patchy adhesion, corners that lift, and a print that will likely start to fail after the first wash. If you want to create products you can stand behind and sell with confidence, a heat press is a non-negotiable part of your toolkit. The Gildan 5000 is a top-tier blank; it deserves a professional application.

Do Heather Colors Need Different Heat Press Settings?

Yes, and this is a detail that trips up a lot of people! While most Gildan 5000 colors are 100% cotton, the heathers are a different beast entirely—usually a 50/50 cotton/polyester blend. Polyester is much more sensitive to heat and can easily scorch or develop that dreaded shiny "press box" if you're not careful.

For any of the heather variants, dial back your temperature to the 280-300°F range. It's always a good habit to run a quick test on a scrap piece of fabric or a misprinted shirt whenever you're working with a new blend. A few seconds of testing can save you a lot of frustration and wasted inventory.

Ready to create stunning, professional-quality custom apparel? Raccoon Transfers provides premium DTF transfers with next-day shipping, ensuring your projects are never delayed. Explore our easy-to-use Gang Sheet Builder and get started at Raccoon Transfers.