Heat Transfer vs Screen Printing Guide

Share

When you're trying to decide between heat transfer and screen printing, it really comes down to just two things: how many shirts you need and how complex your design is. Think of it this way: screen printing is the go-to workhorse for big jobs with simpler, limited-color designs. On the other hand, heat transfer shines when you need small batches or one-offs with intricate, full-color graphics.

Choosing Your Apparel Printing Method

Getting ready to create custom apparel? The first step is getting a handle on the real differences between heat transfer and screen printing. These two methods are worlds apart in how they get a design onto fabric, and each has its own sweet spot when it comes to cost, look, and feel.

Your choice here will ripple through the entire project, affecting your budget, the production timeline, and even how the final shirt feels and holds up after a few washes.

To make the right call, you have to think about scale and detail.

- Screen Printing: This is a classic, time-tested technique. It works by pushing ink through a mesh screen (like a stencil) directly onto the fabric. It’s built for cranking out large quantities efficiently, so your cost per shirt drops dramatically the more you order.

- Heat Transfer: This modern method involves printing your design onto special transfer paper or film first. Then, a heat press is used to bond that design onto the garment. It’s incredibly flexible, making it perfect for single items, small runs, and designs with photorealistic detail.

Many of today's print-on-demand businesses are built around digital methods like heat transfer. Looking at services like Printify, a popular print on demand platform, shows just how these newer methods stack up against traditional screen printing in the e-commerce world.

These are just two of many options out there. If you're serious about starting an apparel business, it's worth getting familiar with all the different ways to get a design on a shirt. We cover this in more depth in our guide to fabric printing techniques.

Heat Transfer vs Screen Printing Quick Comparison

To help you see the differences at a glance, we've put together a quick comparison table. This should give you a high-level view to help you decide which method fits your project's needs.

| Factor | Screen Printing | Heat Transfer |

|---|---|---|

| Best For | Large bulk orders (50+ items) | Small batches & single items |

| Design Complexity | Simple graphics, limited colors | Full-color photos, complex details |

| Durability | Very high, long-lasting | Good, but can crack over time |

| Cost Per Item | Decreases significantly with volume | Remains relatively consistent |

| Setup Cost | High (for creating screens) | Very low to none |

Ultimately, this table makes it clear: if you have a big order and a straightforward design, screen printing is tough to beat. But for smaller, more detailed projects, heat transfer offers the flexibility you need.

To really get a handle on the differences between heat transfer and screen printing, you have to look past the finished shirt and dig into how each method actually works. They both get a design onto a garment, but their processes are worlds apart, and that affects everything from setup time and cost to what the print feels like in your hand.

It’s these technical details that make one process perfect for a certain job and the other a better fit for something completely different. Nailing these down is how you make a smart choice that lines up with your order size, design complexity, and budget.

The Screen Printing Workflow

At its heart, screen printing is a classic, stencil-based craft. The whole process revolves around creating a separate screen for every single color in your design.

-

Screen Creation: First, a mesh screen is coated in a light-sensitive emulsion. The design is printed on a transparent film, which is then laid on the screen and hit with a powerful light. This light hardens the emulsion everywhere except where the design is, so when you wash the screen, a perfect stencil of your artwork remains.

-

Ink Application: The screen is then positioned over the garment. A thick, durable ink (usually plastisol) is poured onto the screen and pulled across with a squeegee. This pushes the ink through the open mesh of the stencil and directly onto the fabric, laying down one color of the design.

-

Curing: Once every color has been applied using its own screen, the garment goes for a ride through a big conveyor dryer. The heat cures the ink, creating a chemical bond with the fabric's fibers. This is what gives screen prints their legendary durability.

This whole setup process—making a screen for each color—is why screen printing has higher upfront costs. But once you're set up, it becomes an incredibly efficient and cheap way to print a lot of shirts.

The Heat Transfer Method

Heat transfer, particularly with modern methods like Direct-to-Film (DTF), is much more of a digital affair. Instead of making physical stencils, the design is printed onto a special carrier material first.

Key Insight: The fundamental difference is in how the design is applied. Screen printing forces ink into the fabric fibers, while heat transfer uses heat and pressure to bond a printed layer onto the surface of the fabric.

The process kicks off by printing the design onto transfer film or vinyl. The real work happens at the heat press. This machine clamps down on the garment with the transfer on top, using a combination of high heat—often up to 400 degrees Fahrenheit—and serious pressure to peel the design from its backing and lock it onto the shirt. If you want to see this in action, our guide on how to heat press breaks it down step-by-step.

The demand for on-demand, custom apparel has made this method explode in popularity. In fact, the global market for heat transfer materials is expected to reach USD 2.27 billion by 2034, a clear sign that this technology is here to stay.

Durability and Final Print Quality: How They Stack Up

Beyond the process and cost, the real test of any custom apparel is how it looks and feels after some wear and tear. This is where we get into the nitty-gritty of the heat transfer vs. screen printing debate: how long will the design last, and what does it feel like against your skin? The answer to both lies in how the design becomes one with the fabric.

When you screen print, the ink doesn't just sit on the surface; it penetrates and forms a chemical bond with the garment's fibers. It truly becomes part of the shirt. This deep integration is why screen-printed designs are so resilient, holding up against cracking, peeling, and fading wash after wash.

Heat transfers, on the other hand, typically create a distinct layer that rests on top of the fabric. While today's transfer technology is leaps and bounds ahead of what it used to be, this surface-level application can be more susceptible to the stresses of washing and wearing over time, especially if the care instructions aren't followed.

The Feel of the Print

The tactile quality of the print—what people in the industry call the "hand"—is a major point of difference. Because screen printing ink soaks right into the material, the final design feels incredibly soft and smooth. With certain inks, like water-based ones, you can barely feel the print at all.

Heat transfers, particularly older vinyl methods, can sometimes have a thicker, more plastic-like feel. This can make the garment a bit stiffer in that area and reduce breathability. However, modern techniques like Direct-to-Film (DTF) have changed the game, producing a much softer, more flexible result that gives screen printing a run for its money. You can dive deeper into this in our complete guide to DTF durability.

The Bottom Line: Screen printing is the heavyweight champion of durability. By embedding ink directly into the fabric, it's perfect for merchandise or uniforms that need to last. Heat transfers place the design on the surface, making them a fantastic, versatile choice for one-off gifts or short-term event apparel where extreme ruggedness isn't the top priority.

Real-World Longevity and Vibrancy

There's a reason screen printing dominates the decorated apparel world. It’s known for producing sharp, vibrant prints that can take a beating in the laundry. Heat transfers, in general, just can't match that long-term endurance and are more prone to peeling or fading down the road. This durability gap is precisely why over 60% of bulk custom T-shirts are made using screen printing.

If your project demands longevity—think daily work uniforms or merch for a band's year-long tour—screen printing is the clear winner. The colors stay bright and the print stays put, delivering a professional quality that endures.

But heat transfers have their own strengths. For a handful of shirts for a bachelorette party or a single, personalized gift, the durability is perfectly fine. The ability to print a full-color, photorealistic image for a special event often trumps the need for a design that will last a decade. It all comes down to what the job calls for.

Breaking Down the Costs and Turnaround Times

Let's be honest, for most projects, the final decision comes down to two things: how much it costs and how quickly you can get it done. The financial and time commitments for screen printing and heat transfer are worlds apart, and understanding the difference is key to picking the right method.

The Cost-Per-Shirt Breakdown

Screen printing is all about economies of scale. The big hurdle is the upfront setup cost. You have to create a custom screen for every single color in your design. That initial investment means printing just a handful of shirts is rarely worth it—the setup cost alone would make them incredibly pricey.

But once those screens are prepped and the press is running, the cost per shirt drops dramatically. This is why screen printing is the undisputed king for large orders. The more you print, the cheaper each individual shirt becomes.

Heat transfer works on the opposite principle. There are practically no setup costs, which makes it a fantastic choice for one-off designs, prototypes, or very small batches. The cost to produce the first shirt is the same as the cost to produce the twentieth. It’s a straightforward, pay-as-you-go model where labor and material costs stay consistent per item.

The Speed Equation: Setup vs. Production

When we talk about speed, it’s not just about how fast a single shirt is printed. You have to look at the entire process from start to finish.

Screen printing is a classic tortoise-and-hare story. The setup is the slow part—burning screens, mixing inks, and aligning the press takes time and precision. Once that's done, however, it's a sprint. A good screen printing setup can crank out hundreds of shirts an hour.

Heat transfer is the opposite. It's incredibly fast for that first shirt. You can go from a digital design on your computer to a fully finished garment in just a few minutes, since there's no screen-making involved. This one-at-a-time process, however, becomes a serious bottleneck when you need to produce a large volume.

The Bottom Line: If you need 500 identical t-shirts for a corporate event next week, screen printing is your best friend. Its high-speed production run is built for volume. But if you need a last-minute personalized birthday gift or a dozen team jerseys with different names and numbers, heat transfer’s speed and flexibility are unbeatable.

The decorated apparel market is massive—valued at USD 28.98 billion in 2023 and expected to reach USD 68.17 billion by 2030. This growth shows just how much demand there is for custom gear. While screen printing dominates for large-scale production, its high setup cost for small jobs is exactly why methods like heat transfer are becoming so popular. You can dig deeper into the decorated apparel market trends on Grand View Research. This fundamental difference in the heat transfer vs. screen printing debate really shows how the right choice always comes back to your specific project needs.

Ideal Use Cases for Each Printing Method

Knowing the technical specs and cost breakdowns of heat transfer vs. screen printing is a great start. But the real key is figuring out which method is the right tool for your specific job. This is where theory hits the pavement.

Let's walk through some real-world scenarios. We'll look at situations where one method is the obvious winner, taking the guesswork out of your decision and making sure you get the result you're after. Picking the right process from the get-go saves you from costly mistakes and ensures the final product looks and feels exactly how you envisioned it.

When to Choose Screen Printing

Screen printing's biggest advantage is its efficiency in large quantities. The initial setup costs are higher, sure, but those costs get absorbed quickly across a big order. Once the press is running, the price per shirt drops dramatically, making it the undisputed champ for bulk projects.

You should lean toward screen printing for jobs like these:

- Large-Scale Event Merchandise: Got a concert, festival, or 5K charity run? When you need to print hundreds (or thousands) of identical shirts, screen printing will give you the best bang for your buck.

- Corporate Uniforms and Staff Apparel: For businesses that need to outfit their entire team, screen printing delivers a durable, professional look that keeps branding consistent across the board. It's built to last through repeated washes.

- School Spirit Wear: Think sports teams, school clubs, or fundraising events. These situations almost always involve a high volume of a single design, which is the perfect sweet spot for screen printing.

- Fashion and Apparel Brands: If you're a brand dropping a new design for a seasonal collection, you're likely producing a large batch. Screen printing gives you that high-quality, soft-to-the-touch feel that retail customers have come to expect.

Key Takeaway: If your order is for 50 or more pieces and the design doesn't have a ton of colors, screen printing is almost always going to be the more durable and cost-effective option.

When Heat Transfer Is the Right Call

Heat transfer shines exactly where screen printing stumbles: on small, highly-customized, or one-off jobs. Because it has virtually no setup cost, it’s perfect for projects that demand unique details or for dipping your toes in the water with a new idea.

Heat transfer is your best bet for:

- Personalized Gifts: Want to make a single shirt with a family photo or a funny inside joke for a friend's birthday? Heat transfer makes it fast, easy, and affordable.

- Team Jerseys: This is a classic example. When every player on the team needs their own name and number, heat transfer is the only practical way to go. Personalization is its specialty.

- Small Business Merch Tests: If you're a small brand or creator and want to see if a new shirt design will sell, heat transfer lets you produce a small handful without committing to a huge, expensive inventory.

- One-Off Prototypes: Designers often need a single physical sample to see how a concept looks on a real garment. Heat transfer is the perfect tool for creating a quick, inexpensive prototype before locking in a full production run.

Ultimately, the heat transfer vs. screen printing debate often comes down to one simple trade-off: scale versus customization.

How to Make the Right Choice for Your Project

So, heat transfer or screen printing? It's easy to get bogged down in the technical weeds, but figuring out the right method for your project is actually pretty straightforward. Instead of overthinking it, just ask yourself a few key questions. Your answers will almost always point you toward the best, most cost-effective choice for your custom apparel.

Let's start with the most important factor: volume.

Key Decision Factors

First off, how many shirts are you making? If you’re just doing a handful of items—say, under 50 pieces—both methods are still on the table. But once you get into larger runs of 50 or more identical designs, screen printing almost always makes more sense financially. The setup is more involved, but the cost per shirt drops dramatically as the quantity goes up.

Next, think about your design and how long you need it to last. Is it a simple, one-color logo for a weekend event, or a highly detailed, full-color photograph for a retail product line? Durability is a huge piece of the puzzle.

Final Takeaway: At the end of the day, it really comes down to two things: how many pieces you're printing and how long you need the print to hold up. A big batch of promotional shirts for a one-time event has completely different requirements than a single, high-quality personalized gift. Your printing method should reflect that.

Your bigger picture strategy also plays a role. For instance, if you're creating a private label brand through Amazon FBA, your production needs will be very different from someone making shirts for a local fundraiser.

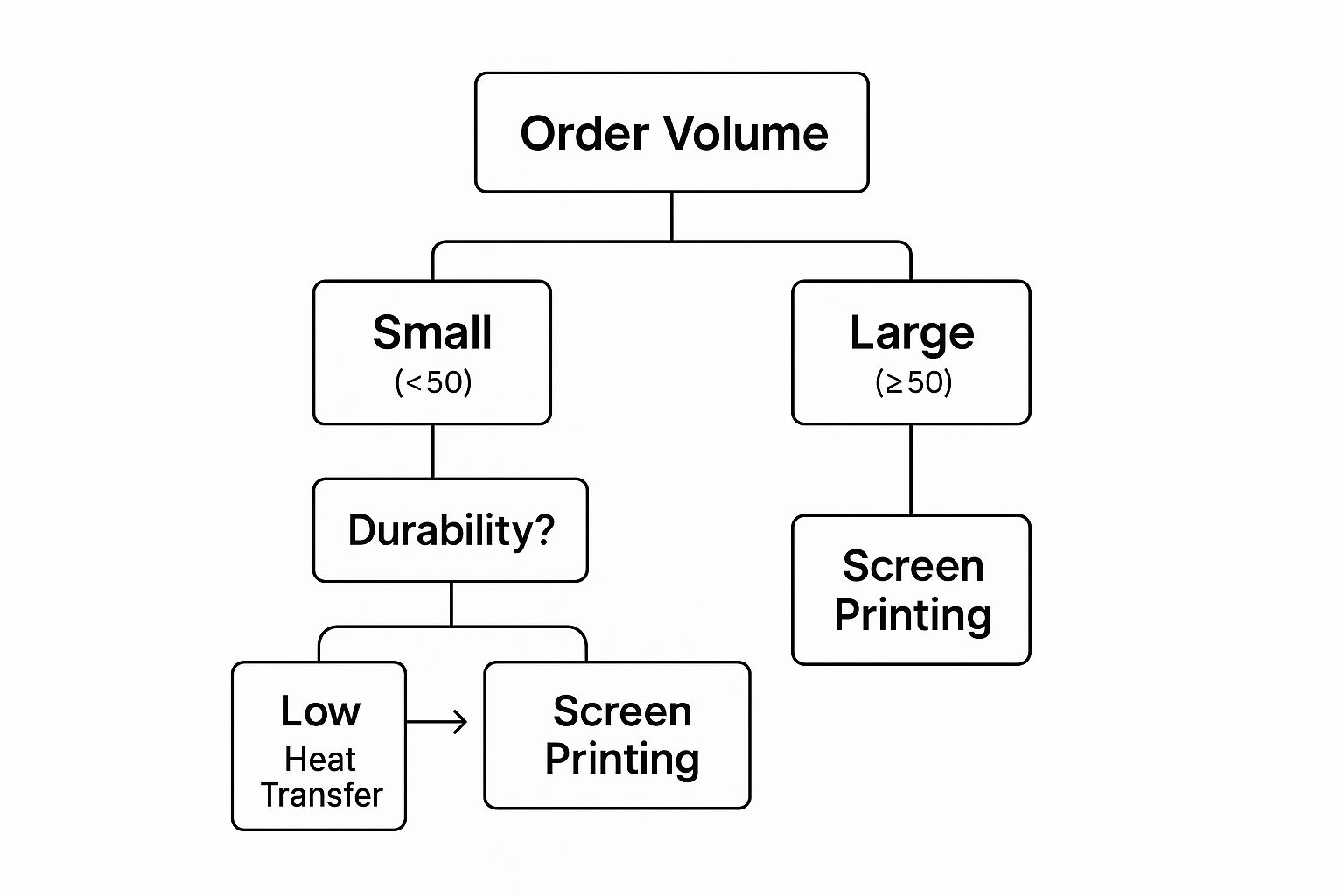

To make it even clearer, this decision tree walks you through the process. It starts with your order size and then brings durability into the mix for those smaller batches.

As you can see, large orders are a straight shot to screen printing. If you’re working with a smaller quantity, your next move depends entirely on how tough you need that print to be.

Got Questions? We've Got Answers.

Even with a full breakdown, you might still be weighing the specifics. Let's tackle some of the most common questions that pop up when you're on the fence between heat transfer and screen printing. This should help you lock in your decision.

Can I Use Either Method on Any Fabric?

Not quite. Screen printing is a true workhorse on popular materials like cotton, polyester, and their blends. Its main limitation? It can struggle with fabrics that can't take the heat, since the inks need to be cured at high temperatures to set properly.

Heat transfers, especially the newer Direct-to-Film (DTF) transfers, really shine in this area. They're far more adaptable and can be pressed onto a huge variety of materials—cotton, poly, nylon, leather, and even some tricky performance wear. Because you can fine-tune the heat and time, heat transfer is often the go-to for more delicate or unusual fabrics.

The Takeaway: While screen printing handles the basics brilliantly, heat transfer gives you more freedom to work with a wider range of materials, especially those sensitive to high heat.

What's Better for Photos or Intricate Gradients?

When it comes to printing photorealistic images, detailed illustrations, or designs with smooth color fades, heat transfer is the hands-down winner. Digital methods like DTF can reproduce millions of colors with incredible precision, much like a high-end photo printer.

Screen printing, by its very nature, needs a separate screen for every single color. This makes recreating complex, multi-colored images both difficult and expensive. A master printer can work magic with advanced techniques, but it's a complicated process. If you want a straightforward, photo-quality result, heat transfer is the most dependable and budget-friendly choice.

Which Process Is Friendlier to the Environment?

It's a question we're hearing more and more. Traditionally, screen printing has a bigger environmental footprint. The process often relies on plastisol inks (which contain PVC) and uses a good amount of water and chemicals to clean and prepare the screens. Water-based inks are a much better alternative, but the process itself still tends to produce more waste.

On the other hand, heat transfer printing, particularly DTF, is generally seen as a greener option. The inks are water-based, and because the design is printed precisely onto a film, there’s very little waste. It's a process that uses less water and energy, making it a solid choice for anyone focused on sustainability.

Ready to bring your complex, full-color designs to life with a durable, eco-friendly solution? At Raccoon Transfers, we specialize in premium DTF transfers that work on almost any fabric. Build your custom gang sheet and get started today!