How to Price Custom Shirts for Profit

Share

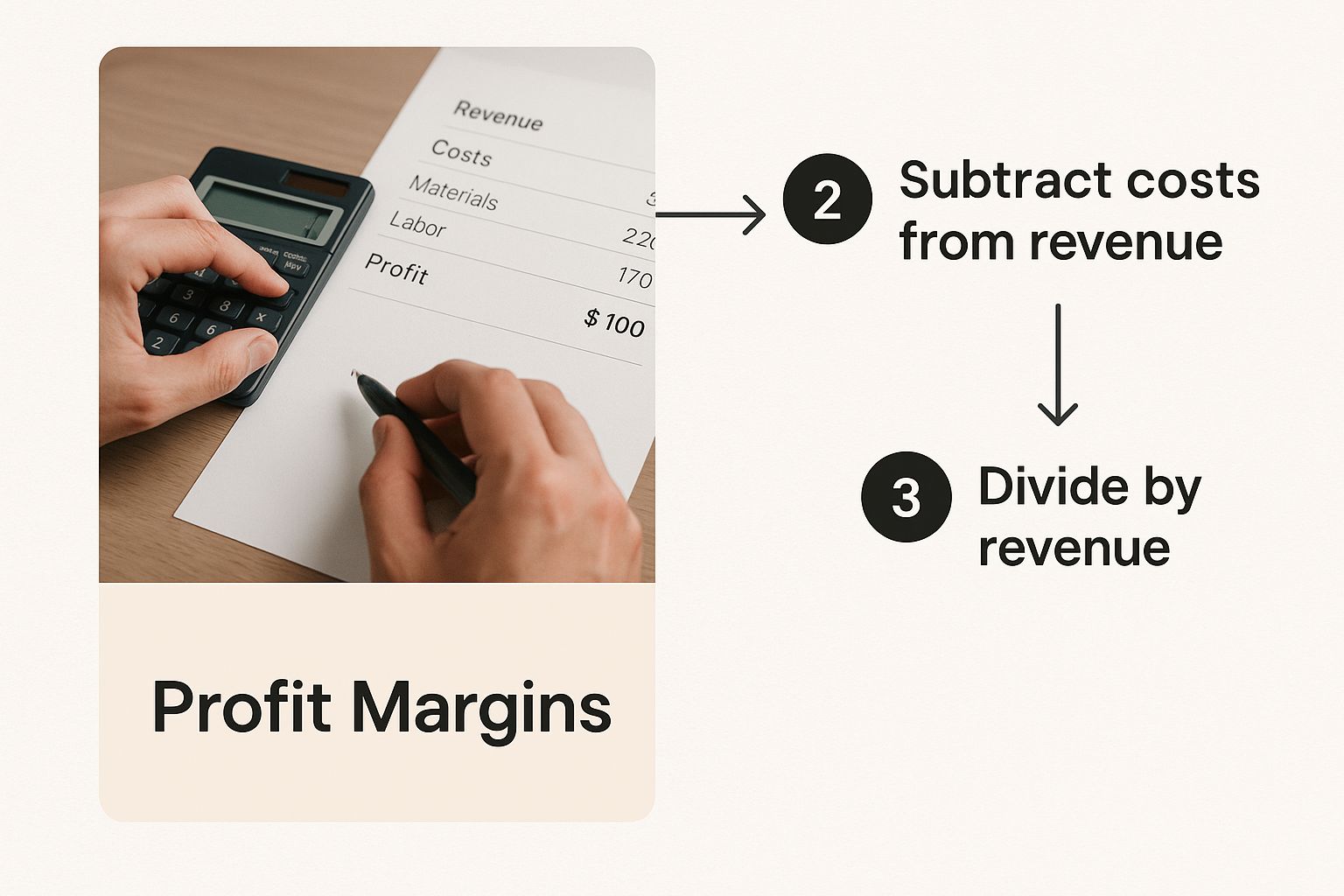

Figuring out how to price your custom shirts is one of the most critical steps you'll take. It’s the difference between a side hustle that barely breaks even and a truly profitable business. The simple formula? Add up your materials, labor, and overhead, then add a profit margin that makes sense for your market.

As a quick rule of thumb, a lot of shops start by calculating their total cost per shirt (the blank tee, supplies, and your time) and then multiplying it by two. This usually gets you in the ballpark of a 50% profit margin and gives you a solid starting retail price.

Building Your Custom Shirt Pricing Foundation

Let's be real—getting your pricing right is what turns this passion project into a sustainable company. It's about so much more than just covering what you spent on that last order of blank tees. You're building a financial framework that ensures you actually make money and can grow with every single sale.

Breaking down how to price custom shirts can feel like a huge task at first, but it gets a lot easier when you look at it piece by piece. Once you have a solid pricing strategy, you can quote new projects without second-guessing yourself. It saves you from the classic beginner's mistake of undercharging just to land a client, which is a fast track to burnout.

Core Pricing Components to Consider

Before you can even think about what to charge, you need a crystal-clear picture of what it costs you to make one shirt. So many new sellers just look at the cost of the blank shirt and call it a day. That's a huge mistake. A truly accurate price accounts for everything.

Here are the key things you absolutely must track:

- The Blank Garment: This is your biggest and most obvious cost. The price tag on a blank tee can swing wildly depending on the brand, material (think 100% cotton vs. a fancy tri-blend), style, and even the color.

- Printing Materials: What are you actually using to create the design? This could be your DTF transfers, screen printing inks and emulsions, embroidery thread, or sheets of heat transfer vinyl.

- Labor and Time: Your time is not free! You have to account for the hours you put into everything from setting up the design file and running the machine to weeding vinyl and neatly packaging the final order.

- Overhead Expenses: These are all the "silent" costs of keeping the lights on. We're talking about workshop rent, your design software subscriptions, the electricity bill, and any money you spend on marketing.

By dissecting your process into these distinct categories, you begin to see the true cost of production. This detailed view is the first step toward creating a price that not only covers expenses but also fairly values your skill and effort.

Avoiding Common Pricing Mistakes

Getting this foundation right from the get-go will help you sidestep some painful (and costly) rookie errors. One of the biggest mistakes I see is people just looking up what a competitor charges and copying them. You have no idea what their cost structure looks like—they might get better deals on blanks, have lower overhead, or be way more efficient. Their numbers are not your numbers.

Another trap is making your quotes overly complicated. Your pricing needs to be transparent and simple for a customer to understand. A clean, well-structured price list or a straightforward quoting process builds trust and makes the entire sales conversation smoother for both of you. Focus on these fundamentals, and you’ll build a pricing model that can actually support your business long-term.

Calculating Your True Cost Per Shirt

Before you can even think about profit, you have to know exactly what it costs to produce a single shirt. This is your Cost of Goods Sold (COGS), and getting this number right is the foundation of a healthy business. If you don't nail this down, you're essentially flying blind—and you could be losing money on every single sale without realizing it.

Calculating your COGS isn't just about the price of the blank tee. That's a classic rookie mistake. To get the real number, you have to account for every single physical item that goes into making and shipping that final product to your customer.

Breaking Down Material Costs

The blank shirt is obviously the biggest line item, but all the other "consumables" add up and can seriously impact your bottom line. What you'll need to track will depend on your printing method, but the goal is the same: account for everything.

Think about all the bits and pieces you use daily:

- Inks and Fluids: For DTG printing, this means the ink and pre-treatment solution used for each specific print.

- Transfers and Vinyl: If you're working with heat transfers (like DTF) or vinyl, you need to calculate the cost of the film or vinyl used for that particular design.

- Screen Printing Supplies: This is a big one. You've got ink, emulsion, screen prep chemicals, and even a tiny fraction of the screen's lifespan cost.

- Embroidery Materials: Don't forget the thread and stabilizer backing. Every inch counts.

Pro Tip: I like to think of it like baking a cake. You wouldn't price the whole cake based on just the cost of flour, right? You have to include the eggs, sugar, butter, and frosting. It's the exact same logic for pricing custom shirts.

The fabric of the shirt itself is a huge variable. A basic 100% cotton tee will have a much lower base cost than a premium tri-blend or an eco-friendly bamboo shirt. Understanding these differences is key. If you're not sure where to start, you can dive into our guide on the best t-shirt materials to see how fabric choices affect both quality and price.

To give you a clearer picture, here’s what a sample COGS calculation might look like for one shirt.

Sample Cost Breakdown Per Shirt (DTG Printing Example)

This table illustrates a sample calculation of the Cost of Goods Sold (COGS) for a single custom shirt using Direct-to-Garment (DTG) printing.

| Cost Component | Example Cost per Shirt | Notes |

|---|---|---|

| Blank T-Shirt | $3.50 | Mid-weight 100% cotton tee from a wholesaler. |

| DTG Ink | $1.25 | Based on an average full-color front print. |

| Pre-Treatment Fluid | $0.30 | The cost of the fluid needed to prep the shirt for printing. |

| Poly Mailer | $0.25 | The cost of the shipping bag. |

| Thank-You Insert | $0.10 | A small branded card included in the package. |

| Packing Slip & Tape | $0.05 | Minor supplies, but they still add up. |

| Total COGS | $5.45 | Your true cost to produce and package one shirt. |

As you can see, the small things really do add up to a significant portion of the total cost.

Don't Forget The Finishing Touches

The costs don't stop once the ink is dry. How you package and present your product is part of your COGS and is something many sellers forget to factor in, especially when they're starting out.

These "finishing costs" might seem small one by one, but they add up fast when you're shipping hundreds of orders. Make sure your list includes:

- Poly Mailers or Boxes: Your primary shipping container.

- Thank-You Cards or Inserts: Any branded materials you pop in the package.

- Hang Tags or Labels: If you add custom branding directly to the garment.

- Packing Slips and Tape: The little operational supplies needed to seal the deal.

Getting this level of detail is crucial. The custom apparel market is competitive, and while direct material costs often range from $3–$7 per shirt, your final price has to reflect your unique situation. By calculating every component—from the ink right down to the shipping tape—you're building a solid cost foundation that ensures you're never just guessing at your prices.

Got your material costs figured out? That's a solid start, but it's really just the tip of the iceberg. If you want to price your custom shirts for actual profit, you have to nail down two of the most commonly forgotten expenses: your labor and your business overhead. Getting this wrong is the fastest way to feel busy but broke.

Your time is money. It’s a cliché for a reason. From the initial customer email to the final trip to the post office, every minute you spend on an order needs to be accounted for. That’s your labor cost.

Then you've got overhead—all those nagging background costs that keep the lights on and the business running. Think of it this way:

As you can see, labor and overhead aren't just minor details; they're foundational parts of your pricing that ensure you're actually building a sustainable business.

Putting a Price on Your Time

First things first, you need to decide what your time is worth. What’s a fair hourly wage? Look up what print shop technicians or graphic designers make in your area to get a baseline, but don't undervalue your own expertise. Let’s go with $20 per hour as a starting point.

Now for the revealing part: grab a stopwatch and time everything for a standard order. No guessing!

- Prep Work: How long does it take to answer emails, create a mockup, and get the design files ready to print?

- Production: This is the hands-on stuff. Time the printing, the weeding, the pressing—the whole shebang.

- Finishing Touches: Don't forget the time it takes to check for quality, neatly fold and bag the shirt, and box it up for shipping.

Let's say after timing yourself, you find that a single shirt, from start to finish, takes you 15 minutes. Your $20 hourly rate breaks down to about $0.33 per minute. So, your true labor cost for that one shirt is $5.00 (15 minutes x $0.33). That $5.00 has to be in your final price, period.

Factoring In Your Overhead

Overhead costs are all the expenses you pay just to keep your business alive, whether you sell one shirt this month or a thousand. They're the persistent, non-negotiable bills.

Think of overhead as the rent you pay for your business to exist. It includes everything from the electricity powering your equipment to the software you use for design. Every single shirt you sell must contribute a small amount to covering these essential costs.

The trick is to break down those big monthly bills into a simple, per-shirt cost. Here’s how you do it:

- List all your monthly business expenses. Add up everything: rent for your workspace, utilities, internet, software subscriptions like Adobe Creative Cloud, marketing ads, insurance, etc.

- Estimate your monthly shirt volume. Be realistic here. How many shirts do you actually sell in a typical month?

- Do the math. Divide your total monthly overhead by your average number of shirts sold.

For example, let's say your monthly overhead adds up to $500. If you consistently sell around 250 shirts per month, your overhead cost per shirt is $2.00 ($500 / 250 shirts).

This calculation also helps you understand the impact of major equipment. The cost and maintenance of a professional DTF printer, for instance, are a significant part of your overhead. To see how different machines can affect your numbers, check out our guide on choosing the best DTF printer for t-shirt printing.

Choosing Your Pricing Strategy

You've done the hard work of crunching the numbers and figuring out your total costs. That gives you your financial floor—the absolute minimum you need to charge to break even. Now comes the more strategic part: deciding how to price your shirts to not only make a profit but also attract the right customers.

This is where you move beyond simple accounting and start thinking like a marketer. The custom t-shirt world is booming, with projections showing the market growing from $4.9 billion in 2024 to nearly $9.0 billion by 2033. All that growth is fueled by people wanting unique, personalized apparel. It’s a huge opportunity, but it also means you need a smart pricing strategy to stand out. You can find more details about this expanding custom apparel market on imarcgroup.com.

Common Pricing Models for Apparel

There isn't one single "right" way to price your shirts. The best approach really depends on your brand, your customers, and what you’re trying to achieve. Many successful shops actually blend a couple of these strategies together.

Let's break down the three most popular models you'll see in the apparel industry.

-

Cost-Plus Pricing: This is the most straightforward method. You simply take your total cost per shirt and add your desired profit on top. If a shirt costs you $10 to make (including materials, labor, and overhead) and you want a 50% margin, you’d price it at $20. It's simple, predictable, and ensures you're profitable on every sale.

-

Value-Based Pricing: This strategy isn't about what the shirt costs you, but what it's worth to the customer. Are you using premium, eco-friendly blanks? Are your designs incredibly unique and artistic? If you’re offering something special that people can't get elsewhere, you can charge a premium for that perceived value.

-

Competitive Pricing: This is all about market awareness. You'll need to do some digging to see what your direct competitors are charging for similar products. Armed with that knowledge, you can position your prices slightly below, on par with, or even above theirs, depending on how your brand compares in quality and service.

A quick word of caution: Researching your competitors isn't about blindly copying their prices. It's about understanding the going rate. Your goal is to find a sweet spot where you're competitive in the market but still comfortably profitable based on your own unique costs and brand value.

To help you visualize which approach might be the best fit for your business, here's a quick comparison.

Pricing Strategy Comparison

| Pricing Model | How It Works | Best For | Potential Pitfall |

|---|---|---|---|

| Cost-Plus Pricing | Add a fixed markup (e.g., 50%) to your total cost per shirt. | Shops prioritizing simplicity and guaranteed profit on every item. | Can leave money on the table if customers would happily pay more. |

| Value-Based Pricing | Set prices based on the perceived value to the customer (e.g., unique design, premium quality). | Niche brands with a strong identity or highly unique products. | Requires a deep understanding of your target customer's willingness to pay. |

| Competitive Pricing | Base your prices on what similar competitors are charging. | New businesses entering a crowded market or those in a price-sensitive niche. | Risks a "race to the bottom" if you only compete on price, not value. |

Ultimately, choosing a model—or a combination of models—comes down to knowing your numbers, your brand, and your market.

Structuring Prices for Different Scenarios

The custom apparel business isn't a one-price-fits-all world. A single shirt for a birthday gift is a totally different order than 200 shirts for a corporate event, and your pricing needs to reflect that. Having a flexible structure is key. To dig deeper into this, check out these 10 Ecommerce Pricing Strategies That Actually Boost Your Profits.

Here are a few ways to build that flexibility into your pricing:

-

Bulk Order Tiers: This is a must. You can encourage larger orders by offering tiered discounts. For instance, charge a standard price for 1-10 shirts, then offer a 10% discount for 11-25 shirts, and so on. It’s a classic win-win.

-

Complexity Charges: A simple, one-color text design takes far less time and effort than a photorealistic graphic with five different colors. Your pricing should reflect that. You can add a flat fee for complex designs or charge per additional color or print location (like adding a logo to the sleeve).

-

Setup Fees: If you're screen printing, charging a setup fee is standard practice. This fee covers the time and materials needed to prepare each screen for a print job. It's what makes smaller screen print runs financially possible without having to charge an astronomical price per shirt.

By establishing a core pricing model and then layering in these flexible structures, you create a system that’s fair, easy for customers to understand, and—most importantly—consistently profitable for your business.

Advanced Tactics to Maximize Profit

Once you've nailed down your core pricing, it's time to get a little more strategic. Think of it as moving beyond just covering your costs and starting to really dial in your profitability. These are the kinds of insider moves that separate the hobbyists from the pros, helping you boost your margins and increase how much you make from each sale.

One of the best ways to do this is by offering value-added services. These are the premium options that customers are genuinely happy to pay extra for. Think about things like design help, rush orders, or even offering higher-end shirt materials. As the custom apparel world keeps growing, these services are exactly what smart businesses are using to stay ahead. For a deeper dive into market trends, maggieframes.com has some great analysis.

Offer Strategic Upsells

Your job isn't just to sell a shirt; it's to sell a better experience. People ordering custom apparel are often in a specific situation—planning an event, launching a brand—and they're usually willing to pay a bit more for convenience, speed, and top-notch quality.

Here are a few high-margin services you can roll out right away:

- Rush Orders: This is a classic for a reason. For those last-minute planners, a guaranteed quick turnaround is a lifesaver. Charging a 25-50% premium for this is standard and well worth it for the customer.

- Design Assistance: How many times have you received a fuzzy, low-resolution logo? Instead of just saying no, offer to clean it up or provide some creative guidance for an hourly design fee.

- Premium Packaging: If you know an order is a gift, offer an upgrade to a branded box or a custom-printed note. It's a small touch that adds a lot of perceived value.

These little add-ons can make a huge difference in the total value of each and every transaction.

Leverage Pricing Psychology

Sometimes, how you show your prices is just as important as the numbers themselves. A few simple psychological tweaks can make your pricing feel more appealing and nudge customers toward bigger purchases.

Take charm pricing, for example. We've all seen it: ending prices in .99 instead of a round number. Selling a shirt for $24.99 instead of $25.00 might seem silly, but it works. Our brains tend to anchor on that first number, making the price feel significantly lower than it actually is.

Another powerhouse technique is bundling. Don't just sell one shirt. Create a package deal—maybe a t-shirt, a hat, and a sticker—for one attractive, slightly discounted price. This is a fantastic way to increase your average order value while moving more of your inventory at the same time.

Finally, think about how you can group designs together to slash your own production costs. The savings you generate can be passed along to your customers through bulk discounts, making you more competitive. The best way to do this is by using a DTF gang sheet builder. It lets you cram multiple designs onto a single transfer sheet, which dramatically cuts down on material waste and your cost per print.

Got Questions About Pricing Custom Shirts? We've Got Answers.

Even with a solid plan, a few tricky questions always seem to pop up when you're dialing in your custom shirt pricing. Nailing these details is what separates the pros from the rookies and can have a huge impact on your bottom line.

Think of this as your go-to guide for those "what if" scenarios. We'll tackle some of the most common pricing hurdles we see shop owners face, from setting profit goals to handling those pesky shipping costs.

What’s a Good Profit Margin for Custom Shirts?

For most custom shirt jobs, you'll want to aim for a profit margin somewhere between 30% and 50%. This sweet spot gives you enough room to cover all your expenses, pay yourself, and still have cash left over to grow the business.

Of course, not every order is the same. The "right" margin really depends on who you're selling to.

- Selling directly to customers? For those one-off designs or small online orders, you should be aiming higher—think 50% or more. These jobs usually require more hands-on time per shirt, from design tweaks to customer service.

- Handling wholesale orders? When you're printing in bulk, a lower margin of 20% to 30% is pretty standard. You make less on each individual shirt, but the sheer volume makes the entire order highly profitable.

The most important thing is to know your numbers inside and out. Calculate your total cost per shirt first—blanks, labor, supplies, and overhead. Once you have that magic number, you can confidently add your margin and see how it stacks up against the competition.

How Should I Price for Shipping?

Shipping can make or break a sale, so you have to be strategic about it. Get it wrong, and you'll see a lot of abandoned carts. Get it right, and you can actually increase your average order value.

There are really three ways to approach it:

- Pass the exact cost on. This is the most straightforward method—you charge the customer precisely what the carrier charges you. It’s transparent, but a high shipping cost revealed at the very end can be a real conversion killer.

- Offer a flat rate. A simple, predictable fee (like $5.99) for all orders makes things easy for your customer. You might lose a little on a big, heavy order to a faraway state, but you'll probably make a little on a small, local one. It usually evens out.

- Roll it into the price and offer "free" shipping. Everyone loves free shipping. You simply build the average shipping cost into the price of your shirts. This is a powerful marketing tool, and many shops use it to encourage bigger orders by offering it on purchases over a certain threshold, like $75.

Should I Charge a Setup Fee for Screen Printing?

Yes. One hundred percent, yes. Charging a setup fee for screen printing isn't just common; it's essential. This isn't about padding the invoice—it's about covering the real, tangible costs of getting a job ready for the press.

A setup fee covers the labor and materials needed to burn and prepare a screen for every single color in a design. A fee of $20 to $40 per screen is typical.

Make sure you list this charge clearly on your quotes. Being upfront about it helps your customers understand the process and shows them why screen printing is so much more cost-effective for bulk orders, where that initial setup cost is spread thin across dozens or hundreds of shirts.

Ready to create stunning, profitable custom apparel without the hassle? Raccoon Transfers provides premium, easy-to-apply DTF transfers with next-day shipping, helping you deliver top-quality products to your customers faster. Explore our solutions at https://raccoontransfers.com and streamline your production today.