Methods of Printing on Shirts: A Quick Guide

Share

When you're trying to figure out the best way to get a design onto a shirt, it really boils down to what you're trying to accomplish. For massive orders, Screen Printing is often the go-to. For incredibly detailed, one-off prints, Direct-to-Garment (DTG) is a star. Then you have the incredibly flexible Direct-to-Film (DTF), which plays well with just about any fabric you throw at it.

Getting a handle on the unique pros and cons of each is the first real step to making sure your final product looks amazing.

Choosing Your Perfect Shirt Printing Method

Diving into custom apparel can feel like a lot at first. There are so many printing techniques out there, but a simple analogy helps: think of it like picking the right tool for a project. You wouldn't use a sledgehammer to hang a tiny picture frame, right? In the same way, the method that works brilliantly for 300 corporate event tees is completely wrong for a single, super-detailed photo shirt for a birthday gift.

Every technique delivers a different combination of appearance, texture, longevity, and price. Your choice will ultimately be shaped by answering a few straightforward questions:

- How many shirts are you making? Some methods get much cheaper per shirt on big runs, while others are perfect for printing just one.

- How complex is the artwork? A simple one-color logo is a different beast entirely than a full-color photograph with subtle gradients.

- What's the material? Cotton, polyester, and blends all have their own best-fit printing methods.

To give you a head start, we've put together a quick comparison table below. It lays out the most popular methods of printing on shirts side-by-side so you can see where each one shines. If you want to go even deeper into the world of fabrics, our guide on various fabric printing techniques is a great resource.

Key Takeaway: There's no single "best" printing method. It's all relative. The right choice depends completely on your order size, design complexity, fabric type, and the final look you're going for.

Think of this as your foundational guide. We're here to clear up the confusion so you can pick a technique confidently. Whether you're launching a clothing line, outfitting a sports team, or just making a cool one-of-a-kind shirt, knowing these basics is your key to success.

Quick Comparison of Popular Shirt Printing Methods

This table breaks down the essentials, giving you a snapshot of how the top printing methods compare when it comes to durability, ideal use cases, and cost.

| Printing Method | Best For | Feel & Durability | Cost Efficiency |

|---|---|---|---|

| Screen Printing | Large bulk orders (50+) with simple, bold designs. | Thick, vibrant, and extremely durable. Can feel slightly heavy on the fabric. | Very high for bulk orders; expensive for small runs. |

| Direct-to-Garment (DTG) | Detailed, full-color photographic prints on 100% cotton. | Soft, breathable, and integrated into the fabric. Fades slightly over time. | Excellent for one-offs and small orders; less efficient for bulk. |

| Direct-to-Film (DTF) | Vibrant, full-color designs on a wide range of fabrics. | Stretchy and durable with a smooth, slightly raised feel. | Great for small to medium runs with no minimums. |

Use this as a starting point to narrow down your options before diving into the specific details of each method in the sections that follow.

Screen Printing: The Time-Tested Industry Standard

When you picture a classic printed t-shirt—the kind with a bold band logo or a crisp graphic for a company event—you're almost certainly thinking of screen printing. For decades, it's been the undisputed champ of the apparel world, loved for its incredible durability and vibrant, punchy colors.

At its heart, the process is a lot like using a highly refined stencil. A mesh screen is stretched over a frame, and a stencil of your design is applied to it, blocking off the areas where you don't want ink to go. A squeegee then pushes ink across the screen, forcing it through the open mesh and directly onto the fabric. The key thing to know is that each color in a design needs its own separate screen.

While the technique's roots trace back to China's Song Dynasty (960–1279 AD), it really hit its stride in the 20th century. The game-changer was the invention of plastisol ink in the 1960s, which supercharged its capabilities and cemented its status as the go-to for large-scale production. You can get a great overview of these foundational t-shirt printing methods on Shirtworks.co.uk.

Why Screen Printing Dominates for Bulk Orders

The real magic of screen printing kicks in when you need to print a lot of something. Yes, creating the screens for each color takes time and has an upfront cost, but that initial investment gets spread across the entire print run. This means the price per shirt plummets as the quantity goes up.

For instance, printing 500 shirts with a simple two-color logo is incredibly efficient this way. Once the two screens are made and the press is set up, each shirt can be printed in seconds. This makes it the perfect choice for:

- Event Merchandise: Think concert tours, festivals, and fun runs where you need thousands of identical shirts.

- Company Uniforms: Businesses get consistent, tough branding across their entire staff at a low per-unit cost.

- School and Team Apparel: It’s ideal for cranking out large batches of spirit wear or team jerseys with graphics that last.

The bottom line is simple: the more you print, the less you pay for each shirt. This unbeatable economy of scale is why screen printing has held the top spot for big projects for so long.

Strengths and Limitations of This Method

Like any technique, screen printing has its trade-offs. It absolutely shines in some areas, but it's not the right tool for every single job.

Key Advantages:

- Unmatched Durability: The ink, especially plastisol, is laid down in a thick layer that cures and bonds right into the fabric. A quality screen-printed design can easily outlast the shirt itself, resisting cracking and fading for years.

- Vibrant and Opaque Colors: This method produces stunningly bright and solid colors that really pop, even on the darkest fabrics. If you need a design to stand out, this is how you do it.

- Cost-Effective at Scale: This is its superpower. Once you hit a certain number of items—usually around 24-50 pieces—it’s tough for any other method to beat its per-shirt price.

But it’s not without its downsides. That setup-intensive process makes it completely impractical for small orders or one-off custom prints. The cost of creating the screens would make a single shirt ridiculously expensive.

Screen printing is also at its best with designs that use a limited number of solid colors. Trying to reproduce a photograph or a design with subtle color gradients gets complicated and expensive, fast. Each individual shade would require its own screen, driving up the complexity and the price. In those cases, other methods of printing on shirts become much smarter options.

Direct-to-Garment: The Master of Photographic Detail

If screen printing is the workhorse for big, bold designs, then Direct-to-Garment (DTG) is the artist, a specialist in capturing incredible detail and a jaw-dropping spectrum of color.

Think of your home office inkjet printer. Now, imagine swapping out the paper for a t-shirt. That's DTG in a nutshell. It uses special water-based inks that are finely sprayed onto the fabric, soaking right into the cotton fibers instead of sitting on top like screen printing ink. The result? A print that feels incredibly soft, breathable, and practically part of the shirt itself.

This whole approach is a newer kid on the block in the apparel world. While the first commercial DTG printer was technically invented by Matthew Rhome way back in 1996, it wasn't until after 2005 that the technology really hit its stride and became a go-to option. It completely changed the game for custom apparel, making photorealistic quality possible without the massive setup headaches of older methods. You can dive deeper into its history and the evolution of print-on-demand at Printful.com.

The Best Use Cases for DTG Printing

DTG's superpower is its ability to nail complex, full-color images with absolute precision. Since it works just like a printer, there are no color limits and no setup fees for each color you add. This makes it the undisputed champion for a few key situations.

This method is the perfect choice for:

- Photorealistic Prints: Want a photo of your dog or a vibrant landscape on a shirt? DTG is your best bet. It captures every subtle gradient and tiny detail with stunning accuracy, something other methods just can't touch.

- Print-on-Demand Businesses: For any online store built on unique, artistic designs, DTG is a dream come true. You can print and ship one-off orders as they come in, meaning you never have to risk money on a big batch of inventory that might not sell.

- Small Custom Orders: Got a family reunion or a small-batch art project? DTG makes it easy and affordable to create just a handful of highly personalized shirts.

Key Insight: DTG shines exactly where screen printing stumbles—on small orders with tons of colors and intricate details. You're essentially trading the bulk-order speed of screen printing for total artistic freedom on individual pieces.

Understanding the Trade-Offs

As amazing as DTG is, it's not a silver bullet. You have to know its limitations to decide if it’s the right fit for your project. The biggest things to consider are fabric type and color.

DTG's water-based inks are formulated to bond with natural fibers, which means the technology works best on 100% cotton garments. You can print on some cotton/poly blends, but the more polyester you have, the more the vibrancy and durability of the print take a hit. Printing on dark shirts also adds a step: they need a special pre-treatment and a white ink underbase to make the colors pop, which can add to the cost and slightly change the feel.

If you're trying to decide what works for different materials, our guide on the differences between DTF and DTG printing breaks it down even further.

On top of that, DTG just doesn't scale for large quantities in the same way screen printing does. The printing process is slower on a per-shirt basis, so the cost per item stays relatively high, even for bigger orders. Durability can also be a factor. A high-quality DTG print is solid, but it’s generally more prone to fading over dozens of washes compared to a screen print.

Direct-to-Film: The Versatile Modern Solution

As the custom apparel world keeps moving forward, a new contender has shown up that neatly sidesteps the limitations of older methods. That technique is Direct-to-Film (DTF) printing, and it’s quickly becoming a go-to for its incredible flexibility and punchy, vibrant results.

Think of DTF as a smart hybrid. It borrows the incredible, full-color detail of DTG and merges it with the workhorse fabric versatility of screen printing. The result? A best-of-both-worlds solution that avoids a lot of common printing headaches.

Instead of applying ink straight onto a shirt, the design is first printed onto a special transfer film. That printed film then gets a dusting of fine adhesive powder. Finally, the film is laid on the garment and heat-pressed, which bonds the ink and adhesive right onto the fabric. It's a simple-sounding process, but it’s what gives DTF its massive range.

Why DTF is a Game Changer for Fabric Choice

One of the biggest hurdles in decorating apparel has always been fabric compatibility. DTG, for instance, really needs 100% cotton to look its best, while sublimation is strictly a polyester-only game. DTF just blows right past those barriers, making it one of the most adaptable methods of printing on shirts out there.

So, how does it work on everything? Because the design is applied with a heat-activated adhesive, the ink doesn't need to soak into specific types of fibers. This means it sticks beautifully to a huge range of materials:

- Cotton and Cotton Blends: From your standard tees to cozy hoodies.

- Polyester: Perfect for athletic wear, team jerseys, and performance gear.

- Synthetics: Works great on tricky fabrics like nylon and rayon.

- Even Leather and Denim: This opens up a whole new world for custom jackets and unique fashion pieces.

This adaptability gives designers and businesses total freedom. You no longer have to pick your fabric based on what your printer can handle; you can pick the fabric you want and still get a stunning, full-color print. If you want to dive deeper, our guide on what is Direct-to-Film printing breaks down the entire process from start to finish.

Key Advantage: DTF’s ability to print on virtually any fabric, light or dark, without pre-treatment makes it an exceptionally versatile and efficient option for diverse apparel lines.

Balancing Durability with a Quality Feel

Of course, a great print has to do more than just look good—it needs to feel right and hold up over time. DTF transfers are engineered for both. The final print is remarkably durable and can handle dozens of wash cycles without cracking, peeling, or fading.

On the shirt, a DTF print feels smooth and flexible. It has a bit of stretch, so it moves with the fabric instead of feeling like a stiff, heavy plastic patch. While it does sit on top of the fabric (much like a screen print), the modern adhesives and thin ink layers give it a much softer hand-feel than old-school plastisol transfers.

This perfect balance makes it ideal for everything from everyday t-shirts to high-performance activewear, where both comfort and resilience are non-negotiable. The prints hold onto their brilliant color saturation wash after wash, keeping the design looking fresh.

Extending Versatility with UV-DTF

The core technology behind DTF has also unlocked possibilities beyond just clothing. A newer spin-off, known as UV-DTF, uses a similar film-based process but with UV-cured inks. Instead of using a heat press, these transfers are applied more like a high-tech sticker, allowing them to adhere to hard, non-porous surfaces.

This exciting development means you can put permanent, full-color branding on items like:

- Glassware and mugs

- Phone cases

- Metal water bottles

- Plastic and acrylic goods

Suddenly, the same vibrant, detailed printing you use for apparel can be applied to promotional products, custom gifts, and all sorts of hard goods. UV-DTF is an incredibly powerful tool for any brand looking to expand its merchandise, offering the toughness of industrial printing with a simple peel-and-stick application. It brings high-quality customization to a whole new world of products.

Beyond the Big Three: Exploring Niche Printing Methods

While Screen Printing, DTG, and DTF handle the lion's share of t-shirt jobs, there's a whole other world of specialized printing techniques out there. These methods are perfect for unique projects where the big three might not be the best fit, from custom team jerseys to one-off artistic pieces. Knowing when to use them is the mark of a true printing pro.

One of the most common and approachable methods you'll see is Heat Transfer Vinyl, or HTV. The best way to think of it is like creating a high-end, super-durable sticker for your shirt. You start with a sheet of colored vinyl, a machine cuts out your design, and then you peel away the extra material—a process known in the biz as "weeding."

From there, you just place the design on the shirt and use a heat press to lock it in. The heat activates a powerful adhesive, bonding the vinyl directly to the fabric. This straightforward process makes HTV the undefeated champion for simple, bold graphics, especially those with just one or two colors. It’s the go-to for putting names and numbers on sports jerseys or creating crisp, single-color company logos.

Heat Transfer Vinyl: When Bold and Simple is Best

The real power of HTV is in its simplicity and the punchy, vibrant results it delivers. Because you're working with solid sheets of colored vinyl, the final graphic is incredibly opaque and pops off any color garment.

HTV is the perfect choice for:

- Team Uniforms and Jerseys: It's the standard for adding player names and numbers with a clean, professional look.

- Simple Logos and Text: If your design is just a logo or a few words, HTV is a durable and cost-effective option.

- Small, Custom Orders: The setup is so quick and easy, making it ideal for one-off projects or small batches without breaking the bank.

But it has its limits. HTV isn't built for complex, multi-color designs or photos. Every single color requires its own separate layer of vinyl that has to be cut, weeded, and pressed, which gets complicated and time-consuming fast. The final print also has a distinct feel—it sits on top of the fabric, which isn't for everyone, especially if you're after a super-soft feel.

Dye Sublimation: Where Ink Becomes Part of the Fabric

Now for something completely different: dye sublimation. This process is pure magic, creating stunning, permanent prints that have absolutely zero texture. Instead of laying ink on the fabric, sublimation uses a special ink that, when heated, turns directly into a gas.

This gas then infuses into the polyester fibers of the shirt and solidifies, becoming a permanent part of the material itself. You literally can't feel the print. Because the ink is in the fabric, the design is incredibly vibrant, totally breathable, and will never crack, peel, or fade. It’s the king of durability.

The one major catch? Sublimation only works its magic on light-colored, 100% polyester garments or specialty items with a specific polymer coating.

Key Insight: Sublimation printing creates a completely seamless and permanent design by turning ink into a gas that bonds directly with polyester fibers. This makes it perfect for all-over prints on athletic apparel where breathability and longevity are critical.

This unique quality makes sublimation the number one choice for performance activewear, custom cycling jerseys, and those wild "all-over print" shirts where the design covers every inch of the garment, seam to seam.

Before we jump into the side-by-side comparison, it's helpful to see where these niche methods fit in the broader context of apparel decoration. Each one shines under different circumstances.

Niche Printing Method Use Cases

| Method | Best Fabric Type | Ideal Design | Common Use Case |

|---|---|---|---|

| HTV | Cotton, Polyester, Blends | Simple text, numbers, single-color logos | Sports jerseys, small custom orders, promo apparel |

| Sublimation | 100% Light-Colored Polyester | Full-color, all-over prints, photos | Performance wear, photo gifts, custom jerseys |

As you can see, the choice really boils down to two things: what your shirt is made of and what your design looks like. For a cotton shirt with a simple logo, HTV is your hero. For a polyester performance tee with a complex, all-over pattern, sublimation is the only way to go.

A Nod to the Originals

To really appreciate how far we've come, it helps to look back at the roots of printing. Long before any of us were thinking about digital printers or heat presses, artisans were decorating textiles by hand. These foundational techniques paved the way for everything we do today.

For example, block printing and stencils were some of the very first ways to mass-produce printed shirts. Artisans would carve designs into wooden blocks, dip them in ink, and press them onto fabric. Stenciling offered a bit more artistic freedom by letting them apply paint through carefully cut-out shapes. You can dive deeper into the fascinating history of apparel printing on dubhumans.com.

By understanding these specialized methods and their history, you get a much richer picture of the apparel printing world. Every technique, from the simple reliability of HTV to the scientific wizardry of sublimation, has its own unique place and purpose.

Making the Right Choice for Your Project

So, how do you sort through all these methods of printing on shirts without getting overwhelmed? It's actually simpler than it looks. The key is to stop thinking about which method is "best" and start thinking about which one is best for your specific project.

It all boils down to balancing four critical factors. Think of it as a quick sanity check before you place an order. Answering these four questions will help you zero in on the perfect printing technique, so you don't end up paying for something you don't need or getting a result that just doesn't work.

Four Factors for Choosing a Printing Method

Before you pull the trigger on a printing method, walk your project through this simple evaluation. Each factor plays off the others, so looking at them together is the secret to a great result.

-

Order Size (Volume): How many shirts do you need? If you're running a big batch of 50 or more identical shirts, screen printing is a no-brainer. The per-shirt cost drops dramatically at scale. For just a few shirts or even a single one-off, methods like DTG, DTF, or HTV will be much friendlier to your wallet.

-

Design Complexity: Let's talk about your artwork. Got a full-color photograph or a design with subtle gradients and tons of colors? DTG is the undisputed champion of detail. But if you’re working with a simple, bold logo or some text, the clean look of screen printing or HTV is often the better, more cost-effective choice.

-

Fabric Type: What's the shirt made of? This is a big one. DTG really shines on 100% cotton. Sublimation, on the other hand, is strictly for light-colored polyester fabrics. If you need a workhorse that can handle just about anything—cotton, poly-blends, and even some synthetics—DTF is the most flexible player in the game.

-

Budget and Turnaround: What’s your budget, and when do you need the shirts? Screen printing has some setup costs, which makes it pricey for small orders but cheap per shirt for big ones. DTG and DTF have basically no setup fees, making them fantastic for quick-turnaround projects and small orders without breaking the bank.

The goal isn't to find the single "best" method overall, but the best method for your project. A corporate order for 500 polo shirts has completely different needs than a single photo tee for a birthday gift.

For instance, say you need 300 shirts with a simple two-color logo for a company fun run. Screen printing is the clear winner here; it’s durable and incredibly cost-effective in bulk. But if you're launching an online store featuring dozens of unique, artsy designs with lots of colors, the print-on-demand freedom of DTF or DTG is a much smarter business decision.

Once your shirts are printed and ready to go, remember that great presentation is everything. This is especially true if you're selling online, where taking high-quality photos for your online listings can make or break a sale.

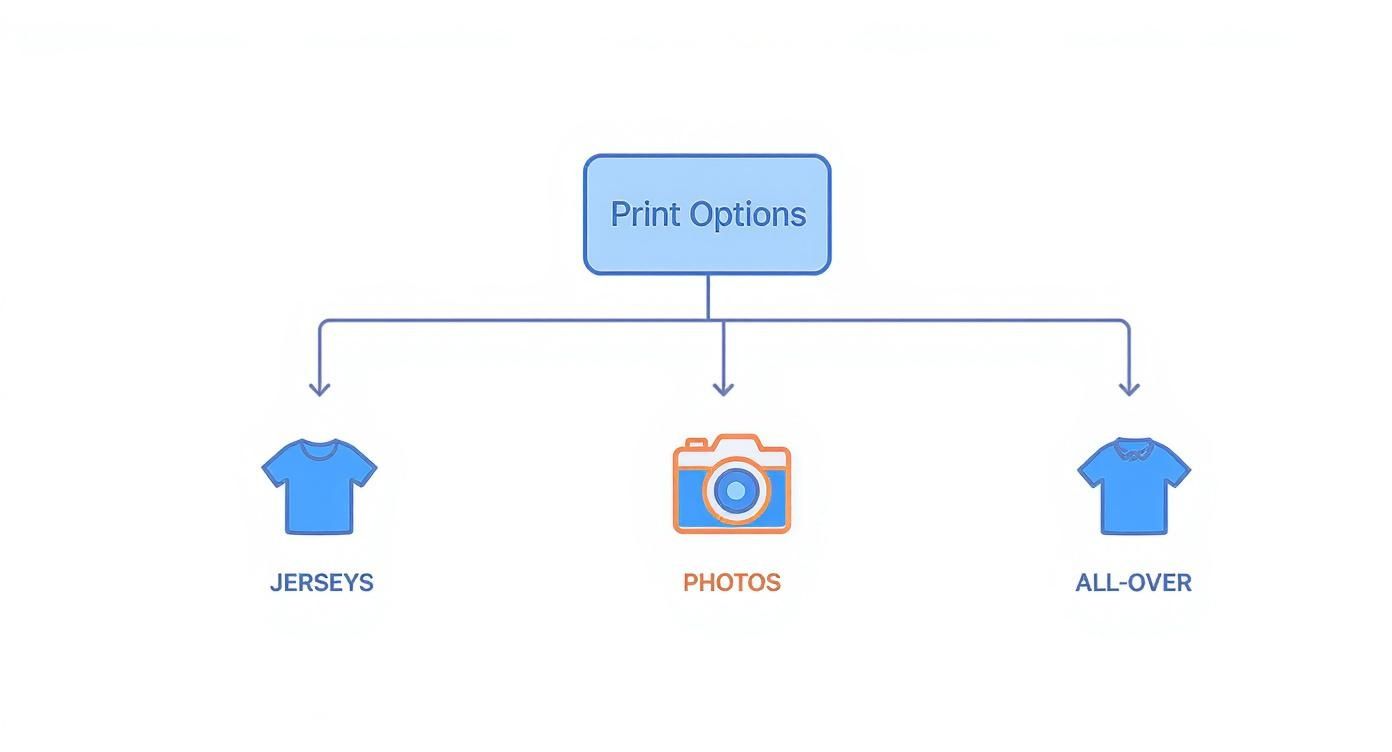

A Visual Guide for Niche Projects

Sometimes your project is a little more specialized, like creating team jerseys or an all-over print fashion piece. This handy decision tree can help you visualize the best path for those unique items.

As you can see, the end goal of your project points you directly to a specific technology. By matching what you need to what each printing method does best, you're setting yourself up for a professional, high-quality result every single time.

Got Questions About Shirt Printing? We've Got Answers.

When you're digging into the different ways to print on a shirt, the same few questions always seem to pop up. Getting straight answers is the key to picking the right method for your project, your budget, and the look you're going for. Let's break down some of the most common ones.

Which Printing Method Lasts the Longest?

If you're looking for a print that will truly go the distance, screen printing has always been the heavyweight champion. The process lays down a thick, durable layer of plastisol ink that cures right onto the fabric. Honestly, it often outlasts the shirt itself, holding up against fading and cracking through years of washing.

But there's a new contender that's getting incredibly close: Direct-to-Film (DTF). Today's DTF transfers are built for toughness, offering fantastic washability and flexibility. The print actually moves and stretches with the fabric, which helps it avoid the cracking you sometimes see with older transfer methods. It’s a seriously durable modern choice.

What’s the Most Budget-Friendly Option for a Small Business?

For anyone just starting out, keeping initial costs low is everything. While screen printing is incredibly cheap per shirt on huge orders, the setup fees for small batches can be a dealbreaker. This is where the newer digital methods really come into their own.

- Direct-to-Film (DTF): For all-around value and flexibility, DTF is tough to beat. You don't pay setup fees for each color, and it works on just about any fabric you can think of. This means you can offer a wide variety of products without investing in different machines, and the cost per shirt stays low even if you're just printing one.

- Heat Transfer Vinyl (HTV): If you're doing simple, one-color designs—think logos or text—HTV is a fantastic, low-cost starting point for small runs. The material is inexpensive and the process is pretty simple for basic graphics.

For a small business, DTF hits that sweet spot. It gives you low startup costs, no minimum orders, and the power to create brilliant, full-color designs on nearly any garment, which is a huge plus for profitability.

Can I Actually Print a Photograph on a Shirt?

You absolutely can! Printing photos on apparel is one of the coolest things you can do with modern technology. But, and this is a big but, not every method is up to the task.

Direct-to-Garment (DTG) is the undisputed king of photo-quality detail. It works just like a paper inkjet printer but for fabric, flawlessly recreating millions of colors, smooth gradients, and tiny details. The one catch? For the best, most vibrant results, DTG really needs a 100% cotton shirt.

DTF is another fantastic option for printing photos. It can also produce gorgeous, high-resolution images with a full spectrum of colors. The big advantage here is that DTF can put those photorealistic prints on polyester, cotton blends, and other synthetic fabrics that DTG just can't handle. This opens up a ton of creative freedom for what you can print on.

Ready to bring your vibrant, durable designs to life on any fabric? Raccoon Transfers specializes in premium DTF transfers that make custom apparel easy. Explore our gang sheet builder and get started today at https://raccoontransfers.com.