A Practical Guide to printing methods for t shirts

Share

Picking the right way to print a T-shirt is a bigger deal than you might think. The best choice really comes down to what you're trying to accomplish. If you're printing a huge batch of shirts with a simple logo for a 5k run, you'll want something different than if you're creating a single, super-detailed photorealistic shirt for an art project.

Decoding T-Shirt Printing Methods

Getting into custom apparel can feel a little overwhelming at first. A great print job brings your design to life with vibrant, lasting color. But the wrong one? That’s how you end up with faded graphics, peeling letters, and a box of shirts you can’t use.

Think of this guide as your map. We're going to walk through the most popular techniques in the T-shirt world, breaking down how they work and what they're truly good for. It's all about matching the right process to your specific project—get that right, and you're golden.

Key Factors to Consider

Before we jump into the different methods, let's talk about what actually matters when you're making a decision. There isn't a single "best" way to print a shirt; it’s about finding the best fit for your needs. Each method strikes a different balance between cost, quality, and what it can handle.

Here’s what you need to have straight in your mind first:

- Design Complexity: Is your design a simple one-color logo, or a full-blown piece of art with gradients and tiny details? Some methods love simplicity, while others are built to handle photorealistic complexity.

- Order Volume: How many shirts are you making? A one-off custom gift requires a totally different approach than an order of 500 for a company event. The price per shirt often plummets with higher quantities, but only for certain methods.

- Fabric Type: What's the shirt made of? 100% cotton behaves very differently from a polyester performance tee or a tri-blend. Inks and printing processes are finicky and often designed to work with specific fibers.

- Budget and Durability: What’s your budget per shirt, and how long does this print need to last? A cheap promotional giveaway doesn't need to survive a decade of washes, but a shirt for your clothing brand absolutely does.

Figure these things out first, and you’ll be able to confidently choose the right tool for the job.

Quick Guide to T-Shirt Printing Methods

To give you a bird's-eye view, here's a quick comparison of the most common T-shirt printing methods. Use this table to quickly narrow down your options based on what's most important for your project.

| Printing Method | Best For | Durability | Cost Per Shirt (High Volume) |

|---|---|---|---|

| Screen Printing | Simple designs (1-4 colors) in large batches (50+) | Very High | $ |

| DTG Printing | Full-color, detailed designs in small batches or one-offs | Good | $$$ |

| Heat Transfer Vinyl | Simple text, numbers, and logos for small orders | High | $$ |

| Dye Sublimation | All-over prints on 100% polyester fabric | Extremely High | $$$ |

| DTF Printing | Detailed, vibrant designs on a wide range of fabrics | Very High | $$ |

This chart is a great starting point, but the devil is in the details. Now, let’s dig into what makes each of these methods tick so you can understand the nuances behind the numbers.

The Enduring Power of Screen Printing

When you think of classic T-shirt printing, you're probably picturing screen printing. It’s the tried-and-true method that has dominated the apparel industry for decades, and for very good reasons.

Think of it as creating a custom stencil for each color in your design. A thick, vibrant ink is then pushed through that stencil—or 'screen'—directly onto the fabric. The result is a bold, incredibly durable print that sits slightly raised on the shirt, giving it that professional, high-quality feel that lasts wash after wash.

How Does Screen Printing Actually Work?

The whole process is a bit like a well-oiled assembly line. It might seem complex at first, but the core idea is pretty simple and has been perfected over many years.

Here’s a quick look at the steps involved:

- Breaking Down the Design: First, the digital artwork gets separated into individual layers, one for each color. If your design has three colors, you'll need three separate screens.

- Making the Screens: Each screen is a fine mesh stretched tightly over a frame. It's coated with a light-sensitive emulsion. The design for one color layer is printed onto a transparent film, which is then placed on the coated screen and blasted with intense light. The light hardens the emulsion everywhere except where the design is, creating a perfect stencil when the soft parts are washed away.

- Applying the Ink: The T-shirt is secured on a flat surface, and the first screen is carefully aligned on top. A squeegee is used to pull a thick layer of ink across the screen, forcing it through the mesh stencil and onto the fabric.

- Curing: This process gets repeated for every color, with a quick flash-dry in between to set the ink. Once all the colors are on, the shirt goes through a big conveyor dryer to cure the ink at high heat, making the design permanent.

This detailed setup is precisely why screen printing is the king of bulk orders. Once those screens are made, cranking out hundreds—or even thousands—of identical shirts is remarkably fast and cost-effective.

When Is Screen Printing the Right Choice?

There's a reason screen printing still commands about 53.9% of the global custom T-shirt printing market. Its leadership is built on producing vibrant, tough-as-nails prints that don't fade after a few washes, all while being incredibly economical for large runs. This makes it the go-to for corporate uniforms, event merchandise, and any promotional gear where a crisp, colorful look is non-negotiable.

So, when should you absolutely choose this method?

Key Takeaway: Screen printing is unbeatable for large-volume jobs with relatively simple designs. The upfront setup cost gets spread out, so the more you print, the cheaper each shirt becomes.

It’s the perfect match for projects like:

- Band Merch: Printing hundreds of tour shirts with the same bold logo.

- Corporate Events: Outfitting your entire team for a trade show or company picnic.

- School Apparel: Creating durable, consistent uniforms or spirit wear for students.

- Charity Races: Making thousands of T-shirts for all the participants.

On the flip side, all that setup for multi-color designs makes it a poor choice for small batches or one-off prints. If you need 500 shirts with a two-color design, screen printing is your best bet. But if you just want a single shirt with a full-color photograph, you'll be better off with another method. To see how it stacks up against other popular techniques, check out our guide comparing heat transfer vs screen printing.

The Rise of Modern Digital Printing

As technology sprinted forward, so did the printing methods for t shirts. We've moved far beyond the days of just stencils and screens, stepping squarely into the digital realm. Leading this new wave is Direct-to-Garment (DTG) printing, a technique that’s surprisingly easy to understand. Just picture your home inkjet printer, but built to print directly onto fabric.

Instead of separating a design into color layers for different screens, a DTG printer applies specialized water-based inks straight onto the shirt. This process unleashes an incredible spectrum of millions of colors, making it the perfect choice for designs loaded with detail. We’re talking about complex illustrations, smooth gradients, or even photorealistic images that would be a nightmare to attempt with screen printing.

This kind of digital tech has completely reshaped the custom T-shirt world. DTG allows for stunning, high-resolution prints pulled directly from a computer file. This shift toward digital has been a game-changer for smaller orders, cutting down on setup costs and waste while speeding up delivery times. You can see just how much this has impacted the industry in this analysis of the custom t-shirt printing market.

How Does DTG Printing Work?

The real beauty of DTG is its precision and simplicity. The process completely skips the manual labor of making screens, offering a streamlined, digital-first operation from the moment you upload your file.

Here’s a quick look at how a design goes from a digital file to a piece of wearable art:

- Pre-Treatment: First things first, the shirt gets a light spray of a special pre-treatment solution. This is especially important for dark-colored garments. Think of it like a primer for a wall—it helps the ink bond properly with the fabric fibers instead of just soaking in and looking dull.

- Digital Printing: The shirt is then carefully smoothed onto a flat platen, which slides it right into the DTG printer. The printer's heads move back and forth across the fabric, spraying ink directly onto the surface to recreate the design with incredible accuracy.

- Ink Curing: Once printed, the shirt is moved to a heat press or a conveyor dryer. This final step is crucial; the heat locks the water-based ink into the fabric, making the design durable enough to handle the wash.

One of the biggest wins here is the lack of setup costs for each new design, which has opened the door for a whole new level of creativity.

Why Choose DTG Printing?

DTG has carved out a very specific—and very powerful—niche in the custom apparel world. It’s the undisputed champion for print-on-demand businesses and independent artists who need to produce a single, unique shirt without a huge upfront investment.

Key Advantage: DTG shines when producing high-detail, full-color prints for small orders or one-off items. It delivers a soft-hand feel, where the ink becomes part of the fabric rather than sitting on top of it like a plastic shield.

You should seriously consider DTG for your project if you have:

- Complex Artwork: Your design is packed with colors, gradients, or has photographic elements.

- Small Order Volume: You just need one or a handful of shirts, which would make screen printing far too expensive.

- Print-on-Demand Needs: You want to sell your designs online without ever touching inventory.

- Soft Print Feel: You want a print that feels like it’s part of the shirt itself, not a thick, heavy layer sitting on top.

But DTG isn’t perfect for every job. The process is slower for bulk orders, so it's not as cost-effective as screen printing when you need a large run. It also works best on 100% cotton or high-cotton blends because the water-based inks are formulated to bond with natural fibers. It’s also easy to confuse with similar tech, but our guide explains what DTF printing is and how it’s different in both process and what fabrics it can handle.

Exploring the World of Heat Transfer

When we talk about heat transfer printing, we're really talking about a whole family of different techniques. It's an incredibly versatile world, perfect for everyone from weekend hobbyists to budding entrepreneurs.

The core idea is simple: instead of putting liquid ink straight onto a shirt, you first create your design on a special carrier material. Then, using a heat press, you transfer that design onto the fabric with a combination of heat and pressure. It's a cleaner, often simpler approach that unlocks some truly unique and eye-catching results.

Let's dive into two of the biggest players in the heat transfer game: Heat Transfer Vinyl (HTV) and Dye-Sublimation. They both use a heat press, but that's where the similarities end. The way they work and the final look and feel are completely different.

Heat Transfer Vinyl: Bold, Tactile, and Versatile

Think of Heat Transfer Vinyl (HTV) as creating custom, high-end "stickers" for your apparel. The process starts with a sheet of colored vinyl. A special cutting machine, like a Cricut or Silhouette, precisely cuts your design into the vinyl. After that, you pull away all the excess material—a process known as weeding—leaving just your design on its clear carrier sheet.

From there, you just place it on the shirt, press it with heat, and the design's adhesive backing permanently bonds to the fabric.

It's a wildly popular method, and for good reason:

- Awesome Specialty Finishes: This is where HTV truly shines. You can go way beyond flat color. Think glitter, shimmering holographic foils, fuzzy flock with a suede-like feel, and even glow-in-the-dark vinyl. It adds a tactile dimension you can't get with ink.

- Sharp, Punchy Graphics: Because you're cutting from solid sheets of color, HTV is fantastic for creating graphics with crisp, clean edges. It’s the go-to for text, logos, and bold, simple vector designs.

- Works on Almost Anything: HTV isn't picky. It plays well with a huge range of fabrics, including cotton, polyester, and common blends, making it incredibly flexible.

Want to make custom team jerseys with names and numbers? Or maybe some sharp-looking polos with a company logo? HTV is your answer. Its strength is in creating bold, simple designs with incredible textures that literally stand out.

The trade-off? HTV isn't built for complex, multi-color designs like photographs. Every color is a separate layer of vinyl you have to cut, weed, and press. For intricate artwork, it quickly becomes too bulky and time-consuming.

Dye-Sublimation: Vibrant, Permanent, and Part of the Fabric

Dye-sublimation isn't just a layer on top of a shirt; it's pure chemistry in action. The process is fascinating. First, you print your design onto special transfer paper using solid sublimation inks. When you apply intense heat and pressure with a heat press, those solid inks do something amazing: they turn directly into a gas, completely skipping the liquid phase.

This gas then permeates the polyester fibers of the garment. As it cools, the ink solidifies again, becoming a permanent part of the fabric itself. The result? A stunningly vibrant, full-color print that you can't even feel. It’s not sitting on the surface, so it will never crack, peel, or fade.

This unique process has its own set of rules and rewards:

- Unbeatable Durability: Since the ink is in the fabric, the design is as durable as the shirt itself. It will easily outlast the garment, wash after wash.

- Photorealistic Quality: Sublimation can reproduce millions of colors, making it perfect for printing high-resolution photos and complex images with smooth gradients and fine details.

- Strict Fabric and Color Limits: Here’s the catch. Sublimation chemistry only works on 100% polyester or high-polyester blend fabrics. And because the ink is translucent, you have to print on white or very light-colored garments for the design's colors to show up true and bright.

Sublimation is the undisputed champion for all-over prints on performance sportswear or for creating custom photo gifts on polyester T-shirts where permanence and brilliant color are everything. If you're looking for a similar full-color result on other fabrics, exploring heat transfer paper printing is a great alternative to consider.

Making the Final Decision for Your Project

Okay, we've walked through the nitty-gritty of each printing method. Now comes the big question: which one is right for your project? It can feel a bit overwhelming, but the choice really just boils down to matching the method's strengths to your specific needs.

Think of each technique as a different tool in a workshop. One is a powerhouse for mass production, while another is a fine-tipped pen for detailed, one-of-a-kind artwork. By weighing a few key factors—your design, your quantity, and your fabric—you'll find the perfect fit.

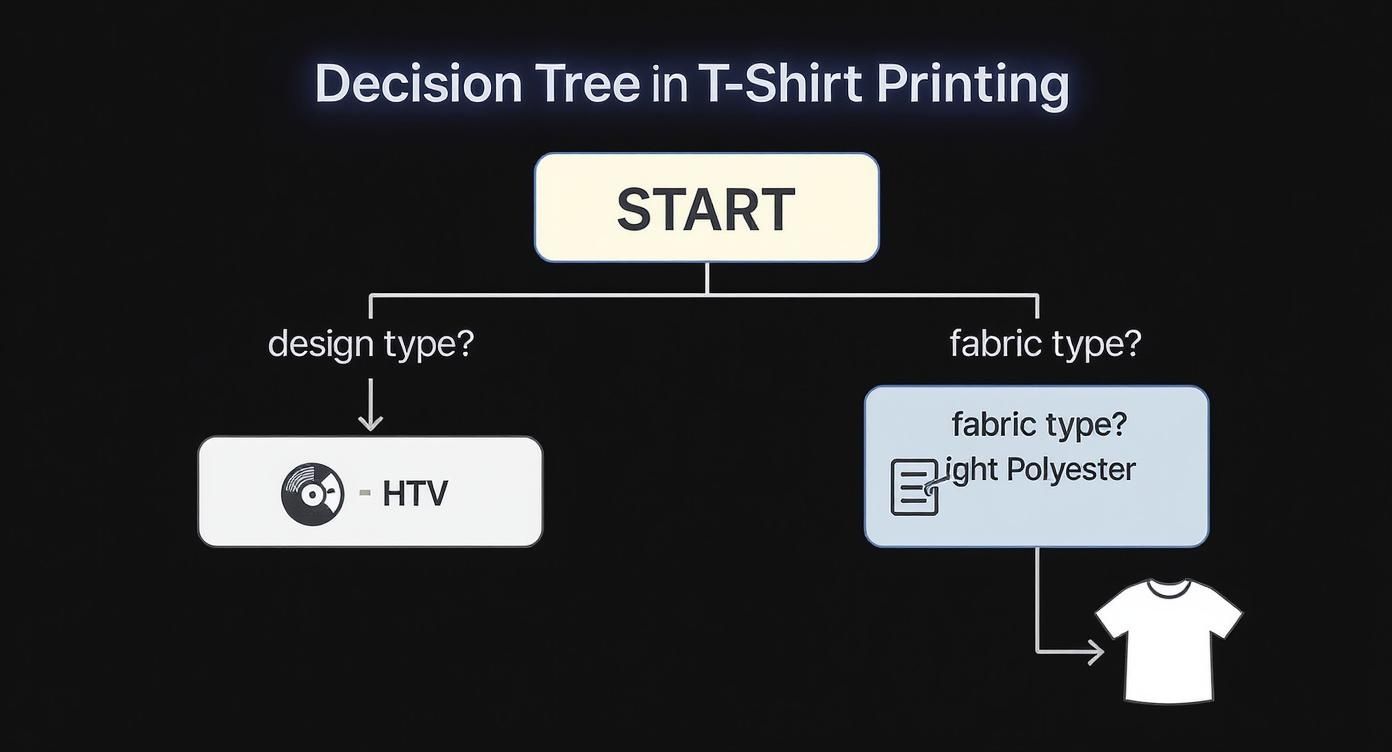

This decision tree infographic is a great starting point, helping you visualize the best path forward based on your design and material.

As you can see, your design's complexity and your fabric choice are the first major forks in the road, immediately pointing you toward the most practical options.

Detailed Comparison of T Shirt Printing Methods

To really bring everything into focus, nothing beats a head-to-head comparison. The table below breaks down the four primary techniques across the most critical variables, from cost-effectiveness to the final feel of the print on the garment. This is designed to help you make an informed choice for your specific needs.

| Feature | Screen Printing | DTG (Direct-to-Garment) | Heat Transfer Vinyl (HTV) | Dye-Sublimation |

|---|---|---|---|---|

| Best For | Large batches (25+) with simple, bold designs. | Photorealistic, multi-color art on small batches or one-offs. | Simple text, logos, and numbers, especially with special finishes. | All-over, vibrant prints on 100% light-colored polyester. |

| Durability | Extremely high. The thick ink cures to the fabric and withstands many washes. | Good. Durable for dozens of washes, though minor fading can occur over time. | High. Quality vinyl is very durable but can crack or peel if applied poorly. | Permanent. The ink becomes part of the fabric and will never crack, peel, or fade. |

| Feel on Shirt | A slightly thick, raised layer of ink that sits on top of the fabric. | Very soft and breathable. The ink soaks into the cotton fibers. | A distinct, smooth, and sometimes plastic-like layer on top of the shirt. | No feel at all. The print is completely integrated into the fibers. |

| Cost (Low Volume) | Very high due to extensive setup costs for each color screen. | Low, as there are no setup costs per design. Ideal for single items. | Moderate, making it a good choice for small, custom orders. | Moderate to high, depending on the size of the print. |

| Cost (High Volume) | Very low. The most cost-effective method for large production runs. | High. The cost per shirt does not decrease significantly with volume. | Moderate. The cost of materials and labor scales with each shirt. | High. The cost per shirt remains relatively consistent. |

This side-by-side view makes it much easier to pinpoint which method truly aligns with your budget, quality standards, and overall vision.

Practical Scenarios and Real-World Examples

Tables and stats are great, but let's put this into practice. Seeing how these choices play out in the real world is the best way to get a feel for what you need.

Scenario 1: The Emerging Clothing Brand

You're launching an online store and want to sell T-shirts featuring your intricate, full-color digital art. To keep costs down, you plan to use a print-on-demand service, printing and shipping each shirt only after it's sold.

Winning Method: DTG (Direct-to-Garment)

This is a no-brainer. DTG is the champion of on-demand, full-color printing. Because there are no setup fees, you can print a single shirt with millions of colors just as easily as you can print a dozen. It gives you total creative freedom without the financial risk of holding inventory.

Scenario 2: The Annual Company Picnic

Your company needs 300 shirts for its big employee event. The design is the classic two-color company logo—it needs to look sharp and hold up for years to come.

Winning Method: Screen Printing

For a big run with a simple design, screen printing is the undisputed king. Yes, there's an initial setup cost, but when you spread that cost across 300 shirts, the price per item becomes incredibly low. You'll get a vibrant, tough-as-nails print that represents the brand perfectly.

Scenario 3: The Local Youth Sports Team

You're in charge of outfitting a soccer team with 15 players. Every jersey needs the team logo on the front, plus a unique player name and number on the back.

Winning Method: Heat Transfer Vinyl (HTV)

HTV was practically made for this job. It’s perfect for creating crisp, bold text and numbers, and customizing each jersey with a different name is simple. Plus, high-quality vinyl is durable enough to handle the wear and tear of a competitive season.

The Future of Custom Apparel Printing

The world of custom T-shirts is always in motion, and the technology behind it is evolving faster than ever. The printing methods for T-shirts are getting smarter, quicker, and a whole lot greener. If you're in the apparel game, keeping an eye on these changes isn't just about staying current—it's about making smart moves for the future.

Two huge forces are steering this ship: a serious demand for sustainability and the non-stop growth of ecommerce. Shoppers want to know their clothes are made with care for the planet, and that's pushing the entire industry to clean up its act.

The Push for Sustainability

Let's be real: ignoring environmental impact is no longer an option. People want to feel good about what they buy, and the apparel world is finally catching on. This shift is sparking some pretty cool innovations aimed at making the whole process more sustainable.

We're seeing major improvements in a few key areas:

- Eco-Friendly Inks: The move away from old-school plastisol inks to water-based alternatives is a game-changer. These newer inks are biodegradable and don't rely on harsh chemicals, making them a much kinder choice for the environment.

- Energy-Efficient Technology: Digital methods like DTG and DTF are lean, mean, printing machines. They use way less water and electricity than screen printing. Plus, since they're built for printing on demand, they slash overproduction, which is one of the biggest sources of textile waste.

This focus on sustainability is more than just a passing trend; it's becoming the standard way of doing business.

The future of apparel printing is one where top-notch quality and environmental responsibility go hand-in-hand. As the tech gets better, the greenest option is often becoming the most efficient and budget-friendly one, too.

E-Commerce and Global Customization

Thanks to social media and online storefronts, the hunger for unique, personalized gear is now a global phenomenon. On-demand printing has opened the doors for artists and small businesses to launch their own brands without a massive upfront investment, feeding a worldwide culture of hyper-customization.

This wave is hitting especially hard in emerging markets. Take the Asia Pacific region, for example. It's quickly becoming the most exciting market for custom T-shirt printing, on track to hold a massive 39.4% revenue share. This explosion is fueled by a huge youth population, growing cities, and the undeniable power of social media in dictating what's cool. For a deeper dive into these numbers, check out this detailed industry report.

At the end of the day, the future of T-shirt printing is all connected. New technology will keep making custom apparel easier to create, while our collective conscience will shape how those products get made. For anyone in this space, staying ahead means embracing both.

Got Questions About T-Shirt Printing? We’ve Got Answers.

Jumping into the world of custom t-shirts brings up a ton of questions. It's easy to get tangled up in the details when you're just trying to figure out the best way to print your design.

To clear things up, here are some straightforward answers to the most common questions we hear from artists, brands, and creators just like you.

Which T-Shirt Printing Method Lasts the Longest?

When you’re talking about pure durability, two methods are clear winners: screen printing and dye-sublimation.

Screen printed shirts are workhorses. The ink is thick and cured right onto the fabric, so it can take a real beating in the wash without giving up. Dye-sublimation takes it a step further—the ink actually becomes part of the polyester fabric fibers.

That means a sublimation print is permanent. It won’t crack, peel, or fade, ever. It will literally last as long as the shirt does. DTG is also very durable, but you might see some slight fading over dozens of washes. HTV’s lifespan really comes down to the quality of the vinyl and how well it was applied.

What's the Best Way to Print Photos on a Shirt?

If you want to print a photograph or any design with complex colors and gradients, Direct-to-Garment (DTG) is the hands-down champion. Think of it like a professional photo printer, but for fabric. It can replicate millions of colors and tiny details with stunning accuracy.

Sublimation is another great option for photorealistic prints, but it has one major catch: it only works its magic on light-colored, 100% polyester shirts. Screen printing, on the other hand, just isn't built for photos. Its process of separating colors is perfect for bold, simple graphics, not subtle photographic shades.

I'm a Small Business. Which Printing Method Should I Choose?

That's a great question, and the right answer really hinges on your business model and what you can invest upfront.

- Selling Online with Print-on-Demand? Go with DTG. It has zero setup costs per design, which means you can sell shirts one at a time as orders roll in without ever touching inventory.

- Printing Simple Logos in Small Batches? For basic text or one-color graphics, Heat Transfer Vinyl (HTV) is a fantastic low-cost starting point. It’s perfect for getting off the ground.

- Ready for Bulk Production? Screen printing is your best friend once you’re ready to print 25 or more of the same design. The cost per shirt drops dramatically at higher volumes, making it incredibly economical.

Thinking this way helps you stay nimble. You can use the most efficient and cost-effective method for where your business is right now, and scale up as you grow.

Ready to bring your vibrant, full-color designs to life on any fabric? At Raccoon Transfers, we specialize in high-quality DTF prints that offer incredible durability and detail. Upload your artwork and create your custom gang sheet today!