Sublimation vs DTG Printing A Complete Guide

Share

Here’s the thing about custom apparel printing: the core difference between sublimation and Direct-to-Garment (DTG) is all about how the ink meets the fabric.

Think of it this way: sublimation dyes the very fibers of the material, infusing ink into polyester for a design you can’t even feel. On the other hand, DTG printing is more like a high-tech painter, laying ink on top of natural fabrics like cotton to create incredibly detailed graphics. It’s not about which is better, but which is the right tool for the job.

Understanding the Core Differences

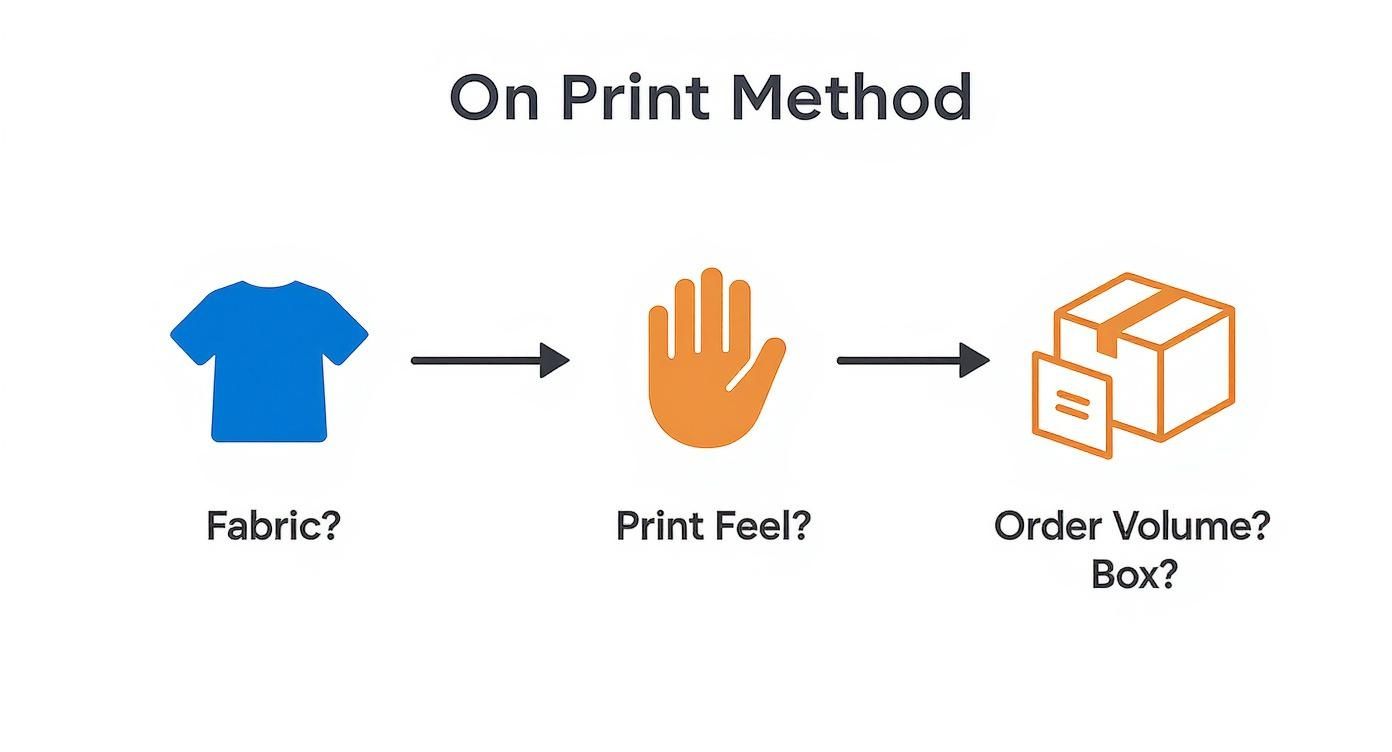

When you’re weighing sublimation vs DTG, the decision really boils down to three things: the material you're using, the kind of feel you want the final print to have, and how many pieces you're making. Each technique has its own sweet spot, and they often serve completely different needs.

Sublimation is king when it comes to synthetic fabrics, especially 100% polyester. The magic happens when heat turns solid dye into a gas, which then bonds permanently with the polyester fibers. The result is a seamless, breathable design that’s literally part of the shirt. It will never crack, peel, or fade, which is why it's the standard for performance athletic wear and those eye-popping all-over-print shirts.

DTG, however, was built for natural fibers—think cotton, bamboo, or linen. It operates a lot like the inkjet printer on your desk, spraying water-based inks directly onto the garment. This method captures stunning detail and a massive range of colors, making it the perfect choice for complex graphic tees, especially for print-on-demand businesses that need to print on classic cotton shirts.

This decision tree gives you a clear path for choosing the right method based on what your project demands.

As you can see, the journey starts with your fabric choice. From there, the path to the best printing method for your specific apparel project becomes much clearer.

Quick Glance Sublimation vs DTG Comparison

To get you started, here's a simple breakdown of the main differences between sublimation and DTG. This table should help you quickly see which method might be a better fit.

| Feature | Sublimation | Direct-to-Garment (DTG) |

|---|---|---|

| Best Fabric | 100% Polyester or high-poly blends | 100% Cotton, natural fiber blends |

| Print Feel | No feel, ink is part of the fabric | Slightly raised, soft-hand feel |

| Color Vibrancy | Extremely vibrant, photorealistic | Excellent detail, vibrant on light shirts |

| Durability | Permanent, will not crack, peel, or fade | Good, but may fade over many washes |

| Best For | Sportswear, all-over prints, hard goods | Graphic tees, small runs, detailed art |

This quick comparison highlights how each technique shines in different areas. Your project's specific needs—from the t-shirt material to the design's complexity—will ultimately point you in the right direction.

How Each Printing Process Actually Works

To really get to the heart of the sublimation vs. DTG debate, you have to understand how each method physically puts an image onto a shirt. While both use heat, their approaches are worlds apart, which directly impacts the look, feel, and lifespan of the final print. Think of it less like two similar painting styles and more like the difference between dyeing fabric and using a high-tech printer.

This mechanical contrast is exactly why one is king for polyester and the other reigns on cotton. Each process was built from the ground up for specific materials and goals.

The Sublimation Process: A Chemical Transformation

Sublimation is a pretty neat bit of chemistry. It’s a process where solid ink turns directly into a gas, skipping the liquid phase entirely. This is how it permanently dyes the fibers of the fabric, resulting in a print you literally cannot feel.

Here’s a breakdown of how a digital file becomes a finished garment:

- Print the Transfer: First, we print the design onto special sublimation transfer paper with unique dye-based inks. The image has to be a mirror image of what you want the final design to look like.

- Apply Heat and Pressure: The printed paper is placed on a polyester-based item and secured in a heat press. The press brings the heat—typically around 375-400°F—along with firm, even pressure.

- Gas Infusion: This is where the magic happens. The intense heat causes the solid dyes on the paper to sublimate into a gas. The pores of the polyester fabric open up, and the gaseous dye permeates the fibers, bonding with them at a molecular level.

- Cool Down and Finalize: As the garment cools, the ink solidifies and becomes a permanent part of the fabric. Peel away the transfer paper, and you’re left with a vibrant, full-color design that won’t crack, peel, or wash out.

Sublimation isn’t about printing on a shirt; it’s about infusing a design into it. The ink becomes one with the polyester, which is why the print feels like it was always part of the fabric.

This method is just one of many ways to get a design onto apparel. If you want a bigger picture, you can explore various fabric printing techniques in our detailed guide to see how they all stack up.

The DTG Process: A Precision Application

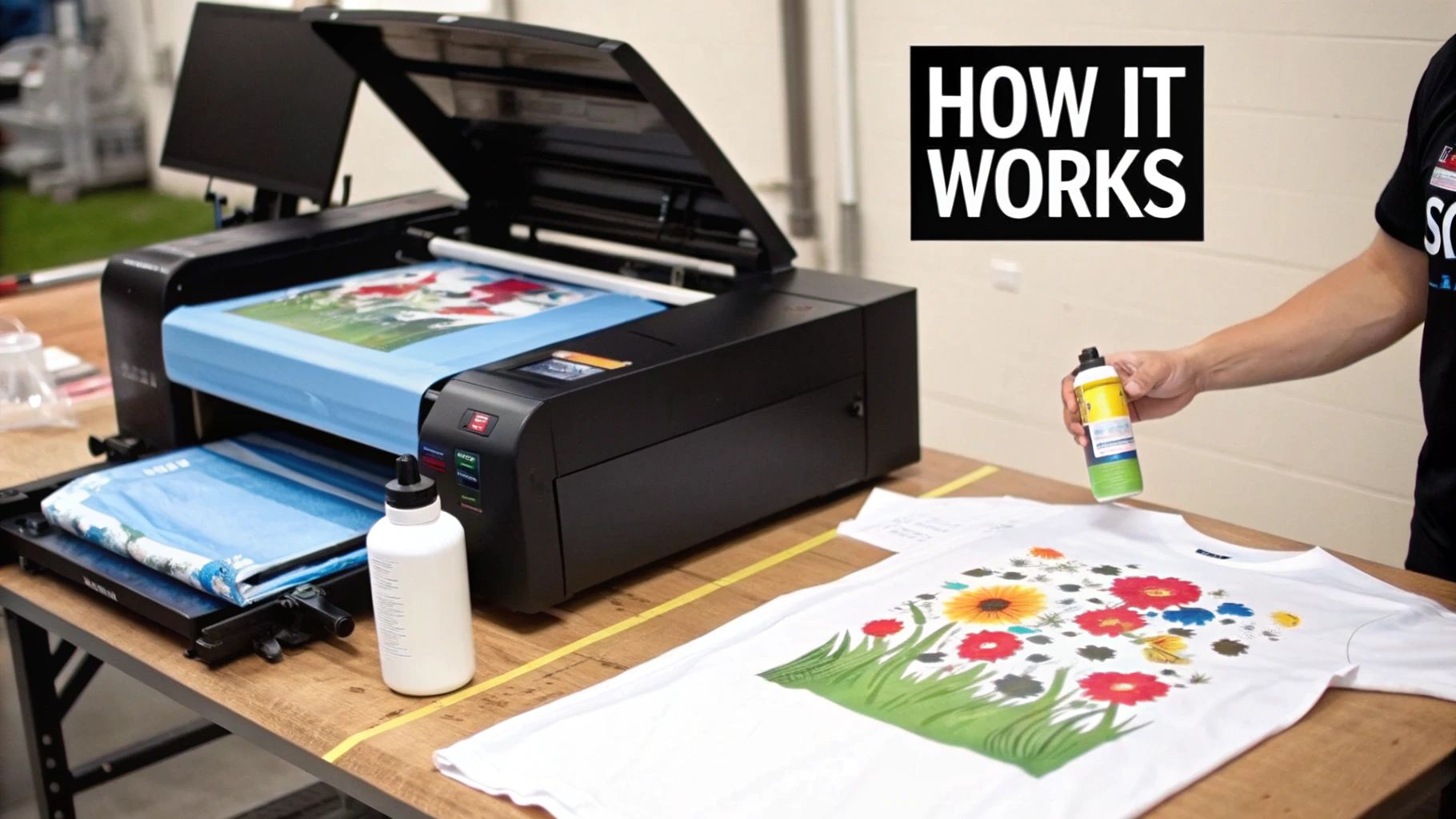

Direct-to-Garment (DTG) printing works a lot like the inkjet printer in your office, just on a much more advanced and specialized scale built for fabric. It sprays a very fine layer of ink directly onto the surface of the material.

The DTG workflow looks a bit different, especially when you're printing on dark-colored shirts:

- Pre-Treatment: First, the garment gets sprayed with a pre-treatment solution. This liquid acts like a primer, creating a smooth surface that helps the water-based ink stick properly instead of just soaking into the fibers.

- Dry the Solution: The pre-treated garment goes into a heat press to completely dry the solution, getting it ready for printing.

- Direct Printing: The shirt is carefully loaded onto the DTG printer's platen. For dark fabrics, the machine lays down a base layer of white ink first. Then, it meticulously prints the colored inks right on top, allowing for incredible detail and color accuracy.

- Final Curing: The finished print gets one last trip to the heat press. This final cure is crucial—it bonds the water-based inks to the fabric fibers, locking in the design and making sure it holds up in the wash.

Comparing Print Quality, Feel, and Longevity

When you get right down to it, the real showdown between sublimation and DTG is all about the final product. How a design looks, feels, and holds up over time are the things that matter most. Both methods can give you a fantastic-looking shirt, but the way they get there creates some really distinct differences in texture and durability.

The tangible result—what you can actually see and touch—is where one method often pulls ahead, depending entirely on what you’re trying to achieve with the garment.

The Tangible Feel of the Print

The most immediate difference you'll notice is how the print feels. A sublimated design has absolutely no feel at all. Seriously, you can’t feel it. Because the ink turns into a gas and bonds directly into the polyester fibers, it’s not a layer sitting on top of the fabric; it literally becomes the fabric. This is fantastic for things like athletic wear, as it keeps the garment's original soft feel and breathability completely intact.

DTG prints, on the other hand, have a very soft but slightly raised texture. The water-based inks are sprayed directly onto the cotton, creating a thin, flexible layer that bonds with the fibers. Modern DTG technology is a world away from those thick, plastic-like transfers of the past, but you can still feel a subtle difference between the printed area and the rest of the shirt.

The core difference in feel is simple: Sublimation infuses the design into the material, making it undetectable to the touch. DTG applies ink onto the material, creating a soft layer you can feel.

Color Vibrancy and Detail Reproduction

If you're looking for colors that absolutely pop, sublimation is tough to beat. The process creates incredibly bright, photorealistic colors that almost seem to glow on polyester fabric. The catch is that the ink is translucent, so it works best on white or very light-colored garments where the fabric's color won't muddy the design's hues.

DTG also produces a wide range of colors and is brilliant at capturing fine details, complex gradients, and photorealistic images with amazing clarity. Its killer feature is the ability to print on dark fabrics, which it achieves by laying down a white ink underbase first. That said, the colors on a DTG print can sometimes look a touch less saturated than a sublimated one, especially after the first wash, just because of how cotton fibers absorb the ink. For a deeper dive, check out our guide on heat transfer and sublimation printing.

Longevity and Durability Over Time

This is where sublimation really flexes its muscles. Because the design is molecularly bonded to the polyester fibers, it’s completely permanent. A sublimated print will never crack, peel, or fade. It can handle endless washing, stretching, and sun exposure without losing its original vibrancy. The print will genuinely last as long as the shirt itself.

DTG prints are also quite durable when you treat them right, but they just aren't as bulletproof as sublimation. Over time and with many wash cycles, the ink on a DTG print can start to show signs of fading or minor cracking, especially if you use harsh detergents or high heat in the dryer. Following the care instructions is key to getting the most life out of a DTG-printed shirt.

These differences in application and durability have a big impact on the market. Right now, sublimation makes up 37.3% of the digital textile printing ink market, a testament to its efficiency and permanent results on polyester goods like sportswear.

A Realistic Look at Costs and Profitability

When you're deciding between sublimation and DTG, money is a huge part of the conversation. It's not just about what you pay to get started, but what keeps the lights on long-term. Each method has a completely different financial footprint, and figuring out which one fits your business is crucial. Your choice really boils down to your scale, what you plan to sell, and who you're selling to.

Breaking Down the Initial Investment

Let's be direct: getting into DTG printing requires a bigger wallet upfront. A professional-grade DTG printer isn't cheap, and when you add a pre-treatment machine and a quality heat press, you're looking at a serious capital investment. This setup is built for businesses that want to specialize in high-detail, on-demand printing, especially for the premium cotton apparel market where customers are willing to pay more.

On the other hand, sublimation is a much more approachable starting point. You can get a solid sublimation printer, a reliable heat press, and all the necessary inks and paper for a fraction of the cost of a DTG setup. This lower barrier to entry makes it a fantastic option for startups or small shops looking to branch out into polyester-based products like activewear, team jerseys, or promotional mugs.

If you need help finding the right gear without breaking the bank, check out our guide on the best printer for sublimation and heat transfer.

Per-Print Costs and Finding Your Market

Once you're up and running, the cost per print is where the real differences emerge.

Sublimation inks and paper are generally quite affordable. This keeps your cost per item incredibly low, particularly when you're cranking out larger batches. That efficiency is what makes sublimation a workhorse for bulk orders where you can really build your margins through volume. Think team uniforms or branded corporate giveaways.

DTG's cost per print tends to be higher, mostly because the ink—especially the white underbase needed for dark garments—is more expensive. But its real advantage is the total lack of setup for individual designs. This makes it the undisputed king of one-off custom orders and print-on-demand services, letting you tap into the personalization trend without forcing customers into minimum orders.

The profitability question isn't just about the cost of ink and materials. It's about matching your production method to the right market. DTG shines with high-value, low-volume custom work, while sublimation dominates cost-effective, high-volume production for specific product niches.

Market trends tell a similar story. The global dye sublimation market was valued at $14.9 billion and is expected to hit $28.0 billion by 2030. Meanwhile, the DTG market, while smaller at $1.92 billion, is projected to grow faster and reach $3.90 billion by 2030. These numbers show sublimation's established power in certain sectors, but DTG's rapid growth points directly to the booming demand for personalized, on-demand clothing.

Ultimately, your printing method is only one piece of the puzzle. To truly succeed, you need to pair it with smart sales and marketing. Thinking about choosing the right ecommerce marketing platform to drive revenue and protect margins is just as important as choosing the right printer.

When to Choose Sublimation or DTG

So, when does it make sense to use sublimation, and when is DTG the right tool for the job? Getting past the technical details and into real-world scenarios is where the rubber meets the road. The best choice really boils down to what you’re making, who you’re selling to, and how your business operates.

Think of sublimation as the specialist. It's the go-to for incredibly vibrant, long-lasting products, especially things that aren't your standard cotton t-shirt. Because it permanently dyes polyester fibers and polymer-coated surfaces, it opens up a whole different world of products. This makes it a clear winner for certain high-performance niches.

The Ideal Scenarios for Sublimation

Sublimation really shines when you need eye-popping, edge-to-edge designs that have to last, provided you're using the right materials. It’s the perfect fit for creating premium items that can take a beating.

You'll want to choose sublimation for projects like these:

- Performance Sportswear: Team jerseys, cycling kits, athletic gear—anything that needs to stretch and breathe. Sublimation prints become one with the fabric, so they’ll never crack, peel, or fade, no matter how many times they're washed.

- Custom Hard Goods: This is a huge one. Think personalized coffee mugs, mousepads, phone cases, and keychains. Sublimation produces sharp, photo-quality images that are literally baked into these polymer-coated items.

- Full-Coverage Photo Products: If you're making things like custom photo blankets or all-over-print shirts, sublimation is really the only way to get that seamless, edge-to-edge look without feeling the print at all.

- Branded Lanyards and Banners: The process is perfect for creating bold, permanent colors on polyester fabric, making it a favorite for promotional materials that need to look crisp and professional.

When to Pick Direct-to-Garment (DTG)

DTG is the undisputed king of the custom cotton apparel world. It’s an absolute powerhouse for any business model built around personalization and on-demand printing. Its magic lies in its ability to reproduce complex, full-color designs directly onto natural fabrics with zero minimum order requirements.

DTG is your best bet in these situations:

- Branded Cotton T-Shirts for Startups: Got a new clothing line? DTG lets you print detailed logos and intricate graphics on classic cotton tees without having to sink a ton of cash into bulk inventory.

- Detailed Graphic Tees for Artists: If your artwork involves complex illustrations, subtle gradients, or photorealistic details, DTG captures that nuance beautifully on a cotton canvas.

- Personalized On-Demand Merchandise: Selling custom baby onesies or one-off t-shirts in an online shop? The print-as-you-sell model of DTG is incredibly efficient and profitable.

Ultimately, the sublimation vs. DTG decision is a strategic one. Sublimation owns the world of polyester performance wear and hard promotional goods, while DTG absolutely dominates the market for personalized cotton fashion and on-demand apparel.

The popularity of these methods also shows some interesting regional trends. The Asia Pacific region, for example, is a leader in dye sublimation. Meanwhile, in Europe, DTG made up 36.7% of the market, fueled by a huge appetite for personalized clothing and a growing focus on sustainability. That push for eco-friendly production is a major force shaping both industries.

If you're curious to see how these trends are playing out, you can find more great insights into the global printing market on Accio. Choosing the right method isn't just about the technology; it's about aligning your production with your product goals and what your customers truly value.

Common Questions About Sublimation and DTG

Even after breaking down the details, you might still have a few questions rolling around in your head. Let's tackle some of the most common ones that come up when people are trying to decide between sublimation and DTG.

Can You Use Sublimation on Cotton T-Shirts?

Simply put, no. Sublimation printing just doesn't work on 100% cotton. The whole process is a chemical reaction where special dye turns into a gas under heat and bonds permanently with polyester fibers. Cotton, being a natural fiber, doesn't have the right polymer structure for the ink to grab onto. If you try it, the design will look faint and wash out almost completely.

To get those punchy, vibrant sublimation results, you need polyester. You can get away with some poly-blends (like a 65/35 split), but the image will look faded and have a "vintage" feel because the ink only dyes the polyester threads. For the best, most vivid colors, 100% polyester is the way to go.

Is DTG or Sublimation More Eco-Friendly?

Both methods are a huge step up from older, messier printing techniques, but they have different environmental strengths. Sublimation is a dry process that uses solid inks, which means it produces practically zero water waste. Plus, the transfer papers used are often recyclable, which is a nice bonus.

DTG printing, on the other hand, shines with its use of non-toxic, biodegradable water-based inks. This cuts out a lot of the harsh chemicals you'd find in traditional screen printing. The real win for DTG, though, is its on-demand nature. It helps fight the massive textile waste problem caused by overproduction because you only print what you sell.

Both DTG and sublimation are far more sustainable choices than traditional screen printing. It really comes down to your priorities: are you focused on cutting water usage (sublimation) or reducing textile waste (DTG)?

Which Method Is Better for Small Businesses?

This completely depends on what kind of business you're building. There's no single "better" option.

- For a print-on-demand online store: DTG is almost always the answer. It's built for creating one-off, high-quality prints on cotton shirts with no real setup cost per design. It's the engine that powers the custom t-shirt world online.

- For a shop selling niche products: Sublimation often has a lower cost to get started. The equipment is more accessible, making it perfect for someone who wants to focus on things like polyester sportswear, personalized mugs, phone cases, or other hard-surface promo items.

So, if your dream is to sell custom-designed cotton tees to individual customers, DTG gives you the flexibility you need. If you're planning to outfit local sports teams with custom jerseys or launch a line of unique photo gifts, sublimation is a fantastic and profitable starting point.

Does DTG Work on Polyester?

It can, but it’s not what DTG was designed for. Originally, DTG was developed specifically for natural fibers like cotton. While there have been improvements in inks and pre-treatment fluids that allow for printing on some polyester, the results can be hit or miss. You often end up with less vibrant colors and run into problems with the ink not sticking or lasting as long.

When it comes to printing on polyester, sublimation is still the undisputed champion. It guarantees vibrant, permanent colors that literally become part of the fabric. If you're comparing the two for athletic wear or any synthetic garment, sublimation will give you a superior, more reliable result every time.

Ready to bring your custom apparel ideas to life without buying a bunch of expensive equipment? At Raccoon Transfers, we specialize in premium Direct-to-Film (DTF) transfers that give you the versatility of DTG with incredible durability. Create your custom designs with us today