The Ultimate Guide to T-shirt Fabric Material

Share

Picking the right t-shirt fabric is the single most important decision you'll make for your apparel line. Get it right, and your customers will love the way it feels and wears. Get it wrong, and even the best design won't save it.

The big three players are 100% cotton for that classic soft feel, 100% polyester for activewear that needs to perform, and blends that give you a bit of both worlds. Getting a handle on these is your first step to making a shirt people will actually want to wear.

Your Quick Guide to T-Shirt Fabric Selection

Let's be honest, staring at a list of fabric options can feel like reading a different language. You’ve got "ringspun," "tri-blend," "GSM," and a dozen other terms flying around. This guide is here to cut through that noise.

We’ll start with the big picture to help you make a quick, smart choice right from the get-go.

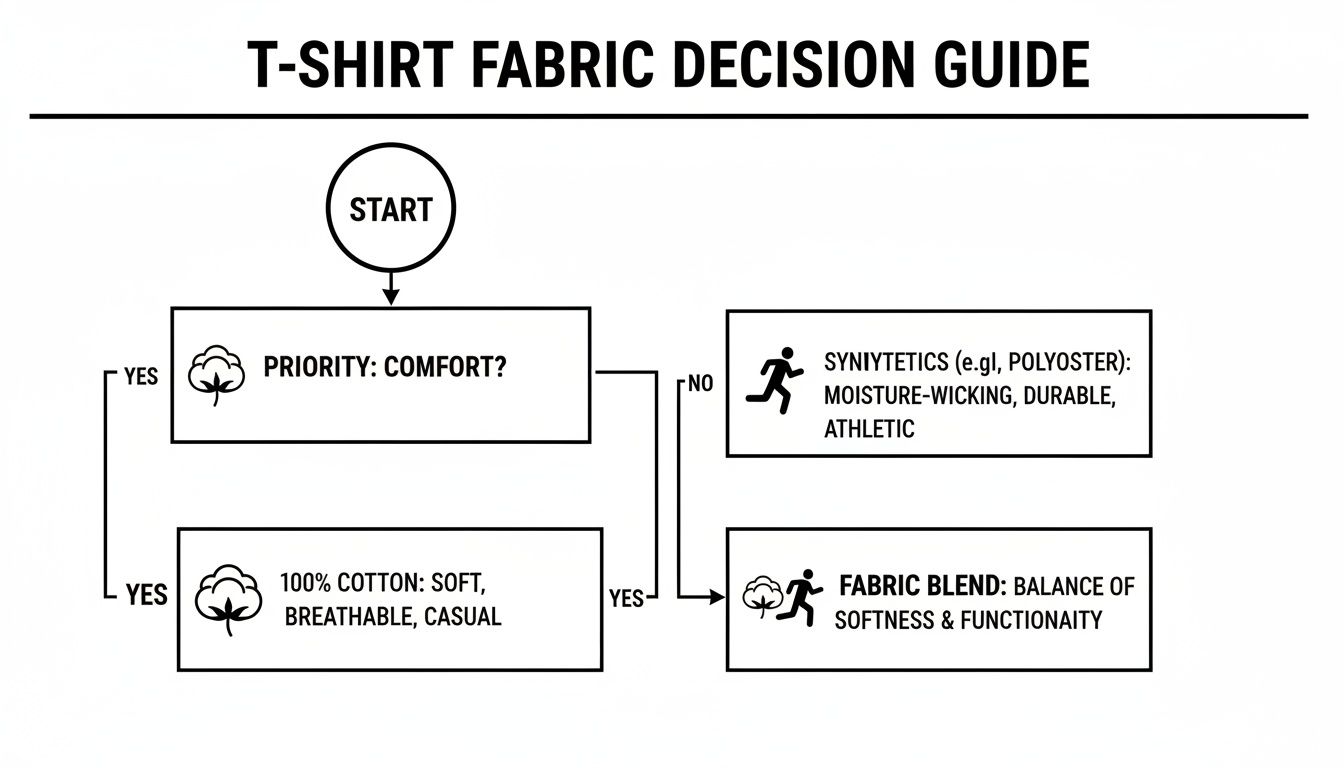

This flowchart is a great way to visualize your decision. Think about what your primary goal is—is it all about comfort, pure performance, or finding a happy medium?

As you can see, the perfect fabric for your project really just depends on what the shirt is for. Your end goal is what should guide you toward cotton, synthetics, or a blend.

T-Shirt Fabric At a Glance

To make things even simpler, here’s a quick-reference table that puts the most common t-shirt fabrics head-to-head. Use it to compare the pros and cons at a glance, from how a design will print on it to how well it will hold up after a dozen washes.

| Fabric Type | Best For | Feel & Comfort | Print Quality | Durability |

|---|---|---|---|---|

| 100% Cotton | Everyday retail, brand merch, and general wear. | Soft, breathable, and feels great against the skin. The classic tee feel. | Excellent. Provides a perfect, smooth canvas for DTF and screen printing, resulting in vibrant, crisp designs. | Good, but it can be prone to shrinking and fading over time if you don't wash it with a little care. |

| 100% Polyester | Activewear, sports jerseys, and performance apparel. | Smooth, lightweight, and wicks moisture away; not as breathable as cotton. | Good, especially for sublimation. DTF prints well but needs care to prevent dye migration (color bleed). | Excellent. It resists shrinking, stretching, and wrinkling, making it incredibly tough. |

| Cotton/Poly Blends | All-purpose use, promotional items, and casual staff wear. | The best of both worlds—soft like cotton but with added durability and wrinkle resistance. | Very good. It’s a versatile surface that handles most printing methods beautifully, including DTF. | Very good. The blend of fibers makes the whole garment stronger and longer-lasting. |

| Tri-Blends | Premium retail, fashion-forward apparel, and vintage-style fitness wear. | Exceptionally soft with a slight heathered look and a stylish, flattering drape. | Good, but the mixed texture can give prints a slightly muted, retro look. It’s a vibe. | Good. The three-fiber mix creates a strong fabric that still has a lot of flex and movement. |

This table should give you a solid starting point. Each fabric has its place, and knowing the core differences is key to matching the right material to your specific vision.

Decoding the Big Three: Cotton, Polyester, and Blends

When you think of a classic t-shirt, what comes to mind? For most of us, it’s 100% cotton. This natural fiber is the undisputed champion of comfort, celebrated for its soft feel and incredible breathability. It’s the reason a brand-new cotton tee can feel like an old favorite from the very first wear.

Cotton’s grip on the apparel world is massive. About 95% of all cotton grown globally ends up in our clothes, making it the backbone of the industry. With over 2 billion t-shirts flying off the shelves each year, this humble fiber supports a market projected to hit $330 billion by 2025.

But here’s the thing—not all cotton is the same. Knowing the difference is what separates a standard tee from a truly premium one.

The Different Faces of Cotton

Your basic cotton shirt is a solid, reliable choice. But its upgraded cousins offer a whole different level of quality.

- Ringspun Cotton: Instead of just spinning cotton fibers into yarn, the ringspun process tightly twists and thins the strands. This creates a much finer, stronger, and noticeably softer yarn. The result? A t-shirt that feels smoother on the skin and holds up better over time.

- Combed Cotton: This technique takes ringspun cotton one step further. Fine brushes are used to literally comb through the fibers, pulling out any impurities and short strands. Only the longest, straightest, and best fibers remain, creating an exceptionally soft fabric with a perfect surface for printing.

These premium cottons provide a fantastic canvas for Direct-to-Film (DTF) transfers. The smooth surface allows for sharp details and vibrant colors that truly pop.

Polyester: The Performance Powerhouse

Polyester used to have a reputation as a cheap, scratchy alternative, but those days are long gone. Today's 100% polyester is a modern performance hero. This synthetic fabric is engineered for one thing: resilience. It wicks moisture, holds its shape, and stands up to abuse.

Think of it like this: cotton absorbs sweat like a sponge, quickly becoming heavy and clingy. Polyester, on the other hand, is designed to pull moisture away from your skin and push it to the fabric's surface to evaporate. That’s why it’s the standard for sports jerseys and activewear—it keeps you dry, resists wrinkles, and looks great wash after wash.

Blends: The Best of Both Worlds

So, what happens when you combine the soft, natural feel of cotton with the durable, moisture-wicking power of polyester? You get a blend, one of the most versatile and popular fabrics out there. The most common is the 50/50 blend (50% cotton, 50% polyester), which strikes a fantastic balance.

A 50/50 blend is the practical workhorse of the t-shirt world. It marries the comfort of cotton with the durability and wrinkle-resistance of polyester, creating a low-maintenance garment that’s perfect for everything from promotional giveaways to daily staff uniforms.

These blended tees are soft, durable, and much less likely to shrink than 100% cotton. This synergy makes them a go-to, cost-effective choice for a huge range of applications. For a deeper dive into how these two fibers stack up, check out our complete guide on cotton vs polyester.

Broadening your textile knowledge is always a good idea. For instance, exploring the materials used for academic wear can offer surprising insights into how different fabrics are chosen for specific purposes.

Tri-Blends: The Luxury Option

Finally, we arrive at the tri-blend. This premium fabric is typically a mix of three materials: cotton, polyester, and rayon. It's the rayon—a semi-synthetic fiber made from wood pulp—that gives tri-blends their magic. It creates a uniquely soft texture and a stylish, fluid drape that looks amazing.

Tri-blends have a signature heathered look and feel incredibly lightweight. While they do come with a higher price tag, their superior comfort and modern fit make them a favorite for high-end retail brands. They offer a luxurious feel that instantly sets them apart from the crowd.

What Fabric Weight and Knit Really Mean

Have you ever picked up two t-shirts, both labeled 100% cotton, yet one feels light and breezy while the other feels thick and almost bulletproof? The secret isn’t just the fiber—it’s the fabric’s weight and how it was constructed. Getting a handle on these two specs is key to truly understanding t-shirt quality.

Think of fabric weight like the difference between a sheet of notebook paper and a high-quality wedding invitation. They're both paper, but the heavy cardstock has a completely different feel and purpose. For fabrics, we measure this "thickness" in GSM, which stands for Grams per Square Meter.

It’s pretty straightforward: a higher GSM number means the fabric is heavier and more dense. This isn't a simple case of "heavier is better," though. It's all about matching the weight to the shirt's intended use.

Understanding GSM T-Shirt Weights

Knowing the common GSM ranges is like a cheat code for sourcing blanks. You can get a solid idea of a shirt's feel and durability just from this one number.

- Lightweight (Under 150 GSM): These are your airy, drapey tees perfect for summer or fashion-forward fits. They feel incredibly soft and breathable but might not be the most durable option for heavy-duty use.

- Medium-weight (150-200 GSM): This is the gold standard for a great all-around t-shirt. It’s the sweet spot—substantial enough to feel high-quality and hold up well to washing, but still comfortable and breathable for everyday wear. Most premium retail shirts fall in this range.

- Heavyweight (200+ GSM): We're talking workwear and high-end streetwear here. These shirts are built like tanks, offering a structured fit and incredible durability. The fabric feels thick, rugged, and has a real premium presence.

Jersey vs. Interlock Knit: The Feel Factor

Weight is only half the story. The way the individual threads are looped together—the knit—is what really defines the fabric's texture, stretch, and smoothness. While there are countless knitting techniques, the t-shirt world is dominated by two main players: Jersey and Interlock.

Jersey knit is what you probably picture when you think of a t-shirt. It's a single-knit fabric, giving it that familiar softness and comfortable stretch. Interlock, on the other hand, is a double-knit—think of it as two layers of jersey knitted together back-to-back into a single, integrated fabric.

That double-knit construction gives Interlock a completely different character. It’s noticeably smoother, thicker, and more stable than Jersey. It also provides an incredibly flat and uniform surface, making it an amazing canvas for high-detail printing.

Here’s how they stack up:

| Knit Type | Construction | Key Characteristics | Best For |

|---|---|---|---|

| Jersey Knit | Single Knit | Soft, stretchy, comfortable, classic t-shirt feel. | Everyday tees, fashion fits, general apparel. |

| Interlock Knit | Double Knit | Smoother, more stable, thicker feel, less stretch. | Premium apparel, polos, garments needing structure. |

Once you start looking at both GSM and knit type, you can move past just choosing a fiber. You can really dial in your selection to find the perfect blend of weight, feel, and durability to bring your specific vision to life.

How Your Fabric Choice Affects Print Quality

Picking a t-shirt fabric is about way more than just how it feels. Think of it as choosing the perfect canvas for your art. The fabric's texture, smoothness, and the fibers it's made from will directly impact how your ink sits, how the colors pop, and ultimately, how long your design lasts. Nailing this choice is what separates a good-looking shirt from a great one.

Imagine you're an artist. A smooth, primed canvas is going to give you crisp lines and brilliant colors. In the t-shirt world, 100% ringspun cotton is that perfect canvas. Its fibers are tightly woven and create an incredibly smooth surface, which is exactly what you want. This lets inks—especially from Direct-to-Film (DTF) transfers—bond perfectly, giving you sharp, vibrant prints that really stand out.

But the moment you start working with synthetic fibers like polyester, the game changes. Polyester just doesn't absorb ink the same way cotton does, and the way it's dyed at the factory can create some real headaches for printers.

Printing on Synthetics and Blends

Printing on 100% polyester is kind of like trying to paint on a slick, non-porous surface. Modern methods like DTF have made it much easier, but you still have to be careful. The number one problem is something called dye migration. This is when the dye from the shirt itself "bleeds" into your ink during the heat-pressing process, messing up your colors. That crisp white print on a red polyester tee? It can easily turn pink if you're not careful.

To get around this, you need to use special dye-blocking inks or be very precise with lower heat settings to get a clean, durable print that stays true to color.

Blended fabrics like a 50/50 cotton/poly or a tri-blend offer a fantastic middle ground. The cotton in the mix gives the ink a good, stable surface to grab onto, while the polyester adds durability. Prints on these fabrics often come out with a softer, slightly muted, or "vintage" vibe, which is a really popular look.

How Different Fabrics Perform With DTF

Direct-to-Film (DTF) has taken the industry by storm because it works on almost anything. But "works on" doesn't mean "looks the same on." The fabric you choose still makes a huge difference in the final result.

- 100% Cotton: This is the undisputed champion for DTF. You’ll get the boldest colors, the sharpest details, and the most durable prints because the ink and natural fibers are a perfect match.

- Polyester & Blends: DTF is a great option here, too, but you'll need dye-blocking transfers or precise temperature control to stop that pesky dye migration. The final print feels softer and has excellent stretch, making it ideal for activewear.

- Tri-Blends: The unique texture from the cotton, polyester, and rayon blend gives these shirts their signature soft, heathered look. A DTF print on a tri-blend will have a slightly faded, retro aesthetic that looks intentional and very cool.

Printing Method and Fabric Compatibility

See how different fabric materials hold up to various printing techniques to ensure your designs come out perfectly.

| Fabric Material | Best For DTF Printing | Screen Printing Notes | Key Considerations |

|---|---|---|---|

| 100% Cotton | Excellent. Produces sharp, vibrant, and opaque prints with outstanding durability. | Excellent. A classic combination. Water-based and plastisol inks work beautifully. | The gold standard for most high-detail, full-color designs. |

| Polyester | Very Good. Requires dye-blocking transfers to prevent dye migration. | Challenging. Requires special poly-blocking inks and lower cure temperatures. | Can be tricky but yields great results for athletic apparel with the right technique. |

| 50/50 Blends | Very Good. Offers a good balance of vibrancy and a softer feel. | Good. Often used to create a softer, more "vintage" print aesthetic. | A versatile and popular choice that combines the best of both worlds. |

| Tri-Blends | Good. Creates a desirable faded, retro look that complements the fabric. | Good. The print will naturally look more muted and worn-in, which is often the goal. | The texture of the fabric will show through the print more. |

Choosing the right fabric for your printing method is one of the most important decisions you'll make. If you want to dive deeper, our guide covering various fabric printing techniques breaks down even more options.

In the end, the best t-shirt material is one that not only feels great to wear but also makes your design look its absolute best. Understanding how ink and fabric play together is the key to avoiding costly mistakes and making sure every shirt you produce is something you can be proud of.

Making Your T-Shirts Last Longer

You can pick the perfect t-shirt, but if you don't care for it properly, you’ve only won half the battle. How you wash and dry a shirt is what really protects your investment and keeps that custom print looking sharp.

Following the right care instructions makes sure the fit, feel, and design you carefully selected will last for years, not just a few washes.

The number one killer of a great t-shirt? Washing it wrong. Every fabric reacts differently to heat and agitation, so tossing everything in on the same setting is a recipe for disaster. For instance, cotton's natural fibers will shrink up in hot water, while the synthetic fibers in polyester can get wrecked by a hot dryer cycle.

Essential Care Tips by Fabric

To keep your shirts looking like they just came out of the box, you've got to match your laundry routine to the material. This simple step is your best defense against common problems like shrinking, fading, pilling, and a cracked print.

- 100% Cotton: Wash cotton tees in cold water. Always. This is your best defense against shrinking and keeps the color from bleeding. If it has a print, turn it inside out before washing and either tumble dry on low or, even better, let it hang dry.

- 100% Polyester: This stuff is pretty tough and can handle warm water, but you still want to stick to a low heat setting on the dryer. Too much heat will eventually break down the synthetic fibers, and you'll lose that soft, smooth feel.

- Blends (Cotton/Poly): These versatile shirts are best washed in cool or warm water—never hot. Tumble dry on a low or medium setting. The polyester gives them a bit more shrink resistance than pure cotton, but high heat is still the enemy.

Sticking to these simple rules does more than just keep your shirt looking good. It can extend the life of the garment by up to 50%, ensuring the fabric stays soft and the print remains crisp and crack-free.

Solving Common Fabric Problems

Even if you do everything right, you might still run into a few issues. Don't worry, most of them are easy to fix—or even better, prevent.

Ever notice those little fuzzballs on your blended shirts? That’s called “pilling,” and it’s usually caused by friction from other clothes in the wash. Simply turning your shirts inside out before you wash them can make a huge difference.

For cotton shirts, fading is the main culprit. Steer clear of harsh detergents and try not to hang them in direct, blazing sunlight if you line-dry. A little bit of know-how about your chosen t-shirt fabric material is all it takes to keep every piece in your collection looking its absolute best.

Tips for Sourcing Fabrics Like a Pro

Picking the perfect t-shirt fabric material is one thing, but finding a supplier who can deliver it consistently is where the real work begins. Your brand's reputation hinges on this partnership. Whether you go with a massive distributor or a small boutique mill, you need to know you can count on them for consistent quality, color, and stock levels.

You're stepping into a huge industry—the global shirt fabric market was worth about $25.8 billion in 2023. That’s a lot of competition, which makes your supplier choice even more critical.

Before you even think about placing a bulk order, get samples. Always. This is the only way to truly feel the fabric, check the fit, and—most importantly—see how it holds up to your printing method. A shirt can look amazing in a product photo, but you won't know how it really performs until you get your hands on it and run a test print.

Vetting Your Partners

Finding a great supplier means doing a little homework and asking the right questions. You want to partner with companies that are open about how and where they make their products.

Here's what to dig into:

- Inventory Consistency: Ask them straight up: "If I reorder this exact shirt in six months, will it be the same?" You can't afford surprises.

- Ethical Standards: Do they have any certifications for ethical labor or sustainable manufacturing? This matters to a lot of customers.

- Support: What happens when something goes wrong? Send their customer service a test email and see how quickly—and helpfully—they respond.

A great supplier is a partner in your business. Their reliability directly impacts your ability to deliver a consistent, high-quality product to your customers and scale your operations smoothly.

Once you’ve found that perfect material, you'll need to get your numbers right. Knowing how to calculate fabric yardage like a pro is a skill that will save you a lot of money and headaches down the road.

Ready to start your search? We’ve put together a list of trusted partners in our guide to the best wholesale blank apparel suppliers.

A Few Common Questions About T-Shirt Fabrics

Diving into the world of t-shirt fabrics can feel a bit overwhelming, but usually, it boils down to a few key questions once you're ready to choose. Let's tackle the most common ones.

What’s the Best All-Around T-Shirt Fabric?

If you're launching a new clothing brand, you really can't go wrong with a 100% ringspun cotton tee. It has that premium, soft touch that customers immediately notice, and it creates a beautifully smooth canvas for printing.

The other fantastic option is a CVC (Chief Value Cotton) blend, something like a 60/40 cotton/polyester mix. This gives you the best of both worlds—it keeps most of the cottony softness while borrowing polyester's durability and wrinkle resistance. It's a true workhorse fabric.

For a new brand looking for that sweet spot of quality, comfort, and printability, stick with ringspun cotton or a solid CVC blend. Think of them as reliable foundations that will make both your customers and your designs happy.

Does a Higher GSM Always Mean Better Quality?

Nope, not at all. Think of GSM as weight, not quality. A higher GSM just means the fabric is heavier and denser. This is perfect if you're going for a durable, structured feel, like what you'd find in premium heavyweight streetwear.

But sometimes, you want the opposite. A lighter GSM (around 140-160) gives you a breezy, breathable shirt with a nice drape, which is ideal for a summer line or a more fashion-forward fit. Real quality is a mix of the right GSM for the job, the type of fiber used, and the quality of the knit itself.

Why Do Some Polyester Shirts Feel Softer Than Others?

This all comes down to modern manufacturing. The good stuff, often called microfiber or performance polyester, is spun from incredibly fine threads. The result is a fabric that's silky-smooth, soft, and amazing at wicking away moisture.

On the flip side, older or cheaper polyester was made with thicker, coarser fibers, which is what gives it that scratchy, plastic-like reputation. When you're looking at poly shirts, keep an eye out for terms like "spun polyester"—it’s a good sign you’re getting a much softer, higher-quality garment.

Ready to see your designs pop on the perfect fabric? Raccoon Transfers specializes in top-tier DTF prints that look incredible on cotton, blends, and polyester. Get vibrant, tough, and super easy-to-apply transfers shipped out the next day. Start creating with us today!