Find the Best Heat Press Machine for Shirts – Top Picks & Reviews

Compartir

If you're serious about making custom shirts that look truly professional, you need a heat press that delivers consistent heat and even pressure. Forget the household iron—that’s a recipe for peeling vinyl and disappointment. We're talking about a tool that makes your creations look like they came from a high-end shop, wash after wash.

A 15x15 inch model is pretty much the gold standard for most t-shirt work, and great options from brands like Cricut and VEVOR have made pro-level results accessible for everyone from home crafters to small business owners.

Your Guide to the Top Heat Press Machines for Shirts

Let's cut through the noise. Choosing the right heat press is the single most important decision you'll make for creating durable, high-quality custom apparel. It’s what separates amateur results from professional ones.

This guide is designed to help you pinpoint the perfect machine for your needs. We'll focus on the features that actually matter, so you can invest with confidence.

What Really Matters for Flawless Shirts

When it comes down to it, three things are absolutely essential for getting a perfect print every time:

- Consistent Heat: The entire heat platen needs to maintain a steady temperature. Any cold spots will ruin your transfer, guaranteed.

- Even Pressure: Uniform pressure is key to embedding the design deep into the fabric's fibers. This creates a permanent bond that won’t crack or peel.

- The Right Platen Size: A 15x15 inch platen is the sweet spot for adult t-shirts. It’s large enough for most designs without being too bulky to handle.

Once you understand these fundamentals, you can ignore the confusing marketing jargon and focus on what truly affects performance. It’s no surprise the demand for these machines is growing. The heat press market was valued at USD 1.5 billion in 2024 and is projected to hit USD 2.8 billion by 2033.

Expert Take: Finding the "best" heat press isn't about a single winner. It's about matching the machine to your goals, whether you’re crafting for fun or building a business from your home.

To make things easier, let's start with a quick look at our top recommendations.

Top Heat Press Machines for Shirts at a Glance

This summary table gives you a bird's-eye view of our favorite machines. We've categorized them by who they're best for and highlighted their standout features to give you a clear starting point.

| Model Name | Best For | Platen Size | Key Feature |

|---|---|---|---|

| Cricut Autopress | Hobbyists & Crafters | 15" x 12" | Zero-effort auto-pressure |

| VEVOR Clamshell Press | Small Businesses | 15" x 15" | High durability for volume |

| Fancierstudio PowerPress | Beginners on a Budget | 15" x 15" | Simple, no-frills operation |

| HTVRONT Auto Heat Press | Home-Based Sellers | 15" x 15" | Auto-release and safety features |

Each of these machines excels in its own way, and one of them is likely the perfect fit for your specific projects and budget. Now, let's dive deeper into what makes each one stand out.

Comparing Heat Press Designs for Your Workspace

When you're hunting for the best heat press for shirts, it's easy to get lost in specs like temperature and pressure. But the real game-changer? It’s how the machine actually fits into your workspace and daily grind. The three main designs—clamshell, swing-away, and draw—each come with their own distinct personalities, pros, and cons. Getting to know them is the key to picking a machine that helps, not hinders, your creative flow.

Let's break down each style, looking at how much room they really take up, how easy they are to use for printing shirts, and what the safety situation is. This will give you the practical context you need, whether you’re setting up in a dedicated workshop or carving out a small corner of your home.

The Compact Clamshell Press

The clamshell heat press is the go-to for most beginners and home crafters, and for good reason: it’s a massive space-saver. As the name implies, it opens and closes on a hinge, with the top platen lifting straight up. Because it operates vertically, it has the smallest operational footprint of the bunch.

But there's always a trade-off. That compact design means you're working in a tight space. The gap between the hot upper platen and the lower one is pretty limited, which can make it tricky to line up detailed designs or work with thicker items like hoodies. You have to be mindful of your knuckles getting too close to that hot surface.

- Best For: Anyone with limited space, like a small craft room or apartment. It's also perfect for cranking out straightforward, single-layer shirt designs quickly.

- Workflow Impact: Super fast and efficient for simple jobs. You just lower the handle, press, and lift it straight back up.

- Space Requirement: Minimal. The machine's physical footprint is pretty much all the space you need.

The Unobstructed Swing-Away Press

A swing-away heat press does exactly what it sounds like: the top heat platen swings out horizontally, moving completely away from the lower platen. This single feature is a huge deal because it gives you a totally unobstructed view and access to your workspace.

That clear access makes life so much easier when you're arranging a shirt, perfectly aligning a complex transfer, or handling bulky garments. You can work without constantly worrying about burning your hands. The catch? The space it needs. A swing-away requires almost double its own footprint to accommodate that swinging platen, making it a no-go for tight quarters.

Key Differentiator: The swing-away's biggest win is its clear, open work area. This design dramatically cuts the risk of accidental burns and allows for the kind of careful, precise alignment you need for professional-quality results.

The Ergonomic Draw Press

Think of the draw heat press as a smart hybrid, borrowing the best ideas from both clamshell and swing-away models. With a draw press, the top platen stays put while the bottom platen slides out toward you like a drawer.

This clever mechanism gives you an open, accessible workspace for placing your garments and transfers—just like a swing-away—but without needing all that extra side-to-side clearance. You get fantastic access and a major safety boost while keeping the machine's footprint more contained. Many users find draw presses more ergonomic, too, since you aren't reaching under a hot platen.

- Best For: Small business owners who demand precision and safety but can't spare the wide-open space a swing-away requires.

- Workflow Impact: It really improves comfort and accuracy during setup. The slide-out tray lets you work on your layout without ever putting your hands near the heat source.

- Space Requirement: More than a clamshell but less than a swing-away. It just needs some clear space directly in front of it.

Ultimately, the right design comes down to your personal workspace and the kind of projects you tackle. A clamshell is brilliant for fast, simple production in a small spot. But if you’re aiming for more complex, professional-level work, a swing-away or draw press will give you the precision and safety you need to do it right.

Evaluating The Performance Features That Make or Break a Shirt Printing Business

Okay, let's get past the looks and talk about what really matters: performance. A heat press's ability to consistently churn out professional-grade shirts comes down to a few critical features. Getting these right is the difference between a smart investment and a constant source of frustration.

We're going to break down the core specs that directly impact the quality and durability of your custom apparel. This isn't about finding the machine with the biggest numbers; it's about understanding how these elements work together to create a print that lasts.

Platen Size and Why It Matters

When you're pressing shirts, the platen—that heated plate doing all the work—is everything. You'll see a lot of sizes out there, but there's a good reason the 15"x15" platen is the industry standard. It’s the sweet spot between versatility and practicality.

A 15"x15" press is big enough to handle the vast majority of adult t-shirt designs, from a simple chest logo to a full-front graphic. It’s also got plenty of room for other hot sellers like tote bags and hoodies. Sure, a smaller 9"x12" press works for kids' clothes, but you'll quickly feel boxed in when an adult-sized order comes through. On the flip side, a massive 16"x20" press is usually overkill for standard tees, taking up more space and electricity than you need.

Key Insight: A 15"x15" platen is your workhorse. It equips you to handle over 90% of typical apparel jobs without the cramped feel of a smaller press or the unnecessary expense and size of a larger one.

Choosing the right size from the get-go saves you from a costly upgrade later. Think of it as the foundation of your entire production setup.

The Critical Role of Heat Consistency

Uneven heat is the silent killer of a good print. Your press might read 350°F, but if it has cold spots, parts of your transfer simply won't stick right. This is what leads to peeling vinyl, blotchy sublimation prints, and a pile of wasted shirts.

Top-tier heat presses solve this with thick platens that have multiple heating elements woven through the entire surface, ensuring true edge-to-edge heat. Budget models often cut corners here, using a single, cheaper heating element that creates major temperature swings across the platen.

When you're comparing machines, look for:

- Thicker Platens: A hefty metal platen holds and distributes heat far more evenly.

- Multiple Heating Coils: More coils mean fewer opportunities for cold spots to ruin your work.

- Reputable Brands: Established names have a reputation to protect and invest in the components that deliver reliable performance.

This is where digging into user reviews is a goldmine. People are quick to share their frustrations with peeling transfers, which almost always points back to poor heat distribution.

Understanding Pressure and How to Apply It

Heat gets all the attention, but precise, even pressure is its equal partner. The right amount of pressure is what fuses the transfer's adhesive deep into the fabric's fibers, creating a bond that can actually survive the wash.

Different transfers need different levels of pressure, and knowing your settings is key.

- Heat Transfer Vinyl (HTV): Usually needs firm, even pressure to properly activate the glue.

- Sublimation: Requires light to medium pressure. Too much can cause the ink to bleed or "ghost."

- Screen Print Transfers: Often demand very firm pressure to get that plastisol ink to bond perfectly.

Getting the application process down is non-negotiable. For a deep dive into the right settings and techniques, our guide on how to use a heat press is a great place to start. A superior machine will always give you the ability to fine-tune your pressure with confidence.

The demand for quality custom apparel isn't slowing down. While North America and Europe are huge markets, the Asia-Pacific region is growing the fastest, driven by a boom in small businesses and shoppers hungry for personalized gear. By investing in a press with rock-solid heat and pressure control, you’re setting yourself up to deliver the professional quality this growing market expects.

A Detailed Showdown Of Leading Heat Press Models

Specs on a product page only tell you half the story. The real test of the best heat press machine for shirts is how it actually performs day-in and day-out. This is where we'll pit the top models against each other, looking at them through the lens of real-world scenarios you’ll face.

Instead of a generic feature list, we’re going to dig into how those features help—or hinder—different kinds of creators. For instance, how does an automatic pressure system really benefit a high-volume Etsy shop compared to a manual knob for a crafter working with unique materials? This breakdown is all about giving you clear, situational advice.

Battle Of Automation: The Cricut Autopress Vs. The HTVRONT Auto Press

If you’re all about speed and simplicity, automation is your best friend. Both the Cricut Autopress and the HTVRONT Auto Heat Press aim to take the guesswork out of pressing, but they get there in slightly different ways, which makes them better suited for different workflows.

The Cricut Autopress is the champion of "set it and forget it." Its killer feature is its ability to automatically sense the thickness of your blank—be it a t-shirt or a hoodie—and apply the perfect pressure every time. You literally close it with two fingers, and the machine does all the work, even popping open when the timer is up. No knobs, no guessing.

On the other hand, the HTVRONT Auto Heat Press still requires you to set the pressure yourself, but its real magic lies in its auto-open feature and extra safety measures. Once the countdown finishes, the platen lifts on its own. This is a massive help for anyone trying to multitask, run several presses at once, or just avoid scorching a shirt because they got distracted.

Key Differentiator: The Cricut Autopress delivers true zero-effort pressure, which is perfect for crafters who are constantly switching between materials of different thicknesses. The HTVRONT’s auto-open function is a workflow game-changer for anyone focused on high-volume production.

Situational Recommendation:

- Best for Multi-Material Crafters: The Cricut Autopress wins hands-down if your projects jump from thin tees to thick fleece, since you never have to mess with pressure settings.

- Best for High-Volume Etsy Shops: The HTVRONT Auto Heat Press is the smarter pick for sellers cranking out dozens of similar items. That auto-open feature will save you time and prevent costly mistakes.

The Workhorse Comparison: VEVOR Clamshell Vs. Fancierstudio PowerPress

For a lot of small businesses and serious hobbyists, the dream machine is a durable, no-frills workhorse that just gets the job done. The VEVOR Clamshell and the Fancierstudio PowerPress are two titans in this space, beloved for being affordable and reliable.

The VEVOR Clamshell feels like it was built to last. It typically has a thicker platen and a sturdier frame, ready to handle the grind of daily commercial use. You adjust the pressure with a big, top-mounted knob that lets you apply some serious force—perfect for things like stubborn plastisol transfers that need a firm, even press.

The Fancierstudio PowerPress is the quintessential beginner’s press. It’s incredibly straightforward, with simple digital controls for time and temperature. It might not have the heavy-duty feel of the VEVOR, but its simplicity is its biggest selling point. It’s not intimidating, letting new users start pressing great-looking shirts without a steep learning curve.

Situational Recommendation:

- Best for Small Businesses Scaling Up: Go with the VEVOR Clamshell. It’s the more robust of the two, built to withstand constant use and deliver the powerful, consistent pressure you need for professional-grade transfers.

- Best for Beginners on a Budget: You can’t beat the Fancierstudio PowerPress as an entry point. It gives you all the core functions you need to get fantastic results without overwhelming you with bells and whistles.

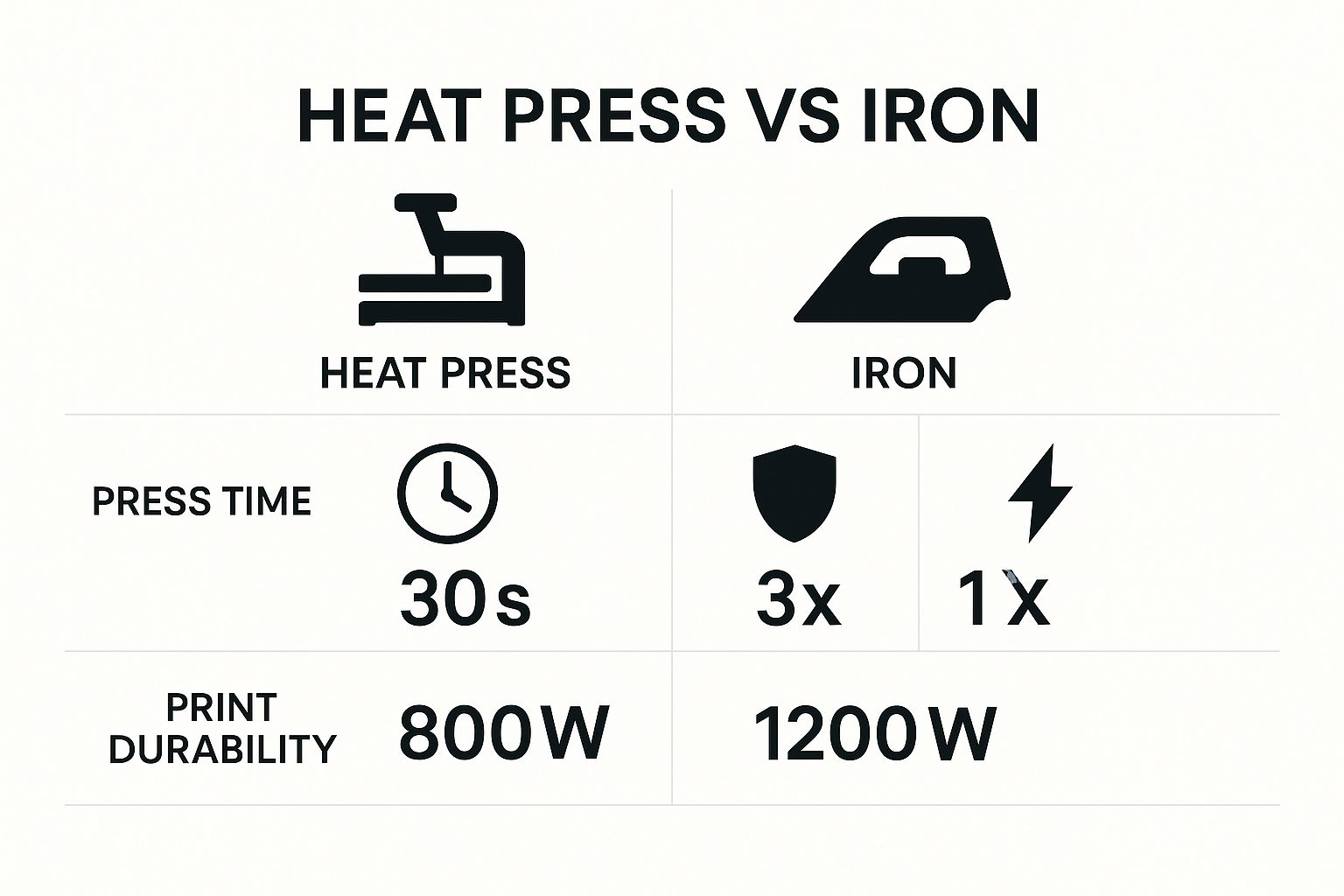

This is where you really see how much better a dedicated heat press is than a home iron, especially when it comes to consistency and durability.

As you can see, a heat press isn't just a time-saver; it uses less energy and creates a print that will actually last.

Precision And Control: Manual Vs. Automated Pressure Systems

One of the biggest debates in the heat press world comes down to manual versus automated pressure. Your choice here directly impacts how much control you have over the final product and how easy your workflow is.

Manual pressure, like you’ll find on a VEVOR Clamshell, is all about tactile control. You turn a physical knob to dial in the exact pressure you need, whether it’s a light touch for delicate fabrics or maximum force for thick transfers. This is a huge plus for experienced pros who know that different transfers have different needs. For example, screen print transfers often demand a temperature of 350°F to 375°F and very firm pressure to cure properly.

Automated systems, like the one in the Cricut Autopress, completely remove the guesswork. The machine is smart enough to adapt to the item's thickness and apply what it calculates to be the best pressure. This approach is incredibly user-friendly and delivers amazing consistency from one press to the next, which is key to reducing errors and waste.

Key Differentiator: Manual pressure gives experts ultimate control to fine-tune settings for specialty jobs. Automated pressure offers foolproof consistency and simplicity, making it perfect for beginners or anyone who values speed.

The explosive growth in demand for custom apparel is what’s pushing these innovations forward. The global heat press machine market was valued at around USD 1.36 billion in 2022 and is expected to hit USD 2.3 billion by 2033. This trend shows a clear need for machines that serve both precision-focused experts and efficiency-driven newcomers.

Situational Recommendation:

- Ideal for Complex, Multi-Color Designs: A manual press like the VEVOR often gets the nod here. Layering vinyl or using specialty films can require tiny pressure adjustments that an automated system just can't make.

- Ideal for Fast-Paced Environments: An automated press like the Cricut Autopress is built for speed and consistency, making it a star performer for live event printing or banging out a large batch of standard t-shirt orders.

At the end of the day, finding the best heat press machine for shirts is about matching a machine’s strengths to your goals. Whether you crave effortless automation, rugged reliability, or granular control, there’s a model out there with your name on it. For those ready to step up their game, exploring a premium heat press can unlock the professional features you need to take your creations to the next level.

How to Select the Right Heat Press for Your Goals

Choosing the right heat press isn't about finding the one "best" machine on the market. It’s about finding the best machine for you. The needs of someone making a few shirts on the weekend are completely different from a growing Etsy shop or a small business ramping up production.

Instead of just rattling off a list of features, let's figure out what you actually need based on your goals. When you know which user profile you fit into, you can focus on the specs that matter most for your projects and future plans, without blowing your budget on bells and whistles you'll never use. This way, you invest in a machine that feels less like a tool and more like a partner.

Profile 1: The Hobbyist and Creative Explorer

If you're just dipping your toes in, your main goal is to learn the ropes and have some fun. You’re likely trying out different designs, making gifts for friends and family, and working from a craft corner or home office.

For the hobbyist, simplicity and safety are king. You need a machine that’s easy to figure out and won’t feel intimidating.

Features to Prioritize:

- User-Friendly Controls: Simple digital displays for time and temperature are a must. Machines with presets or automated functions are even better.

- Compact Design: A clamshell model or a small auto-press will fit neatly into a shared space without taking over your life.

- Safety Features: Look for an auto-shutoff function and an insulated body. These are huge for peace of mind when you're working in a non-dedicated workshop.

A press like the Fancierstudio PowerPress or a Cricut EasyPress is a great starting point. They deliver solid performance without bogging you down with complicated settings.

Key Takeaway: For hobbyists, the best press is one that removes creative roadblocks. An easy-to-use, safe, and compact machine will have you making pro-quality shirts faster and with a lot less frustration.

Profile 2: The Etsy Seller and Side Hustler

As an Etsy seller, you're past the experimental phase. Now, it's all about consistency, efficiency, and getting orders out the door. You’re producing in small-to-medium batches, and your reputation rides on every single shirt looking perfect.

Your needs are a step up from a hobbyist's. Durability and repeatable results are non-negotiable because every wasted shirt is money out of your pocket.

Features to Prioritize:

- Consistent Heat and Pressure: You need a machine with a thick platen and quality heating elements to avoid the dreaded cold spots that can ruin a transfer. Even pressure is what makes your designs last through wash after wash.

- A 15"x15" Platen: This is the industry-standard size for a reason. It’s versatile enough to handle the vast majority of adult t-shirt orders, making it a smart long-term investment.

- Durability: Look for a machine with a solid, sturdy build that can handle being used every day without its performance dropping off.

A workhorse clamshell like the VEVOR 15"x15" or an auto-open model like the HTVRONT Auto Heat Press are fantastic options here. They’re built to withstand regular use and produce the professional results your customers are paying for.

Profile 3: The Small Business Owner Scaling Up

For a small business owner, time is money. You’re laser-focused on cranking out as much product as possible, minimizing mistakes, and scaling up to meet growing demand. Your heat press isn't just a tool anymore—it's the engine of your entire operation.

At this level, workflow efficiency and fine-tuned control are what really matter. You need a machine that can keep up with your pace and give you the precision required for a wide range of garments and transfer materials.

Features to Prioritize:

- Advanced Pressure Control: Whether it's a high-quality manual adjustment knob or a slick auto-pressure system, you need pinpoint control for different fabrics and transfer types.

- Swing-Away or Draw Design: These designs are a game-changer for workflow. They give you a clear, unobstructed view of the platen, which speeds up your layout process and drastically reduces the risk of burns during long, high-volume sessions.

- Heavy-Duty Construction: Your machine is going to be running for hours every day. Investing in a commercial-grade press is essential for longevity and protects your business from the disaster of costly downtime.

Matching your machine to your specific goals is the surest way to get the most value from your investment and empower you to create amazing shirts, no matter where you are on your journey.

Common Questions About Heat Press Machines

When you're diving into the world of heat pressing, a lot of questions pop up. It makes sense—you want to get professional-quality shirts, and getting clear answers is the first step to making a smart purchase. Let's tackle some of the most common queries I hear all the time.

My goal here is to give you the straight scoop so you can understand the real-world differences between machines, materials, and methods. From picking the right size platen to figuring out what else you can press besides vinyl, this will get you started on the right foot.

What Is the Best Heat Press Size for T-Shirts?

For most people printing on adult T-shirts, a 15x15 inch platen is the sweet spot. I almost always recommend it as the go-to size because it’s big enough for standard designs without being a massive, expensive beast.

Sure, if you’re only doing small stuff like kids' clothes or tote bags, a 9x12 inch press could work. And if your thing is oversized hoodies or all-over prints, you might need to jump up to a 16x20 inch machine. But for a typical shirt business, the 15x15 inch model gives you the best balance of function and cost.

Can I Use a Home Iron Instead of a Heat Press?

Look, you can use a home iron for some basic craft-store vinyl, but it's not a real replacement for a heat press. An iron just can't deliver the three things you absolutely need for a print that looks professional and actually lasts.

A professional transfer requires:

- Consistent Heat: An iron is full of hot and cold spots, which means your transfer won't apply evenly.

- Precise Temperature: A heat press holds an exact temperature, which is critical for different types of transfers to bond correctly.

- Uniform Pressure: A press clamps down with even, heavy pressure that you simply can't replicate by leaning on an iron.

If you use an iron, you're rolling the dice. The designs often start peeling, cracking, or fading after just a few washes. If you want results that last, a dedicated heat press isn't a luxury—it's a necessity.

Key Insight: It all comes down to reliability. A heat press gives you the same commercial-grade results, every single time. A home iron will never give you that kind of consistency.

What Materials Can I Press Besides Vinyl?

A good heat press opens up a huge range of creative options way beyond standard Heat Transfer Vinyl (HTV). Because you can dial in the exact temperature and pressure, you can work with all sorts of professional transfer materials.

You can press a whole lot more, including:

- Sublimation Prints (for polyester or poly-coated blanks)

- Direct to Film (DTF) Transfers

- Screen Print Transfers (plastisol-based)

- Heat Transfer Paper designed for both light and dark fabrics

- Rhinestones and Embroidery Patches

Every material has its own unique recipe for success. As a general rule, many transfers press somewhere between 350°F and 375°F. For a detailed breakdown, check out our comprehensive heat press temperature guide. It lays out the ideal settings for different materials to help you nail the perfect press every time.

At Raccoon Transfers, we specialize in high-quality DTF transfers that bring your designs to life with vibrant color and lasting durability. Explore our custom transfer options today!