Best Vinyl for Heat Press: Top Picks & Tips for Perfect Results

Compartir

Figuring out the best vinyl for your heat press isn't about finding a single magic material. It really comes down to what you're trying to create. If you're working on a project with simple, bold graphics, standard Heat Transfer Vinyl (HTV) is your workhorse. But for something like a photorealistic image, you’ll want to reach for printable HTV.

This guide will walk you through the options so you can pick the right material and get those professional, durable results you're looking for.

Your Guide to the Best Vinyl for Any Heat Press Job

Choosing the right material is probably the most important decision you'll make when creating custom apparel. It's no surprise the demand for personalized gear has pushed the heat press market to a value of $1.2 billion in 2024, with projections hitting $2.3 billion by 2033. This growth is all about the amazing things you can do with materials like heat transfer vinyl. You can dive deeper into this trend by reading the full heat press market report.

While HTV is a fantastic and versatile place to start, it's not the only game in town. Another popular method you'll hear about is Direct-to-Film (DTF). The biggest difference is that DTF can handle unlimited colors and super smooth gradients without any layering. This gives it a serious edge for photorealistic prints or designs with tons of detail.

For projects with intricate details or many colors, DTF's print-and-press workflow is often more efficient than weeding multiple layers of vinyl.

Still, for single-color logos, team names, or simple text, standard HTV is the undisputed king of speed and simplicity. There’s a time and a place for every material.

To make this crystal clear, here’s a quick guide to help you match the right vinyl to your specific project.

Quick Vinyl Selection Guide for Your Project

Use this table to quickly match your project's needs with the right type of vinyl, helping you make a confident choice from the start.

| Vinyl Type | Ideal for Projects Like | Key Advantage |

|---|---|---|

| Standard HTV | Bold text, logos, simple graphics | Easy to cut, weed, and press for fast results. |

| Printable HTV | Full-color photos, complex patterns | Handles unlimited colors and gradients in one layer. |

| Specialty Vinyl | Adding texture and unique effects | Creates standout finishes like glitter, flock, or metallic. |

Think of this table as your starting point. Once you know the general category, you can explore the specific brands and finishes that will bring your vision to life.

Understanding the 2 Main Types of Heat Transfer Vinyl

When you start working with heat press vinyl, you'll quickly discover two main players on the field: Polyurethane (PU) and Polyvinyl Chloride (PVC). While they both fall under the heat transfer vinyl (HTV) umbrella, they couldn't be more different in feel and function. Getting a handle on their unique properties is the first—and most important—step to creating projects that not only look fantastic but also perform the way you want them to.

The biggest difference boils down to feel and flexibility. Think of it this way: PU is your go-to for anything that needs to be soft and move with the body. It’s incredibly thin and stretchy, which is why it’s the top choice for apparel. On the other hand, PVC is the tough, durable option for items that need to be rugged.

PU Vinyl: The Clear Winner for Apparel and Comfort

If you’re making anything people will wear, PU vinyl is almost always the right choice. Its lightweight and flexible nature allows it to integrate beautifully into fabric, so the design feels like part of the shirt, not a stiff plastic patch sitting on top. This is what pros call a soft "hand."

Imagine a big, bold graphic on a t-shirt. With PU, that shirt remains comfortable and moves naturally. If you used a stiffer material, you'd create a rigid, unbending section. This is exactly why PU dominates the custom apparel world, from fashion tees to performance activewear.

The market for heat transfer materials is booming, with industry analysts projecting it will hit $2.055 billion by 2025. PU’s blend of durability, vibrant color, and comfort is a huge part of that growth. If you want to dive deeper, you can explore more on these market trends and vinyl properties.

PVC Vinyl: The Workhorse for Durability and Structure

PVC vinyl is thicker, more rigid, and built to last. You definitely wouldn't put it on a buttery-soft t-shirt, but its toughness makes it the perfect solution for items that don’t stretch and need to handle a lot of abuse.

Think of PVC as the heavy-duty option for projects where durability trumps softness. Its structure makes it ideal for:

- Canvas Tote Bags: Great for applying a crisp logo that needs to hold its shape and resist scuffs.

- Banners and Signs: Perfect for creating bold graphics that won't warp or distort over time.

- Sports Jerseys: Often used for names and numbers that require maximum resilience against rough contact.

Expert Insight: It’s simple. Choose PU for anything you want to feel soft and flexible against the skin. Go with PVC for projects where ultimate durability and rigidity on non-stretch surfaces are what matter most.

By matching the vinyl's core characteristics—soft and stretchy PU or tough and rigid PVC—to what your project demands, you're paving the way for a professional-quality result. This first decision influences everything that follows, from the application process to how the final product feels and holds up over time.

Printable HTV vs. Standard HTV for Complex Designs

When your designs get more ambitious than simple text or single-color logos, you’ll hit a fork in the road. Do you stick with standard heat transfer vinyl (HTV), or is it time to explore printable HTV? For bold graphics, team names, and any job where clean lines and speed are your top priorities, standard HTV is your workhorse. The cut-weed-press process is straightforward and incredibly efficient.

But what about designs with gradients, intricate patterns, or even photographs? That’s where printable HTV comes in. It’s the only way to get those complex, multi-color graphics onto a garment in a single layer. Think of it less like traditional vinyl and more like a high-tech sticker sheet you print on with a specialized printer, then cut and press. This opens the door to unlimited colors and detail that layering standard vinyl could never achieve.

Workflow and Equipment Needs

The real difference between these two vinyl types boils down to your workflow and the gear you need. For standard HTV, a good vinyl cutter and a heat press are all you need to get started. You cut your design from a pre-made colored sheet, weed away the excess vinyl, and press it onto your shirt. Simple.

Printable HTV is a whole different ballgame. It demands a serious investment in a large-format printer that uses specific eco-solvent or solvent inks. This isn't your average desktop printer; it's professional-grade equipment that represents a significant jump in both cost and complexity. The process is also more involved: you print the design, wait for the ink to cure, cut it out, and then use a separate transfer mask to move it to the garment.

Key Takeaway: Stick with standard HTV for speed and simplicity on single-color jobs. Only consider printable HTV when the design—like a full-color photo—is too complex for layering and you have access to the right commercial printing equipment.

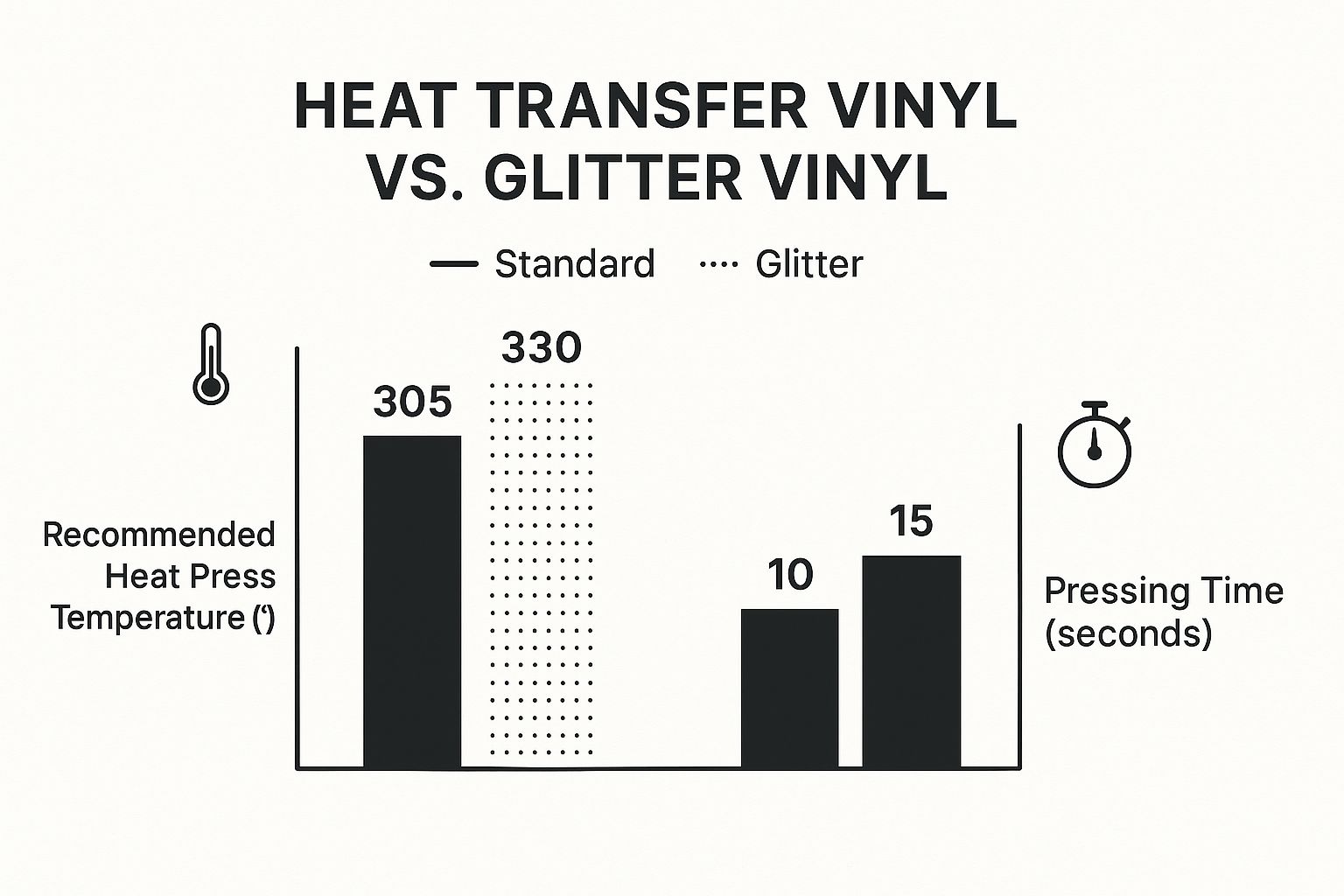

This chart gives you an idea of the specific settings needed for different vinyl types. Even "standard" materials have unique requirements for a perfect application.

As you can see, specialty materials like glitter often need a higher temperature and more press time to get a solid bond compared to your everyday HTV.

The Advantages of DTF Over Vinyl

While printable HTV solves the color problem, there's another player in the game that often does it better: Direct-to-Film (DTF) transfers. DTF isn't vinyl at all. It's a completely different process where designs are printed onto a special film, backed with an adhesive powder, and then heat-pressed onto the fabric.

For complex, full-color designs, DTF beats both standard and printable HTV in several key areas:

- Zero Weeding: This is the big one. With DTF, there is absolutely no weeding involved, which can save you a massive amount of time and frustration on detailed designs.

- Softer Feel: DTF transfers are incredibly thin and flexible. They have a much softer "hand" (the way a design feels on the shirt) than printable HTV, which can sometimes feel like a thick, heavy sticker.

- Better Stretch and Durability: Because they're so flexible, DTF transfers stretch with the fabric. This makes them less prone to cracking over time and ideal for performance wear or knit fabrics.

- Vibrant, Unlimited Colors: DTF technology is fantastic at reproducing photorealistic images, fine details, and smooth gradients with incredible pop and clarity.

- No Layering Required: Unlike standard HTV, which requires tedious layering for multi-color designs, a complex DTF print is applied in a single press. This eliminates bulk and simplifies the application process dramatically.

- Fabric Versatility: DTF works brilliantly on a wider range of fabrics, including cotton, polyester, blends, nylon, and even treated materials, often without needing special low-temp adhesives.

For most people—from small business owners to serious crafters—ordering pre-made DTF transfers is a much smarter and more cost-effective route than investing in a printable HTV setup. You get the color freedom of printable vinyl combined with a better feel, superior durability, and a much simpler application process. It’s quickly becoming the go-to for anything beyond basic, single-color work.

When Should You Choose DTF Instead of Vinyl?

While we've been talking about the best vinyl for a heat press, there's another major player in the custom apparel world that every creator needs in their toolkit: Direct-to-Film (DTF). It’s important to get one thing straight from the start—DTF isn't vinyl. It's a completely different printing process, and that distinction is key because DTF solves many of the common headaches that come with both standard and printable HTV.

Instead of cutting designs from sheets of colored vinyl, DTF technology prints your digital artwork directly onto a specialized film. This film gets an adhesive powder coating, is cured, and then it's ready for you to press. When your project demands photo-quality images or complex designs with a ton of colors, DTF often becomes the clear winner.

Unlock Unlimited Color and Detail

The biggest selling point for DTF is its ability to perfectly reproduce unlimited colors, smooth gradients, and incredibly fine details. If you've ever tried to create a multi-color design with traditional HTV, you know the struggle of layering individual pieces of vinyl. It’s a tedious process that adds noticeable bulk and weight to the finished shirt.

Printable HTV helps with the color problem, but it often has a thick, heavy feel and just can't match the crisp detail or soft touch of a DTF transfer. With DTF, your entire design is printed as one single, lightweight layer, no matter how complex it is.

This makes DTF the go-to choice for:

- Photographic Prints: Recreating high-resolution photos on fabric without any loss of clarity.

- Complex Illustrations: Handling designs with subtle shading, intricate linework, and a huge color palette.

- Brand Logos with Gradients: Perfectly rendering those smooth color transitions that are simply impossible with layered HTV.

DTF completely eliminates the layering puzzle. You get the full spectrum of color and detail in one quick press, resulting in a clean, professional finish that feels like part of the fabric, not something sitting on top of it.

Workflow and Feel: The Deciding Factors

Maybe the most beloved benefit of using DTF is that you can say goodbye to weeding vinyl. Forever. Anyone who has lost hours picking tiny, frustrating pieces of vinyl out of an intricate design knows what a monumental workflow upgrade this is. Your DTF transfer arrives ready to press, transforming even the most complex jobs into a simple, efficient task.

This efficiency is a massive advantage for any business or serious crafter dealing with high-volume orders or highly detailed work. All the time you save by not weeding can go directly into making more products and growing your brand.

On top of that, DTF transfers feel remarkably soft and stretchy. Unlike some vinyl types that can feel stiff and plasticky, a DTF print sinks into the fabric's weave, allowing it to stretch and move with the garment. This flexibility helps prevent the cracking and peeling that can plague less forgiving materials, especially on performance wear or stretchy knits. If you want to learn more about its impressive durability, you can read our guide on how long DTF transfers last.

When Vinyl Still Comes Out on Top

Even with all of DTF's strengths, traditional vinyl definitely still has its place. For simple, one-off designs—think a single-color name and number on a sports jersey—the quick cut-and-press process of standard HTV is often faster and more practical than ordering a DTF transfer.

Most importantly, HTV is the only game in town for achieving unique, textured finishes. If your project absolutely needs the tactile pop of glitter, the raised, velvety feel of flock, or the stunning shimmer of holographic vinyl, then specialty HTV is your answer. DTF can print a picture of glitter, but it can't replicate that physical texture and sparkle. The best vinyl for heat press applications that require specialty effects is, without a doubt, HTV.

Using Specialty Vinyls for Standout Finishes

When your basic heat transfer vinyl just won't cut it, specialty vinyls are where the real fun begins. These aren't your everyday materials; they're designed to add unique textures and eye-catching effects that can turn a standard t-shirt into a premium, high-impact garment. If your goal is to make a product that genuinely pops, these finishes are your secret weapon.

Think of specialty vinyls as the tools you reach for to add a sensory dimension to your designs. You can bring in the brilliant sparkle of glitter, the soft, fuzzy feel of flock, or the stunning shimmer of a metallic or holographic finish.

Glitter and Flock for Textured Effects

Two of the most popular choices here are Glitter HTV and Flock HTV. Glitter is pretty self-explanatory—it’s a vinyl packed with sparkling flakes that deliver an amazing, textured shine. It’s a go-to for so many projects:

- Holiday apparel that needs a festive touch.

- Cheer and dance uniforms that have to catch the light on stage.

- Kids' clothing and accessories where a bit of sparkle makes all the difference.

Flock HTV offers a completely different experience. It has a soft, raised, almost suede-like texture that feels incredible to the touch and adds a premium, retro vibe. It’s perfect for giving logos on hoodies an old-school look or adding a touch of sophisticated, velvety texture to upscale apparel. For a complete guide on applying these unique materials, check out our tutorial on how to heat press.

High-Impact Metallics and Holographics

If you're aiming for a fashion-forward or truly dramatic design, Metallic and Holographic vinyls are where you should look. Metallic vinyls give you that smooth, chrome or brushed-metal finish, adding a sleek, modern edge. They work incredibly well for logos or text that need a bit of polished sophistication.

Holographic vinyl kicks it up a notch. It produces a stunning, rainbow-like shimmer that shifts and changes depending on the light and viewing angle. This effect is perfect for creating futuristic designs, on-trend streetwear, or any piece that absolutely needs to command attention.

The demand for personalized apparel is a huge force pushing the heat transfer market. Trends that favor unique clothing, particularly among younger shoppers, have really poured fuel on this fire.

This isn't just a feeling; the numbers back it up. Market forecasts predict the heat transfer vinyl industry will grow at a steady clip of 4.4% annually through 2033. This growth is all about the power of customization, and specialty vinyls are at the heart of it. You can dive deeper into these consumer trends in this heat transfer market analysis.

While DTF transfers are fantastic for photorealistic color and intricate detail, they simply can't reproduce the physical texture of these materials. If your design truly needs that glittery sparkle, a soft velvety feel, or a true metallic sheen, specialty HTV is the only way to get that authentic, hands-on effect.

You can have the coolest design in the world, but if you put the wrong vinyl on the wrong shirt, you’re just setting yourself up for disappointment. Getting that professional, long-lasting finish that feels great to wear all comes down to matching your vinyl to the fabric.

It’s the step that separates the pros from the beginners. Get it right, and your designs will look fantastic wash after wash. Get it wrong, and you'll see cracking, peeling, or even a melted shirt.

For Everyday Cottons and Blends

Let’s start with the easy stuff. For your classic wardrobe staples—think 100% cotton t-shirts, hoodies, and most poly/cotton blends—you can’t go wrong with a standard PU heat transfer vinyl. This is your workhorse HTV. It’s thin, flexible, and fuses beautifully with these fabrics, creating a soft finish that doesn't feel like a clunky plastic shield on your chest.

Tackling Tricky Fabrics: Stretch and Heat-Sensitive Gear

Things get more interesting when you're working with performance wear. If your garment tag mentions spandex, Lycra, or elastane, you need a vinyl that can stretch right along with it. Slapping a standard, rigid vinyl onto a yoga top is a recipe for disaster; the design will crack and pucker the first time it’s worn. For these, a dedicated high-stretch HTV is an absolute must.

Honestly, though, for stretchy garments, I often find myself reaching for Direct-to-Film (DTF) transfers instead. DTF offers incredible stretchability that matches or even beats the best stretch vinyls. The real win? It maintains a much softer feel and lets you press full-color, complex designs in one go—no tedious layering required.

My Golden Rule: Always, always do a test press. Use a scrap piece of the same material or a hidden spot on the garment itself. This five-second check confirms your heat, pressure, and timing are dialed in, saving you from ruining a perfectly good shirt.

Heat-sensitive fabrics like nylon, some polyesters, and rayon are another common hurdle. These materials can easily scorch or even melt at the high temperatures required for standard HTV. The solution here is to use a specialized low-temperature application vinyl. These are engineered to adhere securely at lower heat settings, so you get a solid bond without damaging the delicate fabric.

For these tricky jobs, checking the manufacturer's specs for both the vinyl and the garment isn't just a suggestion—it's essential.

Troubleshooting Common Heat Press Vinyl Issues

Even when you're using the best vinyl for your heat press, things can still go wrong. It happens to everyone. The real key to getting those flawless, professional results is knowing how to fix the little problems that pop up along the way.

From peeling designs to layering mistakes, let's walk through how to solve some of the most common frustrations you'll encounter.

Properly Layering Different Vinyl Types

One of the first questions people ask is how to layer different types of vinyl without making a mess. Thankfully, there’s a golden rule that makes it easy: specialty vinyls like glitter or flock must always be the top layer. Their unique textures just won't allow another layer to stick on top of them.

When you're building a multi-layered design, just tack down the bottom layers with a very short press—a few seconds is all you need. This keeps the vinyl from shrinking or getting overcooked. Once all your base layers are in place, add the top layer and give it one final, full-duration press to fuse everything together.

What Causes Vinyl to Peel After Washing

There's nothing more frustrating than seeing your beautiful work start to peel off after the first wash. This problem almost always boils down to one of three things: temperature, pressure, or time. If your design is failing, it’s a sure bet that one of those settings was off.

Here’s a quick mental checklist to run through before you press:

- Pre-press the garment: Don't skip this! Pressing the blank shirt for 5-10 seconds gets rid of moisture and wrinkles that can ruin adhesion.

- Verify your settings: Always double-check the vinyl manufacturer’s recommended settings. They aren't just suggestions.

- Ensure sufficient pressure: You should feel some firm resistance when you lock down your press. If it closes too easily, the adhesive isn't getting forced into the fabric fibers.

For a more detailed breakdown, our complete heat press temperature guide gives you specific settings for all kinds of materials.

Key Takeaway: Understanding the difference between a hot peel and a cold peel vinyl is critical. Hot peel means you can pull the carrier sheet off immediately, which is great for moving quickly. Cold peel vinyl needs to cool down completely before you remove the carrier, a vital step for ensuring detailed designs and specialty films adhere perfectly.

Ready to skip the weeding and layering altogether? Raccoon Transfers specializes in high-quality, full-color Direct-to-Film transfers that arrive at your door ready to press. Perfect for any fabric, our DTF transfers give you vibrant, durable results with a super soft feel. Upload your design and get started at https://raccoontransfers.com.