Find Custom T-Shirts Near Me - Your Ultimate Local Guide

Compartir

A quick Google search for "custom t-shirts near me" will give you a list, but the best local printer for your job is rarely the first one on the page. The real trick is finding a shop that’s a perfect match for what you need, whether that's screen printing for a big run of event shirts or direct-to-garment (DTG) for a one-off tee with a super detailed design.

How to Find the Best Local T-Shirt Printer

Finding the right local partner is about so much more than just finding someone close by. You're looking for a business that gets your vision, can work with your budget, and can hit your deadline.

The demand for personalized gear is exploding. In fact, the global custom t-shirt printing market is on track to hit around USD 11.37 billion by 2035, all because people want unique stuff that stands out. You can read more about this trend in Future Market Insights' analysis on custom apparel market growth. All this growth is great for you—it means more options. But it also means you need a solid plan to sort through them all.

Look Beyond a Basic Search

Sure, start with a Google search. But don't let that be the end of it. The best printers are often the hidden gems that don't have a massive marketing budget but do amazing work. You just have to know where to look.

To really find the good ones, you need to dig a little deeper.

- Check Out Local Directories: Sites like Yelp or Thumbtack are goldmines for finding print shops with honest-to-goodness customer reviews. Don't forget your local Chamber of Commerce, too.

- Use Social Media: Hop on Instagram or Facebook and search for hashtags like #AustinTshirtPrinting or #CustomApparelFlorida. This is my favorite way to see a shop’s latest projects and get a vibe for their style.

- Ask Around: This is often the best method. If you know any local business owners, event coordinators, or even high school coaches, ask who they trust for their print jobs. A word-of-mouth recommendation is priceless.

A great local printer doesn't just put ink on a shirt; they act as your creative partner. They're the ones who will give you solid advice on which brand of shirt to use, what ink colors will pop, and how to place the design so it looks fantastic.

When you're starting out, you might run into a few different kinds of local businesses. Here's a quick breakdown of what you'll typically find.

Quick Guide to Local Printer Types

| Printer Type | Best For | Common Services |

|---|---|---|

| Boutique Print Shop | Small businesses, bands, artists needing high-quality, creative work on smaller orders. | Screen printing, DTG, embroidery, design consultation. |

| High-Volume Screen Printer | Large events, corporate orders, schools, and anyone needing 50+ identical items. | Bulk screen printing, vinyl transfers, uniform supply. |

| "Big Box" Franchise | Last-minute, simple projects or when you need a wide range of promotional products. | DTG for single shirts, vinyl, basic embroidery, mugs, signs. |

| Home-Based/Etsy Seller | Highly personalized one-off gifts, small Etsy-style orders, or specialty niche designs. | Heat transfer vinyl (HTV), sublimation, single DTG prints. |

Taking the time to build a solid shortlist from these different sources will save you a ton of headaches down the road. This upfront effort is what separates a frustrating experience from a project you're truly proud of.

Screen Printing vs. DTG: What’s the Right Call for Your Shirts?

As you start talking to local print shops, you’ll quickly hear two terms thrown around: screen printing and Direct-to-Garment (DTG). Getting a handle on these isn't just technical jargon—it’s the key to making sure your project turns out looking great, stays on budget, and lasts.

Think of it this way: screen printing is like using a stencil to paint a wall. It's incredibly efficient for creating bold, simple designs over and over again. On the other hand, DTG is more like a sophisticated photo printer, applying ink directly onto the fabric to capture every last detail and color. Each has its place, and picking the right one is crucial for finding the best "custom t-shirts near me" for your specific needs.

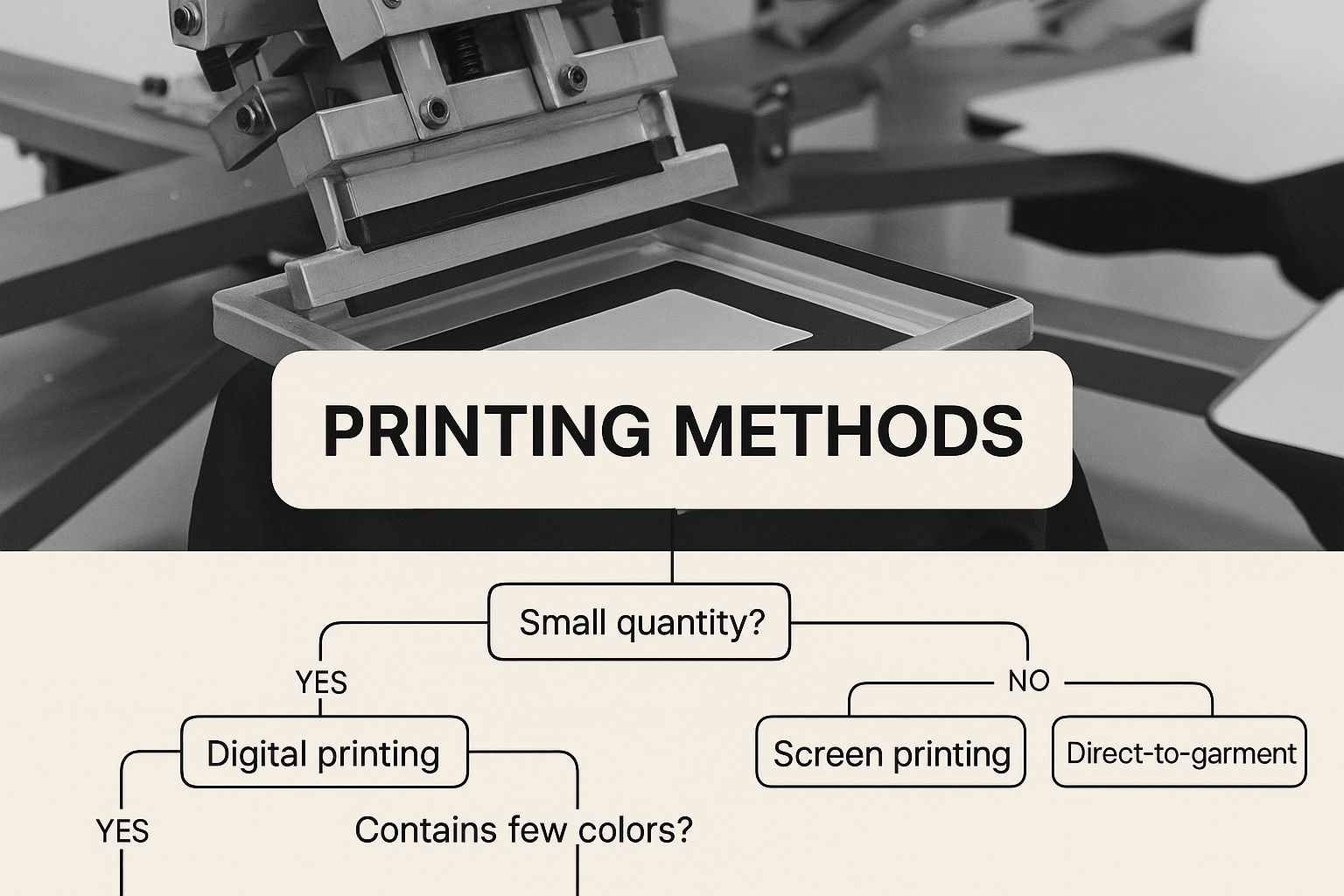

This visual breakdown really simplifies the decision.

As you can see, it really boils down to two things: how many shirts you need and how complex your design is.

The Case for Screen Printing

Screen printing is the undisputed king of large-volume orders. The process is old-school but effective: a custom screen (think of a high-tech stencil) is made for each color in your design. All that setup takes time and money, but once it's done, the cost per shirt plummets as you print more.

This makes it the perfect choice for:

- Big Batches (24+ Shirts): We’re talking about orders for corporate events, family reunions, charity runs, or your band’s merch table.

- Simple, Punchy Graphics: It's ideal for logos or text with just a few solid colors. The ink sits right on top of the fabric, giving it that classic, slightly raised feel that’s super vibrant and built to last wash after wash.

The trade-off? It’s not built for small, one-off jobs or designs that look like a photograph. Creating a bunch of screens for a full-color, detailed image for just a handful of shirts just doesn't make financial sense.

My Two Cents: If your design has a limited color palette and you need more than a couple dozen shirts, screen printing is almost always going to give you the best bang for your buck. Just make sure to ask about their minimum order quantity (MOQ) upfront.

When to Go with Direct-to-Garment (DTG)

Direct-to-Garment is the modern answer for projects where screen printing just won’t cut it. A DTG machine functions a lot like the inkjet printer you have at home, spraying eco-friendly, water-based inks directly into the fabric. This method is a game-changer for intricate and colorful designs.

You’ll want to opt for DTG in these scenarios:

- Small Orders or One-of-a-Kinds: Just need one shirt for a birthday gift or a few prototypes for your clothing line? DTG has you covered with no minimums.

- Photographs and Complex Art: If your design is loaded with gradients, fine lines, and a whole rainbow of colors, DTG can reproduce it with incredible fidelity. The ink soaks right into the cotton, leaving the shirt feeling soft and breathable.

The catch is that DTG is typically more expensive per shirt on larger runs, and it performs best on 100% cotton fabrics. While the tech is always getting better, colors can sometimes look a bit less vibrant on polyester blends. If you want to get really granular, our breakdown of DTF vs. DTG printing methods explores the latest technologies you might encounter.

Getting a Real Quote: How to Vet Printers and Get It Right the First Time

You’ve done your “custom t-shirts near me” search and have a list of local contenders. Now comes the most important part: figuring out who can actually deliver the goods. A slick website doesn't always equal a quality print, so a little due diligence now will save you a world of headaches later.

This isn't just about finding the lowest price. It's about finding a partner who gets your vision and has the skills to execute it. Luckily, the custom apparel market is on fire, set to jump from $8.17 billion in 2024 to an estimated $13.55 billion by 2029, largely thanks to corporate branding and event merch. What does that mean for you? Fierce competition. The good shops are eager to prove they’re the best with transparent pricing and top-notch work. You can read more about the growth of the custom t-shirt industry and its key drivers.

Do a Little Online Detective Work

Before you even think about sending an email, put on your detective hat. A print shop’s online presence tells you a lot about their work ethic and quality standards.

Start with their website portfolio. Don't just glance at the photos; look for consistency. Are the colors popping? Are the lines sharp? More importantly, do they show examples of the type of printing you need? A shop that excels at single-color screen prints for a local 5k might not be the right fit for your detailed, multi-color art project.

Then, hop over to their social media, especially Instagram. This is often where you'll find the real, unfiltered, day-to-day work. It’s a great way to see what just came off the press. It also gives you a vibe for their personality. A shop that’s actively and proudly posting its latest creations is a shop that’s confident in what it does.

How to Actually Read Customer Reviews

Google and Yelp reviews are your best friend, but you have to know how to read them. A perfect five-star rating isn't always the full story, and a couple of bad reviews aren't necessarily a red flag—especially if the owner responded professionally and tried to make it right.

Look for the details. A generic "Great service!" is nice, but a review that says, "They nailed our specific Pantone color match for our brand" or "The print still looks brand new after ten washes" tells you something genuinely useful.

Scan for patterns. If you see ten different reviews all raving about their lightning-fast turnaround but a few mention communication is a bit slow, you know what to expect. On the other hand, if everyone says the quality is incredible but they sometimes miss deadlines, you know to build a little extra time into your schedule. This helps you paint a realistic picture before you commit.

How to Ask for a Quote (and Get an Accurate One)

Want a quote you can actually count on? You have to give the printer everything they need to know. A vague email like "how much for 50 shirts?" is going to get you a vague, unhelpful price range. Your goal is to eliminate all the guesswork on their end.

When you reach out, make sure your first email includes these key details:

- The Shirts: Tell them the exact brand and style number if you know it (e.g., Bella+Canvas 3001), the shirt color, and a full breakdown of quantities per size.

- Your Artwork: Attach your design file. A high-resolution vector file (.ai, .eps, .pdf) is always best. If you only have a .jpeg, send it over and ask if they offer design services to get it print-ready.

- The Print Specs: Be specific. How many colors are in your design? Where does it go (front, back, left sleeve)? And what are the approximate dimensions in inches?

- Your Deadline: This is a big one. Be upfront about when you need the shirts in your hands. This tells them if they can fit you in their regular schedule or if you’ll need to talk about rush options.

Laying all your cards on the table from the start helps the printer give you a truly accurate quote that won’t suddenly inflate with hidden setup fees or other surprises. It’s the first step in building a great partnership.

Preparing a Print-Ready Design File

The journey from a great idea to a fantastic custom t-shirt often hits a major snag right at the starting line: a poor-quality design file. I've seen it happen more times than I can count. Submitting a blurry, low-resolution, or incorrectly formatted file is the most common—and entirely avoidable—mistake.

Getting this step right from the outset is crucial. It ensures your local printer can bring your vision to life without frustrating delays or disappointing, pixelated results. Think of your design file as the blueprint for your shirt. If that blueprint is fuzzy or uses the wrong measurements, you can't expect a great final product.

Vector vs. Raster: What Your Printer Really Wants

When you talk to any seasoned print shop, they'll almost always ask for a vector file. These are your .AI, .EPS, or .SVG files, and for good reason. They're built with mathematical formulas, not pixels.

This means a vector graphic can be scaled to any size—from a tiny pocket logo to a massive banner—without losing an ounce of sharpness. It's the undisputed champion for logos, text, and any design with clean lines and solid colors.

Then you have raster files like .PNG, .JPEG, or .PSD. These are made of tiny squares called pixels, which is perfect for photographs and highly detailed, multi-tonal artwork. But there's a catch. If you try to enlarge a small raster image, it just stretches the pixels, resulting in that dreaded blurry, blocky look. If a raster file is your only choice, make sure it’s high-resolution—at least 300 DPI (dots per inch)—and created at the exact size you want it printed.

Submitting a high-quality, print-ready file from the start is the single best way to ensure a fast turnaround. It completely eliminates the back-and-forth emails and potential redesign fees that can bog down your project.

Nailing the Technical Details

Getting the file type right is a huge part of the battle, but a few other technical details can make or break your print job. Paying attention to these shows your printer you’re prepared and serious about quality.

Here’s what to double-check before you hit 'send':

- Color Mode Matters: Your screen displays colors in RGB (Red, Green, Blue), which is designed for digital viewing. Printers, however, use a different "language": CMYK (Cyan, Magenta, Yellow, Black). Always convert your design to CMYK to ensure the colors on the shirt look like they did on your screen.

- Outline Your Fonts: Ever opened a document and seen the text completely messed up because you didn't have the right font? The same thing happens with print files. To avoid this, you need to "outline" your fonts (sometimes called "convert to curves"). This simple step turns the letters into un-editable vector shapes, locking them in place forever.

- Check Your Transparency: If you want the t-shirt's color to show through parts of your design, you need to save it as a .PNG file with a transparent background. A .JPEG file will automatically fill any empty space with a solid white box, which is almost never what people want.

Before sending your files to a printer, running through a quick checklist can save you a ton of headaches. It ensures every technical detail is spot-on, which means no last-minute fixes or unexpected delays.

Design File Checklist for T-Shirt Printing

| Checklist Item | Why It's Important | Recommended Format/Setting |

|---|---|---|

| File Type | Ensures scalability and print quality. | Vector (.AI, .EPS, .SVG) is preferred; Raster (.PNG) is acceptable if high-res. |

| Resolution | Prevents pixelation and blurry prints. | 300 DPI minimum for any raster elements. |

| Color Mode | Matches on-screen colors to printed colors. | CMYK (not RGB). |

| Fonts Outlined | Prevents font substitution issues at the printer. | All text converted to shapes/curves. |

| Transparent Background | Ensures only your design prints, not a white box. | Use a format that supports it, like .PNG. |

| Final Dimensions | Confirms the print will be the correct physical size. | Set the artboard/canvas to the exact print dimensions (e.g., 11" x 14"). |

This checklist is your best friend. A file that ticks all these boxes is one that any print shop will be happy to work with, making the whole process smoother for everyone.

Don't Guess on Size and Placement

Finally, never leave the size and placement of your design up to interpretation. What looks "centered" to you might look completely different to someone else. The best way to communicate your vision is with a simple mock-up. It doesn't need to be fancy—a screenshot of your design placed on a t-shirt template works perfectly.

More importantly, be specific with your dimensions. Instead of saying "make it big," say "print the front graphic at 11 inches wide." If you're unsure, our guide on choosing the right graphic size for your t-shirt is a great resource for visualizing standard dimensions. Providing these clear instructions guarantees there are no surprises when you finally get your hands on your new shirts.

Placing Your Order and Getting That Proof Right

You’ve done the legwork. You found a great local printer, your design is polished, and you're ready to make it happen. Now comes the most important part: finalizing the order and approving the digital proof.

This is your final checkpoint before the presses start running. Think of the proof as the binding contract for your design. Once you give it the thumbs-up, that’s exactly what they’re going to print. Any mistake that gets past this stage is, unfortunately, on you.

Don't Just Glance—Scrutinize the Proof

The digital proof (or "mock-up") is the printer's way of showing you precisely what your final shirt will look like. It lays out the design's size and placement on the shirt, the colors, and the garment style. It’s easy to get excited and just click approve, but you need to examine this thing like a hawk.

Here's exactly what I look for on every proof:

- Spelling and Grammar: It's shocking how a typo can hide in plain sight after you've looked at a design a dozen times. Read every single word out loud.

- Color Check: Do the ink colors match the Pantone or CMYK codes you provided? Remember, your screen's calibration can affect how colors look, but they should be a very close match to your specifications.

- Size and Placement: Is the graphic actually 11 inches wide like you asked? Is it centered properly? Is it sitting 3 inches below the collar, or does it look too low? Be specific.

- Shirt Details: Double-check the invoice or work order that comes with the proof. Make sure the t-shirt brand, style code, color, and the size breakdown are all 100% correct.

One of the most painful (and expensive) mistakes in this business is approving a proof with an error. Seriously, take your time. If you can, have a friend or colleague give it a second look. And whatever you do, never approve a proof from your phone. You can't see the fine details. Always view it on a full-sized computer screen.

Lock in the Final Details

Once you've approved the proof, you're ready to lock in the rest of the order. This is where you confirm the money, the timeline, and all the logistical nuts and bolts.

Before you pay a dime, get these details confirmed in writing:

- The Final Invoice: Does it match the quote you were given? Look for any unexpected setup fees, shipping costs, or sales tax.

- Payment Terms: Most shops will ask for a 50% deposit upfront. This covers the cost of the blank shirts and gets your job into the production queue. The final balance is usually due when you pick up the order.

- A Firm Completion Date: Don't settle for "sometime next week." Ask for a specific date your order will be ready for pickup or will ship out. A professional shop will give you a hard deadline.

The custom t-shirt market is booming, with the Asia Pacific region leading the charge thanks to massive corporate and event orders. You can see just how big the custom apparel market is on Precedence Research. This global demand means your local printer is likely very busy, which is why getting a firm timeline is non-negotiable. It ensures your project doesn't get lost in the shuffle.

And if you're taking the DIY route with transfers, knowing what to do next is just as important. Our guide on how to properly use a heat press will walk you through getting a perfect application every single time.

Got Questions About Local T-Shirt Printing? We've Got Answers.

When you first start Googling "custom t-shirts near me," a bunch of questions probably come to mind. It's completely normal to want to get the lay of the land before you place an order. We're going to tackle the most common questions we hear, giving you clear, no-nonsense answers so you can order with confidence.

Getting these details sorted out upfront—from what it's going to cost to whether you can bring in your own shirts—is the best way to save time and avoid headaches later. Let's get into it.

How Much Is This Going to Cost Me?

There’s really no one-size-fits-all answer here; the final price tag for custom tees depends entirely on the specifics of your job. The biggest cost drivers are the printing method used, how many shirts you need, the complexity of your design, and the quality of the shirt itself.

Just to give you a ballpark, a larger run of 50+ shirts with a simple two-color logo using screen printing might land you under $10 per shirt. But if you're looking for a single, super-detailed, full-color shirt printed with DTG on a high-end brand, you could be looking at something closer to $25 to $35.

The golden rule of custom printing is that volume is your best friend. The price per shirt almost always drops—often dramatically—as your order size goes up. Make sure you get a detailed, itemized quote that breaks down all the costs for your specific project.

What’s a Realistic Turnaround Time?

For most local print shops, a standard turnaround time is somewhere in the 7 to 14 business day range. That clock doesn't start ticking until after you’ve signed off on the final digital proof and paid your deposit.

Of course, that timeframe isn't set in stone. A few things can move the goalposts:

- The Shop’s Current Workload: If they're in the middle of a massive order for a city marathon or a local festival, your timeline might get pushed back.

- How Complex Your Order Is: A straightforward, one-color print on the chest is a lot faster to knock out than a multi-location job with custom tags and sleeve prints.

- The Size of Your Order: Printing 25 shirts is obviously going to be quicker than running 500.

If you find yourself in a bind and need shirts ASAP, don't sweat it. Most shops offer rush services for an extra fee, sometimes getting production done in just a few days. The most important thing is to be crystal clear about your deadline from the very first conversation.

Can I Bring My Own Shirts?

This comes up all the time, and the honest answer is: it depends on the shop. Some printers are perfectly fine with what’s known in the industry as "contract printing," where you supply the blank apparel.

Be aware, though, that they usually won't guarantee the print quality on garments they aren't familiar with. On the other hand, many shops prefer you to order from their own catalogs of tried-and-true brands. This lets them stand behind their work because they know exactly how their inks and machines perform on those specific fabrics. It's always best to ask about their policy right out of the gate.

Ready to skip the guesswork and get vibrant, durable designs for your project? Raccoon Transfers specializes in high-quality DTF transfers that make custom apparel easy. Build your custom gang sheet today!