A Guide to the Different Types of T-Shirt Printing Methods

Compartir

Choosing the right t-shirt printing method is a huge decision. It's the one that dictates the look, feel, cost, and longevity of your final product. The big four in the game right now are Screen Printing, Direct-to-Garment (DTG), Heat Transfer Vinyl (HTV), and the newer powerhouse, Direct-to-Film (DTF). Each has its own sweet spot, and picking the right one depends entirely on what you're trying to create.

Choosing Your Ideal T-Shirt Printing Method

Getting a handle on these different printing techniques is the first real step to making custom apparel that actually looks professional. Whether you're building a brand from scratch, printing merch for your band, or just starting a side hustle, how you print matters—a lot.

This guide will cut through the fluff and get into the real-world trade-offs. We’ll look at how these methods stack up when it comes to the things that actually affect your bottom line and your brand's reputation: order size, design detail, and fabric choices. The goal is to give you the confidence to pick the perfect method for your vision.

Key Factors to Consider

Before we jump into the deep end, let's talk about the core factors that will steer your decision. Honestly, it almost always comes down to a balance of these five things:

- Design Complexity: How intricate is your artwork? Are we talking a single-color logo or a full-blown photorealistic masterpiece?

- Order Volume: Are you making a single prototype or gearing up for a run of 500 shirts?

- Fabric Compatibility: What are you printing on? Basic cotton, a tricky polyester performance tee, or a blend?

- Budget: What's your target cost per shirt? And what can you afford for setup?

- Durability: How many washes does this print need to survive before it starts to crack or fade?

The "best" printing method doesn't exist. It's all about matching the technique's strengths to your project's needs—from the fine lines in your design to the number of shirts you need to get out the door.

To get the ball rolling, this table gives you a quick snapshot of where each method really shines. Think of it as your cheat sheet.

| Printing Method | Best For | Design Style | Fabric Focus |

|---|---|---|---|

| Screen Printing | Bulk Orders (50+) | Simple, bold graphics | Cotton & Blends |

| DTG Printing | Small Batches & Photos | Detailed, multi-color | 100% Cotton |

| HTV Printing | One-offs & Text | Logos & numbers | Cotton & Polyester |

| DTF Printing | Versatile Batches | Complex & vibrant | Nearly Any Fabric |

An Overview of T-Shirt Printing Techniques

When you're looking to get a design onto a t-shirt, it’s easy to think all printing is the same. But the reality is, the method used dramatically changes everything—from the cost and feel to the durability of the final product. Each technique has its own personality, perfectly suited for some jobs and completely wrong for others.

Let's break down the four most common methods you'll encounter in the custom apparel world. Understanding how they work is the first step in figuring out which one makes sense for your brand, so you can avoid a costly mistake and find the perfect fit.

Screen Printing: The Traditional Workhorse

Screen printing is the old-school, time-tested champion of the t-shirt world. The process is pretty hands-on: you push ink through a stenciled mesh screen directly onto the fabric. The catch? You need a separate screen for every single color in your design.

It all starts by burning your artwork into a screen to create a stencil. Ink is then spread over the screen, and a squeegee forces it through the stencil's open areas and onto the shirt. If your design has three colors, you repeat that process three times with three different screens, all while making sure everything lines up perfectly.

Key Insight: Screen printing shines when you're ordering in bulk. The setup is labor-intensive and costly upfront, but once the screens are made, printing hundreds of shirts is incredibly fast and cheap per piece.

The result is a print that’s super vibrant and durable, with a thick layer of ink that sits on top of the fabric. This gives it a classic, slightly raised feel and makes colors pop, especially on dark garments. It’s no wonder it’s still the go-to for concert merch, company uniforms, and large event giveaways.

Direct-to-Garment (DTG): The Digital Specialist

Think of Direct-to-Garment (DTG) as your desktop inkjet printer, but for clothes. A specialized printer sprays water-based inks directly onto the fabric, where they soak into the fibers. This makes it possible to print incredibly detailed, full-color images—we're talking photographs, intricate illustrations, and subtle color gradients with millions of hues.

To get the best results, the shirt (usually 100% cotton) gets a pre-treatment spray to help the ink bond correctly. After that, it’s loaded onto a flatbed and sent into the printer. Because there’s virtually no setup cost for each new design, DTG is perfect for one-off custom shirts or small-batch orders where every tee has a different graphic.

Heat Transfer Methods: Vinyl and Film

Heat transfer printing is a broad category, but it really boils down to two popular players: Heat Transfer Vinyl (HTV) and Direct-to-Film (DTF). Both use a heat press to bond a design to a shirt, but they get there in very different ways.

- Heat Transfer Vinyl (HTV): This is all about cutting shapes from sheets of solid-colored vinyl. A machine called a plotter follows your digital file to cut out the design. You then have to "weed" away all the excess vinyl by hand before pressing it onto the shirt. It's a fantastic choice for simple, bold graphics like team numbers, names, and single-color logos.

- Direct-to-Film (DTF): DTF is a much more modern approach. Your design is printed digitally onto a special transfer film. While the ink is still wet, a powdered adhesive is sprinkled over it and then cured with heat. The finished transfer can then be heat-pressed onto almost any garment.

This is where DTF really pulls ahead. It gives you the full-color, high-detail capabilities of DTG but works on polyester, cotton, blends, and more. This versatility is making it a favorite for small brands that need a flexible, top-quality printing solution without limitations. You can dig deeper into the nuances of these and other fabric printing techniques to see just how they stack up.

Printing Methods at a Glance

To make sense of it all, it helps to see these methods side-by-side. Each one has a sweet spot where it outperforms the others.

| Printing Method | Ideal For | Color & Detail Level | Fabric Compatibility |

|---|---|---|---|

| Screen Printing | Bulk orders (100+ units) of simple, bold designs. | Limited colors. Not great for photos or gradients. | Very versatile; works on cotton, poly, and blends. |

| Direct-to-Garment (DTG) | One-offs and small runs with complex, full-color designs. | Unlimited colors and photorealistic detail. | Best on 100% cotton; struggles with polyester. |

| Heat Transfer Vinyl (HTV) | Simple text, numbers, and single-color logos. | Solid colors only; layering is possible but complex. | Excellent on cotton, polyester, and blends. |

| Direct-to-Film (DTF) | Small-to-medium batches needing full-color on any fabric. | Unlimited colors and fine detail. | Works on virtually any fabric, including synthetics. |

Choosing the right technique comes down to three things: your design's complexity, the type of fabric you're using, and how many shirts you need. This table should give you a quick gut check for which direction to go.

Quality, Durability, and Cost: A Head-to-Head Comparison

Picking the right t-shirt printing method is always a balancing act. You're juggling looks, longevity, and your budget. What works for a simple, bold logo won't be the right call for a photorealistic design, and the best choice for a 10-shirt run is rarely the most economical for 1,000.

Let’s break down the real-world differences between the big four—Screen Printing, Direct-to-Garment (DTG), Heat Transfer Vinyl (HTV), and Direct-to-Film (DTF)—so you can make a smart, strategic choice for your brand.

Print Quality and Detail

The first thing anyone notices is the print itself. The level of detail a method can handle will make or break your design.

Screen Printing is the undisputed champion of bold, vibrant color. The ink is physically pushed through a screen, creating a thick, opaque layer that sits right on top of the fabric. This gives you incredibly rich, saturated graphics that really pop. The trade-off? Detail. Every single color needs its own screen, which makes complex gradients or photographic images a non-starter. It’s perfect for strong, graphic-heavy designs with a limited color palette.

Direct-to-Garment (DTG) is the polar opposite. Think of it as a high-end inkjet printer for t-shirts. It can reproduce millions of colors with stunning, photographic accuracy, making it the go-to for intricate illustrations or high-fidelity photos. The ink soaks directly into the fabric fibers, which gives it a super-soft feel. However, this can sometimes lead to slightly less vibrant colors, especially on darker shirts, when compared to the punch of screen printing.

Heat Transfer Vinyl (HTV) delivers incredibly crisp, clean lines. Since you’re cutting designs from solid-colored vinyl sheets, the edges are perfectly sharp. This makes it a fantastic choice for athletic jerseys, big logos, and bold lettering. It’s not built for complexity, though; intricate or multi-color designs become a nightmare of layering vinyl.

Direct-to-Film (DTF) manages to deliver the best of both worlds. It’s a digital process, so just like DTG, it can handle unlimited colors and fine details with precision. But here’s the key difference: the design is printed onto a special film first, then transferred to the shirt. This means the ink sits on top of the fabric, giving you the vibrant, opaque finish of screen printing with the full-color detail of DTG.

The Bottom Line: For photorealistic detail, your best bets are DTG and DTF. For bold, punchy graphics with just a few colors, screen printing is still king. For simple text and logos, nothing beats the sharp finish of HTV.

How Long Will It Last? Durability and Wash Performance

A killer design means nothing if it cracks, peels, or fades away after a few trips through the laundry. Durability is non-negotiable for any brand that cares about quality.

Screen-printed shirts are legendary for their durability. When the ink is cured correctly, it forms a tough, flexible bond with the fabric that can easily survive dozens, if not hundreds, of washes. Over many years, it might develop that soft, vintage crackle, but it will not peel away.

DTG prints are generally the most delicate of the bunch. Because the ink is absorbed by the cotton fibers instead of sitting on top, it's more prone to fading from washing and sun exposure. A high-quality DTG print can still last for 50+ washes if you care for it properly, but it just doesn't have the raw resilience of screen printing or DTF.

HTV can be quite durable, but its lifespan really depends on the quality of the vinyl and how well it was applied. A professionally pressed HTV design can last for years, but cheap vinyl or a bad press job can lead to the edges peeling or cracking. You can also feel the design on the shirt; it's a distinct, sometimes stiff, layer.

DTF has quickly become a top contender for durability, often going toe-to-toe with screen printing. The water-based ink is incredibly flexible, and the adhesive creates a powerful bond that stretches right along with the fabric. This makes it highly resistant to cracking and peeling. A good DTF print can handle wash after wash and still look great, making it an excellent choice for everyday apparel. If you want to dive deeper, we have a whole article covering the specifics of DTF vs DTG printing.

The Money Talk: Cost Per Shirt and Scalability

Your budget and order size will be a huge factor in your decision. Some methods have high setup costs that pay off in bulk, while others are perfect for small, on-demand orders.

Screen printing is a volume game. The upfront cost to create a screen for each color is significant, which makes it a poor choice for small batches. But once those screens are made, the cost per shirt plummets. It’s no surprise that screen printing dominates the custom apparel market with a massive 56% revenue share; it’s simply the most economical way to handle big orders.

Here’s a quick guide to how scale affects your costs:

- 1-20 Shirts: Screen printing is out. Your best options are DTG, DTF, or HTV.

- 20-100 Shirts: DTF often hits the sweet spot between quality and cost. For designs with just one or two colors, screen printing starts to become a viable option.

- 100+ Shirts: Screen printing becomes the undisputed champ of cost-effectiveness. The price per shirt drops dramatically the more you print.

DTG and DTF have zero setup costs per design. This makes them perfect for small runs, one-off samples, or print-on-demand businesses. The price per shirt stays pretty much the same whether you're printing one or 50, which gives startups and small brands predictable, manageable costs.

HTV is also fantastic for single items or tiny orders, especially for simple things like names and numbers on jerseys. However, the hands-on labor of cutting and weeding the vinyl makes it slow and expensive for any kind of larger production run.

Fabric Compatibility: What Will It Stick To?

Finally, the material of your garment can immediately rule out certain print methods.

| Printing Method | Best Fabrics | Challenging Fabrics |

|---|---|---|

| Screen Printing | Cotton, Polyester, Blends | Textured or heat-sensitive materials |

| Direct-to-Garment | 100% Cotton (especially ring-spun) | Polyester, Blends, Dark Synthetics |

| Heat Transfer Vinyl | Cotton, Polyester, Blends, Leather | Nylon, spandex (requires special vinyl) |

| Direct-to-Film | Cotton, Polyester, Blends, Leather, Nylon | Works on nearly any fabric that can withstand heat |

DTG is famously picky. It needs natural fibers to bond with, so it performs best on 100% cotton. Trying to print on polyester or blends often results in faded, splotchy prints. Screen printing is more adaptable, working well on cotton and blends, but it can struggle with some synthetics.

HTV is a solid all-rounder, adhering well to cotton, polyester, and most common blends. This versatility has made it a favorite for sportswear, which is often made from performance synthetics.

But this is where DTF really pulls ahead of the pack. Its unique transfer process allows it to stick to almost anything. Whether you’re printing on a classic cotton tee, a polyester hoodie, a nylon windbreaker, or even a leather patch, DTF delivers vibrant, consistent results. This unmatched versatility makes it an incredibly powerful option for brands looking to expand their product line beyond basic t-shirts.

Choosing the Right T-Shirt Printing Method for Your Project

Knowing the specs of each printing method is one thing, but the real test is applying that knowledge to your actual project. The "best" choice is never universal; it hinges on your budget, timeline, design complexity, and even who you're selling to.

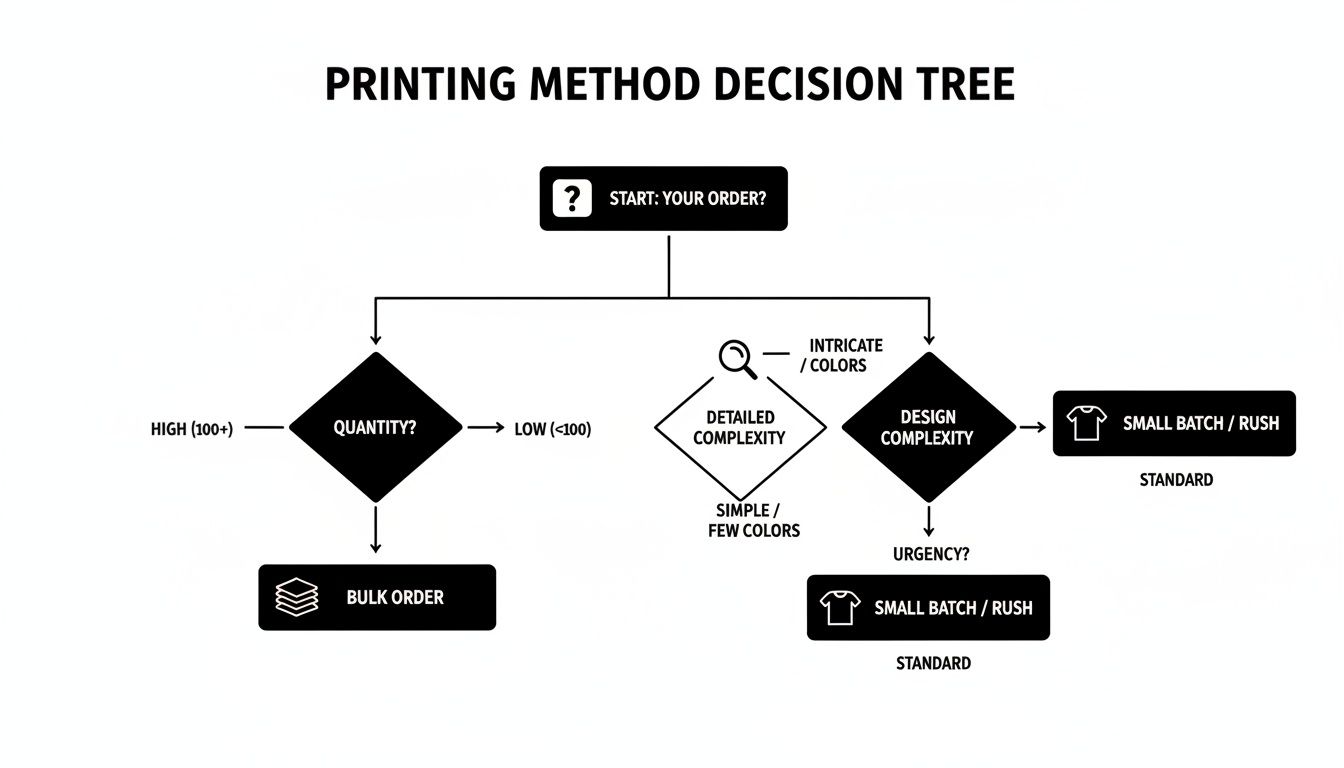

To cut through the noise, let's walk through a few real-world scenarios you'll likely encounter. This decision tree is a great starting point for quickly seeing which path makes the most sense for you.

This visual guide helps you make an initial cut based on the big three: quantity, design detail, and how many you need.

The Emerging Apparel Brand Owner

Let’s start with Alex, who’s launching a new clothing line. Alex has a dozen highly detailed, multi-color designs but is working with a tight startup budget and has zero room for inventory. The plan is to test the waters with a small run of each design on both high-quality cotton tees and some polyester hoodies.

For Alex, the answer is a slam dunk: Direct-to-Film (DTF) printing is the way to go.

- No Minimum Orders: DTF lets Alex print just one or a few of each design without getting hit with massive setup costs. This keeps the initial financial risk incredibly low.

- Fabric Versatility: It works just as beautifully on the cotton tees as it does on the polyester hoodies, giving the whole collection a consistent, premium look.

- Vibrant, Detailed Prints: DTF captures every intricate detail and color in the original artwork, producing prints that are both bright and tough.

Screen printing would be completely out of the question here. The cost to create screens for a dozen different designs for such a small run would be astronomical. DTG could handle the cotton tees, but it would fall flat on the polyester hoodies, forcing Alex to juggle two separate production processes.

The Corporate Event Planner

Now, meet Sarah. She's in charge of a big corporate conference and needs 500 t-shirts for staff and attendees. The design is a straightforward, two-color company logo for the front of identical cotton-blend shirts.

This is a classic bulk-order job where screen printing is the undisputed champion.

The initial cost to create the two color screens gets spread so thin across 500 shirts that the price per piece becomes incredibly low. Plus, screen printing delivers a long-lasting, vibrant print that feels professional and holds up wash after wash, which is great for the company’s image. Once the press is set up, the production speed is unmatched, ensuring the large order gets done on time.

For any high-volume project with a simple design, screen printing delivers a mix of speed, durability, and cost-efficiency that other methods just can't touch.

The Etsy Crafter and Small-Scale Seller

Next up is Ben, an Etsy seller specializing in custom-made t-shirts. His customers are all about personalization—they want unique text, names, or even photorealistic prints of their pets on a single shirt. Orders are unpredictable, and a quick turnaround is essential for those five-star reviews.

When you're diving into a niche, the printing method is crucial to nailing the look and feel. For instance, if you're making graphic tees for cat lovers, you need a process that can capture all that feline personality.

For Ben's on-demand business, Direct-to-Garment (DTG) is his most powerful tool. It’s no surprise that DTG holds a massive 40% market share in the custom t-shirt world; it’s built for handling complex, full-color designs one at a time with no screens needed. Since there are no setup fees, it’s perfect for one-off jobs like a detailed pet portrait. The global custom t-shirt market is valued at USD 5.16 billion and climbing, and DTG's growth is directly tied to the success of print-on-demand sellers like Ben.

For simpler text-based requests like names or funny quotes, Heat Transfer Vinyl (HTV) is also a fantastic, low-cost option that Ben could easily manage from a home studio.

The Sports Team Manager

Finally, let’s look at Maria, who manages a local youth soccer league. She has to outfit 15 teams, each with about 12 players. Every single jersey needs a team logo on the front and a unique player name and number on the back, all printed on moisture-wicking polyester.

This project has Heat Transfer Vinyl (HTV) written all over it.

HTV is the go-to for the crisp, durable names and numbers you see on sports jerseys. The vinyl applies perfectly to polyester and can be pressed with minimal equipment. Screen printing could handle the logos, but creating screens for 180 unique names and numbers would be a logistical nightmare. DTF is a viable alternative, but for simple, bold text and numbers, HTV is usually the faster and more cost-effective choice for this exact scenario.

How DTF Printing Is Changing the Custom Apparel Game

Brands and designers are always on the hunt for that one printing method that can handle everything. Direct-to-Film (DTF) is stepping up as a serious contender, bridging the gap between older techniques by solving many of their biggest headaches. It's quickly becoming the go-to for businesses that need versatility without compromising on quality.

What DTF does so well is cherry-pick the best features from other methods. You get the full-color, high-detail prints of Direct-to-Garment (DTG), but with the punchy, vibrant look and tough durability that used to be screen printing's domain. The final product just feels right—sharp, professional, and built to last.

The Smart Choice for Modern Brands

If you're running a small business or a growing apparel line, the practical upsides of DTF are huge. Forget screen printing's costly color setups and no minimum order requirements. DTF lets you launch new designs without a massive upfront investment, making it perfect for printing on demand.

But where DTF really pulls ahead is its material versatility. While DTG printers are notoriously picky about synthetics, DTF prints stick to just about anything.

- Cotton and Blends: You get bright, clean prints on all your standard tees and hoodies.

- Polyester and Performance Wear: It's a solid, reliable choice for athletic gear.

- Specialty Items: It even works on tricky surfaces like nylon, leather, and hard goods.

This means you can offer a whole product line—from cotton t-shirts to polyester jackets and canvas tote bags—all with consistently great-looking prints.

By printing onto a transfer film first instead of directly on the fabric, DTF neatly sidesteps the material limitations that plague other methods. This makes it an incredibly adaptable tool for any merchandise creator.

Boosting Efficiency and Durability

Beyond its ability to print on almost anything, DTF has real-world advantages that help your bottom line. You can "gang up" multiple designs—logos, sleeve graphics, neck labels—onto one large film sheet. This cuts down on waste and seriously lowers the cost per print.

And the prints hold up. The combination of flexible, water-based inks and a powerful adhesive creates a bond that stands up to cracking and fading, wash after wash. The durability is right up there with traditional screen prints.

For anyone just getting started, taking a moment to understand what DTF printing is can open up a world of possibilities for your projects. It’s a smart path forward for any business that needs quality, efficiency, and creative control in a crowded market.

Your T-Shirt Printing Questions, Answered

Choosing the right printing method can feel like a big decision, so it’s natural to have questions. I get asked these all the time by designers and new brand owners. Let's clear up a few of the most common ones to help you pick the perfect method with confidence.

We'll cover durability, what's possible with detailed designs, and the all-important question of cost. Getting these details right is the key to creating a product you're proud of.

What Is the Most Durable T-Shirt Printing Method?

When you want a print that lasts, you're really looking at two main players: traditional screen printing and modern, high-quality DTF transfers. Screen printing has a legendary reputation for durability because the ink seeps into the fabric itself, creating a bond that’s as tough as the shirt.

A professionally applied DTF transfer, however, is right up there with it. The process uses a seriously strong and flexible adhesive, resulting in a print that holds up against cracking, peeling, and fading through dozens and dozens of washes. It easily matches the resilience of screen printing.

Can I Print a Detailed Photograph on a T-Shirt?

You absolutely can. If you're working with photorealistic images, complex color gradients, or anything with a ton of fine detail, your go-to methods are Direct-to-Garment (DTG) and Direct-to-Film (DTF). Both are digital, so they can reproduce millions of colors with incredible precision.

This is where screen printing hits a wall. It relies on separating each color into a different screen, which just doesn't work for the smooth transitions and nuance of a photograph.

Which Method Is Best for a Small Business?

For most small businesses starting out, DTF printing is a game-changer. There are no setup fees per color, which makes it ideal for small batches or one-off designs, especially those with a full-color palette. This flexibility means you can print on demand and completely sidestep the risk of getting stuck with unsold inventory.

Screen printing, on the other hand, really only makes financial sense when you’re ordering in bulk. You'll typically need to order 50 units or more of the exact same design for the cost-per-shirt to become competitive.

How Does a Gang Sheet Save Money?

A gang sheet is a fantastic cost-saving tool. It's essentially one large sheet of transfer film where you can arrange, or "gang up," multiple designs to be printed all at once. Using a gang sheet builder, you can squeeze every bit of value out of the film, placing different logos, sleeve hits, and even custom neck labels together.

This trick dramatically cuts your cost-per-design. Instead of paying for each graphic individually, you’re just paying for the total area of the film. It's an incredibly efficient way to produce a whole collection of graphics in a single, affordable run.

Ready to bring your vibrant, durable, and detailed designs to life on any fabric? Raccoon Transfers makes it easy with high-quality DTF transfers and a simple online ordering process. Build your gang sheet today and see the difference for yourself. Visit us at https://raccoontransfers.com.