Heat Transfer Vinyl Vs Screen Printing Decoded

Compartir

When you're trying to decide between heat transfer vinyl (HTV) and screen printing, the right answer really comes down to the specifics of your job: how many pieces you're making and how detailed your design is. HTV is the clear winner for small, custom orders with lots of detail. On the other hand, screen printing is the undisputed champ for large-volume runs with simpler graphics, where its cost-efficiency is hard to beat.

It's all about weighing your priorities. Are you looking for the flexibility to create a few custom pieces, or do you need durability and a low price per shirt for a massive order?

Choosing Your Customization Method A Quick Comparison

Picking between these two popular methods can feel like a tough call, but it gets a lot easier when you break it down by your project's needs. Heat transfer vinyl is a brilliant entry point for small businesses, creative hobbyists, or anyone who just needs a one-of-a-kind piece. The process is straightforward: you cut a design from a sheet of vinyl and then use a heat press to apply it to the fabric. This method is fantastic for handling fine details and allows for some really cool special finishes, like glitter or holographic effects.

Screen printing, however, is the powerhouse of the commercial apparel world. This classic technique involves using a mesh screen as a stencil to press ink directly onto the material. The setup is definitely more involved and costs more upfront, but once you're running, it becomes incredibly cost-effective for big orders. The result is a vibrant, soft print that feels like it’s part of the fabric and is built to last. Each method has its place, whether you're creating unique items like personalized lab coats or producing uniforms for an entire company.

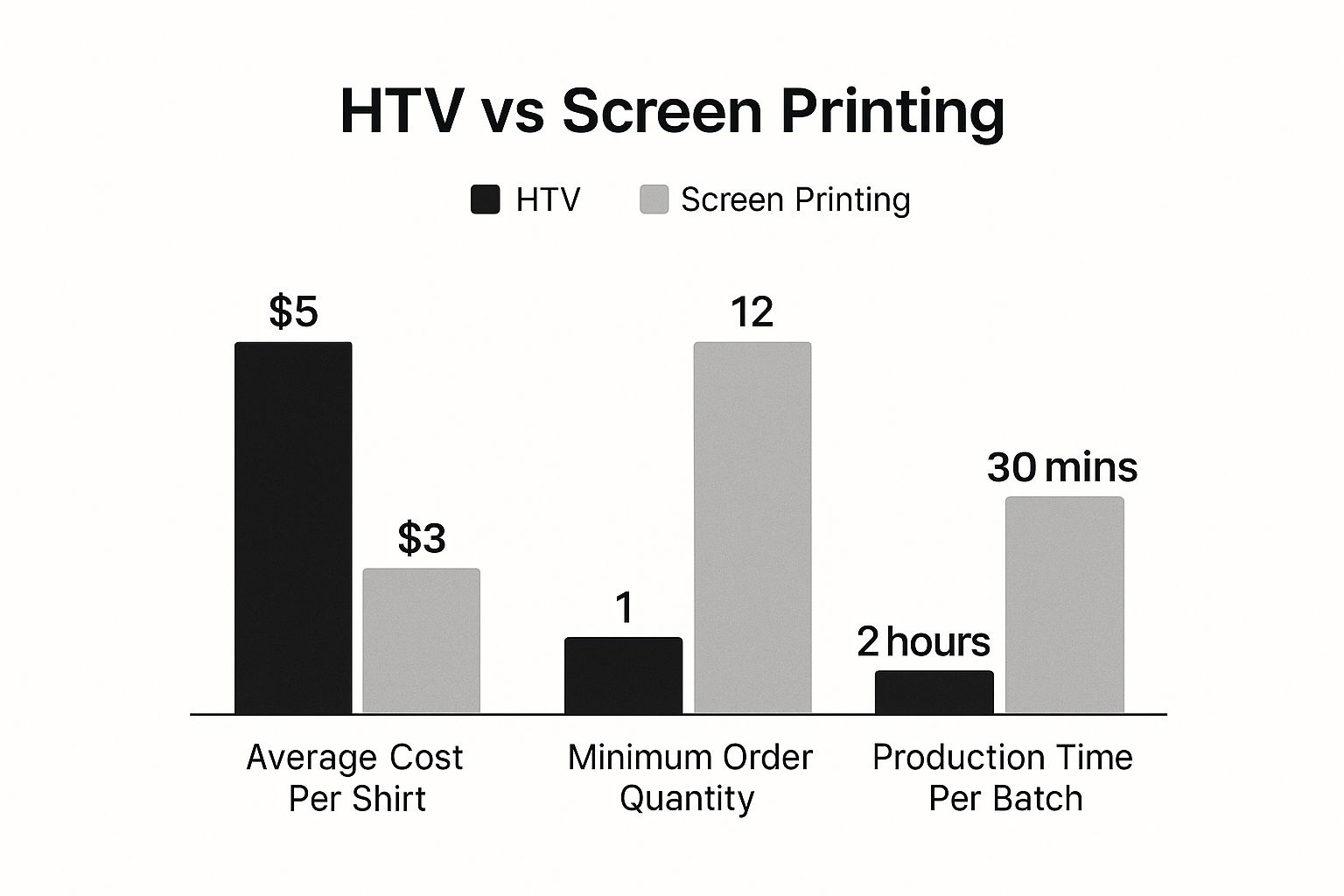

This visual gives you a quick breakdown of the key differences in cost, ideal order size, and the time it takes to get the job done.

As you can see, HTV is perfect for individuals because there's no minimum order. But when you get into bulk production, screen printing’s lower cost-per-shirt really starts to pay off.

HTV Vs Screen Printing At a Glance

Sometimes a simple side-by-side view is the best way to see the differences. This table breaks down the core characteristics of each method to help you make a quick, informed decision. While there are many other fabric printing techniques out there, HTV and screen printing are two of the most popular choices for custom apparel for a reason.

| Factor | Heat Transfer Vinyl (HTV) | Screen Printing |

|---|---|---|

| Ideal Order Size | 1 to 24 items | 25+ items |

| Durability | Good (lasts up to 50 washes) | Excellent (can outlast the garment) |

| Design Complexity | Excellent for complex, multi-color designs | Best for simple designs with few colors |

| Initial Setup Cost | Low (requires a cutter and heat press) | High (requires screens for each color) |

Ultimately, this table highlights the core trade-offs. HTV gives you creative freedom on a small scale, while screen printing offers unmatched efficiency and durability for larger projects.

Understanding The Heat Transfer Vinyl Process

Heat Transfer Vinyl, or HTV, is where digital design gets a very hands-on, tangible finish. It all starts on a computer, where you finalize your graphic. From there, you send the file to a vinyl cutter—a machine that acts like a printer but uses a tiny blade to precisely carve your design out of a sheet of vinyl.

One of the best things about working with HTV is the sheer variety of materials available. You’re not just limited to standard colors. You can get vinyl that’s glittery, holographic, metallic, or even puff vinyl that literally puffs up for a 3D effect when you heat it. This range of textures and finishes is a huge part of its appeal for creating really standout custom apparel. If you're new to this, figuring out which material to use can be a bit overwhelming, but this guide on the best vinyl for heat press is a great place to start.

The Application Workflow

After your design is cut, you move on to the manual part of the process. The next step is called weeding, and it’s exactly what it sounds like. You use a small, sharp tool to carefully peel away all the excess vinyl that isn't part of your design. What you’re left with is your graphic, perfectly intact on a clear, sticky carrier sheet.

That carrier sheet is what holds your entire design together, letting you place it precisely on the garment. Once it’s in position, you use a heat press to apply a specific temperature and pressure for a set amount of time. The heat melts the adhesive on the back of the vinyl, essentially fusing it right into the fabric.

The magic of HTV really comes down to precision and control. You're not working with ink that can bleed or fade; you’re applying a solid, pre-colored material. That means you get perfectly crisp lines and vibrant, consistent color every single time.

This methodical process is exactly why HTV is the perfect choice for certain jobs:

- One-off prototypes for testing a design without committing to a large run.

- Personalized gifts, like a custom t-shirt for a friend’s birthday.

- Custom jersey names and numbers, since every single one needs to be different.

Before HTV became so accessible, many people doing DIY projects used things like iron transfer paper for custom shirts. It got the job done for simple graphics, but it just doesn't have the professional look or durability of vinyl.

Because it's so flexible and doesn't require a massive investment to get started, HTV is a fantastic entry point for hobbyists or small businesses. You can produce high-quality, custom gear right from your workshop. The final design sits on top of the fabric, giving it a distinct, slightly raised feel.

How Screen Printing Works: From Screens to Squeegees

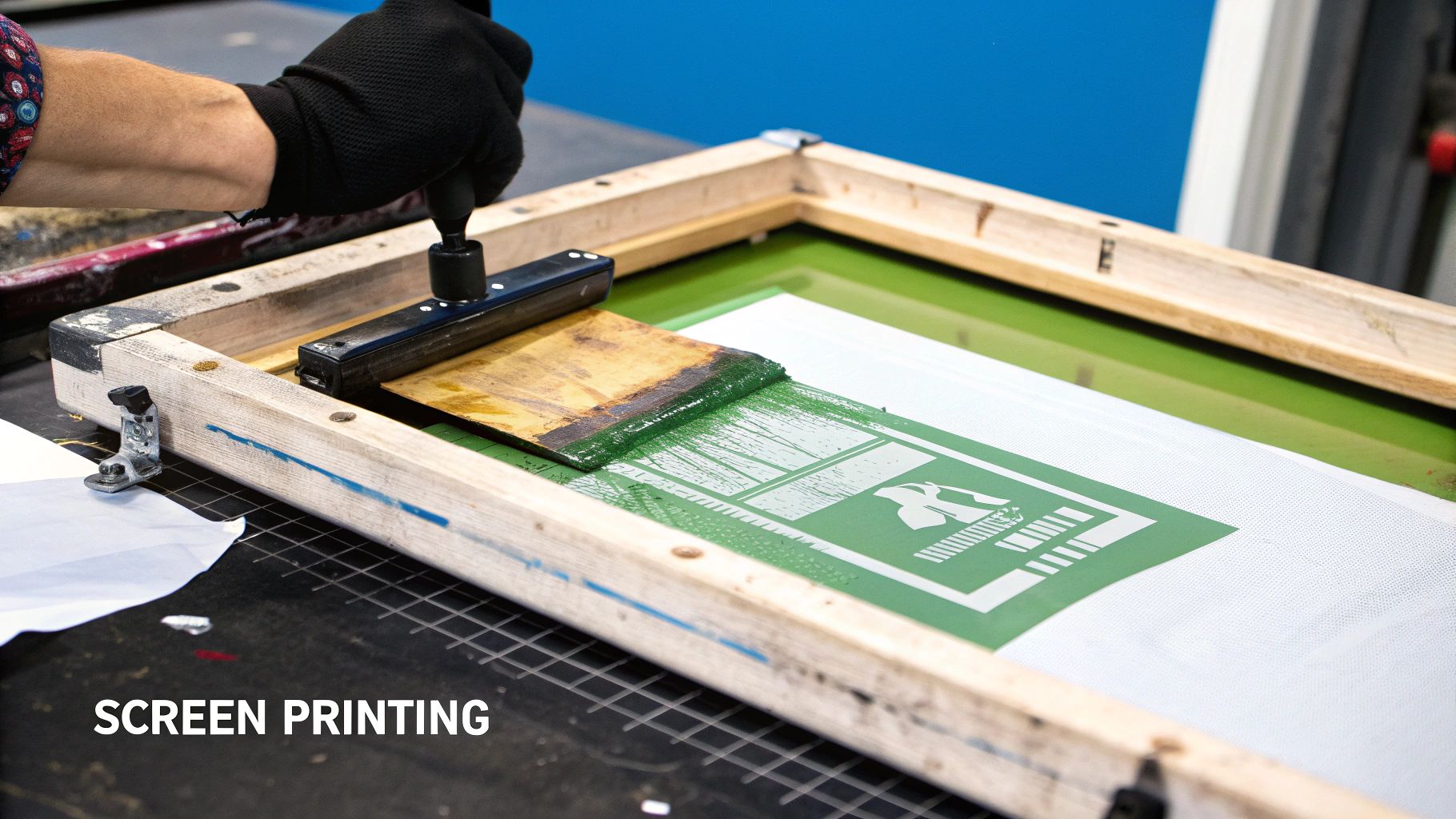

Screen printing is a classic, time-tested method that's been around for ages for one simple reason: it produces vibrant, durable designs that last. It's especially brilliant for large batches. Unlike the digital process of HTV, screen printing is a hands-on technique that uses a stencil to press ink directly into the fabric. Think of it as a more refined, professional version of stenciling.

It all starts with creating a unique screen for each color in the design. A fine mesh is stretched super-tight over a frame, which is then coated with a light-sensitive liquid called emulsion. Once that's dry, the design—printed on a transparent film—is placed on the screen and blasted with a powerful light.

This light exposure hardens the emulsion everywhere except where the design is blocking it. Those unhardened parts wash away, leaving a perfect stencil of the artwork in the mesh. This is the reason multi-color designs need multiple screens and a bit more setup time.

From Ink to Finished Garment

Once the screen is prepped, the real fun begins. The t-shirt (or whatever you're printing on) is laid flat, the screen is positioned on top, and a thick ink is poured along one edge. Then, using a tool called a squeegee, the printer pulls the ink firmly and evenly across the screen.

This simple motion forces the ink through the open parts of the stencil and right onto the garment. If a design has more than one color, this step is repeated with a different screen for each color. It takes a skilled hand to line everything up perfectly to keep the final image sharp.

The core idea behind screen printing is efficiency at scale. The setup is a lot of work for just one shirt, but it becomes incredibly cost-effective when you're printing hundreds or even thousands of the same design.

After all the colors are down, the shirt goes through a large dryer. This cures the ink, permanently bonding it with the fabric's fibers. This curing step is what gives screen-printed designs their legendary durability, allowing them to handle countless washes without cracking or fading.

Why It Dominates Bulk Orders

This robust, repeatable process is exactly why screen printing still holds its own in the custom apparel world, accounting for over 60% of bulk orders globally. Its popularity comes down to being extremely cost-effective for big runs and producing prints that truly last. It’s the go-to for band merchandise, company uniforms, and event apparel for good reason. For a deeper dive into the numbers, you can explore the full custom T-shirt printing market report.

A Detailed Comparison Of Print Feel And Durability

Once you get past the setup and printing process, what really matters in the heat transfer vinyl vs screen printing debate are the results you can see and feel. The texture of the design on the fabric and how well it holds up over time are what truly define a quality product. These two methods couldn't be more different in how they deliver on both fronts.

With heat transfer vinyl, you’re essentially bonding a thin layer of material right on top of the fabric's fibers. This gives the final design a slightly raised feel that's distinct from the garment itself. The texture can vary quite a bit—from a smooth, almost plastic-like finish to unique specialty options like glitter or a fuzzy, suede-like flock.

Screen printing works differently. It pushes ink into the fabric, making the design feel much softer and more like a part of the shirt. This is especially true with water-based inks, which can create a print so soft you can't feel it at all. In the industry, we call this a "soft hand," and it's often the gold standard for retail-quality apparel.

Washability And Long-Term Wear

Durability is where you'll see the biggest gap between these two methods. A professionally applied HTV design can be surprisingly tough, often lasting for up to 50 washes before you might see any cracking or peeling. But its lifespan really hinges on a few key things:

- Quality of the Vinyl: Don't cheap out. Premium vinyl will always last longer than budget options.

- Application Technique: Getting the temperature, pressure, and timing just right is everything. To nail the application, it's a good idea to follow a trusted heat press temperature guide for specific fabrics.

- Care Instructions: How the garment is washed makes a huge difference. Washing inside out and avoiding high-heat dryers will always extend the life of an HTV print.

When it comes to pure longevity, screen printing is the undisputed champ. Because the ink is literally fused with the fabric, a screen-printed design will almost always outlive the t-shirt it's on. It stands up incredibly well to cracking, fading, and peeling, even after years of washing and sun exposure.

Screen printing delivers unmatched softness and longevity by embedding ink into the fabric, making it ideal for retail-quality apparel. HTV, while slightly less durable, excels by offering unique specialty finishes like holographic or puff effects that screen printing cannot replicate.

Performance On Different Fabrics

The type of fabric you're printing on also plays a major role. HTV is a real workhorse here—it sticks well to a huge variety of materials, including cotton, polyester, and common poly-cotton blends. Its consistent performance makes it a go-to for all sorts of different garments.

Screen printing, on the other hand, truly shines on natural fibers like cotton, where the ink can absorb deeply and evenly. It can certainly work on blends, but you might lose some of that signature softness and vibrancy on synthetic materials like polyester unless you use specialized inks and curing methods. This makes fabric choice a critical step if you're chasing that perfect screen-printed finish.

A Look at the Costs and Production Economics

Whether you’re making a single custom gift or gearing up for a major merchandise launch, it all boils down to your budget and deadline. To make the right call, you have to understand the money behind heat transfer vinyl and screen printing. These two methods couldn't be more different in how their costs break down, making each one suited for opposite ends of the production spectrum.

Heat transfer vinyl has a very low barrier to entry. Your initial investment is small—all you really need is a decent vinyl cutter and a quality heat press to get started. This setup is perfect for hobbyists or a small business just dipping its toes in the water. The catch? The per-item cost stays pretty consistent since you're paying for every single sheet of vinyl you use.

Screen printing is a whole different ball game financially. The upfront costs are much steeper. You’ll need to buy screens, emulsion, a variety of inks, and a press. Every color in your design requires its own dedicated screen, and setting each one up takes a good amount of time and effort. It’s this initial setup cost that makes screen printing a non-starter for tiny jobs.

Finding the Tipping Point for Production Volume

The real financial divergence happens when you start scaling up. That hefty setup cost for screen printing is a one-time thing for each design. Once you’ve paid that, the cost to print each additional shirt drops like a rock. The more you print, the more that initial investment gets spread out, drastically lowering your unit cost.

The economic tipping point is simple: it’s where the high setup cost of screen printing becomes cheaper than the ever-growing material cost of HTV. For small, custom runs, HTV wins every time. For volume, screen printing is the undisputed king.

Let's walk through a couple of real-world scenarios to see how this plays out.

Scenario A: 10 Custom Shirts

- Heat Transfer Vinyl: With no setup fees, the cost is easy to calculate—it's mostly just your materials and time per shirt. For a small batch like this, the final price per shirt is reasonable and leaves room for profit.

- Screen Printing: The cost to burn screens for even a simple two-color design would be spread across just 10 shirts. This would make each shirt ridiculously expensive. An order this small just isn't financially viable for screen printing.

Scenario B: 500 Shirts for an Event

- Heat Transfer Vinyl: Imagine cutting, weeding, and pressing 500 individual vinyl designs. The labor alone would be a nightmare, and the material costs would stack up fast, making the total project far more expensive than screen printing.

- Screen Printing: Sure, you have that initial setup fee. But after that, the cost of ink and labor per shirt is tiny. At this volume, your total cost is significantly lower, and once the screens are on the press, you can churn out shirts incredibly quickly. This is exactly where screen printing shines.

When To Choose HTV Or Screen Printing

So, how do you actually decide between heat transfer vinyl and screen printing? Honestly, it’s not about which method is “better” in a vacuum. The right choice comes down to your specific project—what you’re making, how many you need, how complex the design is, and what your budget looks like.

Let's ditch the generic pro/con lists and walk through some real-world situations. This way, you can see how one method clearly pulls ahead of the other depending on the job at hand.

Scenario-Based Recommendations

Here are four common projects that perfectly illustrate the strengths of each technique.

Creating Personalized Team Jerseys

Imagine you're gearing up a local soccer team. Every player needs their own name and number on the back of their jersey.

- Recommended Method: Heat Transfer Vinyl (HTV)

- Why It Wins: This is a slam dunk for HTV. The whole point is customization. Creating a separate screen for every single name and number would be a logistical nightmare and outrageously expensive. With HTV, you just cut the individual designs and press them on. Simple, fast, and cost-effective for one-offs.

Producing 500 Shirts For A Corporate Event

Your company is heading to a big trade show and needs 500 identical t-shirts printed with a two-color logo.

- Recommended Method: Screen Printing

- Why It Wins: When you’re dealing with high volume, screen printing is the undisputed champ. Yes, there's an upfront cost to create the two screens, but once that's done, the cost per shirt plummets. It’s far more efficient and affordable to screen print 500 shirts than it would be to cut, weed, and press 500 individual vinyl transfers.

The core decision really boils down to volume versus variability. HTV is built for unique, small-batch projects. Screen printing dominates when you need large runs of the same design, where its efficiency and cost-effectiveness shine.

Launching An Etsy Shop With Diverse Designs

You’re starting a new t-shirt business online and want to offer a ton of different designs without sinking all your cash into inventory.

- Recommended Method: Heat Transfer Vinyl (HTV)

- Why It Wins: For a startup, flexibility is everything. HTV lets you work on-demand. You can create a shirt only after an order comes in, which means you don't have to guess which designs will be popular or tie up money in boxes of unsold stock. It gives you the freedom to experiment and grow your product line without the risk.

Printing Single-Color Logos For A Merchandise Line

You’re building a brand and need a consistent run of high-quality merchandise featuring your simple, one-color logo.

- Recommended Method: Screen Printing

- Why It Wins: For brand-building, you want quality and durability. Screen printing is the way to go. The ink becomes part of the fabric, giving it a soft feel that won't crack or peel. That professional finish is exactly what you need when your reputation is on the line, ensuring your merch looks great wash after wash.

To make it even simpler, here's a quick guide to help you make the call based on your project.

Decision Guide: Which Method Is Right For You?

This table cuts straight to the chase, matching common project needs with the best printing method.

| Project Scenario | Recommended Method | Primary Reason |

|---|---|---|

| Small batch (1-20 items) with unique names/numbers | Heat Transfer Vinyl (HTV) | Unbeatable for personalization and one-off prints without high setup costs. |

| Large order (50+ items) of the same design | Screen Printing | The most cost-effective and efficient method for bulk production. |

| Print-on-demand e-commerce store | Heat Transfer Vinyl (HTV) | Low startup costs and the flexibility to create designs as orders arrive. |

| Designs with many colors or photorealistic images | Heat Transfer Vinyl (HTV) | Printed HTV handles complex, full-color graphics easily; screen printing gets expensive. |

| Simple, one or two-color designs for a brand | Screen Printing | Delivers superior durability and a professional, soft feel for quality merchandise. |

| Quick turnaround needed for a few items | Heat Transfer Vinyl (HTV) | The process is much faster for small quantities compared to screen setup. |

Ultimately, choosing between HTV and screen printing is a strategic decision. By matching the method's strengths to your project's goals, you can ensure a great result every time.

Got Questions? We've Got Answers

When you're weighing your options between heat transfer vinyl and screen printing, a few questions always seem to pop up. Let's tackle them head-on so you can make the right call for your project.

Which Method Is Better For Intricate Designs?

For designs packed with fine lines, tiny text, or photorealistic detail, heat transfer vinyl (HTV) is the clear winner. The magic is in the process: a digital cutter slices your design with surgical precision, capturing every nuance. This is why it’s the go-to for complex, one-off pieces or very small runs where detail can't be compromised.

Screen printing, on the other hand, hits a wall with super-fine details. Since each color needs its own physical screen, creating stencils for intricate patterns or smooth gradients becomes incredibly difficult, if not impossible. The process just wasn't built for that level of complexity.

How Do I Care For Each Type Of Print?

You want your custom gear to last, and proper care is the key. While both methods are pretty sturdy, one definitely requires a little more TLC than the other.

Here’s the breakdown:

- HTV Garments: Think of these like a nice sweater. Turn them inside out, wash with cold water, and tumble dry on the lowest heat setting. Whatever you do, don't iron directly on the design—high heat is vinyl’s mortal enemy and can cause it to peel or melt. A well-maintained HTV print can look great for up to 50 washes.

- Screen Printed Garments: These are built like a tank. The ink becomes part of the fabric itself, so you can wash and dry them just like any other t-shirt. Honestly, the print will probably outlive the shirt.

The bottom line on care is simple: HTV needs a gentle touch to stay looking sharp, while screen printing is made for everyday wear and tear.

What Fabric Works Best For Each Method?

The material of your garment absolutely matters. HTV is incredibly versatile and plays well with a wide range of fabrics, including cotton, polyester, and common poly-cotton blends. This makes it a fantastic, flexible choice for everything from t-shirts to athletic wear.

Screen printing really shines on 100% cotton. The natural fibers soak up the ink beautifully, resulting in a print that’s both vibrant and incredibly soft to the touch. It can work on blends, but you might notice the finish isn't quite as soft or integrated.

Ready to bring your designs to life without the hassle of screen setup or weeding vinyl? At Raccoon Transfers, we specialize in high-quality, full-color Direct-to-Film transfers that apply in seconds and last for years. Explore our custom DTF transfers today!