Choosing the Best Fabric for T Shirts

Compartir

So, what's the best fabric for a t-shirt? The honest answer is: it completely depends on what you're using it for. For that classic, soft, everyday feel, nothing beats 100% cotton. If you're hitting the gym or need something that can take a beating, polyester is your go-to. And for a perfect middle ground? Blends like a cotton/poly mix give you a versatile shirt that handles almost anything.

Your Quick Guide to T-Shirt Fabrics

Picking the right t-shirt fabric is a lot like choosing the right tool for a job. You wouldn't use a delicate paintbrush to hammer a nail, and you definitely wouldn't wear a thick, heavy cotton tee for a marathon. The material itself is the foundation—it dictates how the shirt feels, how it hangs on your body, and how well it takes a printed design.

Think of it like buying tires. An all-season tire (your cotton/poly blend) is a fantastic daily driver, giving you a solid balance of comfort and performance. But if you’re heading off-road, you need rugged, durable tires (hello, polyester). For a quiet, luxury ride, you'd want premium touring tires, which are the Supima or Pima cottons of the world.

Understanding the Main Contenders

To keep things simple, let's break down the three main players you'll see on the market. Each one fills a specific role, and once you get what they're good at, you can easily find the perfect shirt for your wardrobe or your next project.

- Natural Fabrics: Cotton is the undisputed king here. It’s known for being incredibly breathable, soft on the skin, and naturally hypoallergenic, making it the default choice for casual, everyday wear.

- Synthetic Fabrics: This is polyester's turf. It’s famous for wicking moisture away from your skin, resisting wrinkles like a champ, and holding up to serious wear and tear. That’s why it dominates the sportswear scene.

- Blended Fabrics: This is where you get the "best of both worlds." Materials like a 50/50 cotton-poly or a tri-blend mix natural and synthetic fibers to create a shirt that’s both comfortable and functional.

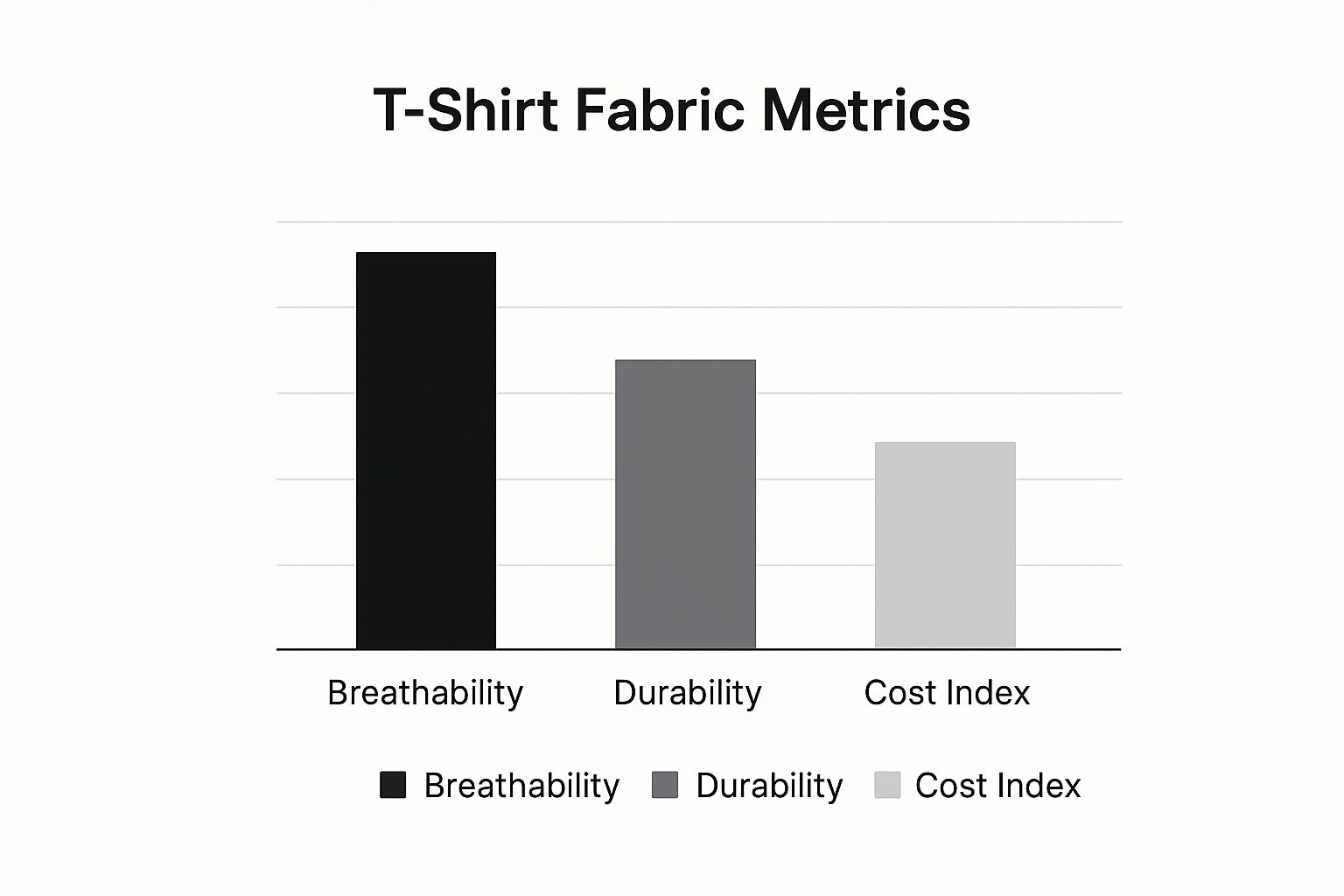

This chart gives you a quick visual on how these fabrics stack up against each other in terms of breathability, durability, and cost. It helps to see the trade-offs all in one place.

As you can see, cotton is a champ for breathability but just okay on durability. Polyester, on the other hand, is a durability workhorse and more affordable, but it's not quite as breathable.

At-a-Glance T-Shirt Fabric Comparison

Sometimes you just need a quick answer. This cheat sheet is designed for exactly that—a fast way to compare the most common t-shirt materials and see which one fits what you need right now.

| Fabric Type | Key Benefit | Best For | Feel | Durability |

|---|---|---|---|---|

| 100% Cotton | Soft, breathable, hypoallergenic | Everyday casual wear, custom printing | Soft and natural | Good |

| 100% Polyester | Moisture-wicking, durable, wrinkle-free | Athletic activities, performance apparel | Smooth and lightweight | Excellent |

| Cotton/Poly Blend | Balanced comfort and performance | Versatile use, from casual to active | Soft with a slight sheen | Very Good |

| Tri-Blend | Extremely soft, great drape | Premium fashion tees, comfortable loungewear | Silky and ultra-soft | Very Good |

This table should help you zero in on whether you're prioritizing a buttery-soft feel, long-lasting durability, or a specific activity, making your choice a whole lot easier.

Why Cotton is the Classic Choice

When you think of the perfect t-shirt, what comes to mind? For most of us, it’s cotton. This natural fiber is the undisputed king of the t-shirt world, and for good reason. It's the benchmark for everything else, offering a blend of softness, breathability, and pure comfort that’s tough to beat for everyday wear.

A good cotton tee is like a favorite pair of jeans—it’s dependable, comfortable, and just seems to get better with age. Its natural fibers let air move freely, which is a huge plus for keeping cool. This simple, effective breathability is why cotton has been the best fabric for t shirts for generations. It just works.

The numbers don't lie. A staggering 60% to 70% of all t-shirts sold globally are made from cotton or cotton blends. And looking at the bigger picture, cotton makes up nearly 35% of all textile fiber production worldwide, cementing its status as the go-to for casual, comfortable clothing. For more stats on these trends, you can always check out data from sources like Statista.

The Different Faces of Cotton

Here’s something a lot of people don’t realize: not all cotton is the same. The quality, feel, and even the price of a cotton shirt depend entirely on the length of its fibers. Think of it like coffee beans—different beans yield wildly different results. Longer fibers can be spun into yarns that are finer, stronger, and much, much softer.

Let's break down the types you'll most likely run into:

- Standard Cotton: This is your everyday, affordable cotton made from shorter fibers. It’s the workhorse of the t-shirt industry and what you'll find in most budget-friendly tees. For a great real-world example, take a look at our deep dive on the Gildan Heavy Cotton t-shirt.

- Ring-Spun Cotton: This type goes through an extra spinning process that straightens out the fibers, making them thinner and smoother. The result is a yarn that's noticeably softer and more durable than standard cotton, giving you a comfier shirt.

- Combed and Ring-Spun Cotton: Now we're getting into premium territory. Before spinning, the raw cotton is physically combed to pull out any impurities and short, scratchy fibers. This leaves only the longest, strongest fibers behind, creating an exceptionally soft and smooth fabric that’s a dream for high-quality printing.

Key Takeaway: It’s simple—the longer the cotton fiber, the softer, stronger, and more premium the t-shirt will feel. Combed and ring-spun cotton is a significant step up in both comfort and durability.

Premium Cottons: Pima and Supima

Ever see a shirt labeled "Pima" or "Supima" and wonder what the big deal is? You've stumbled into the luxury end of the cotton world. These varieties are famous for their extra-long staple (ELS) fibers, which puts them in a class of their own.

- Pima Cotton: Grown mostly in the U.S., Peru, and Australia, Pima has incredibly long fibers that create a silky-soft feel and fantastic durability. Shirts made from Pima are much more resistant to pilling, fading, and stretching.

- Supima Cotton: This is the brand name for top-tier, American-grown Pima cotton. It’s a mark of guaranteed quality—to earn the Supima label, the fabric must be 100% pure Pima from the American Southwest. It represents less than 1% of the world's cotton, making it a truly premium material.

Strengths and Weaknesses of Cotton

While cotton is a fantastic all-rounder, it's not perfect for every single situation. Understanding its pros and cons is key to choosing the right shirt for the job.

Cotton's Advantages:

- Highly Breathable: Its natural structure is a built-in ventilation system, perfect for keeping you cool.

- Soft and Comfortable: It’s gentle on the skin, making it an easy choice for all-day wear.

- Hypoallergenic: It rarely causes irritation, so it's a safe bet for people with sensitive skin.

- Excellent for Printing: Cotton is like a sponge for ink, which means it’s great for getting crisp, vibrant designs with methods like DTG printing.

Cotton's Disadvantages:

- Absorbs Moisture: This is its biggest weakness. Cotton soaks up sweat and water, getting heavy and taking forever to dry. That makes it a poor choice for a workout shirt.

- Prone to Shrinking: If it hasn't been pre-shrunk, a 100% cotton tee can definitely shrink in a hot wash or high-heat dry cycle.

- Can Wrinkle Easily: It creases more than synthetic fabrics, so you might need to break out the iron.

When it comes to everyday comfort, cotton is king. But when you need your shirt to do something—to perform under pressure—it’s time to look at synthetics. This is where engineered textiles take over.

Think about it this way: you wouldn't wear a pair of classic leather boots to run a marathon. For that, you need a modern running shoe designed for breathability, support, and speed. Polyester is the running shoe of the t-shirt world. It's built for action.

Polyester is essentially a type of plastic that’s spun into a remarkably strong and versatile thread. Its very nature gives it a huge advantage for activewear. Unlike cotton, which acts like a sponge for moisture, polyester is hydrophobic—it actively pushes water away.

Why Polyester Is the Go-To for Activewear

So, what does that mean in the real world? When you sweat in a polyester shirt, the fabric doesn't get soaked. Instead, it pulls the moisture off your skin and moves it to the outside of the shirt, where it can evaporate in a flash.

This whole process is called moisture-wicking, and it's the magic behind why polyester keeps you feeling dry and light, even during a tough workout.

This one core feature leads to a whole host of other benefits:

- Incredibly Durable: Polyester fibers are tough. They resist stretching, shrinking, and general wear and tear, meaning your shirt will keep its shape through countless washes.

- Stays Smooth: Thanks to its structure, polyester doesn't really wrinkle. It's a perfect choice for travel or for anyone who hates ironing.

- Holds Color: Dyes lock into polyester fibers and stay put. This means vibrant colors that won't fade easily, even after a lot of sun exposure and washing.

The Performance Payoff: The real game-changer with polyester is how it handles sweat. By wicking moisture away instead of absorbing it, it prevents that heavy, clingy, and cold feeling you get from a sweat-soaked cotton tee. You stay lighter, drier, and way more comfortable.

Beyond Just Polyester

While polyester is the big name in synthetic fabrics, it's not the only one. You'll often find other engineered materials, especially in blends, that add their own unique properties to the mix.

Nylon: Think of nylon as polyester's close cousin. It's also known for being incredibly strong and stretchy. Nylon tends to have a smoother, silkier feel and is a go-to for everything from performance leggings to durable outerwear.

Rayon: Rayon is a bit of an interesting one. It actually starts from a natural source, like wood pulp, but goes through a heavy chemical process to become a fiber. The end result is a fabric famous for its buttery-soft feel and elegant drape, which is exactly why it's a key part of those ultra-cozy tri-blend t-shirts.

The Not-So-Great Side of Synthetics

No fabric is without its flaws, and synthetics are no exception. The main downside is odor retention. That same water-repelling quality can unfortunately create a great environment for smelly bacteria to grow. You might notice a polyester shirt starts to stink faster than a cotton one.

Also, some people just don't love the feel. While manufacturing has come a long way, some synthetics can still feel a bit "plasticky" compared to the soft, natural touch of cotton. It really boils down to personal preference.

At the end of the day, picking the best fabric for t shirts is all about matching the material's strengths to what you need it for.

Getting the Best of Both Worlds with Blends

Pure cotton is famously soft, and pure polyester is a performance powerhouse. But what if you didn't have to choose? What if you could weave the strengths of both into a single, superior t-shirt? That's the magic behind blended fabrics.

Blends are all about creating a material that's truly greater than the sum of its parts.

Think of it like making the perfect cup of coffee. You might combine beans from different regions—one for a smooth, chocolatey base and another for bright, fruity notes. Neither bean on its own creates the perfect balance, but together, they make something special. Fabric blends do the same thing, combining fibers to hit that sweet spot of comfort, durability, and style.

This approach lets fabric engineers dial in specific qualities. Need more wrinkle resistance? Add polyester. Want a softer feel? Up the cotton percentage. The result is a shirt that feels great, holds its shape, and stands up to whatever your day throws at it.

The Classic 50/50 Cotton and Polyester Blend

The most common blend you’ll run into is the classic 50/50 cotton/polyester mix. This fabric is an absolute workhorse, striking a near-perfect balance between the two materials. You get the familiar, natural softness of cotton, but it's reinforced by the strength, wrinkle resistance, and moisture-wicking power of polyester.

This blend is a fan favorite for a few really practical reasons:

- Less Shrinkage: The polyester provides a stable structure, so a 50/50 tee is much less likely to shrink up in the wash compared to a 100% cotton shirt.

- Better Durability: It holds up beautifully to repeated wear and washing, fighting off tears and stretching over time.

- Great Drape: The fabric hangs just right—not too stiff, not too clingy—giving you a comfortable and flattering fit from day one.

Because of this well-rounded performance, the 50/50 blend is the go-to choice for everything from company uniforms and event merch to your favorite everyday tee. It’s affordable, reliable, and just plain comfortable.

You’ll also see a popular variation called CVC, or Chief Value Cotton. These are just blends with more cotton than polyester, like a 60/40 cotton/poly mix. They lean into that extra softness and breathability while still holding onto some of that polyester-driven durability and colorfastness.

The Ultra-Soft Tri-Blend

When supreme, can't-stop-touching-it comfort is the name of the game, nothing comes close to a tri-blend. This premium fabric mixes three distinct materials to create a t-shirt that's exceptionally soft, lightweight, and drapes beautifully.

A typical tri-blend is made of 50% polyester, 25% combed and ring-spun cotton, and 25% rayon. Each fiber is there for a reason, playing a specific part in creating the fabric's signature feel.

The polyester gives it shape and resilience, the cotton brings that classic softness, and the rayon—that's the secret weapon. Rayon is a semi-synthetic fiber made from wood pulp, and it adds a silky, almost fluid quality that gives the shirt its incredible drape and luxurious feel.

The final product is a t-shirt that feels like your most beloved, broken-in favorite, even when it's brand new. Tri-blends are what you'll find in high-end retail shops and fashion-forward apparel lines where hand-feel is everything. The unique fiber mix also creates a subtle heathered, vintage look that's incredibly popular.

To help you keep track of these popular options, here’s a quick breakdown of how their composition shapes their performance and best uses.

Common T-Shirt Blends and Their Properties

| Blend Name (e.g., CVC, 50/50, Tri-Blend) | Material Composition | Primary Advantage | Ideal Use Case |

|---|---|---|---|

| 50/50 Blend | 50% Cotton, 50% Polyester | Balanced comfort and durability | Everyday wear, uniforms, events |

| CVC Blend | 60% Cotton, 40% Polyester | Extra softness with good resilience | Casual tees, brand merchandise |

| Tri-Blend | 50% Poly, 25% Cotton, 25% Rayon | Supreme softness and excellent drape | Premium fashion, retail apparel |

As you can see, a small change in the recipe can create a completely different experience. Understanding these blends is key to picking the perfect blank canvas for your project or the perfect tee for your wardrobe.

How Fabric Choice Impacts Custom Printing

Choosing the right fabric for a t-shirt isn't just about how it feels to wear. It's about what you plan to do with it. The material is the canvas for your design, and that choice will make or break how your print looks, feels, and holds up over time.

Think of it this way: painting on a porous, absorbent canvas like cotton is a completely different game than painting on a slick, non-absorbent surface like polyester. Get this relationship right, and you’ll create a professional, vibrant piece of custom apparel. Get it wrong, and you're in for a world of disappointment.

Matching Fabrics to Printing Methods

The fiber content, weave, and even the color of a t-shirt have a huge say in the final print quality. A super smooth, tightly woven material like ringspun cotton gives you a perfect surface for sharp, crisp details. A rougher, more textured fabric, on the other hand, might soften the design or cause gaps in the ink.

Different printing methods are engineered to bond with specific fibers. Trying to force a mismatch—like using the wrong ink on the wrong fabric—is like trying to paint with watercolors on a sheet of plastic. The ink just won't stick. You'll end up with faded colors, muddy details, and a design that cracks and peels off in the first wash.

Here’s a quick rundown of the most common pairings that actually work:

-

Direct-to-Garment (DTG): This is basically an inkjet printer for clothes. It sprays water-based inks directly into the fabric's fibers. This process is magic on 100% cotton because cotton is incredibly absorbent. The ink soaks right in, creating a super soft, breathable print that feels like it’s part of the shirt itself.

-

Screen Printing: The classic workhorse. Screen printing pushes a thick layer of ink (usually plastisol) through a stencil and onto the fabric. It’s versatile and works great on cotton, blends, and even some polyesters, though synthetics often need special ink additives to make sure the print cures properly and doesn't flake off.

-

Heat Transfer (including DTF): With this technique, you print a design onto a special film or paper and then press it onto the shirt using heat. Heat transfers are the chameleons of the printing world—they stick to just about anything, including cotton, polyester, and blends. The result is a vibrant, durable design that sits on top of the fabric.

The Fabric-Ink Connection: It really boils down to this: natural fibers like cotton absorb ink, while synthetic fibers like polyester repel it. That's why DTG is the king for cotton—it relies on that absorption to create a soft, integrated design.

The Polyester Problem and How to Solve It

Printing on 100% polyester brings a unique headache to the table called dye migration.

Here’s what happens: most printing methods use heat to cure the ink and make it permanent. But when you heat up a colored polyester shirt, the dye that was used to color the fabric itself can turn into a gas. This gas then seeps up into the ink layer of your print, staining your beautiful, crisp white design a murky pink, grey, or whatever color the shirt is.

It’s a frustrating issue, but there’s a fix. Printers use special "dye-blocking" inks or underbases that act as a barrier. There are also low-temperature cure inks designed specifically for polyester that set without reaching the temperature that causes dye migration. This is a perfect example of why knowing the different fabric printing techniques is non-negotiable for getting pro-level results.

Ultimately, the best fabric choice comes down to your project. Want a soft, retail-ready fashion tee? You can't beat DTG on high-quality cotton. Outfitting a sports team with durable performance jerseys? Screen printing or a good heat transfer on polyester—using the right inks—is your best bet. Make the right match from the start, and you'll create a design that doesn't just look great on day one, but for years to come.

Putting It All Together: A Simple Checklist for Your Decision

Alright, we’ve journeyed through the worlds of cotton, polyester, and those clever fabric blends. Now comes the fun part: putting that knowledge to work. Choosing the best fabric for t shirts shouldn't feel like a pop quiz. Instead, think of it as a straightforward process of matching the right material to your specific mission.

This final checklist is designed to help you do just that. It's a simple walkthrough of the key questions you need to ask to land on the perfect fabric for your project.

By thinking through these points, you’ll quickly narrow down the huge sea of options to just a handful of contenders. The goal is to find a t-shirt that looks, feels, and performs exactly the way you need it to.

What's This T-Shirt For?

First things first, what is the t-shirt's main job? Seriously, this one question will steer almost every other decision you make.

- Casual Everyday Wear: Is this a go-to shirt for lounging on the couch, running errands, or just kicking back? If comfort is the top priority, you can't go wrong with 100% combed and ring-spun cotton or a super-soft CVC blend. They just have that classic, breathable feel everyone loves.

- Athletic and Active Use: Will this tee be hitting the gym, the trail, or the practice field? In this case, performance is everything. A 100% polyester shirt or a high-performance poly-blend is a must-have for wicking sweat and keeping the wearer cool and dry.

- Promotional Events or Merch: Is this for a one-off event, a company giveaway, or merchandise for your brand? The classic 50/50 cotton/poly blend is often the perfect workhorse here. It offers a great mix of softness and durability at a price that makes sense.

What Do You Value Most in Feel and Durability?

Next up, you need to think about the balance between a soft hand-feel and long-term toughness. There isn't a single right answer—only what's right for your project.

Ask yourself: Is a buttery-soft, fashion-forward feel the number one goal? If so, a tri-blend is your undisputed champ. Or is rugged, long-lasting resilience for workwear or constant washing more important? In that case, a heavyweight cotton or a sturdy poly-blend will serve you much better.

This is where you weigh luxury against pure practicality. A delicate tri-blend probably won't survive a construction site, just like a stiff, heavyweight tee isn't exactly ideal for a premium loungewear line.

The global shirt fabric market, valued at around $46.39 billion in 2025, keeps expanding because people want fabrics that do it all—comfort, style, and function. This demand has pushed innovation, giving us more specialized blends that combine natural softness with synthetic strength than ever before. You can read more about these trends in the shirt fabric market.

How Are You Printing On It?

Finally, and this is a big one, your printing method has a huge say in your fabric choice. Nailing this step is critical for making sure your design looks sharp and lasts wash after wash.

If you’re using Direct-to-Garment (DTG) printing for a soft, breathable graphic, nothing beats 100% cotton. It provides the perfect absorbent canvas for the ink to sink into.

On the other hand, if you need vibrant, full-color designs that really pop—especially on tricky fabrics like polyester—Direct-to-Film (DTF) transfers are an incredibly versatile solution. Understanding how the fabric reacts to heat is also key; to get it right, check out our guide on heat press settings for DTF transfers.

With this simple framework in mind, you’re ready to choose with confidence.

Your Top T-Shirt Fabric Questions, Answered

You've got the basics down on cotton, polyester, and blends, but a few questions might still be nagging you. Let's clear up some of the most common uncertainties people have when picking out the perfect tee.

Will My T-Shirt Shrink in the Wash?

Ah, the age-old laundry dilemma. The short answer is: it really depends on the fabric.

A 100% cotton shirt is the most common culprit for shrinking. When you wash it in hot water and blast it with high heat in the dryer, you’re releasing all the tension that was applied to the fibers during the manufacturing process. This causes them to snap back to their original, shorter state.

The easiest way to sidestep this is to look for tees labeled "pre-shrunk." These have already been washed and dried, so most of the shrinkage is already out of the way. Blends that include polyester are also a much safer bet, as synthetic fibers are far more stable and resistant to changing shape.

Pro Tip: Want to play it safe with any t-shirt? Always wash in cold water and tumble dry on low. Even better, hang it up to air dry. It's gentler on the fabric and a nice little win for the planet, too.

What Is the Most Eco-Friendly T-Shirt Fabric?

If sustainability is on your mind, you're in luck—there are some fantastic options out there. The best choices are usually natural fibers grown with a lighter touch on the environment.

Here are a few standouts:

- Organic Cotton: This isn't your standard cotton. It’s grown without the harsh synthetic pesticides and fertilizers, which is way better for the soil, water, and the farmers who grow it.

- Linen: Made from the hardy flax plant, linen is a real champ. It needs much less water and fewer pesticides than cotton, making it a seriously green choice.

- Recycled Fabrics: Giving old materials a new life is always a good idea. T-shirts made from recycled polyester (often from plastic bottles) or recycled cotton help cut down on landfill waste and conserve precious resources.

Choosing any of these means you can rock a great-looking shirt and feel good about its impact.

Which Fabric Is Best for Sensitive Skin?

When your skin is easily irritated, you want to stick with the classics. Natural fibers are definitely the way to go.

100% cotton is the undisputed king here. It’s naturally hypoallergenic, soft to the touch, and incredibly breathable. That airflow is key because it helps prevent moisture buildup that can lead to irritation.

For an even softer experience, seek out premium varieties like Pima or combed and ring-spun cotton. Their longer, smoother fibers feel extra gentle against the skin. It’s probably best to steer clear of 100% polyester if you have sensitive skin, as it can sometimes trap heat and sweat, which is a recipe for discomfort for some people.

Ready to see your designs pop on the perfect fabric? At Raccoon Transfers, we live and breathe high-quality DTF prints that look amazing on cotton, polyester, and blends. Creating vibrant, long-lasting custom apparel has never been easier. Jump into our user-friendly Gang Sheet Builder and get started!